System 2000 and EK1 - Oil or do Propane Conversion?

Hi All,

I am trying to decide if and how I should upgrade our boiler system.

Background: 7 months ago we moved into a 26 year old house in Connecticut with the original Weil Mclain Gold Oil cast iron boiler and two 275 gallon oil tanks. 5000 sq ft house with 4200 sq ft space heated by a hydro air system made of the boiler with two air handlers (1 in basement for 1st floor and 1 in attic for 2nd floor). Hot water is indirect heater (HTP SSU-45N) installed in 2020. So 3 total boiler zones. The rest of the house square footage is a finished basement heated via heat pump/minisplits.

We also have a buried 500 gallon propane tank piped to the house that serves a whole house Generac, cooktop, and fireplace.

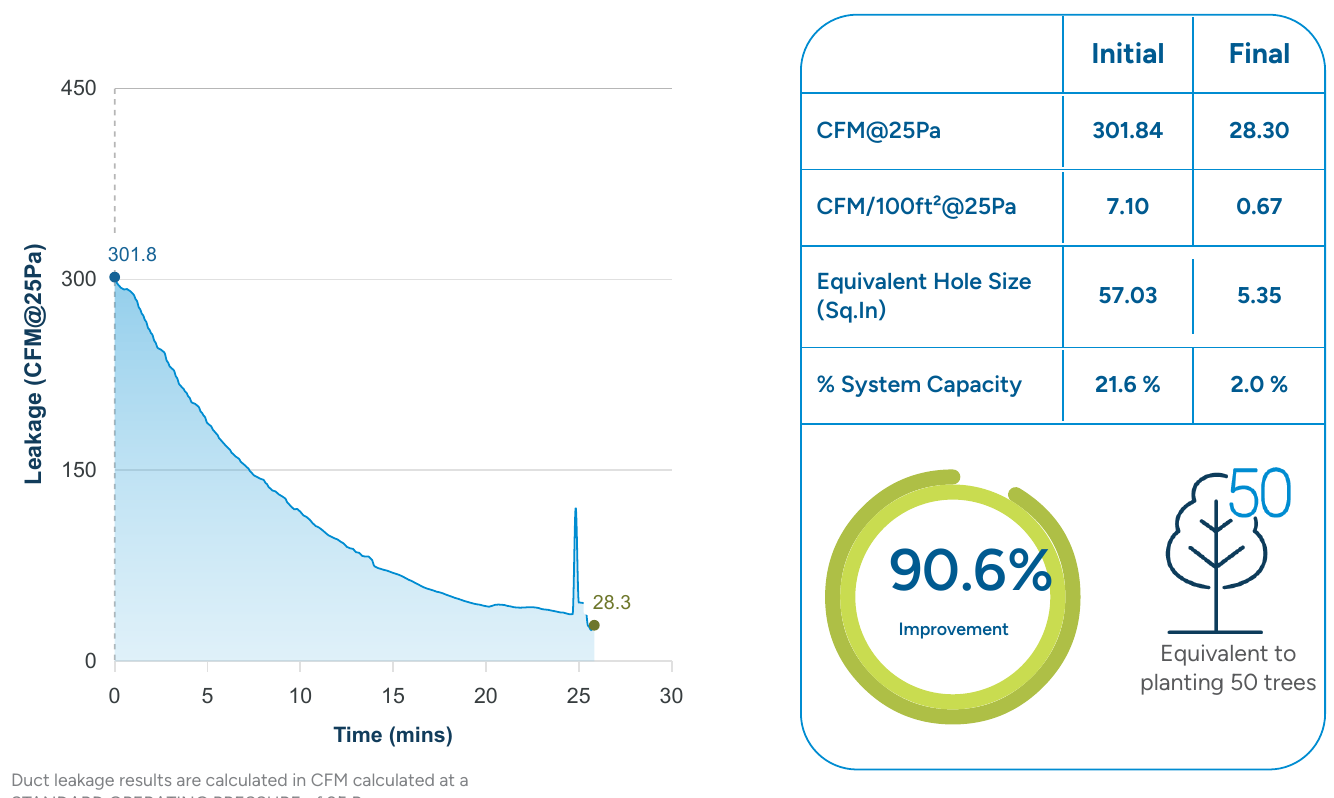

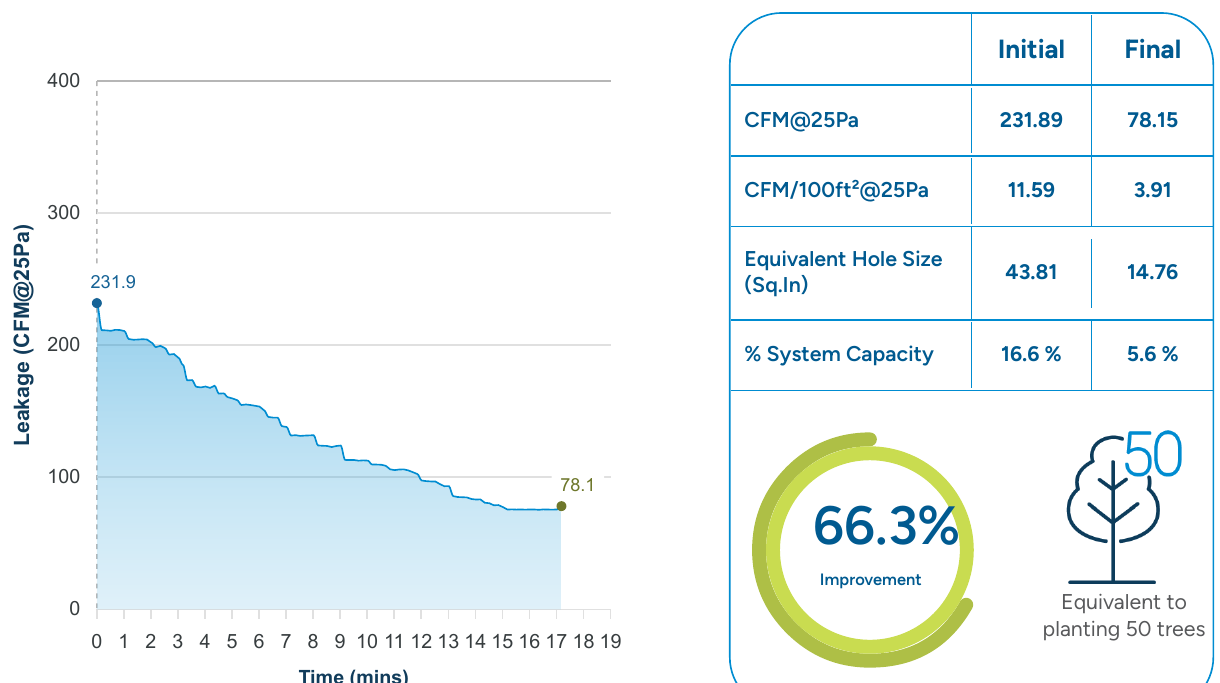

Since moving in, we have already done an energy audit, which resulted in air sealing the attic, aerosealing the air handler ductwork, and adding blown in cellulose to the attic over the original insulation batts. I feel like we have already maxed out available energy efficiency gains.

I suspect that we will use between 1,200 - 1,500 gallons of oil per year in the current setup depending on weather. The oil company that has previously serviced this house estimated 1,600 gallons but that was before energy improvements and I also think the previous owner just kept the thermostats set higher than we do.

We plan to be in the house 20-30 years, so I am considering updating the system now to capture efficiency gains that will pay us back over the years instead of paying more for oil for X number of years before eventually having to replace the boiler anyway.

So I am considering a few different options:

Option 1: replace WM boiler with System 2000 EK1 oil boiler. Our oil company is an experienced EK dealer/installer. I would probably go ahead and replace the two oil tanks at the same time so I don't have to worry about them leaking. I would also probably keep the HTP indirect water heater instead of using the integrated System 2000 storage tank since the HTP is only 5 years old.

Option 2: remove the oil boiler/tanks and convert to propane with high efficiency condensing boiler. I would probably need to bury another 500 or 1000 gallon tank next to the existing 500 gallon tank.

Option 3: convert to propane like in Option 2 but still get the System 2000 EK1 with a propane burner.

Option 4: do nothing. wait until current cast iron boiler leaks to replace. wait until oil tanks leak to replace, etc.

I plan to get pricing on all these options soon but was curious what the helpful people here think.

Thank you!

Comments

-

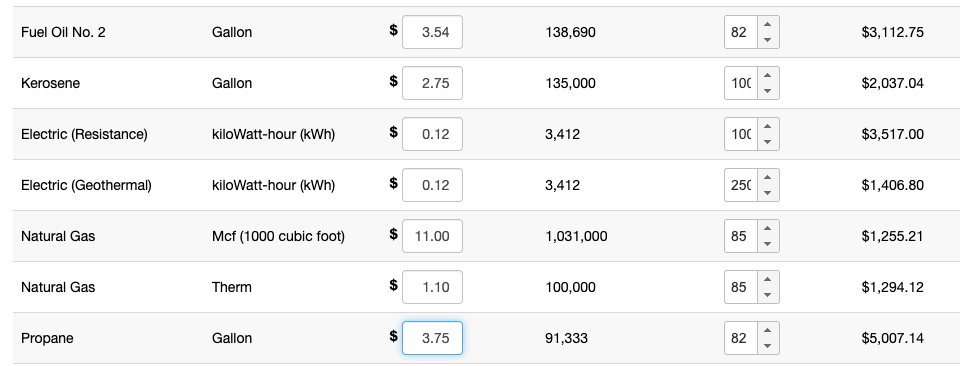

Using last weeks energy costs for CT. Your actual prices may vary. Both operating at 82%

EIA has fuel costs dating back as many years as you want to look.

Oil is the clear winner. Crunch the numbers to see at what $$ LP would be the better choice

LP in my area is currently $2.27, heating oil $3.65

www.coalpail.com for energy calculator

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

We're in a similar size house (4800 sq ft), with similar boilers (two circa 1990 Weil McLain WGO-5's) and similar oil consumption (1200 gal/yr) in similar climate (Boston area). But our DHW is from a natural gas heater.

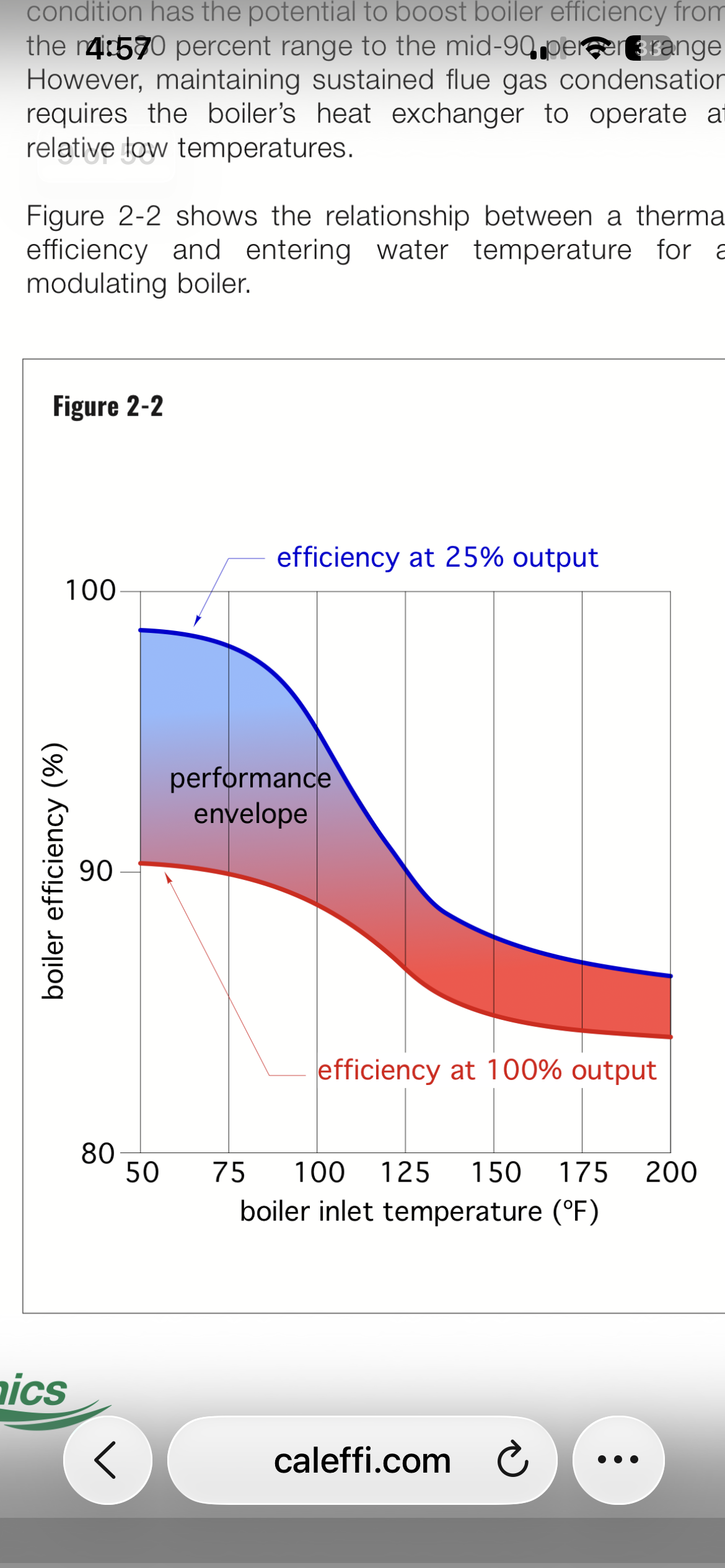

I'm just a homeowner/engineer, not a heating pro, but I've learned a bit from the generous pros here. I've looked at a lot of new heating system options, and the one point warning I would give about considering a switch to a "high efficiency" condensing gas boiler is that you will NOT get the advertised high efficiency number UNLESS your heating system can heat the house for most of the heating season with supply water temperatures below 130 F. If your supply water has to be hotter than that, it will prevent the water vapor in the boiler exhaust from condensing, and you won't get that heat back. Your "high efficiency" condensing boiler is now not so high efficiency.

You'd need someone who knows what they're doing to analyze your system and evaluate how much of the season your boiler would actually be condensing. From that you can then figure how much fuel you'd be saving. Usually it's not as much as you think, because of the inherent limitations of a heating system that was (probably) designed for higher supply water temps.

If it were me, I'd go for the System 2000 EK1. It's a very nice system, and will probably be as high-efficiency as you can get (with the indirect for DHW) without condensing. Support is excellent, and you will avoid many of the headaches that come with servicing/repairing condensing boilers that cost $$ and eat into your fuel "savings." It will last a long time and work well with minimal problems.

It is possible that you could save in the long run with a condensing boiler, but the key is knowing how much of the time the boiler will be able to condense based on your required supply water temp. A heating pro can calculate that. But the unknown unknown is how much more it will cost you to service and repair a condensing boiler.

1 -

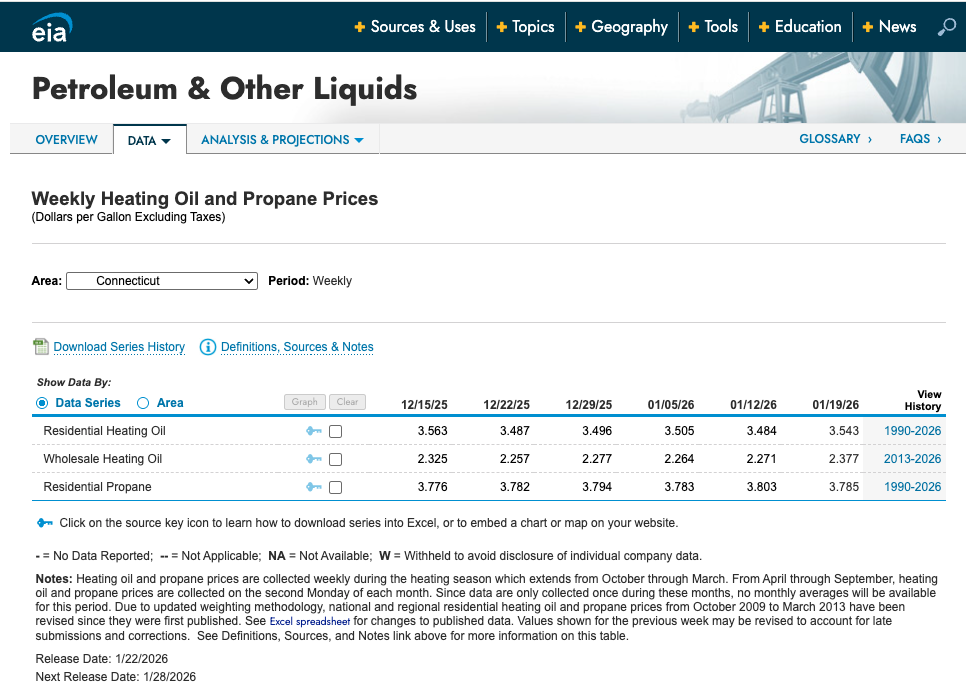

actually even at high operating temperatures the mod con efficiency can be quite impressive

Low return and turned down burners gets you into 90%+ efficiency. 50 degree return at 25% modulation is at the top efficiency

So the rumor about oversized mod cons doesn’t actually pencil ✏️ out

Example from Idronics 25

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Do your sums very carefully… but I think you will find that oil is going to beat LP anywhere in Connecticut., even supposing you can get the extra say 8% condensing all the time. Which you won't.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

304,000 net BTU's for 4,800 sq ft is ludacris if the boilers are firing what they're rated for.

0 -

Haha, yes, you must have missed the last 3 years of my posts discussing this ridiculous oversizing.

I was able to talk our heating oil company into downfiring to 1.0 gph nozzles running at 140 psi for an actual firing rate of 1.2 gph. But even so, we're still oversized by 3x. Outside air temp was 4 degrees last night, and the boilers ran a 33% duty cycle. So our actual building heat loss at near-zero outside air temp is 80-100MBH depending on what you assume for overall boiler efficiency. I use the 100MBH number for convenience and to be conservative. But our design day heat loss is probably closer to 80MBH because we're probably only getting 65% total efficiency out of the boilers.

2 -

Thanks everyone for the responses. Since a couple folks mentioned fuel prices: currently we pay $3.29/gal for oil (capped contract price from July) and just got a 200+ gallon propane delivery at $2.60/gal last week.

If we're going to make a change, my inclination is to go with the EK1 given our long runway in the house and all the good things I've read about them in this forum and elsewhere.

My desire to switch to propane is mostly about getting rid of the hundreds of gallons of oil sitting in my basement, and about only having to deal with one type of fuel delivery in the future. We also already have a lot of the infrastructure for LP in place (likely just need another supplemental tank). But maybe oil is still the way to go.

Someone from the fuel company is supposed to come this week to go over options and I look forward to getting actual prices to compare.

0 -

Your oil is cheaper. $3.29 for oil is about $.0235 per 1,000 BTU. Propane is $.027 per 1,000 BTU. Your 1200 gallons of oil would cost about $4,000; the same amount of heat from propane would be around #4,600.

I don't know about you, but that is NOT the kind of "savings" I can afford…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Your at 26 years and I would say 30 years from a boiler and oil tanks are a good run. I would not consider propane.

Not only is propane more $ but any decent?? service tech can keep a Weil McLain going, a service tech that is good with modcons…..not so much. If your dealer knows EK I would go that way with oil.

Make sure the new boiler is sized correctly. Using hydro air means you need hotter system water which is not to a mod cons advantage

1 -

Great comments all around - it's always encouraging to see homeowners like you ,@ctboiler28, digging into the analysis to make a good long term decision for comfort, efficiency, service, and reliability. Many excellent points have been made already, so I will only chime in on a few.

I come up with the same figures as @Jamie Hall to compare the fuels at 1200 gallons equivalent ($4,000 and $4,600 for oil and LP respectively). A reasonable rule of thumb to calculate the input heat loss is to use 1% of annual consumption on design day and divide by 24. So 1200 gallons would be about 70,000 BTU/hr input (1200 gallons x 138,600 BTU/gallon oil x 1% / 24hours/day). If you are running with an annual efficiency of 80% (generous), that would be 56,000 BTU/hr heat loss. And that covers hot water production as well. The 1% figure is the fraction of heating degree days on design day compared to annual heating degree days (this is a very good approximation everywhere in the Northeast).

In the BNL heat and hot water boiler performance study, the System 2000 low mass with thermal purge design performed with an annual heat and hot water efficiency higher than the 95 AFUE modcon and other condensing boilers tested. Low idle loss is a primary contributor to high annual efficiency - we've discussed this in many other threads, so I won't go into detail here; basically when a boiler shuts off, remaining heat energy is wasted, so finishing "cold" with thermal purge through thousands of cycles is a proven pathway to high annual efficiency. That means you'll get exceptional performance in a 30 year proven boiler. An indirect tank with a coil will provide very good hot water temperature and volume with System 2000, but it will not thermally purge as well as a plate heat exchanger with a stratified storage tank so there is a further opportunity to improve performance when the HTP tank reaches its end of life.

If you decide to stay with oil, Roth and Granby double wall tanks look much more modern and "appliance like" than typical steel tanks, and they have exceptional warranties; maybe something to consider.

Please PM me, call customer service at (908) 735-2066, or reach out to our territory manager from Connecticut, Mark Santangelo (413) 575-0210 msantangelo@energykinetics.com if we can assist with any questions you may have.

Best,

Roger

President

Energy Kinetics, Inc.3 -

contact your propane supplier and tell them you are considering becoming a heating customer and ask them to quote you a price with an additional 1800 gallons of annual volume.

0 -

-

Figured I would provide an update on this - shortly after my original post, I noticed a pin hole leak on the underside of one of my tanks. We replaced the tanks this week with two 275 gallon Roth tanks.

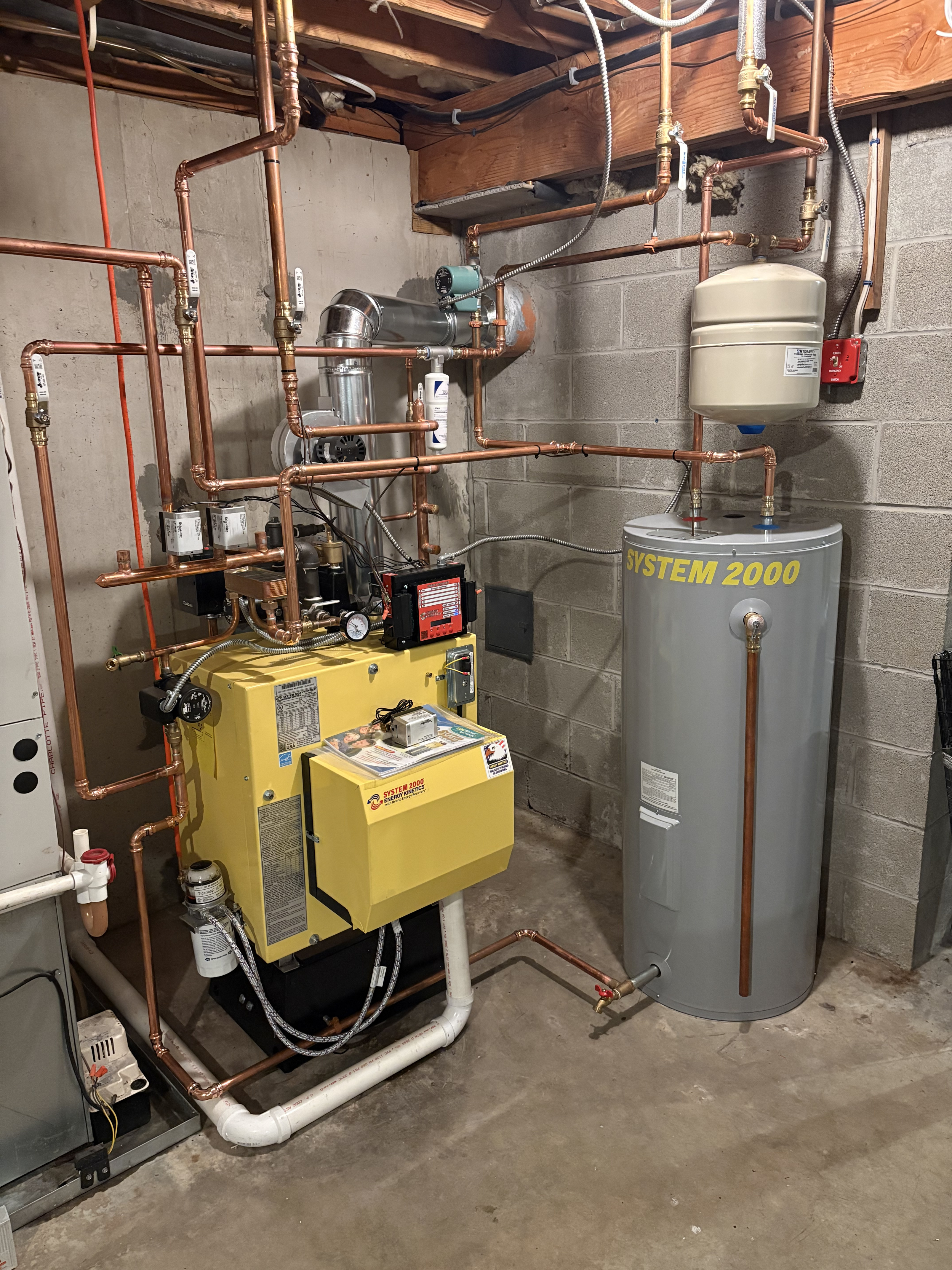

Additionally I decided to go ahead and proceed with installation of the EK1, which is supposed to happen next week. We are installing it with the plate heat exchanger and storage tank.

I have a couple questions regarding setting up the EK1 for hydro air to ensure the installer gets right:

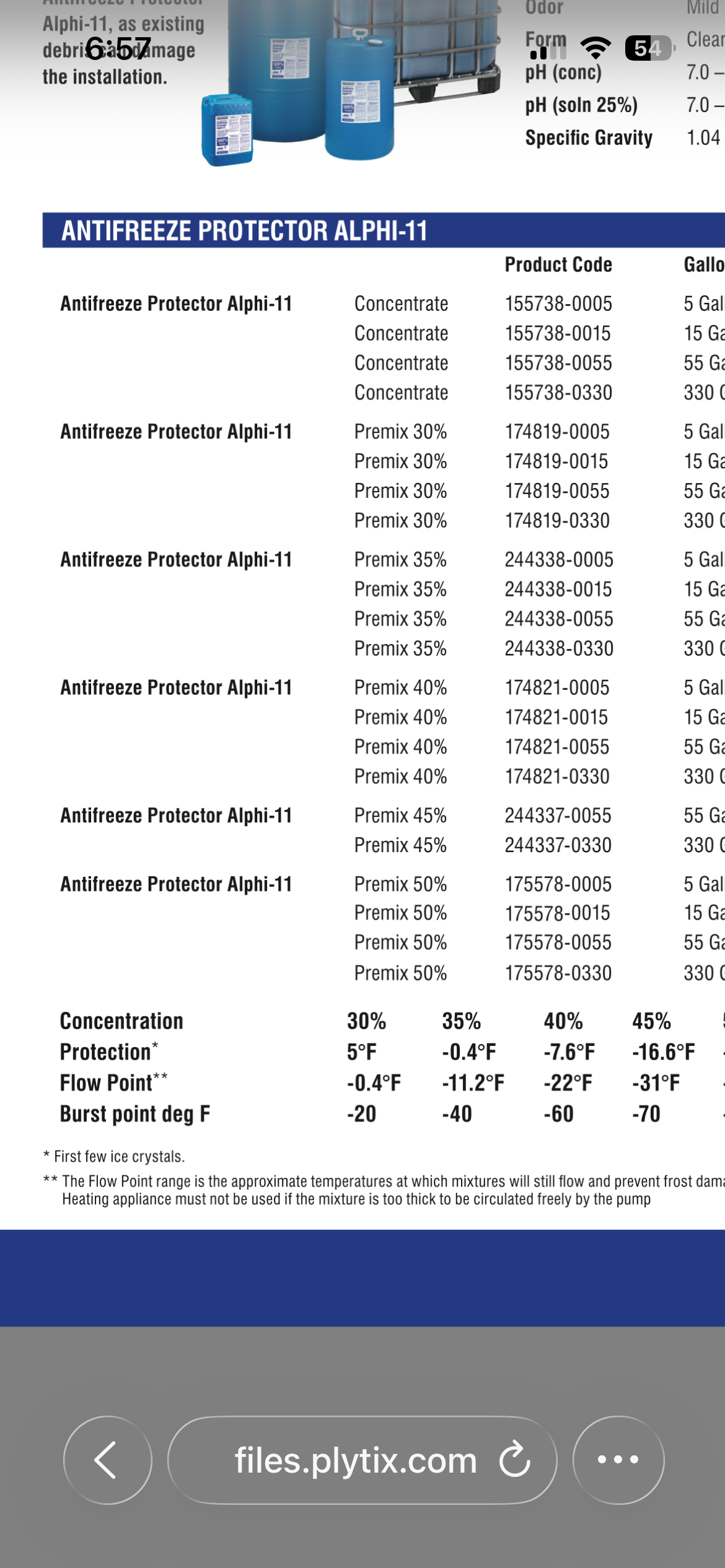

- We have anti-freeze in our boiler circuit since one air handler is in the attic (both air handlers are 3 ton). I believe the current mixture is 50/50. I am reading (29th Edition from July 2005 - possibly out of date?) technical manual for the EK1, and it recommends max 30% PG unless and "only if lower temperature freeze protection is mandatory". Since 30% only offers freeze protection to ~8F and we are in CT and the temps can easily slide below ~8F during winter, is it recommended to increase this? We don't generally have issues with power loss (have a generator) and don't often leave for extended periods during winter.

- Since our system is hydro air, and one zone needs to get all the way up to the HW coil in the cold attic, should we do something to increase the supply water temperature (e.g. raise low return water temp setting)? What's the best way to monitor optimal performance at the upper air handler - check temperature at the attic air handler coil?

- Will the air handler fan control be any different with this setup vs. conventional boiler?

- Anything else in particular I should make sure the installer gets right for our setup?

Thanks @Roger and all.

0 -

I have the same issue at my home - an air handler in the attic above the insulation line. I have a generator for backup in case we lose power, but my plan for the next winter season is to remove all the insulation below the attic air handler and build a well insulated room around the air handler which will essentially place the air handler in the "living area". This will greatly reduce the chances of a freeze even if the generator goes out or in case the boiler suffers a catastrophic failure that can't be repaired or replaced fast enough before the attic coil freezes.

My concern with anti-freeze is that I've read that anti-freeze in a heating system can cause internal corrosion and that it should be flushed and replaced on a schedule. Maybe some pros can comment on that.

1 -

Thank you for placing your confidence in Energy Kinetics and your Energy Kinetics dealer, @ctboiler28 , I'm sure you will have many years of happy heating!

- Attic zones are usually protected with a propylene glycol mixture which either circulates through the entire system or is isolated with a plate heat exchanger and additional circulator and expansion tank on the attic zone. It is fine to use a 50/50 mix when isolated. Using boiler treatment (like 8-Way, which is included with the boiler) keeps the pH above 7, which also prevents corrosion.

- There is no need to change the temperature supply to the attic air handler. If your warm air coil is undersized, you would probably know by now. If that is the case and the air handler cannot keep up, then you could turn on SmartBoost™ to automatically increase the temperature when needed.

- The air handler should be controlled with the end switch on a zone valve. This makes pre-heat, heat, and thermal purge all work seamlessly with the blower.

- I know you are working with an exceptional contractor per our PM, and our territory manager is aware of your installation as well, so I think you should be in great shape for your installation.

Best,

Roger

President

Energy Kinetics, Inc.1 -

50% glycol is crazy IMHO. We always used 30% with no issues. More glycol reduces the heat transfer.

You may hit -8 but the attic even in an unheated home is warmer than the outside. In addition when it is -8 the ahu will not be idle for long.

There is no 100% foolproof way to prevent a freeze up. Glycol freeze point and burst point are very different things. It will start to slush long befor a pipe will burst,

You could also put a separate circulator on the attic AHU and feed it with an injection loop off the boiler and run the attic circ pump to run constantly when below 32 degrees. You could maintain 70 degree water in the attic loop until you have a call for heat

2 -

@ctboiler28 , since the pocketbook is open, have you thought about spray foaming the attic? It'll make the attic part of the conditioned space. Even if the ductwork has air leaks, it won't matter anymore because its dumping and/or pulling from conditioned space. I'm not crazy about glycol at all unless it's got a feed tank, cutoff safety, and low pressure alarms.

0 -

there is a freeze point and burst point

This Fernox at 35% is plenty strong

-40 burst, pumps down to below 0

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@HVACNUT we have pretty large attic, so converting it to a conditioned space would be very costly. We did an energy audit last year and as a result got a good rebate deal on blown in cellulose insulation and airsealing the attic, plus aerosealing the ductwork which greatly reduced CFM loss. The good news is the new cellulose actually covers a good portion of the boiler piping, but it obviously can't get all the way to the HW inlet on the AHU.

@MaxMercy I do wish the construction standards in 2000 would have been to put the AHU in a small conditioned area of the attic. Seems obvious. But it's not going to be practical for me to do that retroactively now. Are you going to build a whole room? You'll need access to the AHU for servicing and replacement.

Good comments from @hot_rod and @EBEBRATT-Ed about the antifreeze mixtures. Good points that actually bursting is unlikely in our climate even in a lower mixture %.

@Roger - the EK manual states the below regarding water quality. Our well water is naturally pH neutral (mid 7's) and we have a water softener (water is hard without it). What would you recommend the water mixture be? Add 20-30% glycol, and then also add the 8-way? Am I reading the below correctly that the EK is shipped with an anti-freeze along with the 8-way?

"Hard water should not be used in combination with generic antifreeze. Energy Kinetics supplies a quality inhibited Propylene Glycol anti-freeze with orange dye and an antifoam agent. 8-Way Boiler Treatment can be added to Energy Kinetics anti-freeze and is recommended in areas of medium water hardness."

0 -

compare the costs of the 2 fuels

https://coalpail.com/fuel-comparison-calculator-home-heating

oil will come out ahead.0 -

Thank you for your posts @ctboiler28 . As @hot_rod stated, what you are really looking for is burst protection. Energy Kinetics includes 8-way boiler treatment with each boiler. The antifreeze would be ordered separately. We recommend 30% antifreeze with 8-way added per the instructions. Some contractors bring in water to mix with the antifreeze, and some antifreeze comes pre-mixed.

Roger

President

Energy Kinetics, Inc.0 -

@pecmsg yeah, and I hope it stays that way. We just installed two new Roth tanks, which was a pretty penny, so this house is committed to oil for the next 2-4 decades unless something crazy happens.

I will post some photos of the complete setup after the new boiler is installed next week.

0 -

Sorry that I don't know how to edit the quoted box to reply to your question to me specifically - if anyone knows how to do that, I'd appreciate the advice how to do so.

Yes, I plan to build a room around the air handler, but I have one wrinkle - there's a whole house fan right next to it, and we LOVE the whole house fans on low humidity nights. The plan is to build a well insulated room using 2X10 walls with rockwool batting and a solid barrier inside and out (haven't decided on thin OSB or rigid foam) and install a pass door for both access to repairing the air handler and to open when using the whole house fan. I might consider a remote door actuator for the pass door with a limit switch to activate the fan when the door reaches full open and shut the fan down when the door starts closing. At least one of the walls will be attached to the others by screws, so if the air handler ever needed replacement, I can remove one wall fairly easily. I'm also considering adding a ceiling vent below the air handler that will allow warmer house air into the attic room.

The room will take up maybe a third of the attic. It won't cover the flexible vents snaking across the attic floor, but I plan to box around those and insulate them.

It is so strange that building codes allowed an air handler which is virtually "outside" the house. In the summer when the AC is running, my AC air handler is sitting in 120F plus temps, and in the winter, my heat air handler is sitting in temperatures in the teens..

I had considered doing a complete attic encapsulation, but it bothers me that there might be a roof leak that will go undetected for a long time if the rafters are fully insulated. I might change my mind on encapsulation though in place of the room. Encapsulation might be a good plan for you?

Back to the air handler being "outside" for a second. I have two separate but identical 2 ton AC units (one for each floor). My lower floor cools just fine but the AC on the second floor is useless during a sunny day. So I did an experiment - I ran just the air handler circ fan (AC off) for 20 minutes on a sunny day about noon, and what I found is that the air coming out of the vents was 12F warmer than what went in! That's with the handler fan running 20 minutes, so the temp diff wasn't heat picked up from stagnant air. If you consider how quickly the air is moving through the handler, it's picking up a LOT of heat. I imagine I'm losing an equal amount of heat in the winter but the boiler has no trouble heating the second floor even with the air handler sitting in sub freezing conditions.

What I do for hot nights is to turn on the whole house fan for an hour with the second floor windows open about 4 o'clock to cool down the attic, then shut the windows about 5 and put the AC on. By the time we get to bed about 10PM, the second floor is nice and cool and dry.

0 -

-

Look at all the commercial buildings with roof top units doing heating and cooling. They sit in the blazing sun in the summer and in the freezing cold in the winter. Nothing but a tin box with 1" of insulation

0 -

@MaxMercy you might want to consider aerosealing your ducts. These are screenshots of the CFM loss reduction before and after for our two air handlers. Our blown in cellulose in the attic also covers the ductwork, which should reduce unwanted heat loss/gain as well. This was essentially free for us to do in CT after energy improvement rebates.

0 -

Yeah, I've seen them, but just because they waste a ton of money doesn't make me feel better about wasting mine.

0 -

Aerosealing is part of the plan, yes. I've already sealed my basement ductwork seams with the brush-on goop in preparation for insulating them (another thing they didn't do in the 1990s in CT… )

0 -

For anyone interested, I have attached photos of our end result on new tanks and boiler. Thanks again to @Roger and all for the help and advice.

3 -

Nice!!

0 -

Very nice work. It's good to see they didn't use the Roth tank twinning kit and ran separate fills and vents. Boiler piping is nice. Everything that needs support has support. There's room to get behind the boiler if needed. Very nice.

Why the power vent? Long horizontal run?

0 -

@HVACNUT I am not sure about the vent. There wasn't one before - is this standard on new EK installs? I was also not expecting to see the inline filter on the domestic water inlet line coming to the circulator. Is this just to prevent sediment in the storage tank perhaps, like anything not already captured by whole house filtration?

0 -

Thank you for your post, @ctboiler28 . Inducers are sometimes used based upon site specific conditions. I've reached out to your territory manager to find out more.

The "filter" is not actually a filter, but an NSF rated Scale Stopper which prevents mineral buildup on the plate heat exchanger and in other areas of the system. It works up to about 25 grains of hardness and is a great combination with our Sealix non-stick silicon dioxide coated plate heat exchangers to provide long term reliable performance in hard water conditions.

Best,

Roger

President

Energy Kinetics, Inc.2 -

Update on a minor issue with our install. I know from @Roger 's previous comment here and from reading other similar forum posts that EK recommends wiring the air handler fan to the end switch on the zone valve for hydro air (essentially a NO contact that closes when the valve is energized). I didn't check this closely enough on day of install and didn't notice until I was watching the operation of the unit more closely yesterday that the air handler is shutting down right after the signal from the thermostat goes away (e.g. T2 on energy manager) even though the valve (e.g. Z2 on energy manager) is staying on for a further 5-10+ minutes. The result is that the blower cycle pushing air into our heated space is rather short compared to the boiler cycle and the thermostat calls pretty frequently. Meanwhile the zone valve never shut while I was watching it, because the thermostat initiates a new call for heat before the zone is done purging.

Below is a picture of the zone valve wiring. I assume there should just be an additional 2 conductors coming out of each valve (wired to end switch contacts) that wire to the appropriate points on the fan coil.

The air handlers are First Co. 36VHBXB-HW. We need the thermostat to still signal the air handler because it also controls the fan for cooling in summer. With this air handler model, can the installer just wire the zone valves to the fan in parallel with the thermostat's connections, so that a signal energizing from either the thermostat or the zone valve(s) keeps the fan on?

So the thermostat's initial call for heat energizes the fan (may be some cold air blown while the boiler preheats depending on its state at that moment), but then the zone valve keeps the fan energized after the thermostat is satisfied, until the zone valve turns off at end of thermal purge?

When I spoke to the installer this morning, they were not sure how to handle this offhand but are coming back tomorrow to look at it.

0 -

Those look like two wire zone valves? If so there is no NO end switch available.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thats not good!

0 -

Taking a quick look at the valve catalog, it looks like the part numbers that have an end switch end in a "A", which this one does not. I can open one later and check to confirm. I am surprised it does not have the end switch included if that is the recommended way to wire these for hydro air. Could they instead double tap the right side outputs of the energy manager to energize both the zone valve and the fan directly?

0 -

Thank you for the information, @ctboiler28 . Our territory manager, Mark Santangelo, is working with your contractor to facilitate this correction. I trust all will be as it should be soon. If you'd like to reach out to him directly to find out more, he can be reached at msantangelo@energykinetics.com , or reach out to us at (908) 735-2066.

Best,

Roger

President

Energy Kinetics, Inc.0 -

"An indirect tank with a coil will provide very good hot water temperature and volume with System 2000, but it will not thermally purge as well as a plate heat exchanger with a stratified storage tank so there is a further opportunity to improve performance when the HTP tank reaches its end of life."

@Roger could you expound on this a little? I am looking to get away from my tankless coil setup but since would sooner use a storage tank than an indirect from your mentioned reasons, but I can't find them? Who makes them?

0 -

Thank you, @RascalOrnery . The higher efficiency is delivered through thermal purge, which only integrates well with a low mass boiler. The control to make it work is built into our Energy Manager, and the tank is specifically designed to integrate with the boiler, control, and plate heat exchanger. Energy Kinetics makes all of these work together. We do offer our Hot Water System "A" Tankless Coil upgrade system; this works with tankless coil boilers, and will only thermally purge once the boiler is also upgraded to a System 2000/Frontier or any of our other boilers with an Energy Manager.

The reason why thermal purge works with a stratified tank is because the boiler can thermally purge down toward the make up water temperature (maybe 60°F) instead of the temperature that the coil in the tank is exposed to (maybe 140°F). This means the boiler finishes cold (heat energy is recovered after the burner shuts off) and the tank finishes hot. I went into detail on this in another HeatingHelp post here.

Best,

Roger

President

Energy Kinetics, Inc.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements