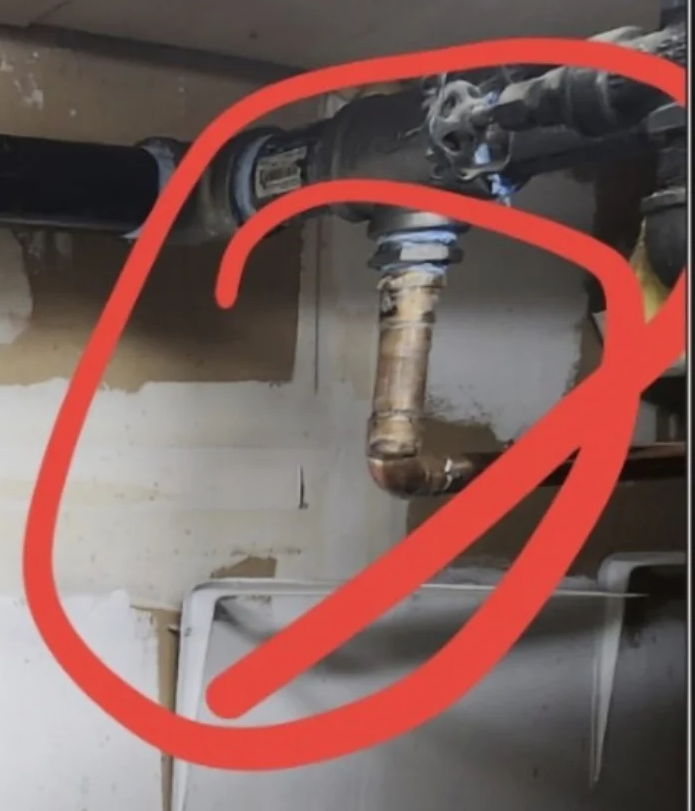

Hartford loop set up .. done wrong or right?

Hello all,

I had my new boiler done a few months ago. I'm experiencing some problems like water hammer, radiator leaking among others.

A plumber told me The Hartford loop is incorrect and he's going to charge me a fortune to fix it. The loop is causing all the problems. I'm not sure I trust this guy.

Is this done wrong or right? Thank you.

Comments

-

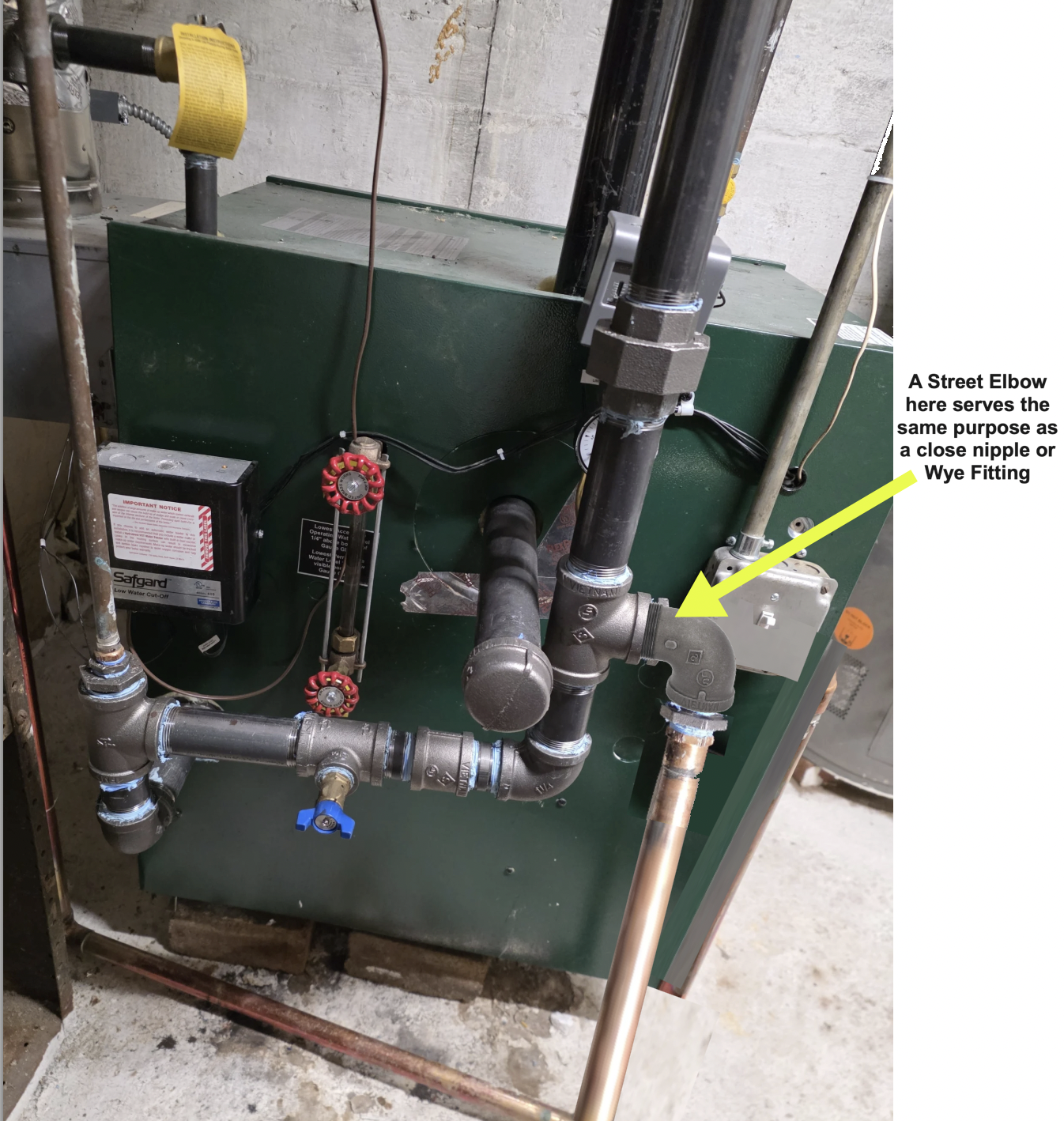

Not the best-looking Hartford loop I have seen but I guess it will work. Take a ruler and check the height off the floor to where the copper tubing comes out of the return tee. Then measure off the floor to the normal water level which is where the boiler MFG marks it or to the center of the gauge glass.

The copper tubing should be 2"-4" below the normal water level. Yours looks high but It could be the camera angle.

Post some pictures of the piping above and around the boiler so we can see if you have other issues.

Why not get the installer back if you need changes and not the plumber?

Did they measure your radiators when they sized the boiler? Did they skim the boiler.

3 -

I am just a homeowner, not an expert. But the more I stare at that picture, the more I see things that concern me....

0 -

Yeah it's wrong. Looks too high to me. As Ed says, the top of the Hartford should be 2 to 4 in. below the normal water line. Also that Tee should be a reducing tee with a Street elbow or a close nipple with an Elbow. With it that long you could get water hammer, especially with it probably being too high.

I don't think that is the right place to put the shutoff valve in the return which is to allow you to do a no return flush. I would put it in the vertical part just below the elbow in the Hartford.

0 -

Wrong and may be the cause of the hammer

It looks like a 8" to 10" long pipe between the copper elbow and the Tee fitting

You want the pipe here to be as short as possible. A street elbow serves the same purpose as a Wye fitting or a close nipple.

Let me know if you liked the story.

Mr. Ed

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Listen to this story and you will hear the explanation of why your Hartford loop is wrong at about time stamp 4:24. I recommend you listen to the entire story but your info is at 4:24

And as the other ED said it might be too high. Two Eds are better than one

Hope this info helps with your repairs

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Let's see some pictures from a couple different angles of the header and the takeoffs from the boiler. There could be something wrong there too, if the installer did what he did with the Hartford Loop.

Just to make you feel a bit better, my installation is a S show in it's own right, being way too high. I have to keep water level higher because of this and monitor water quality like a hawk, along with too small riser and header etc. etc.

0 -

Definitely looks like the Samsonite gorilla got drunk and threw pipe and fittings against the wall and then started putting that mess together.

Is the boiler power switch attached to an exposed ceiling joist?

Having the both the pressure gauge and pressuretrol obstructed by pipe is not safe in my opinion as you cannot simply look at them and you would become complacent and simply forget them.

Is this steam boiler gas fired? The power switch is not visible, is it at the front of the boiler behind a cover?

I hope the power is for the boiler is not direct wired in that junction box.

I hope you get that mess fixed. IN MY opinion a plumbing inspector may tag it because the pressuretrol and pressure gauge cannot be seen easily.

1 -

I would have a Voodoo Doll of my installer but I'm not sure who it is. It may be my neighbor up the street but I'd have to put him on a polygraph to find out 🤣 I plan to fix my HL next off season. I swear lol.

Here is Dan Halohan's specific language in that video (thanks for bringing my attention to it again)

@1 :20 The wet gravity return line, which returns the condensate from the system, rises up from the floorto join the equalizer at a point about 2 in. below the boiler's lowest operating waterline.

@3 :34 The point where the loop connects to the boiler's equalizer is higher than the boiler's “crown sheet”, and that's what provides the safety.

@5 :07 Generally you should connect the close nipple about 2 in. below the bottom of the gauge glass, but check the boiler manufacturer's spec. on this. The centerline of the close nipple has to be below the waterline, but above the boiler's crown sheet. And don't install the close nipple 2 in. below thec enter of the gauge glass because that's probably too high. You see when the water leaves the boiler as steam the level in both the boiler and the equalizer will drop, If it drops below the close nipple, steam will push down through the equalizer into the wet return and create water hammer. This usually happens near the end of the firing cycle and it causes a very noticeable racket.

0 -

-

Here's a Dunkirk Oil Fired Steam Boiler install where they say centerline of Close Nipple is 2 in. below the

centerline of the bottom sight glass tappingwaterline. Much lower than most people seem to be installing them. It's a safety from dry firing (in the case of a leak in the wet return) for crying out loud, and the 2nd one in line after the LWCO fails. Seems to vary a lot by boiler manufacturer though which may be leading to confusion. Peerless says "Pipe the Hartford Loop such that the top of the close nipple is 2 to 4 inches below the boiler normal water line".0 -

@Captain Who (may be off topic here) These are the first pictures I've seen of your sight glass. You speak of monitoring your water quality, what do you have in that boiler that the water is so murky ? Have you ran it with just clean water in it ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

This is after I flushed and re-filled with clean pre-boiled distilled treated with Rectorseal 8-way. That's about the target color of light violet to medium violet (normal phenolpthalein pH indicator). 21 year old boiler and I'm not running it without treatment or lousy super hard tap water with high chlorides. It is running very good now with less than 1/4 in. of bounce in the sight glass (good for this boiler install) and no apparent carry over/wet steam issues. System very quiet now. Just a faint whisper from the vents with very little panting. pH seems to be 9.6 from Hydrion paper but I'm waiting for new batteries for my digital meter. The issue is that I have to keep my water level on the high side due to the improper Hartford Loop, which reduces my steam chest, especially with the 2 in. riser and header that was installed when it is supposed to be 2-1/2 in. (= 56% more cross sectional area) and the boiler is not level being tilted so that water level at the takeoff is about 1/2 in. higher than at the sight glass, and the header is tilted upwards towards the equalizer.

1 -

@Captain Who has a nice project for this summer

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

-

-

-

I am adding some additional pictures. Updates:

- I have replaced all my air valves with plumbers edge air valve from home depot.

- I notice after I drain water from boiler, I don't get the water hammer sounds but after a few days it comes back especially with one radiator that's in the back of the house. And that radiator always leaks a lot of water after that.

- Looks like my return tee is not above the sight glass. It's about in the middle as seen in the picture.

Thanks all.

0 -

the near boiler piping is wrong so any water that gets pushed out of the boiler by the steam is going to go in to the mains instead of in to the equalizer and back in to the boiler. the lower water level may be helping it separate more before it goes in to the riser that should go to a header but goes directly in to the mains instead.

2 -

Your Hartford Loop is way way too high. In order to keep the waterline 2 in. above that close nipple (I use that term loosely because it ain't), you wouldn't even be able to see the waterline in the glass and it would severely limit the steam chest inside the boiler.

Looks like a Bullhead Tee header which is a disaster and a huge no no.

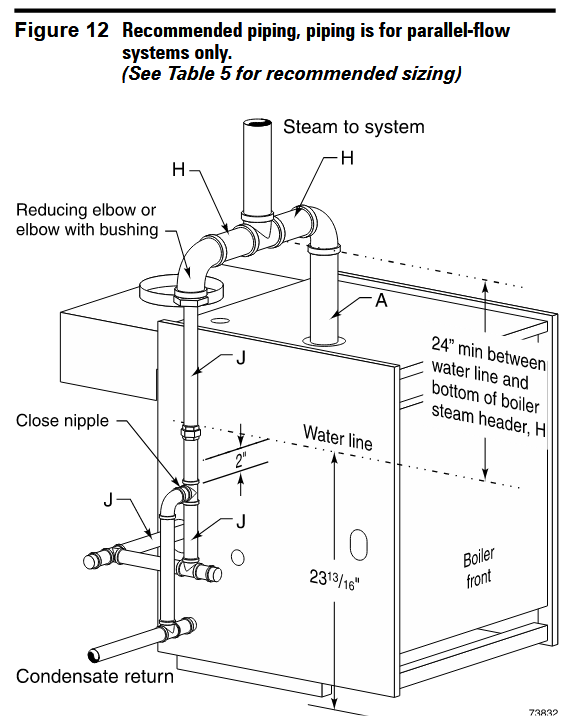

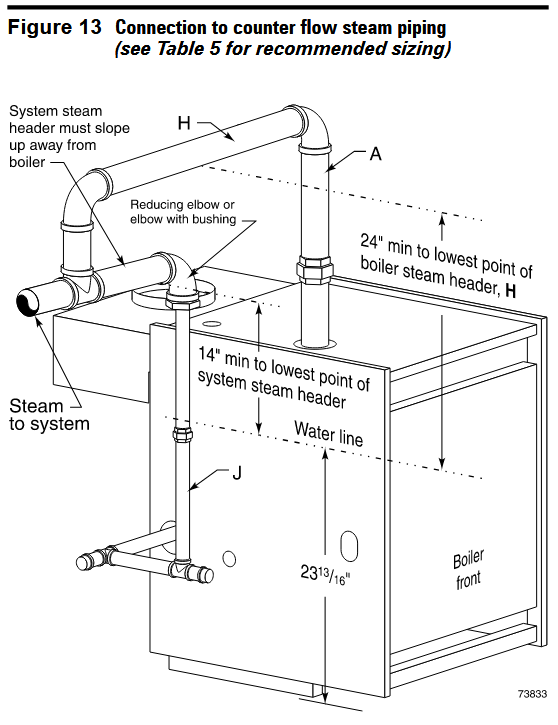

Are the mains sloping upwards away from the boiler, ie. a counterflow supply? Parallel flow would be sloping downwards away from the boiler. If it is counterflow which it appears to be that is compounding the problems because any water coming back into the header will just go down the supply riser, tall as it is, but there is no way it makes it into the equalizer and it just acts to oppose the steam rising and restricting it's flow and making it wetter.

That equalizer is supposed to be coming off of one end of the header (the downward end because it shold be sloped downwards towards the equalizer) but the way they piped the header with a bullhead tee that wasn't going to work I guess.

I feel your pain but your install was quite a bit worse than mine, I'm sorry to say.

When you get it fixed you will be happy though.

1 -

Don’t buy vents from Home Depot. We’re all piling on, sorry about that

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

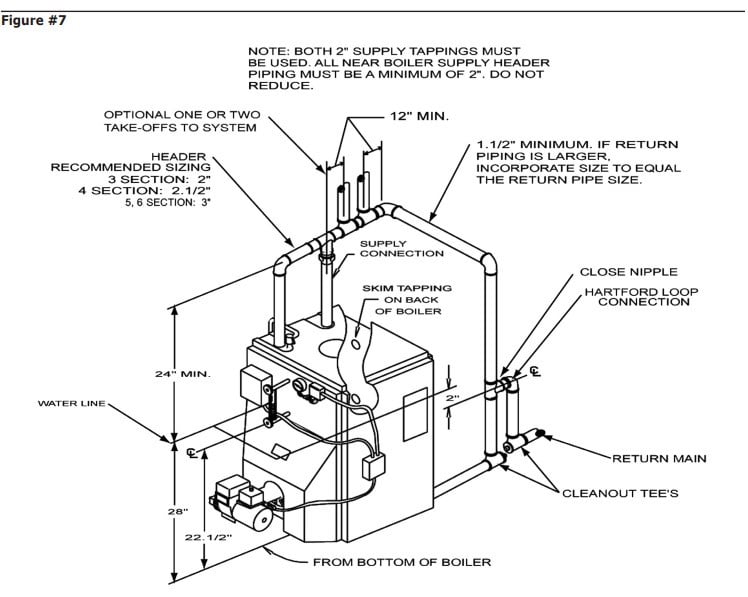

Do you have the manual, you should. If this was a recent install, you should have the installer come back and correct the install, maybe help them to read the manual.

If it is counter flow. Or use drips like it looks like you have.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Thank you all for your help.

So I understand. My problem is

1. header is too short

2. Need to put a close nipple and elbow on hardford loop and possible lower the tee below nwl.

This is causing water hammer (very loud) and one radiator to always leak through air valve when heat is called instead of steam coming through , it gets water coming thru..

0 -

-

the header is nonexistent, it is just a pipe straight up with a tee in it. what should happen is the riser out of the boiler should come up make a 90 to a horizontal, it should have 2 tees in that horizontal section, preferably with the branch straight up or at a 45 to each individually connect to the mains, then after those tees it should continue horizontally with ells as needed to get around to a 90 that drops in to the equalizer that drops down to the return with the tee for the hartford loop in there somewhere. the piping above the boiler is far more important for it to operate properly than the hartford loop. make sure all the pipes are at least the size specified in the manual.

it looks like it is counterflow so there should be drips teed in to the mains that individually drop down and connect to the return before they drop down to the header

1 -

This is the drop to the return from the main. Is this also incorrect? Does it need a elbow and closed nipple also?

0 -

it depends on what happens at the other end of that pipe. if it drops down to the return before it connects to anything else it is probably ok(although dry returns shouldn't be copper but you could argue that is the least bad place that is supposed to be black iron to be copper).

Do the mains slope toward the boiler or the ends of the mains? At the boiler it looks like they are sloping toward the boiler.

1 -

It looks like that is a 'Drip' for a 'Counter Flow' main and if your main(s) are counter flow it should be there That is at least one method to prevent condensate from going back into the steam supply from the boiler.

What looks like a second main does not seem to have a 'Drip', It looks 'Counter Flow' also.

Parallel Flow, the Steam and Condensate flow the same way in the main pipe.

Counter Flow, the Steam and Condensate flow the opposite way in the main pipe.

Which way are the main pipes pitched ???

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

-

Well apparently you have at least two drips. I thought this one was the one near the boiler, upon a second look I now believe it is elsewhere.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Yes I have two drips I think. Is that good or bad ? One is closer to the boiler and this one

0 -

where the drips belong is dependent on how the mains are sloped.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements