That Pesky O₂ Molecule – How Oxygen Finds Its Way Back Into a Steam Boiler

In this weeks video, I talk about that pesky oxygen molecule and how, despite your best efforts, keeps finding its way back into the boiler water. The video goes over the damage it does and how to minimize the damage.

Boiler Lessons

Comments

-

An observation about where oxygen does its real damage:

You are right that oxygen enters cold water and we do of course see returns (usually at the boiler) rot out pretty quick.

However, where do the boilers always fail? At the top of the section, every single time. How is that possible? There's no water up there, there's only air and steam, right?

You also said in your video correctly that the oxygen is forced out of the water as the water is heated. But I would ask "where does that oxygen go?" It is released into the steam chest, or the upper part of each section, where it is free to attack the cast iron. This is why I think it doesn't matter when you heat the water you add to the boiler—regardless that oxygen is going to be freed to attack the boiler.

So in my mind, the best way to keep your boiler from seeing premature rotting death is to use makeup water that was recently boiled, and to use a product such as 8-Way that has oxygen scavenging capability as well as the known corrosion-reducing pH booster chemicals.

Thank you for your video!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Oxygen in hydronic systems gets consumed in the oxidation process. Within days or weeks you should end up with "dead" oxygen starved water. Air left over will be mostly nitrogen.

So if no additional water is added, or O2 is not being pulled in somewhere corrossion should stop.

Does that translate to steam systems? How much water should a typical system take on continually.

The pressure on the water has some to do with air solubility, but that is not an option in steam systems.

Steam specific manufacturers refer to mechanical deareation ad chemicals with sodium sulfite O2 scavengers, and ph control. So as @ethicalpaul suggests treating the steam boiler is just as important, maybe more so, as treating a hydronic boiler.

Some info from the Rhomar manual

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

This is one of my main concerns with my steam boiler. My water make up is from the cold water supply. We've only been in our house 2 seasons so I was only able to insulate some of the mains and condensate returns that were accessible in the basement. Another problem is I don't think I have an easily accessible port to add chemicals. The only vertical piping is the PTR valve and it's soldered in place.

- Where would you recommend I add my treatment chemicals?

- Do you recommend placing an inexpensive small tankless hot water unit & O2 separator inline with my water make up? I would prefer not to pipe off the hot water heater.

Thanks!

0 -

you have it very easy. Your Utica has these side outlets to which you can attach an elbow and a nipple sloped toward the boiler with an optional reducer and ball valve

With this setup you can add treatment or even all your makeup water (I add only heated distilled water because I’m a fanatic)

I don’t recommend a separate water heater setup because it’s too easy to just pour it in yourself every few weeks (minimizing leaks is the first priority)

PS I see from your contractor’s sticker you are in Michigan. Hello from a native Michigander

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

-

Thanks @hot_rod Always there to offer expertise.

@ethicalpaul good point

Ray Wohlfarth

Boiler Lessons0 -

Could we consider rot above the water line as a victim of O2?

What are folks view on a small carbon block filter on the feed water to remove chlorine and light solids… not worth the bother, no point?

0 -

Could we consider rot above the water line as a victim of O2?

Absolutely

What are folks view on a small carbon block filter on the feed water to remove chlorine and light solids… not worth the bother, no point?

Ezzy and Clammy do it. I exclusively use pre-heated distilled water for makeup water, so I'm not one to judge

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

@ethicalpaul hello from MI! Thank you both for the info. I am manually adding make up water around every 7 to 10 days when I hit low water cut off and the house gets cold, so I don't think your suggestion is the correct solution for me. I do appreciate your dedication 🫡. I have looked at every single pipe and wall in my house and I would swear on my life there are no leaks. In terms of ease and function, I think @STEAM DOCTOR's suggestion is the one I feel most comfortable with completing myself.

Is your main concern with an external heater/bubbler that the potential for leaks increases with more connections?

2 -

I don't know physics or water chemistry or metal chemistry or anything like that. I have long assumed that there is not much corrosion below the water level, because that metal is totally submerged in water. The metal above the water line, tends to have water and moisture on it, without being submerged. Would assume that is more likely to corrode. And the more oxygen in that water, the higher the corrosion likelihood is. Can't remember ever seeing a boiler rust out at the actual water level itself.

0 -

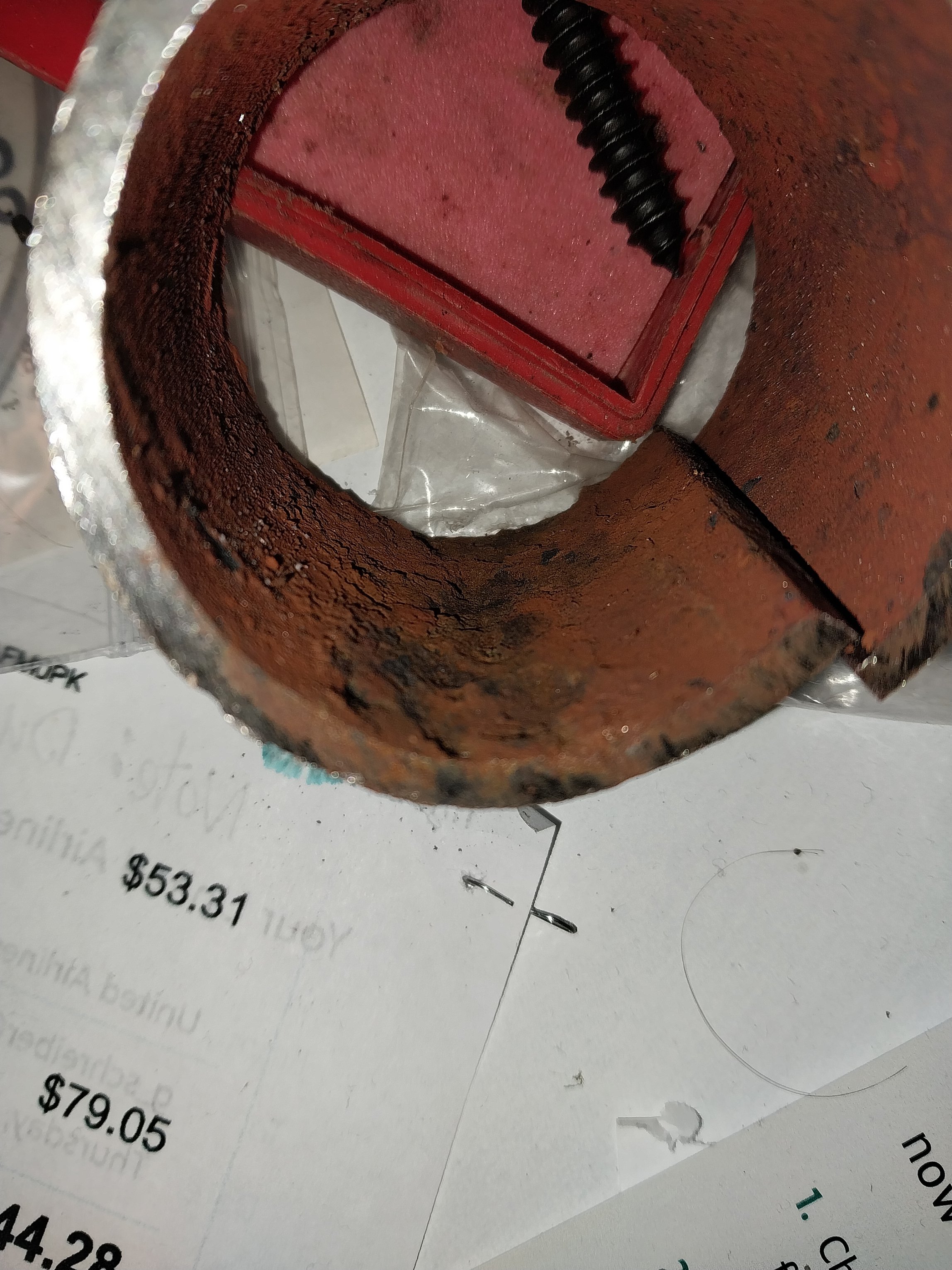

Yes I have noticed the same thing from a distance of this forum @STEAM DOCTOR that all holes seem to always be at the top of the sections.

And yet the other major rot point always seems to be where the wet return hits the boiler, so something interesting happens there as well.

@Day_Tripper that is a lot more water than I like to see being added. Look for leaks of steam or water, especially the vents. There is also the possibility that your boiler has a hole in it as seen in the above picture (but probably smaller). I want to see less than 1" of drop in the gauge glass every month or so during the heating season. Using as much water as you are using will reduce the lifespan of your boiler. Of course if it already has a hole in it that concern is in the past.

Is your main concern with an external heater/bubbler that the potential for leaks increases with more connections?

No, just that it's a lot of hassle for minimal benefit

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

@ethicalpaul I agree that the make up water cadence is too short. I have looked at every vent and wall and joist and pipe and I do not see any obvious leaks. I will say this: my radiators will occasionally hiss for an extended period. I have looked at the vents while this is happening but I don't see an obvious 'drip' of water, perhaps just steam escaping. How can I check my boiler for a hole?

0 -

if your vents are letting steam out, that could be the whole leak.

the easiest way to test the boiler is to overfill it to the header and see if water starts raining down to the floor under the boiler

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

@ethicalpaul I will try and preform the overfill test today but my guess is it's the vents. Here's the long and the short of it. 2 story house with thermostat on 2nd floor. 1st floor only has half the rooms with radiators because the previous owners were morons and removed them from the kitchen and dining room at some point. Because of this, the 2nd floor reaches temp with ease while the 1st floor never gets a chance to 'catch up'. My wife then bumps up the heat from the nighttime program of 68 deg to 73 deg in the morning when we get up so the living room will be ~67 deg. This is when the hissing is most pronounced. The boiler is working to take the house (with missing radiators on half the first floor) from 68 to 73, so the living room where we spend a lot of time in is remotely comfortable.

0 -

You are in a difficult situation with that removed radiation.

But you are exacerbating it with that 5 degree setback at night. I recommend stop doing that and see if the downstairs is able to stay comfortable.

If the upstairs gets too hot for your comfort at night, try covering one or more radiators with blankets until you are comfortable, but keep in mind doing so is similar to removing radiation and may make your system cycle more.

Cycling more isn't a big deal for gas, but could be more problematic for oil.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Hmmm… my experienced HVAC man advises weekly blowdowns of the rust separator on my single pipe low pressure system. Circa early 1900's, massive cast iron. This obviously means that I'm adding water from the city main 40-50 times a year. Any advice on this? Is there such a thing as an inline oxygen eliminator?

0 -

@ethicalpaul Thanks again. I'm going to put that thermostat on a permanent 72 deg hold. We have radiator covers with top hinges that I can close or prop open a bit with plywood to increase/decrease air convection. I'll keep the upstairs covers down and the 1st floor open. Thanks again.

0 -

Can you send a photo of this "rust separator"? You might be referring to a float-style low-water cutoff device

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

As water is heated, the o2 molecules are driven from the water. They bounce around the steam side of the boiler until they end up in the steam and out into the system.

Ray Wohlfarth

Boiler Lessons1 -

Do you think that Rectorseal 8-way can protect steam mains at all? They say it does but I'm skeptical unless there is a lot of carryover. Otherwise it should be distilled water I believe. Here's what 100 years of corrosion inside a steam main that is not pitched correctly looks like. This is the downstream end of a 16 ft. section that went into a Tee for the riser to an upstairs radiator and what it looked like after I cut through it and chiseled it out. Kept it as a souvenir. Even if it is basically distilled water I would think that it would absorb CO2 from the air in the main and create some carbonic acid. But it is obviously very hot and would limit absorption. In the off season I had cool distilled water pooled up in there and saturated with air containing CO2. Would be interesting to know what the pH was. Anyway, you can see that this main rotted out at and below the waterline and there is lots of meat still on the pipe in the upper areas.

0 -

No, I don’t think 8-way protects the mains. I have thought about carryover helping but given that even a sagging, rusting main lasts 100 years, it hardly seems worth it to consider.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

These pictures show corrosion on upstream end better. I'd estimate 1/2 way through penetration at the worst spots. Uneven corrosion must be due to localized differences in alloy composition, and once the pitting corrosion starts a self perpetuating small pool of water exists. Definitely a different situation from boiler corrosion with treated water and mostly de-aerated water and "maybe" some protective effect from scale buildup.

0 -

I have the last radiator on a first floor run that blasts water out of the radiator vent. It has it's own wet return pipe to the main wet return. We have double checked everything for the cause. I have to add a small amount of water to the boiler once a week. For the summer I over fill the boiler with plenty of extra water and Steam Clean is used as a deterrent all of the time.

Any ideas ? Thanks.

0 -

this question would be better as its own discussion thread.

But I would suspect carryover is occurring

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

"Carryover is occurring ? " What is that ?

0 -

Carryover is when the boiler throws water up into the near boiler piping, and/or the header, and possibly as far as up to the radiators where it can potentially fill them and shoot water out of the vents, although that would be a pretty extreme case.

The easiest way to determine it's happening is to observe the gauge glass while this is happening. Does the level dive to the bottom of the glass?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Sorry for the late reply. The sight glass will drop about 2" during a heat cycle.

0 -

That's right at my personal limit…with that drop it's hard to know if it's carrying over or not, but in any case it's not a crazy amount.

Is the vent still blasting? Also define "blasting"—different people have different ideas of how much water is a lot

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I'm a little bit late to the party but I'd say that weekly blowdowns (assuming you have a float type LWCO) are not required under one circumstance. If your boiler is in good operating condition and your float type LWCO has been cleaned and verified to be fully functional and maintained….than RectorSeal 8-way to the rescue!

I was doing weekly blowdowns to get the rusty, muddy sludge out of my LWCO in my ~45 year old Peerless. I took it apart, cleaned it, and put new gaskets on the LWCO and started using RectorSeal 8-way at 1oz/gallon probably 7+ years ago. My pH is about 10.5 and absolutely no more mud/gunk/rust build up inside my boiler. My LWCO water would drain perfectly clear (well, slightly purple) even after weeks/months of not doing a blowdown.

I do it once a month…ish now. Comes out clean every time. This heating season I have added water twice (manual fill only). Each time it was about an inch of water on the site glass.

1 -

And leaks add up fast. For about 10 years I had a leaking radiator. It leaked between two sections but leaked at the top of the radiator so only steam would come out, no water or drips. I considered it "minor".

It would not be visible to the naked eye but you could hear it if you got close to it when the boiler was operating under pressure, say 1-2psi. My boiler is oversized so it does cycle on pressure.

Blowdowns aside I was adding water weekly during the dead of winter. Probably about 1-2" per week on the site glass when it was really cold.

I removed the section of the radiator that was causing the leak and put the radiator back together. No more leak and I now add water maybe twice a year, not including what is lost during my occasional blowdown.

That "little", barely noticeable leak was probably losing a gallon or two of water per week during the coldest part of the year.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements