Steam Drip Pipe Downsizing?

Greetings,

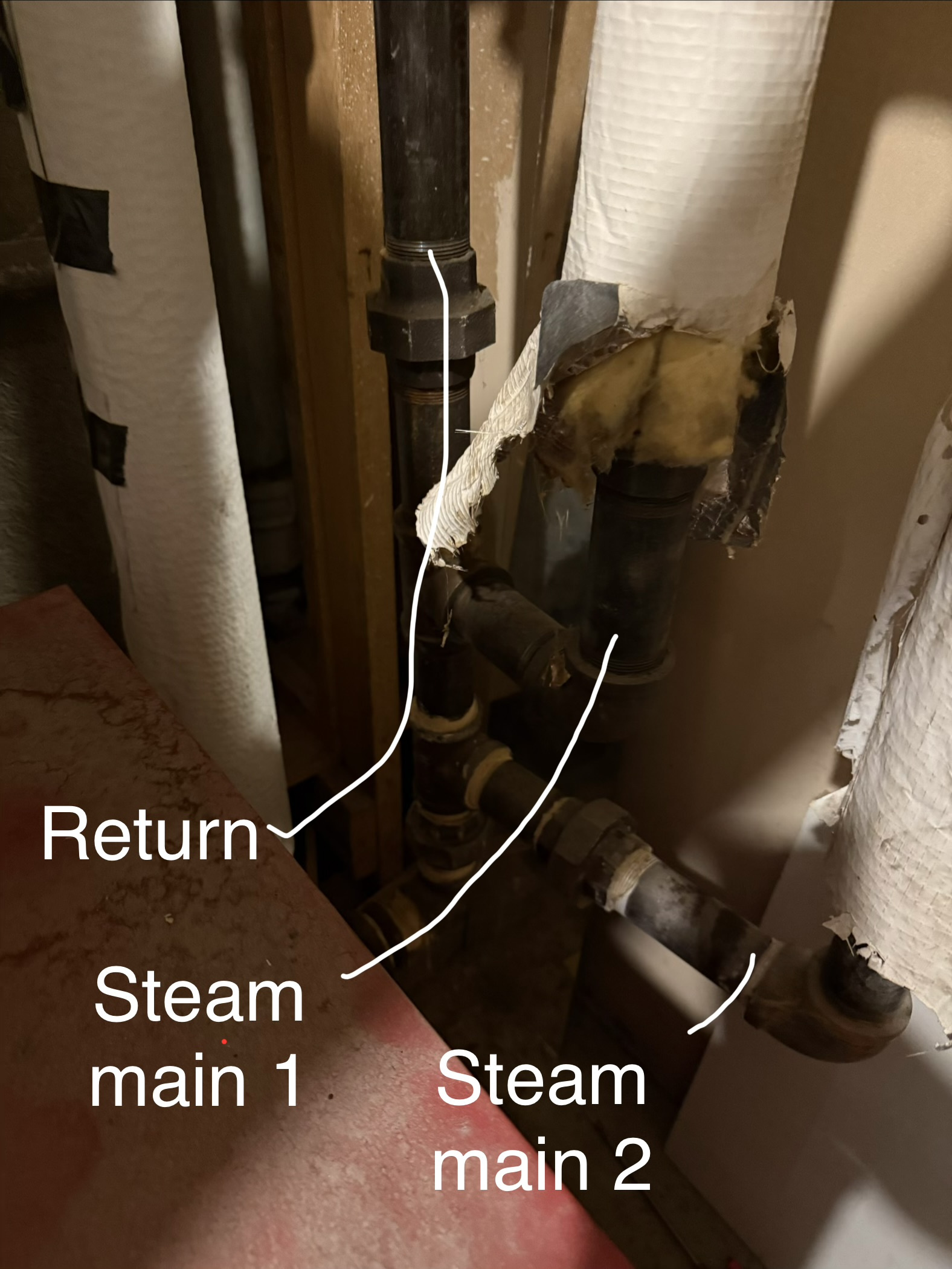

Working with a technician to rework the return (Dry and drip returns for two steam legs) at the boiler. Question I have (have not asked technician yet); Can the pipe size of the steam drip returns be reduced from the 2 inch it currently is to say 1 or 1.5 inch? Example:

The picture above 'Steam main 1' and 'Steam main 2' are the ends of each of the steam mains (drip return(s) I believe is correct nomenclature?). Can these pipes be reduced in size from their 2 inch current size to either 1 or 1.5 inch at the ceiling above the boiler? Example:

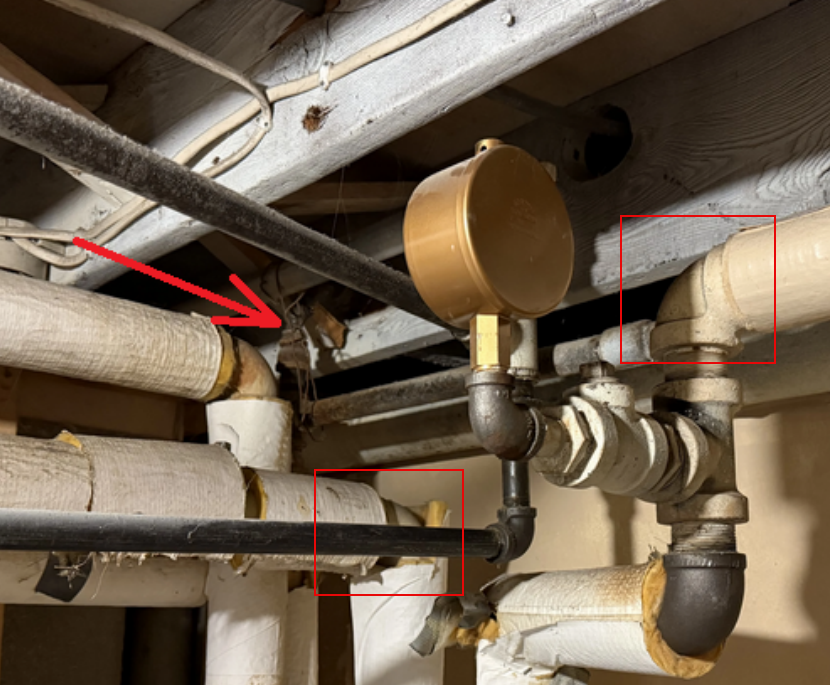

The red squares are the end of steam legs above the boiler. Can these be reduced to 1 or 1.5 inch via an elbow change at the ceiling? The lines will then be brought down to the floor, joined with the dry return then connected to the equalizer at 2 inches below water line to make the Hartford loop. Or do the lines need to remain 2 inch to the floor?

Thank you!

Comments

-

Here is a visual of what I'm thinking:

The elbow would be rotated 90 degrees so that the gorton #2 would be vertical not sideways (couldn't get vendor picture to rotate ;)

0 -

Paint for the win, better visual:

Thoughts?

0 -

1" would have no problem carrying the condensate, the only concern i might have is with it clogging over time. you can use copper once you are below the water line. I'll let the experts comment on what size is needed to keep it from clogging. A tee and a cap or valve at the bottom to flush it would be good too.

0 -

1" might do in a pinch. I'd rather see them reduced to inch and a half, with the reduction in the vertical.

And as someone @mattmia2 suggested, I'd connect all four lines together very near floor level with what is essentially a manifold with an extra T and a plug at each end to make it easy to clean out.

The FOUR lines are "Steam" line 1 (dry return from one steam main), "stearm" main 2 (dry return from the other steam main),"Return", and the line back up to the boiler inlet.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

1" is more than enough to drip a 2" main. Copper is ok only below the boiler waterline if that helps. When you come out of the tee for your vent I like to raise the vent up as high as possible to keep water out of the vent.

It might be simpler to put a 2 x 2 x vent size tee on the end of the 2" main then a nipple and a 2 x 1" 90 degree elbow for the drop

1 -

let's see if i have the math right here on condensate production.

The latent heat of vaporization of 1# of water is 1000 btu.

1 gallon of water weighs about 8.3 lb

so it takes 8300 btu to evaporate 1 gallon of water.

If the boiler output is 100,000 btu/hr

you will boil and condense 100,000 btu/hr / 8300 btu = 12 gallons of water per hour

that is .2 gallons per minute for a 100,000 btu/hr output boiler.

1 -

Yeah that's about right, @mattmia2 . Not much, is it?!

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Of course any carryover will add to the water the return piping has to handle.

0 -

Thank you for all the input. I will work to build out either a 1.0 or 1.5 inch 'manifold' at the floor with plugs on both ends for future cleaning.

It is my understanding that when tying back to the equalizer line, a street elbow of whatever size must be used, is that correct? Going from the 'We've Got Steam Heat!' book by Dan Holohan.

0 -

My boiler is 154,000 BTU so that equates to .0309 gallons per minute. Thank you for the calculations!

0 -

The hartford loop connection in to the equalizer should be a street ell or an ell and a close nipple on the horizontal so there is a minimal surface of water in there if steam ends up going down the equalizer. It usually doesn't cause a problem if it is a longer nipple but the potential is there.

0 -

Question. My boiler is a Smith GB250-S-5H INT model. It has a 2 inch return on the left and right side of the boiler. Currently the equalizer pipe is connected to the left 2 inch return port and the pipes from the returns are connected to the right 2 inch return port.

When the rework is done, should I cap off the right return port on the boiler since the Hartford loops needs to tie into the equalizer at 2 inches below water line, or can the reworked return piping be tied into the right return port on the boiler instead?

0 -

They should tie in to the equalizer so that it can equalize although in practice in a 1 pipe system with overhead returns it probably doesn't actually matter.

0 -

I have a two pipe system; one pipe supplies steam to radiator, other pipe has a steam trap at the radiator and slopes back to boiler for condensate return and air removal.

0 -

oh, i lost track, then the returns have to connect to the equalizer. If the returns connect to the boiler directly and the pressure in the returns is lower than in the mains it could push a significant amount of water out of the boiler and in to the returns to equalize the pressure. On a 1 pipe system the mains and returns are effectively connected together at some point in the system. On a 2 pipe system they are separated by either steam traps or water seals or both.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements