Radiator vent issue

Comments

-

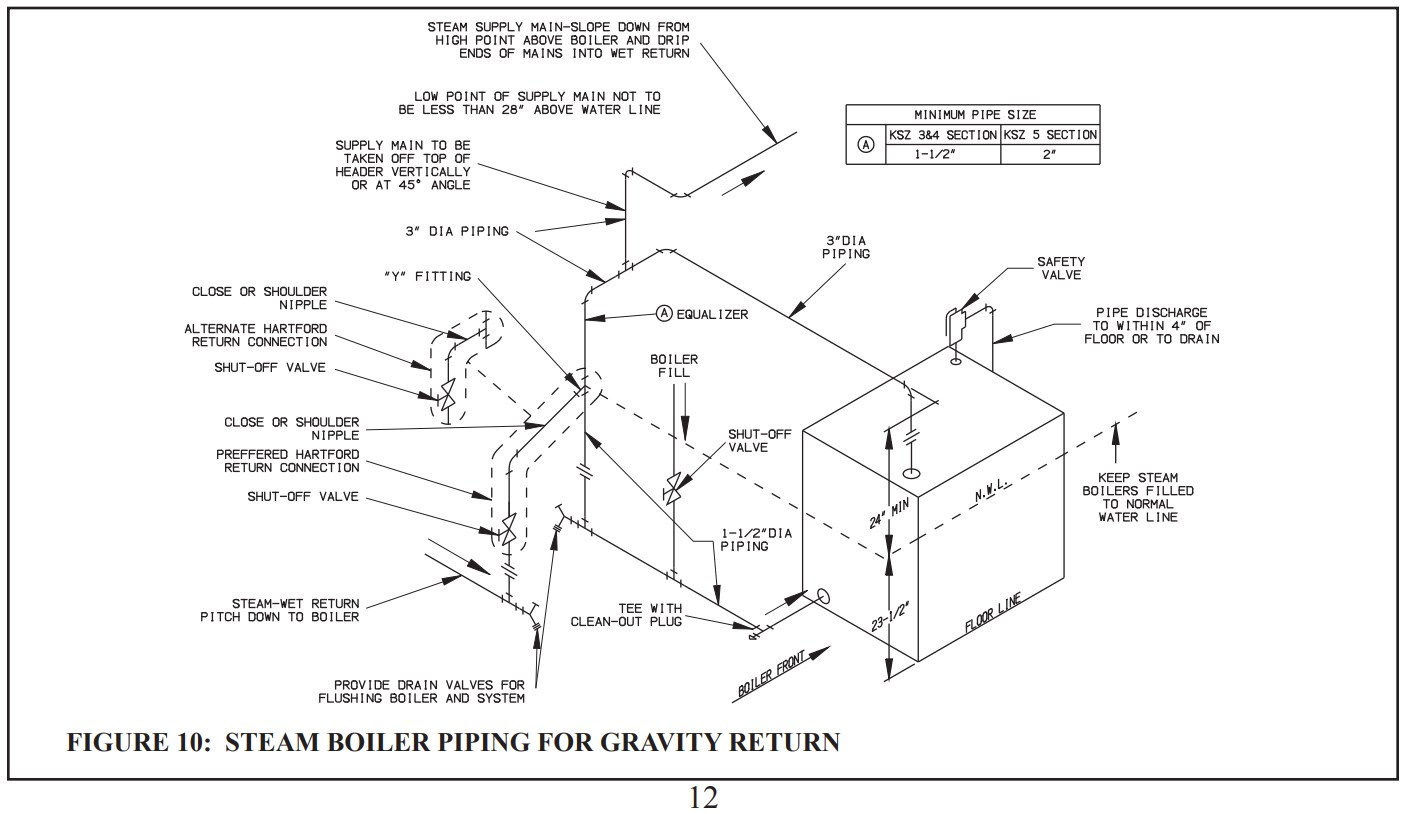

Near Boiler Piping from the manual says the header should be reduced down from 3 in. to 2 in. equalizer (what is yours….1-1/4in.?). Supply pipe to the main is shown as 3 in. but you have 2 at 1-1/2 in. which adds up to 1/2 of the area of the 3in.. I'm surprised they seem to say close nipple top at NWL. First time I've seen it that high and I don't agree with that. You could have carry over/wet steam problems depending upon how much EDR load and how fast the venting and water quality (TSS under 50ppm is mandatory). Header and supply to it are OK though.

0 -

A Gorton #2 is the proper size main vent for that main. It has more than double the venting of the Hoffman #75. The higher the percentage of of the air being purged through the main vent up to the point the main vent closes the lower the amount of air being purged through the radiator vents. Thus, at least until the point the main vent closes you will get less noise from your radiator vents with larger main venting in addition to getting heat to your radiators quicker and more easily balanced.

Is there any main vent on the shorter main going to the right? Any hissing on any of those radiators?

Much of the vent noise issue is going to also depend upon your boiler sizing relative to the connected radiation, although you are somewhat stuck with whatever it is. But if we know that is the case there are some methods to help manage it. Reducing your setbacks in extreme cold certainly helps.

1 -

Edit to add for anyone "disagreeing" (LOL), this is straight from the Crown installation manual on p. 12-13

One of the primary purposes of this near boiler piping is to separate tiny water droplets from the steam exiting the boiler so that “dry” steam is sent to the system. If the near boiler piping is not correct, wet steam will enter the system and the following problems may occur:

• Short cycling on low water

• Boiler or system Flooding

• Hammering

• Failure to heat one or more radiators

0 -

ok….so update…before i was able to do anything…this morning…therm was 69…i moved to 71……about 30 min…some radiators were "going off"…hissing/etc….i went down to the boiler….never saw before…but main vent going crazy and steam coming out. i checked site glass…water was barely visible so i shut off boiler…..water started to come back up……when i turned back on…the "level" did not jump around…but seemed to slowly start to drop. I have automatic water feeder and shut off…any ideas?

0 -

Everything they are describing isn't from "water droplets in the steam" it's from carryover. This isn't surprising because the entire industry seems to have the same confusion about "wet steam" vs "carryover".

Droplets in the water won't cause the LWCO to go off, carryover does.

Droplets in the water doesn't cause system flooding, carryover does.

Droplets in the water doesn't cause hammering, but carryover sure does.

Droplets in the water doesn't cause failure of radiators to heat, but carryover can.

If they had sight glasses and watched their boiler operate when they wrote that, they'd know better. Today we all can know better, if we believe our eyes.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

It could be carryover or possibly a blocked wet return.

The best way to tell the difference is…if you watch an entire call for heat, does the water level dive dramatically?

You say you watched it "slowly drop" which is good, but how long did it take? A clogged return would make the water level drop very slowly because there are a lot of gallons in the boiler where usually carryover is pretty sudden once it starts.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I don't think the semantical argument of what constitutes carry over vs. entrained droplets really is of concern to this homeowner, and it is really quite boring since the same near boiler piping errors which you deny for the most part (and water quality issues) cause both. Obviously they are on different places in the spectrum of wet steam, dryness fraction, 2 phase steam (use whatever terminology one pleases).

0 -

heater guy came out….checked to make sure auto water was clean/working …it was….he added some water….seems like it goes down slowly in site glass…but seems to be keeping water…not like this morning where it was basically non existent. just weird why main vent was going crazy and steam coming out like i never have seen before…..the issue always seems to be in the morning. i lower heat around 10pm at 69….then around 5am..i put to 71….and then increments by 1 degree if needed during the mid morning/afterntoon…but it is jsut that first thing in the morning is the worst….but the "no water" seems to be new

0 -

Is that all the guy did or said?

When you set back your thermostat before retiring for the night and then bump it up in the morning when you arise, you are putting your system through a stress test, where any deficiencies come to light.

0 -

anything i should be doing differently?

yes…i mentioned about the "main vent"…he said that could be the problem…but not sure why water was so low and where it went!

0 -

Well that wasn't the right guy if he had no clues to the low water issue. I'm sure you are feeling very overwhelmed being a novice. I was new to steam heat back in 2005 and had to take a crash course. I picked up "We've Got Steam Heat" and then latter "Lost Art Of Steam Heating" by Dan and learned a lot.

I would not do the setback until everything gets ironed out.

Sit there by your boiler and video a full cycle, maybe with a cooler full of beer (optional) and focus on things like how the main vents sound (check them for steam leakage with a mirror) and the water level in the sight glass, and sound in the returns of condensate returning ( can place your ear or mic near it) etc.. Like a normal denizen of HH (kidding).

0 -

the picnic with your boiler is a very healthy advice. all of us went through that period. there is simply no way around it.

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog1 -

it’s not semantics. One of the two issues (carryover/surging) is easily solvable by fixing the water quality and the other is chasing phantom invisible droplets of water by making piping changes that aren’t likely to do anything.

Admittedly this thread is hard to track, it started out about a couple radiators.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

How does it help the OP to ignore that mechanical wet steam leading into the extreme case of carry over does occur when there are defects in the OP's near boiler piping that "could" be contributing to what they are experiencing? I don't see that it would serve them to suggest that the only thing that could be contributing to their carry over is water quality. First fix what is easiest to fix and of course that is water quality. In my case that is what I am doing and getting by as long as I watch the situation like a hawk. After that is fixed see where you are at and re-assess the situation.

It is incorrect to suggest that dryness fraction doesn't decrease (wetter steam and more entrained droplets of water) as ppm of TSS (total suspended solids) increases (and there are other issues such as pH and TDS) and that it could eventually lead to what everyone would agree would be called carry over. Doesn't help their situation to deny that fact and it is misleading to do so. Where one becomes the other is a waste of time to argue about as well when they are both caused by the same things.

1 -

question…seems like thread for the main vent pipe is 3/4….but Gorton #2 is only 1/2….do i get the Gorton 2 and use a reducer (if so…any recommendations on type of material) or just go with 3/4 HOffman 75?

0 -

Get the reducer and use the Gorton #2. As I said before if the Hoffman was seen releasing gobs of steam then it is shot and can't be trusted anymore.

You can just go down to Home Cheapo and find all the steel fittings you need to adapt to the 1/2" male on the Gorton. Maybe you sent a picture of your main vent before but now I can't find it.

1 -

thanks…i wasnt going to use the "bad" hoffman….i would get a new one….but do you think the reducer/Gorton 2 is the better one to use?

0 -

I replaced #1 with a Gorton #2 and also used a reducer. Exact Details here

0 -

here is where the Hoffman is…..i just need to get reducer (3/4 to 1/2) to use the Gorton 2. Any special reducer and pipe dope i need for this project? thanks

0 -

Nah, just a 3/4×1/2 black Bushing will do it. If you want to be able to get it out in the future, Teflon tape, then dope.

0 -

jsut wondering…if the opeing now to the hoffman is 3/4….will a reducer to 1/2 have any problems?issues?

0 -

No

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Lots of ways to skin the cat. You could just put this in after taking the Hoffman out and then attache the Gorton #2 or you can add a nipple and coupling and extend the vent upwards a bit if you have room or add a couple 45's and extend it over and up or two 90's for a lower upward slope etc…

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 168 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements