Converting Steam System Back To Hot Water

Hello,

I am restoring a 1908 6,000 sqft house that originally had a complex overhead gravity fed system dropping down from the attic. Much of this system was removed in the 1940s when a steam boiler was installed and exposed 1” and 1 1/2” lines were run to each radiator as well as large 3” runs looping the basement to supply them.

I am finishing the basement and need to remove the large runs so am planning to convert the system back to hot water by running a second line to each radiator in black pipe to match what was done in the 40s as returns for the hot water. (Most of the original radiators are there with the bleed valves so I will just remove the Hoffman vents) I am going to use a modern hot water boiler with a circulator to be able to run the new lines in the basement in the joists for head room. What size and material is best for running these lines in the basement? For ease of installation I am trying to avoid using black pipe where it won’t be seen. Is pex a viable option or is copper better? Is it possible for these lines to be sized down with the circulator pump being used?

Photos are of existing steam lines in the basement as well as the original radiators.

Thanks!

Comments

-

My first really stupid question. Why are you not planning to bring the steam system up to running condition? Granted there would be some work to do, but (like moving vents on the radiators to where they should be!) but… surely there is a reason?

Having said that… the question of PEX vs. copper vs. black iron actually requires an answer to another question first: At what temperature do you expect to need to run the hot water system? And to answer that you need to know the heat loss of the various spaces and the size of the installed radiation. That will give you the required maximum operating temperature of the hot water system, and from that you can decide on PEX — which won't take sustained high temperature — or copper or black iron.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

And, @knudsluk , have you pressure-tested everything to make sure it will hold 30# pressure? If not, you might be in for a nasty surprise………..

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting3 -

Thank you for responding! I am not wanting to keep the existing steam system because it was run when the basement was not intended to be used and the pipes are in the way of finishing the space. By going back to hot water I’m hoping to eliminate the need for the pitched piping so the new runs can be put up into the joists as much as possible.

From my rough calculations using the original radiators that were originally sized for a hot water system, I’m assuming around 180 degrees. Ideally less but that would be on the high end.

0 -

Thanks for replying! I haven’t pressure checked anything yet because the system isn’t complete. To be able to move the existing steam runs in the basement up into the joists to be able to finish the basement I am planning to replace them to work as a hot water system again.

0 -

How about the radiators themselves? You never know………………

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

I can disconnect them to check them individually. What diameter of pipe is best for the supply and return lines in the basement for the hot water conversion?

0 -

Depends on how much heat you have to move. Do your heat-loss calculation to get the numbers.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

-

You're going to need to have an idea of the heating load of the house to figure out the pipe size.

This article shows how to use past fuel consumption to estimate heating load:

https://www.greenbuildingadvisor.com/article/replacing-a-furnace-or-boiler

That gives for the whole house. As a rough approximation, you can figure each radiator produces heat output proportional to its size. So you add up the sizes of the radiators and then figure out each radiator's share of the total.

Heat transported by water, in BTU/hr, is equal to flow in gallons per minute times temperature drop times 500. It's customary to assume a temperature drop of 20F, so that allows you to estimate the needed water flow for each radiator. Then you sum the flows of all the radiators on a pipe to get the flow for that pipe. Once you have the flow you can size the pipes.

Since these are rough estimates I'd add a healthy margin of error, it doesn't cost much to upsize the pipes.

0 -

The pipe size to each radiator when using a circulator can be 1/2". That size pipe can move about 15000 BTU at a flow rate of 1.5 GPM with a 20° ∆T. I don't believe that any of your radiators will be larger than 15000 BTU.

What size boiler you are going to use depends on the heat loss of the building, but you don't need anything larger than what your connected radiation will be able to use. (eg. a 200,000 NET BTUh boiler will not be efficient if it is connected to only 50,000 BTUs of radiator.) That will be oversized by 400%.

You should get a manual J heat loss or Hydronics Institute Form 1540WH load calculation completed yourself or by someone else so you din't select a boiler that is way oversized.

This booklet may help you with your pipe size selection Zoning Made Easy or this booklet Idronics vol. 12 to get basic information about your project.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Keep in mind the temperature difference between steam and hot water.

I expect it will be significant, and with lower temperatures, you will need more radiation surface area with hot water than steam. I have heard of this difference to be as much as 40%.

If this is true in your case, you could be in for a big disappointment.

Dennis Pataki. Former Service Manager and Heating Pump Product Manager for Nash Engineering Company. Phone: 1-888 853 9963

Website: www.nashjenningspumps.com

The first step in solving any problem is TO IDENTIFY THE PROBLEM.0 -

Jamie is right about your heating system as top fed steam is simple own and use.

You will be better off economically using top fed steam to heat this place with a modern steamer and a double drop header to make dry steam. You need a steam licensed plumber to help you with this.

0 -

If you read the original post, those radiators were originally hot water radiators. I would guess that they were then oversized when the first rehab was completed with a steamer. Some return pipes were probably removed when it was converted from hot water to a one pipe steam system. In all those years, you might think that some weatherization may have happened and with this renovation some more weatherization will happen again. I would not worry about the radiators being too small.

But the OP probably already knows this.

The real question is: "Can I put PEX above the basement ceiling (first floor) joists and what size it can be?" And the answer is YES you can raise the pipes and the size will depend on the BTU capacity of the installed boiler. That is why he should get the load calc and read the rule of thumb charts in the two booklets I recommended earlier.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

If planning to finish basement because you need more space then cut to the chase and spend some $ . Have a heat lose performed and instead of trying to re use and spend extra on labor just cut to the big chase and remove it all and toss . Have a real hydronic expert perform a room by room heat lose to size both the boiler and the heat emitters . They can pipe it all so you can have all the basement space and head room that you want . Personally i would size for low temps 130/140 max using panel rads w trv and in the long run install a cast iron boiler ( chimney vented)w return temp protection ,you could go w a mod con boiler and forget the return water protection but a few years the yearly maintenance will chew up the mod con savings and a shorter life span then a cast iron boiler . The reason i say low temp is if all goes down hill w gas/oil fuel and where stuck in electric if sized for low enough temp a conversion to air to water heat pump might work and the ultimate answer is it all depends . Even if you do the conversion remember to add a magnetic dirt separator and possibly a wye strainer for sediment issue . personally i would show zero interest in trying to reuse any of the steam piping there's just too much liability and possibly unaccountable time for issue which cannot be seen . I used to be asked about these types of job and i usually pass being there just unrealistic and at a later date some one is left trying to deal w a issue that some one else has created and i sure dont want it to be me .

My personal view is older steam systems w zero insulation and a lack of maintenance and issues always require alot of work and some issues will cost ! Everything has a life span and so does a system at some point things have to be updated and to put it in perspective most home kitchen far exceeds the total cost of a completely update heating system but no one see the heating system but all looking at the big $ put in kitchens and dont forget baths . Some times priority of non required far exceed the costs of the mech of a home very funny stuff .

In my dads words big house big bills, old houses bigger bills plain and simple

peace and good luck clammy

R.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating1 -

Clam's the Man! I'm a "clam-backer."

0 -

i don't understand the bathroom renovation. you are taking this tile set in mud and cast iron and china fixtures that will last 100 years that was built by skilled craftspeople and you're replacing it with this least material they can get away with stuff that will be moldy and falling apart in 20 years. sure, replace some of the plumbing and electrical but what you already have is something you're unwilling to pay for in the replacement.

-1 -

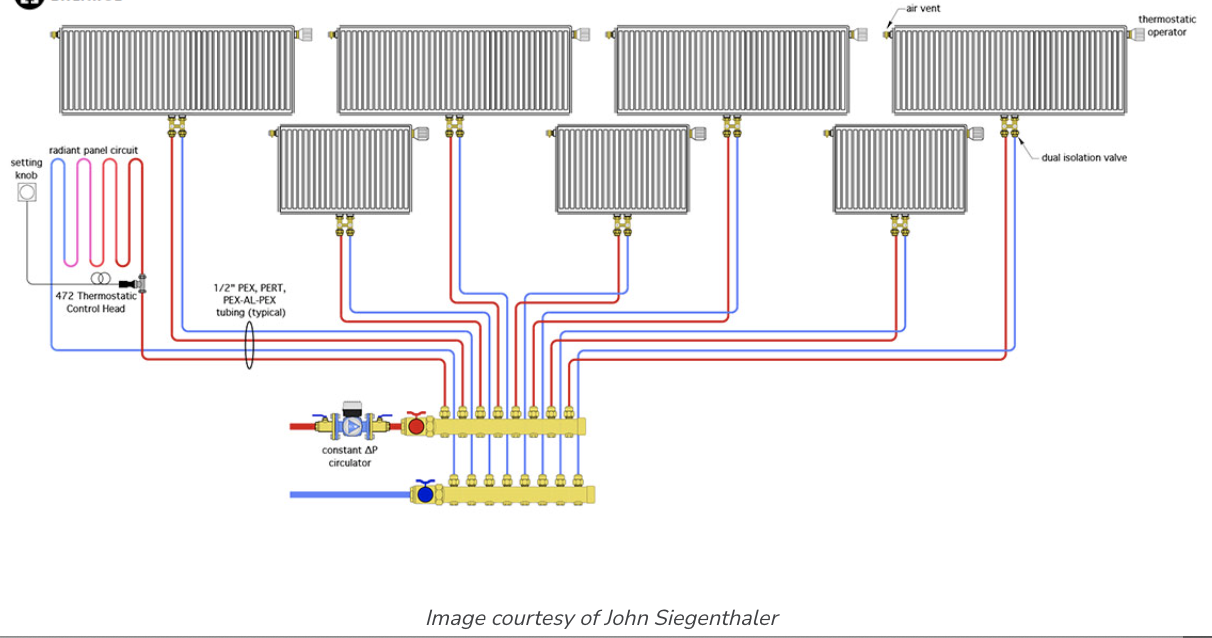

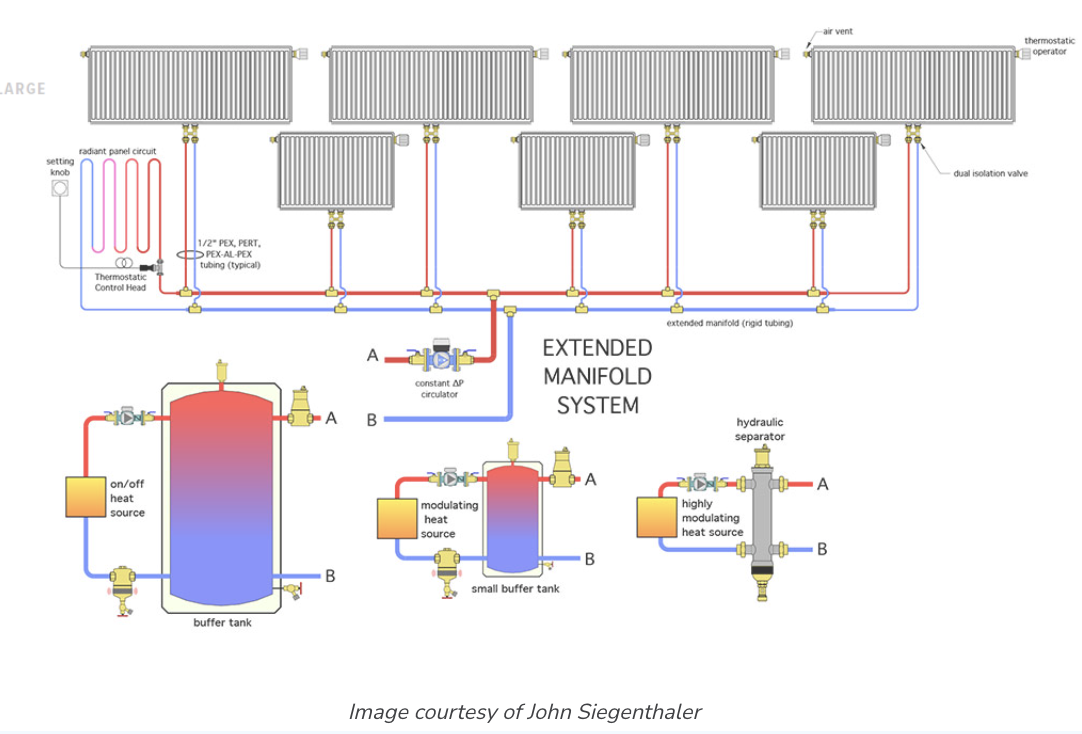

If you go with a small pex redo, a homerun piping method works well. Or in some cases a basement could use an extended homerun manifold and cut down on the amount of pex leader lengths.

TRVs on each radiator give you ultimate adjustability. Multiple radiators in the same room could be served by a single TRV.

Here is an example of a homerun and extended homerun manifold system. Note the radiant zones also if you get your supply temperature requirements within 10° or so degrees.

With a lot of zoning a mod con is my choice or possibly a buffer with an on/ off boiler like cast iron.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thank you for your response. These sources are very helpful. I am working on these calculations this evening, but am keeping the original radiators that were originally sized for the house with the hot water system so am not sizing radiators but calculating to ascertain the btu size of the boiler and pipe sizing. The original gravity hot water runs in the attic are 2” with a 3” riser from where the original boiler was so I’m assuming 1 1/2” will be sufficient for the new runs in the basement with a modern boiler and circulators to tie in to the existing 1” and 1 1/2” lines to the radiators themselves.

1 -

Thank you for your response. These sources are very helpful. I am working on these calculations this evening to figure out the necessary boiler size. I’m thinking to be on the safe side that I should run the new runs in the basement in 1” or 1 1/2” to connect to the existing 1 1/2” black pipe I’m reusing. The original gravity runs in the attic are 2” with a 3” riser from where the boiler was. I realize the 1/2” is probably sufficient but don’t want to underside and have problems. I’d rather spend a little more on supplies than regret it later.

0 -

The original system was clearly hot water. I am happy to post more photos but it was originally sized for hot water and later converted - so the radiator sizing isn’t an issue. If anything they are too large for a modern boiler with circulators as opposed to too small.

0 -

The original system was clearly hot water. I am happy to post more photos but it was originally sized for hot water and later converted - so the radiator sizing isn’t an issue. If anything they are too large for a modern boiler with circulators as opposed to too small. The steam retrofit was poorly done in the 40s and not anything I am looking to preserve beyond the usable supplies to the radiators

0 -

a lot has changed about the structure since 1908. assuming the radiators from then are the right size for a modern system is a mistake.

0 -

the good news would be that the radiators are oversized now after building upgrades over the years. This allows you to operate at lower temperatures. As such 1/2 would be plenty for carrying smaller loads.

Go 3/4 if you wish, but it is a tougher tube to wrangle around

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

some also look like they have been replaced at some point possibly with a salvaged radiator. i don't know if the slenderized radiators existed in 1908.

0 -

They didn't. They came out around 1938 or so.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

The house is almost exactly as it was in 1908. No real layout or square footage changes. The radiators aside from three that were replaced later are all quite large.

0 -

Thanks. I agree on the sizing. Will there be water flow issues tying a small 1/2” pipe in to the existing 1 1/2” black pipe risers I am going to re - use?

0 -

Which are you referring to as the slenderized? The two radiators I posted photos of are the original ornately cast ones with old ports that had been plugged for the gravity system. There are three 1940s small radiators that I am replacing with larger ones but I did not photograph them.

0 -

Why would it be an issue if they are too large? It seems unlikely that they would be too small. It seems like a waste to tear out the original radiators to size down.

0 -

Thanks. That makes sense. I think the extended manifold layout would work the best in this case. Does incorporating TRVs affect efficiency or are they simply for greater temperature control? The house is in a mild climate and the heat will only be used regularly 2 - 3 months of the year so not sure if it is worth the extra effort and expense.

0 -

until i zoomed in i thought the goldish radiator in the corner was a slenderized radiator that was a later design, now i'm not sure because it appears to have one of the arco patterns of decoration but the tubes look thinner

0 -

Ahh, ok. These were made by National Radiator Co.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements