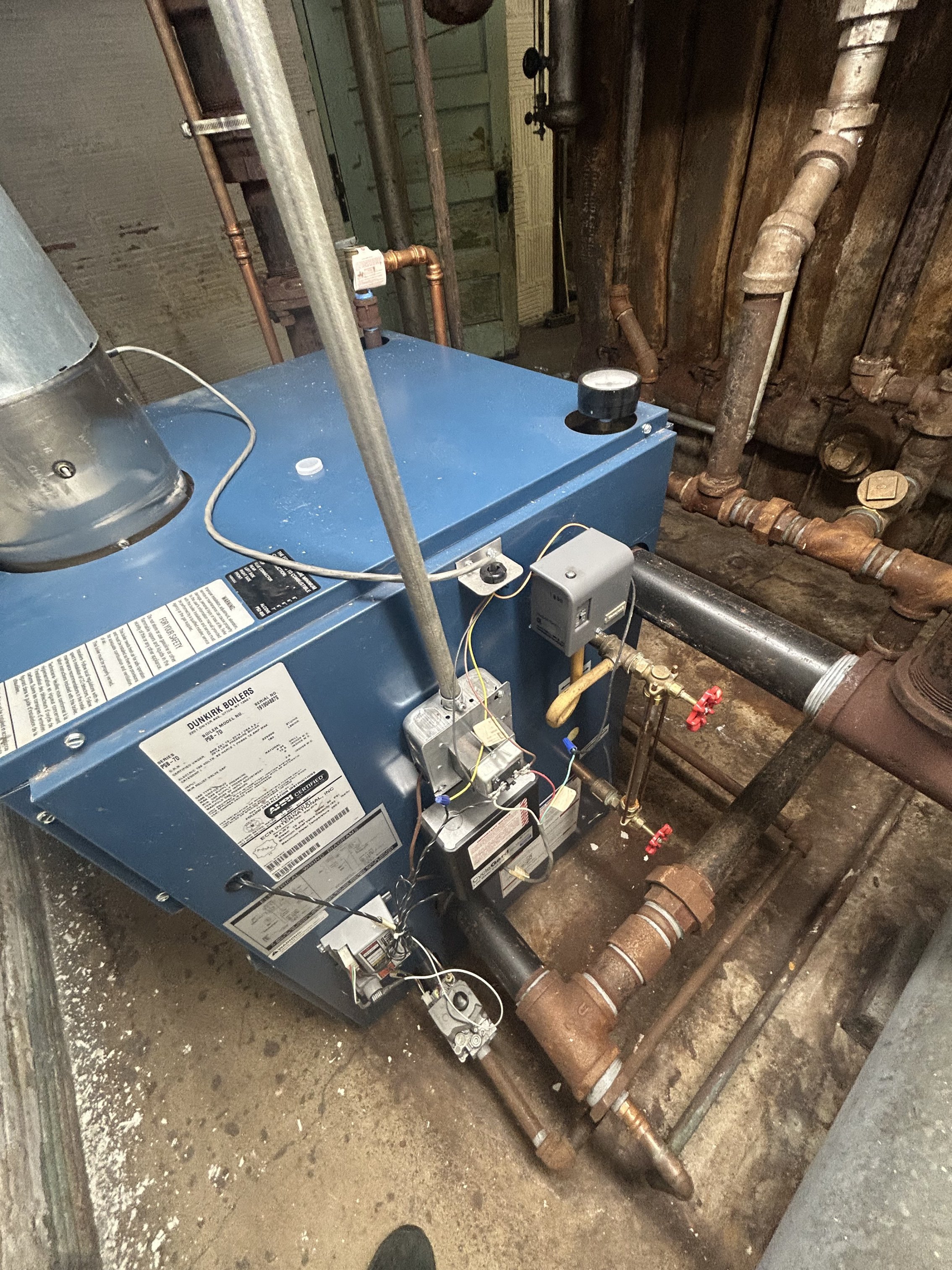

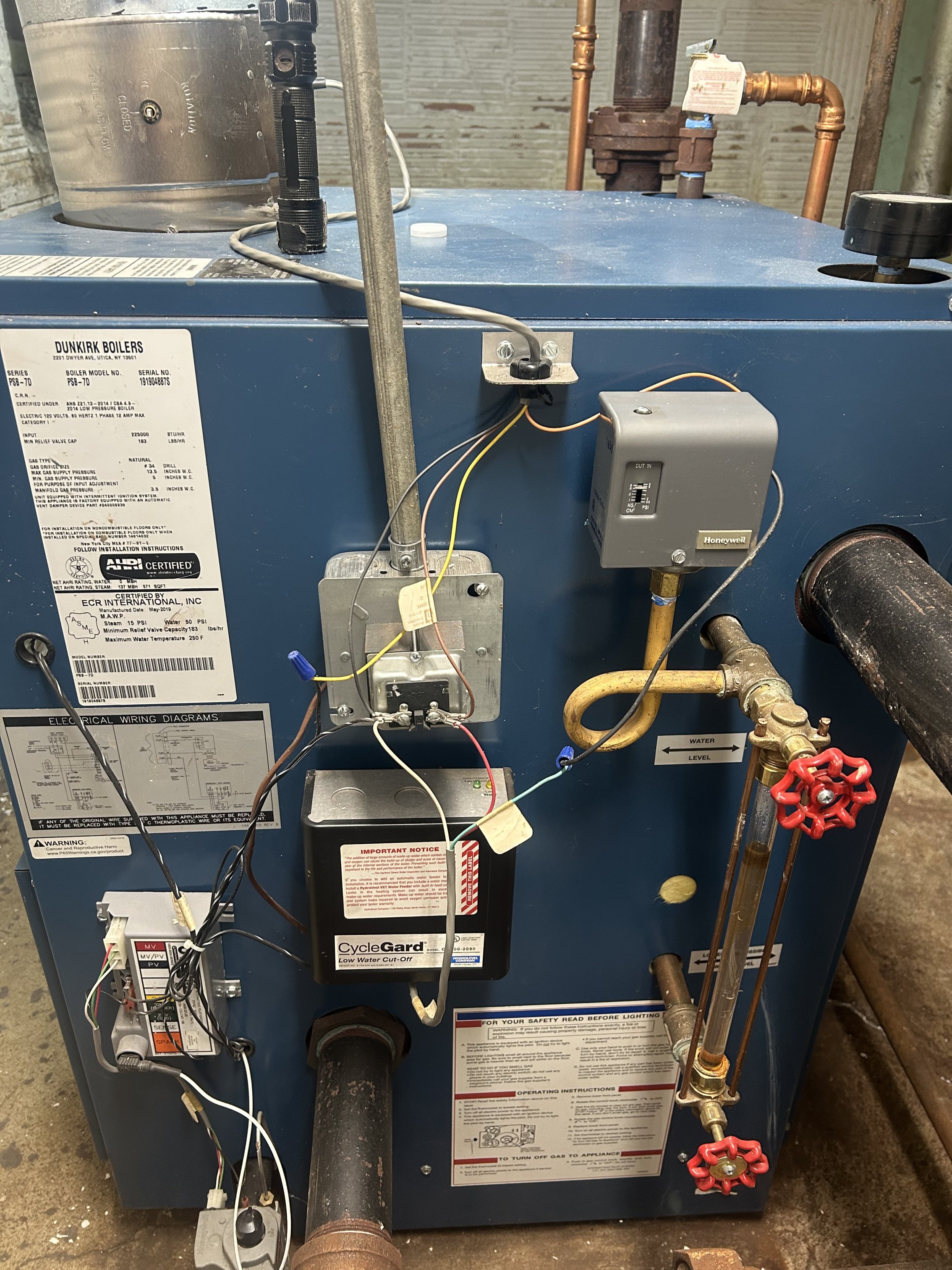

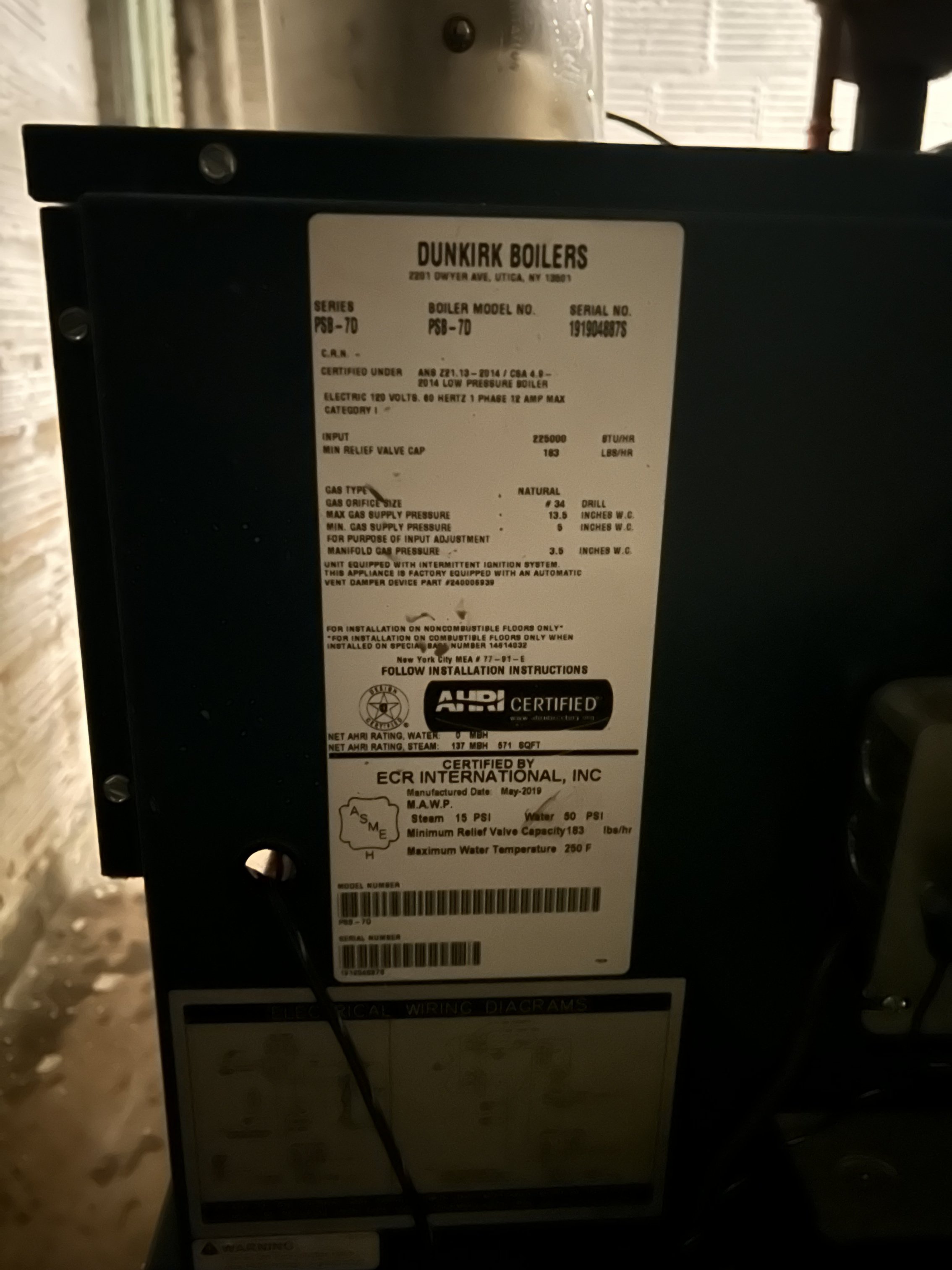

Newer Boiler on Mouat Vapor System

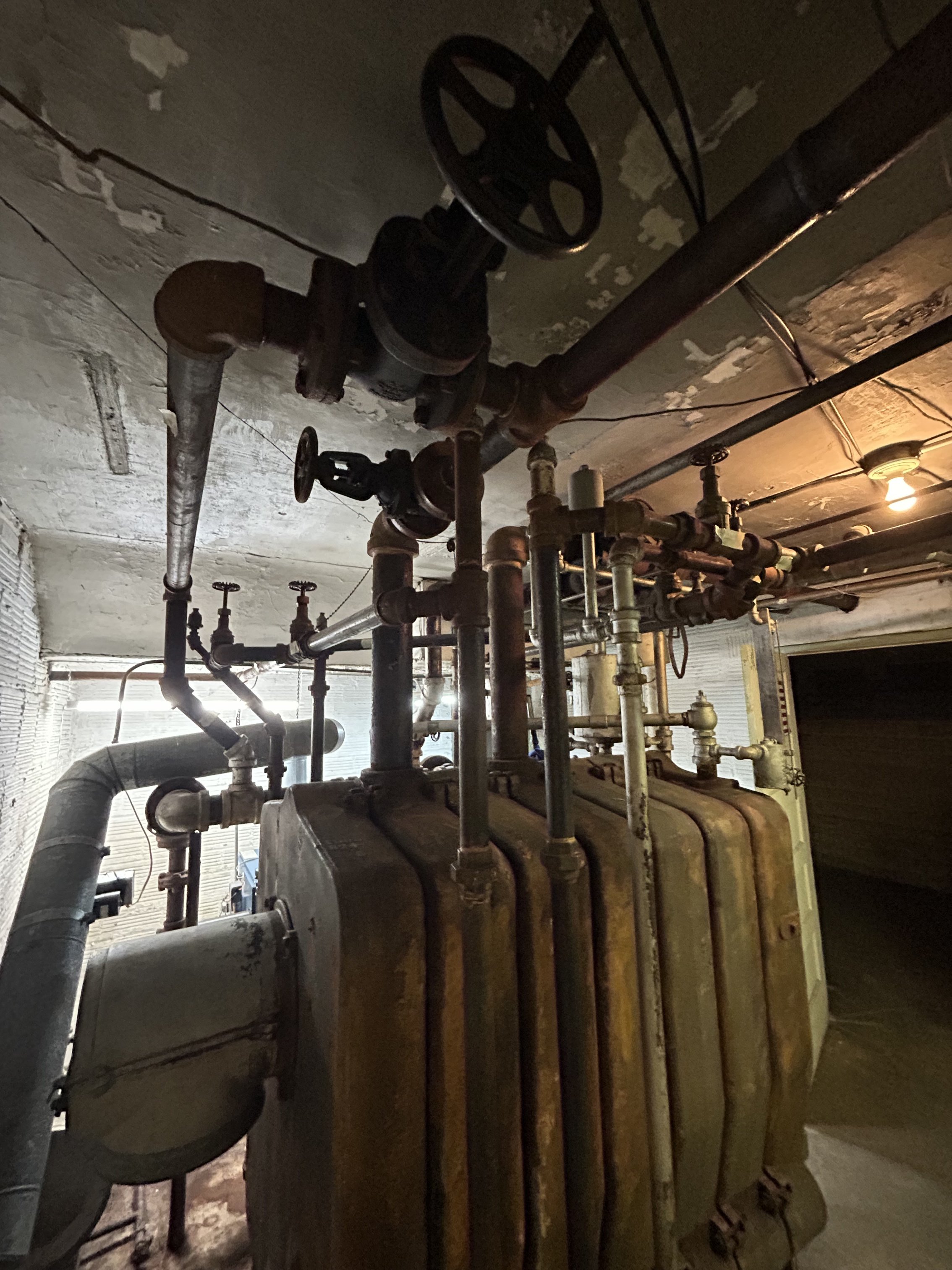

Thanks to all on this forum !! I am trying to make sense of this system in a 100 year old home my son purchased. The original boiler and it’s Mouat control system has been abandoned in place and a new Dunkirk gas fired Boiler has been tied in. The system still uses the original radiators, Mouat radiator valves and water seals. The newer boiler was installed in 2020 and uses a pressuretrol for its control and is set at several pounds of pressure. I have read everything I can find about this setup and know that the original design was to run at just a few ounces of pressure. I have purchased a vaporstat and low pressure gauge to incorporate into the system. I am attaching several photos of the system. I’m trying to figure out why the main steam headers go from 2 1/2” leaving the boiler to a 4” header then immediately back to 2 1/2” pipe. From what I’ve read I should install the vaporstat in series with the pressuretrol and install a low pressure gauge. Any help would be greatly appreciated in insuring that I’m on the right track. The home is in Northeastern Ohio and unfortunately just outside the service area of Gerry Gill. Thanks in advance for your help.

Comments

-

Unfortunately the installer did not pipe it right. Don't know why they can't read the manual.

You have the two boiler supplies opposing each other with the building supplies in between. Since the header is large it may or may not work ok.

No Hartford loop but it may not be needed if that boiler feed tank is in use. Is that tank in use?

What is the 3/4" copper coming off the top of the tank? That doesn't look right. There may be other issues not seen.

1 -

I have one suggestion for you. Pay Gerry Gill (for his time at the home, his travel to and fro and his gas and tolls.) to come out for a consultation and report and you can have your regular plumber follow up on his recommendations and actual work. You will know exactly what needs to be done and he will save you precious time and money. You cannot find a more capable heating expert. Good luck and keep us apprised. Mad Dog

2 -

Thanks for the responses. I have recently offered those things to Gerry and am hoping that he will respond. I am a retired Electrician and Electrical Contractor in Youngstown Ohio. I have not been able to find a plumber - heating contractor in this area familiar with vapor systems. Currently I am as mentioned reading all i can about the system I.E. Gerry, Dan H, Steamhead, Etc. The system is operating but I know not to its potential and is using a lot of gas. Just trying to help my son and his family. As far as the tank being operational it would be a guess. There are three mains and returns. One with a Hoffman 75, the other two have a Trane on them that I have posted on this site for identification help. I guess my main question is am I correct about the pressure it should be running at and the capacity of the main vents. Thanks again for the help.

0 -

Also the system does have an automatic water feed.

0 -

0

-

-

IS YOUR FLUE PIPING HEADING DOWN INTO THE CHIMNEY???

0 -

Yes it actually is. There is a set of stairs between the boiler and the chimney. There is a flue blower installed and I have checked to make sure there is no carbon monoxide issues. It’s very hard to see in the picture because it’s on the back side on this view.

0 -

I have a 100 year old Mouat System too. System is all original except boiler is 1957. Also have a 4 inch header but I my boiler is 2 times the size of your new one and has 4 inch connections so it was tied straight in to the original piping. So I am wondering what the size of your system is.

A Mouat system is designed to run at ultra low pressures. I've never seen more than 3 ounces pressure at the header. I consider my vaporstat to be a safety device only.

For a quick size idea if you haven't calculated the EDR how many radiators are in this system? I have 23 total on 2 floors.

1926 1000EDR Mouat 2 pipe vapor system,1957 Bryant Boiler 463,000 BTU input, Natural vacuum operation with single solenoid vent, Custom PLC control0 -

Thanks for your input. I am in the process of EDR calculations. It is a 3,000 square foot home. When you say the vaporstat is for safety purposes only I’m wondering how you control boiler pressure ?

0 -

The venting on this is too small. Get a Gorton #2 to replace each of the existing vents.

Hopefully @gerry gill will see this.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

do the other radiator valve have the pin in them? those holes are for a pin that sets how far you can open the valve to match the edr of the radiator. if they are all missing the pin, getting that set right is one of the first steps along with figuring out if you're building pressure and limiting it with a vaporstat if you are.

new and large vents is probably a good step too. if the air can't get out you're going to burn a lot of fuel trying to compress it.

0 -

I built a custom control many years ago when I realized that these systems were never designed to be full of steam. Pressure can only build when radiators are starting to get full. These systems were designed with a lot of extra radiation so heating the space does not require filling the radiators at any time. More even heat requires radiators to be only partially full a higher percent of the total time. The standard pressure based control where call time equals burn time has no chance to provide this. That control, which will allow radiators to fill enough to make pressure, is making uneven heat, or at least far less even than it could be. So I even out the burn time required to heat the place in shorter evenly spaced burns and the system never gets close to full so there never is any pressure. I don't have or need any vents on the mains either. Burns are always 2 per hour maximum +/-.

1926 1000EDR Mouat 2 pipe vapor system,1957 Bryant Boiler 463,000 BTU input, Natural vacuum operation with single solenoid vent, Custom PLC control0 -

i mean the easy way to do that would be to use a boiler with an output that was a little less than the connected edr of the system

0 -

The boiler is only five years old so it’s going to have to stay for now. I’m at a loss of understanding how a system can work without venting. As far as pins in the valves on the radiators I will have to check them when I go back there tomorrow. Thanks again for all of the help and input. I will post my progress.

0 -

That's a bit mislleading. IF your boiler happens to be exactly matched to your system, then indeed you would never see much pressure (there will always be a little). But… a boiler that carefully matched is a rare breed indeed, and if it is even slightly too large — maybe only 10% — it will, eventually, build pressure. In that circumstance, you very much want it to stop — not for safety, but it's a waste of fuel and, depending on the exact type of the vapour system, may result in some subtle problems.. So. You use a vapourstat to control that pressure.

You should also have a pressuretrol set at some higher value — say 2 psig — which is a safety device, and will shut off the boiler if, for some reason, the vapourstat doesn't.

It can't, or at best will work poorly. There must be venting somewhere in your system? In a vapour system the most likely location is main vents at the point where the dry returns join and drop to the boiler. If the mains are vented by crossover traps to the corresponding dry returns, that's all you need.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

it is really hard to tell in that system what is connected and what is abandoned.

0 -

Thanks for your comment mattmia. The old boiler and controls are all abandoned in place other than some of the large gate valves. Nothing runs through the abandoned boiler. The gate valve piping has been modified to remove the old boiler from the system. Thanks for your help.

0 -

@dcw1 , Tell your son he has a great system there, and a museum piece.

I do have one vent but is it not on a steam main. It is on the dry return far away from the boiler. I need very little venting because I don't let the air back in once it is pushed out.

Mouat systems were high end and installed in larger homes in NE Ohio. My house is 3500sqft. I have a big boiler that barely burns 50% of the time to heat at -20F. I still can run it with no pressure ever and I don't think size means much as long as long as the boiler is big enough. Actually I think all the advantage goes to the bigger boiler with the right control.

So I expect your new one is big enough. Give us the radiator count and EDR figure. Does it heat everything Ok?

Looking at the Mouat sales literature it looks like that old boiler is in fact the original to the system. Quite a rare prize to have. I've attached the literature here if you don't have it.

Some general comments, as this provides an opportunity to point out some things:

The original design had installed significant extra radiation beyond what was actually needed on purpose. It had lots of extra boiler too. That big old boiler you have still has the low pressure control on top which modulated the damper on the coal fire matching the steam production to the current demand in real time. The boiler never ran on "high" or "off" and the radiation was never close to full. Nothing about the size of the boiler was "critical". The steam production was continuously varying with the demand, all at ultra low ounces of pressure.

What is important to note about the original design:

- Lots of extra installed radiation continuously partly filled never full.

- A big boiler intended to run in the middle of its range - there was no "high" speed and no "off" speed

- 3 ounces of pressure maximum was all that was required to deliver the steam in all states of demand(so why today do we need pressuretrols and vaporstats for this system????)

- The control system reacted in real time to demand changes by sensing very small changes the header pressure

Now contrast that with the standard control they came up with to run the intermittent on/off boiler that replaced the original. That control can ONLY run the boiler on high or be off. That control runs the boiler on high until either the tstat is satisfied or the system fills enough with steam and a pressure well over 3 ounces is detected because radiation that never was needed or intended to fill is now full or close to it. That is an extremely poor substitute for the original except, well, it did solve the coal and smoke problem. This "solution" somehow also launched a quest for the mystical "perfectly matched" boiler size since modulation went away, as if one magical single speed boiler size could possibly replace modulation - wait what? Perfectly matched to what? An amount of radiation never needed or intended to be used? What amount then? And what, the "perfect" boiler size will satisfy the tstat on one continuous burn without the pressure reaching the lowest cut out setting you can put on a vaporstat meaning call time equals burn time? That is the goal? That will not produce heat close to as even as these systems are capable of. Long calls are what prove that heat is even because the temperature is rising from cut in to cut out very slowly. Long calls are what happen when actual net boiler output is closely matched to current demand. That is the only thing that really needs matching to achieve even heating, and that has much more to do with how long and when burns are than it does with the capacity on the boiler nameplate. Perfectly even heat would be a call that never ends right? So if the heat is really even the burn time must be much less than the call time if all you have is a one speed(high only) boiler. They can't be the same or even close to the same. That can't be the result (and surely not the goal) if the project is even heat.Currently my system is showing calling for heat 67% of the time and burning 29% of the time. The weather is mild in the 20's.

I knew nothing of steam when I bought the house 33 years ago. But as I observed this on/off big boiler vaporstat controlled air breathing in and out system run, as an engineer it just seemed crazy. Radiators went from boiling hot down to room temperature back and forth over and over with long waits in between. Air was pushed out of basement vents only to be sucked immediately back in. It was quite apparent that a control with only those two inputs - tstat and a pressure device - had no chance of providing even heat anything like what the original control system must have. So I set about changing things. What was abundantly clear early on was that the control needed to react to the demand in real time somehow, like the original did, for decent results. That and that some form of output modulation was in fact needed, as the dead men obviously knew, so that high speed burns would be divided in pieces shorter in duration and spread out evenly. Its called PWM Pulse Width Modulation. There are many ways to do these things and it really isn't that complicated. Unfortunately no contractor will help with it.

So what did I do? I added a remote temperature sensor to run every burn to the same partial fill amount no matter the starting point cold or not. I stopped letting the air back in and used the natural vacuum to both balance the heat and to provide feedback about the current demand, based on how fast and how much vacuum forms. Subsequent burns start when the remote temp sensor opens again indicating it is time for more steam if a call is still in progress. There isn't a sound now, radiators are just roughly the same warm always unless it is extremely mild out, and no one is aware anything is even happening. Burn times and waits in between are always changing with the conditions. The system always settles in at 2 burns per hour +/- if there is any real demand. Venting ceased to be a consideration. The difference from what I moved into is dramatic.

1926 1000EDR Mouat 2 pipe vapor system,1957 Bryant Boiler 463,000 BTU input, Natural vacuum operation with single solenoid vent, Custom PLC control0 -

Very interesting indeed !! I see you have used a PLC in the system. You have really put some time and thought into your system. The vapor system has very much intrigued me and I have spent a lot of time in my quest for knowledge !! Thanks again to everyone helping me on this journey.

0 -

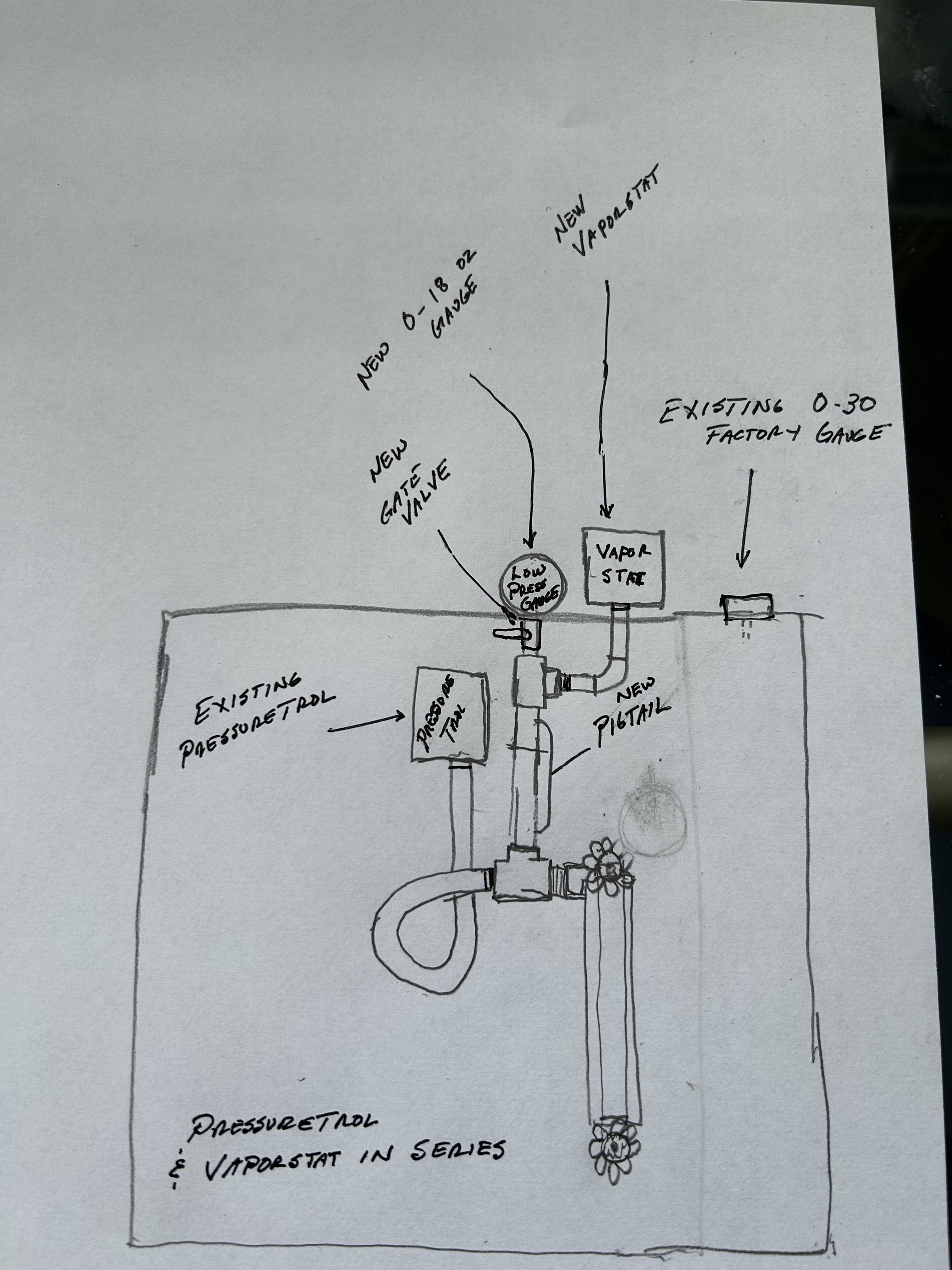

Hello all, I have purchased a Honeywell Vaporstat, 0-18 oz. Pressure gauge and additional pigtail for the system. Does this sketch look the the correct way to install ? Thanks as always !! Bottom picture is current setup.

0 -

that can work, may need to move that wire bracket,

while you're piping, disassemble the upper sightglass valve and make sure it's open and clear all the way back into the boiler, the glass protection rods work well, drain down and do the bottom valve also,

water looks slimey, oiley in the glass, do you have a way to skim?

known to beat dead horses1 -

-

Thanks for the replies. Great idea on the unions. I did have the boiler serviced just a few weeks ago and the plumber added Hercules cleaner to the system. I will blow out and skim again while making the changes. Thanks again.

0 -

Should all the new fittings be brass ?

0 -

-

Thank you.

0 -

-

I would suggest you add a pig tail to the vaporstat, same as you have for the pressuretrol.

As drawn, the vaporstat doesn't have the water seal the pigtail provides to the pressuretrol.

You could rearrange the piping so the one pigtail provides the water seal to both the vaporstat and pressuretrol.

Dennis Pataki. Former Service Manager and Heating Pump Product Manager for Nash Engineering Company. Phone: 1-888 853 9963

Website: www.nashjenningspumps.com

The first step in solving any problem is TO IDENTIFY THE PROBLEM.0 -

it does but we are looking at it head on in the drawing, it is called out but hard to see.

0 -

Yes it is a kinda crummy drawing but I am going to use one. Thanks for your input.

0 -

@Pumpguy said "You could rearrange the piping so the one pigtail provides the water seal to both the vaporstat and pressuretrol."

I would not do this. If the single pigtail got plugged, it would block pressure to both controls. With two pigtails they both have to plug up for that same result.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

Maybe my last comment was confusing. If you look closely at my sketch and picture I am using two pigtails. The existing pigtail for the old pressuretrol and a new additional one for the vaporstat and low pressure gauge.

0 -

Outstanding!!! DCW 1....Glad you took the advice. Tradesfolk just want to be paid for their level of expertise. Gerry Gill and Steve P. are Legends in our trades. Glad it worked out. Keep us apprised please. Mad Dog

0 -

Understood as I mentioned earlier I’m an electrician and electrical contractor.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements