Circulator noise when hot?

Comments

-

I agree with @hot_rod

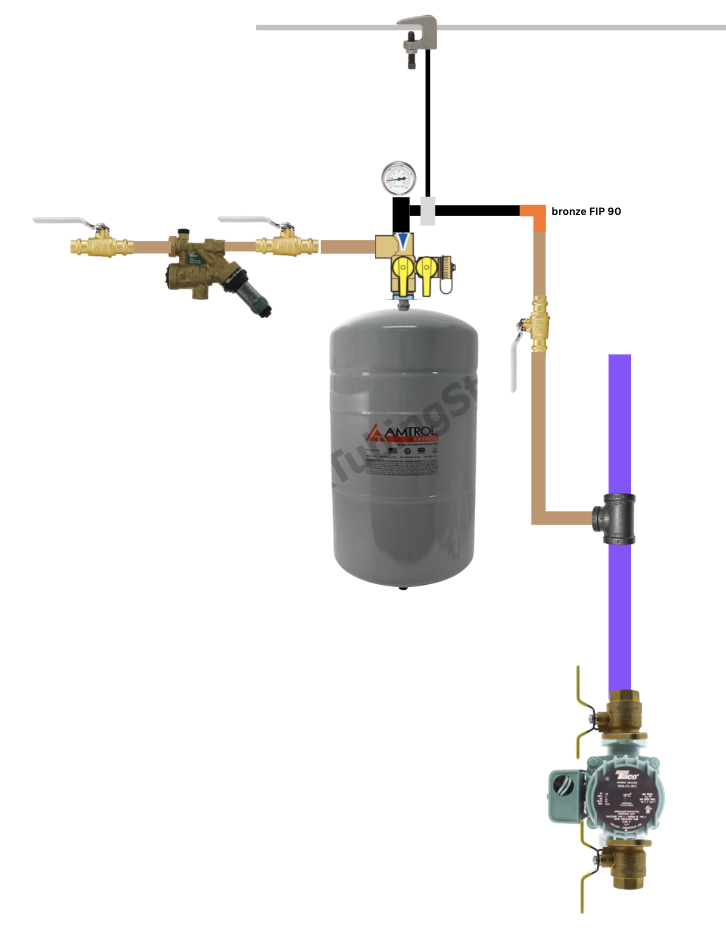

You have a ball valve at the boiler in the MU water. You could put the tee between the ball valve and the boiler. Put the EX tank and a pressure gauge there.

If you have (in addition to the valve we see) another valve upstream of the valve we see that only serves the boiler cut the tees in between the two valves.

Make sure you install the ex tank with the nipple pointed up and support the tank or make sure where you cut the tee in you can support the tee that feeds the tank. A drain where the tanks connects is noce to have

0 -

Thank you @hot_rod and @EBEBRATT-Ed .

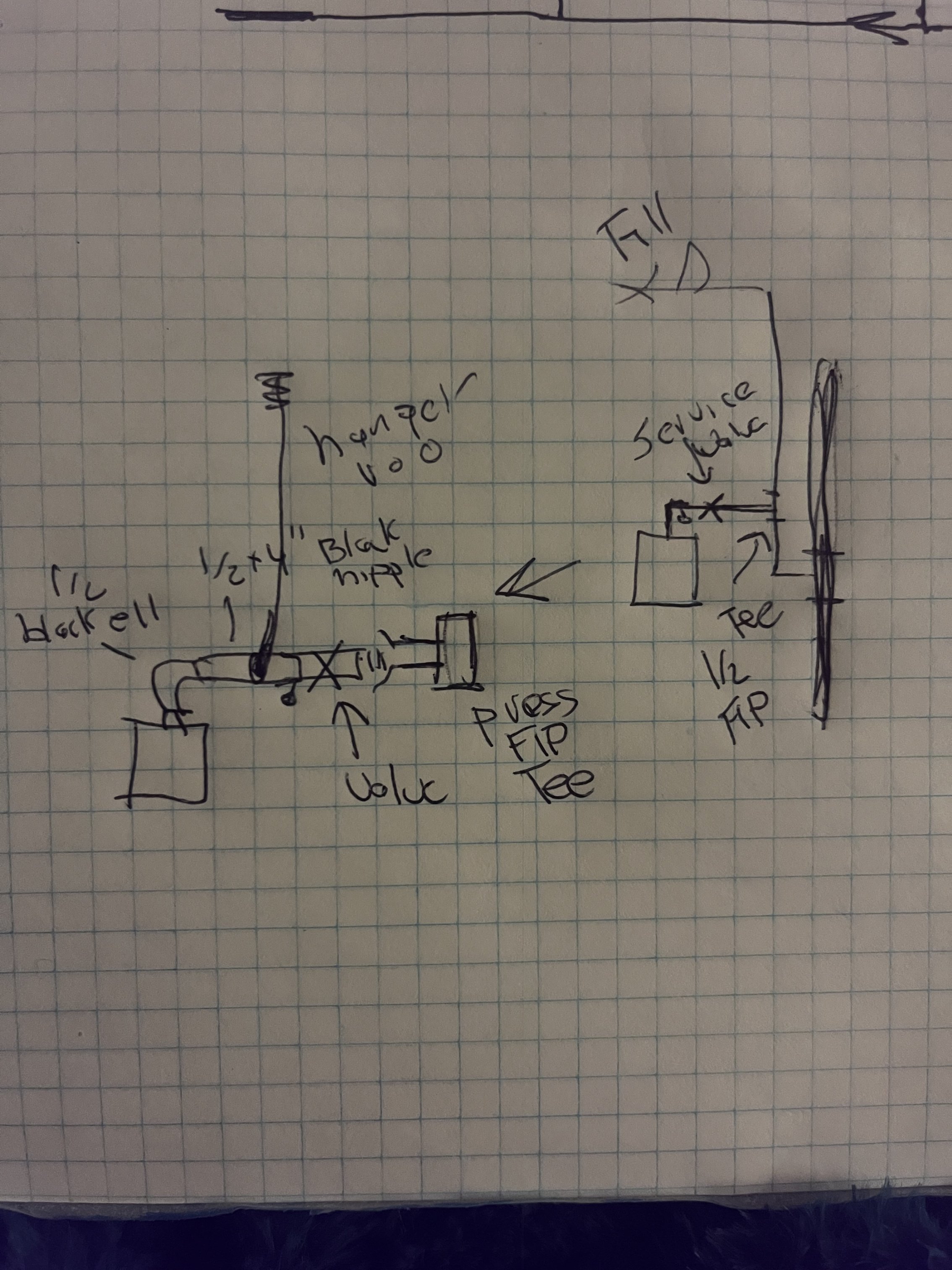

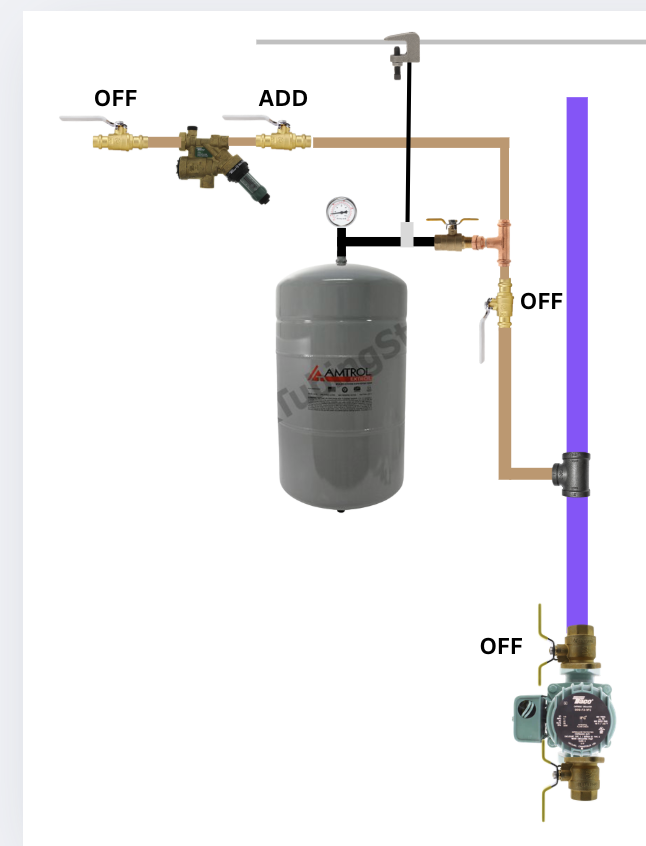

Is this correct? I added a tee with a pressure guage.

I have a steel beam right above the junction where the EX tank would hang. Seeing that this re-pipe woutl be copper and not have the tensile strength

, maybe a short steel or bronze nipple with a clevis hanger of some sort to support the EX. Or am I totally off here! Thank you!

0 -

Yes that will be fine. You could put another hanger on the city water supply to the expansion tank tee. You don't really need it for support, but it might be easier to hang it. One hanger is plenty though

0 -

here is super simple and low cost

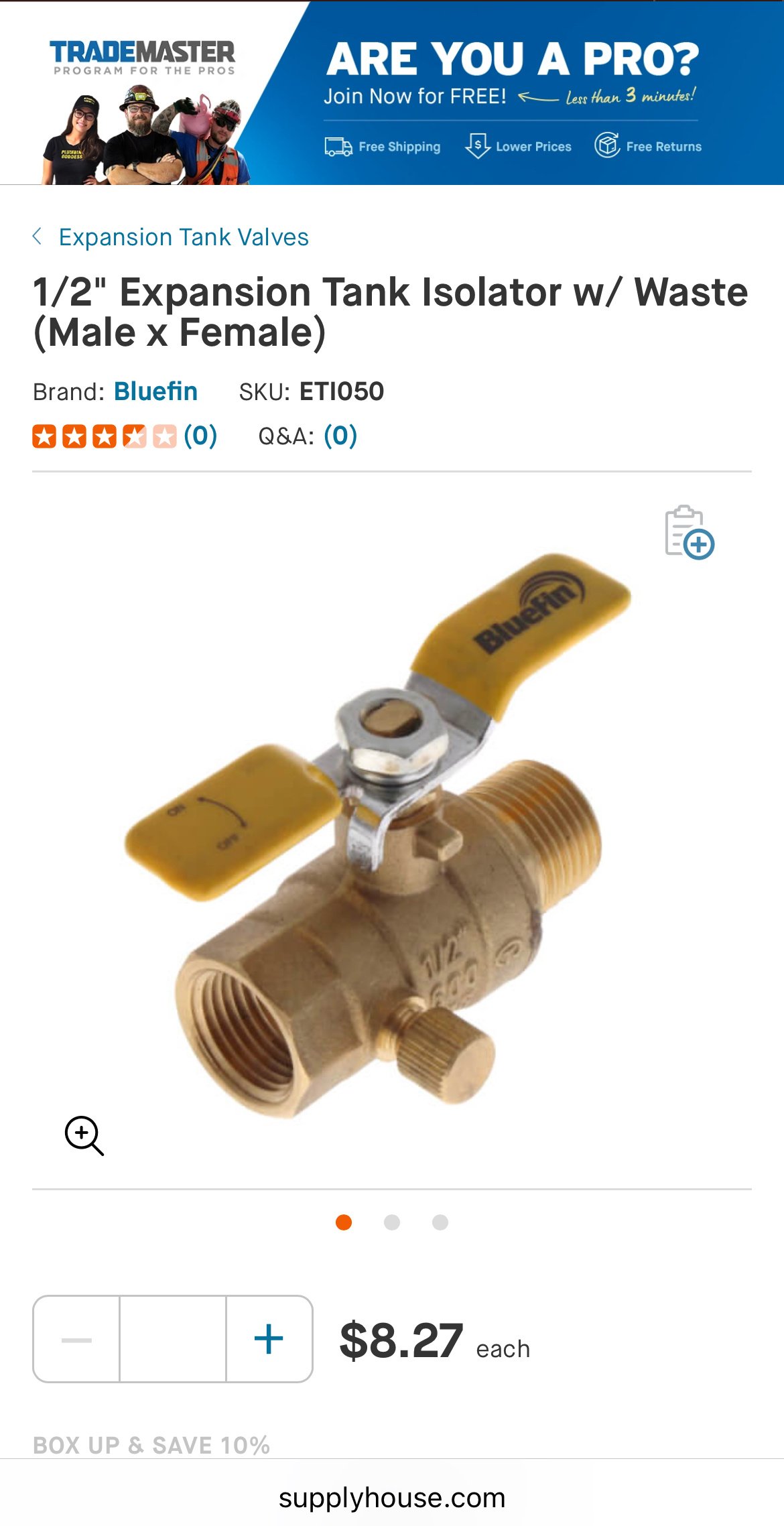

Press in the FIP tee

Screw the iso ball valve into that tee

Screw a 1/2 x 4 black nipple and black ell into the iso valve

Screw tank into ell

Threaded rod or any suitable hanger rod around the black nipple

No need to mess with the fill valve location

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Amazing @hot_rod !

When moving the EX, I would shut off the boiler. Shut off the current service valve for the EX. Close both valves from the MU water. Apply the changes you suggested.

I’m assuming the EX will need to be drained and pressure checked and reset.

How is system pressure then established while the repair is being made if both the EX and the any water are both essentially OFF?This is all so I understand the next steps. I will have a more qualified person with me.

Thank you all very much! Thai forum is truly helpful and generous.

0 -

You are 2/3 of the way there.

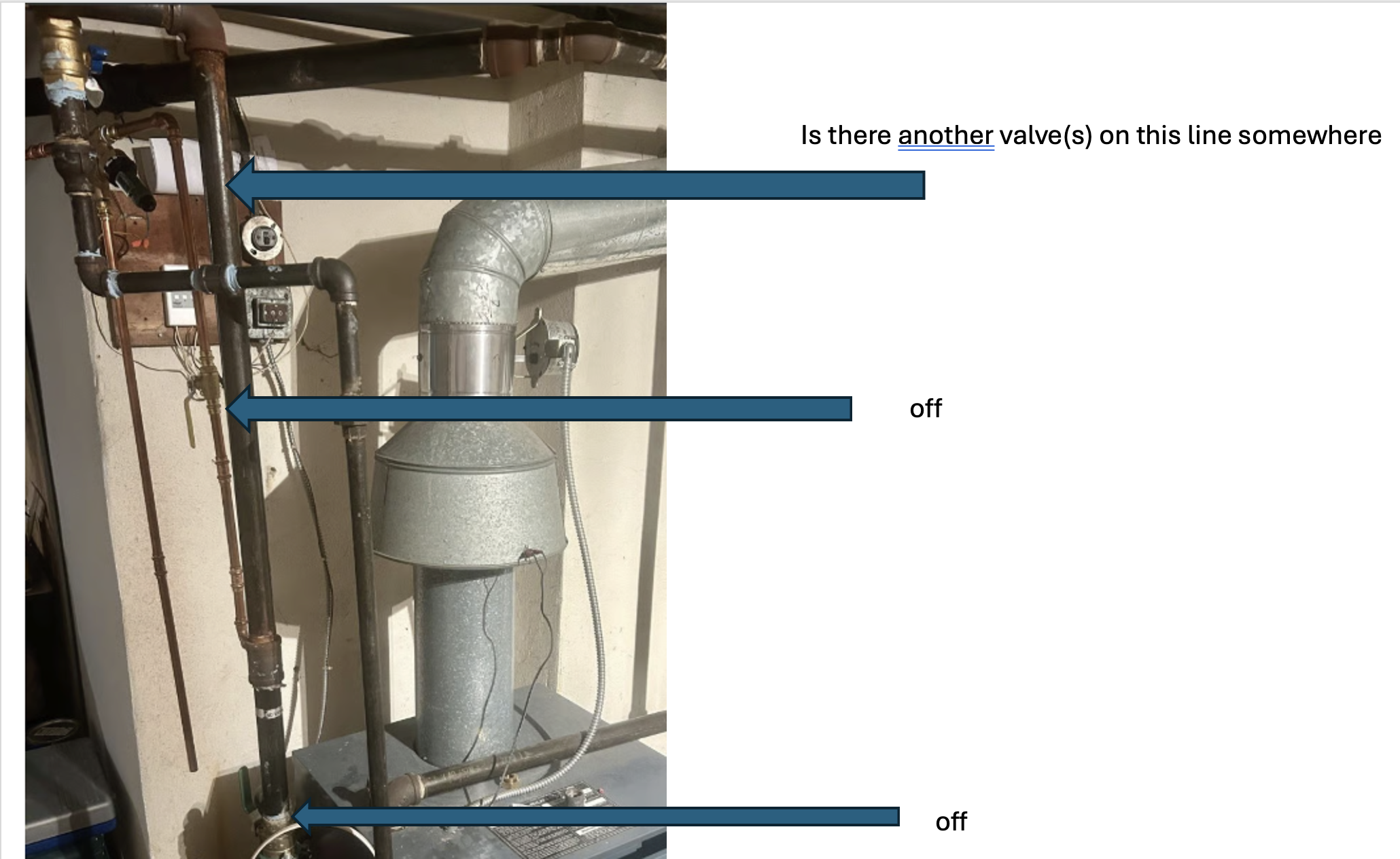

Is there another valve on this return line, or multiple valves?

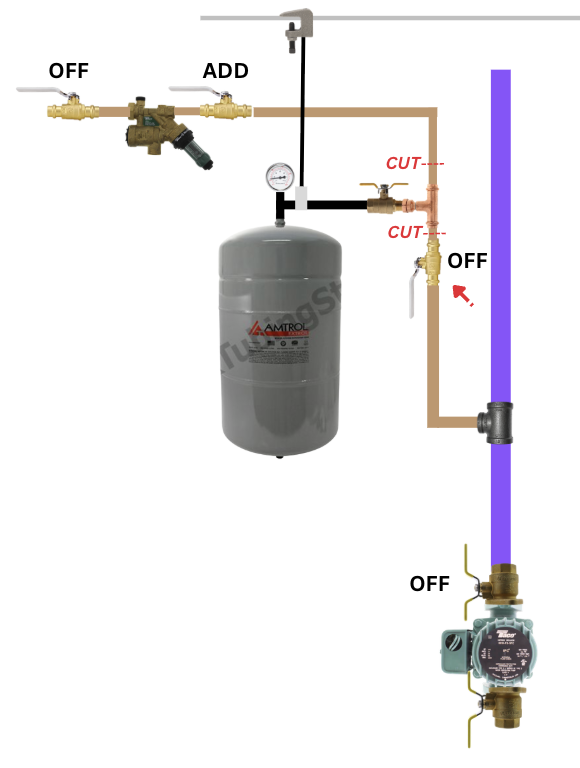

You need to completely isolate that section or pipe, to cut into the 1/2" copper line

or else drain the system down to that level.

If you know a plumber with a freeze cuff, you could freeze the 1/2" line between the two press couplings to cut in the new tee just below the 1/2" valve.

A thrill-seeking plumber may just drop the pressure to zero, cut a press ball valve into the copper line just above the ell where it ties into the black steel tee :)

There are some 1/2" tap a line valves, but quite $$ Although sometimes on ebay they go pretty cheap.\

If you take on this project, remove the tank and plug that yellow tank isolation valve.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thanks @hot_rod . Unfortunately there is no other valves upstream of the circulator on the return.

If I cut the copper pipe above the MU valve, would that provide the isolation?

There is another valve before the Fill valve,

0 -

waters coming down the purple pipe from above, unless you valve it off or drain it out

Lowering to zero pressure and doing a hot stab puts the system at a condition that if you are quick and methodical you could install the additional valve you need.

The same trick is used to change elements in electric water heater tanks without draining them down.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

Thank you, @hot_rod .

So even though I can turn off the ball valve which is currently isolating the MU valve, I would still need to find a way to isolate the 1 1.25" return line?

0 -

Exactly what you show in that diagram, a way to keep any flow from coming down the purple line for your proposed cut for the new valve and tee.

When it comes to a wet "hot" connection into a line I use a push grip valve. Then no power tools are required, which don't always mix well with splashing water :(

This is a handy tee when you don't have a lot of pipe movement available, with FIP for the tank connection

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot_rod and @EBEBRATT-Ed. Before moving forward with this alteration, I'm trying to wrap my head around why this issue has presented itself.

This sound/condition was not present with the original Series 100. A technician replaced the series 100 with a 0015e3 ECM pump reualting in very uneven heating yet no sound/condition. This ECM pup was reaplced this season with a 0010. Much better heating yet now expericing the sound/condition.

My assumption is the 0010 has a higher flow rate and head, and with the expansion tank location and PONPC, creates a low pressure situation on the inlet of the pump? Am I on the right track?

0 -

There is not a huge difference between the Series 100 and the 0010. I would not have expected it to change the operating condition.

If you want the long answer…

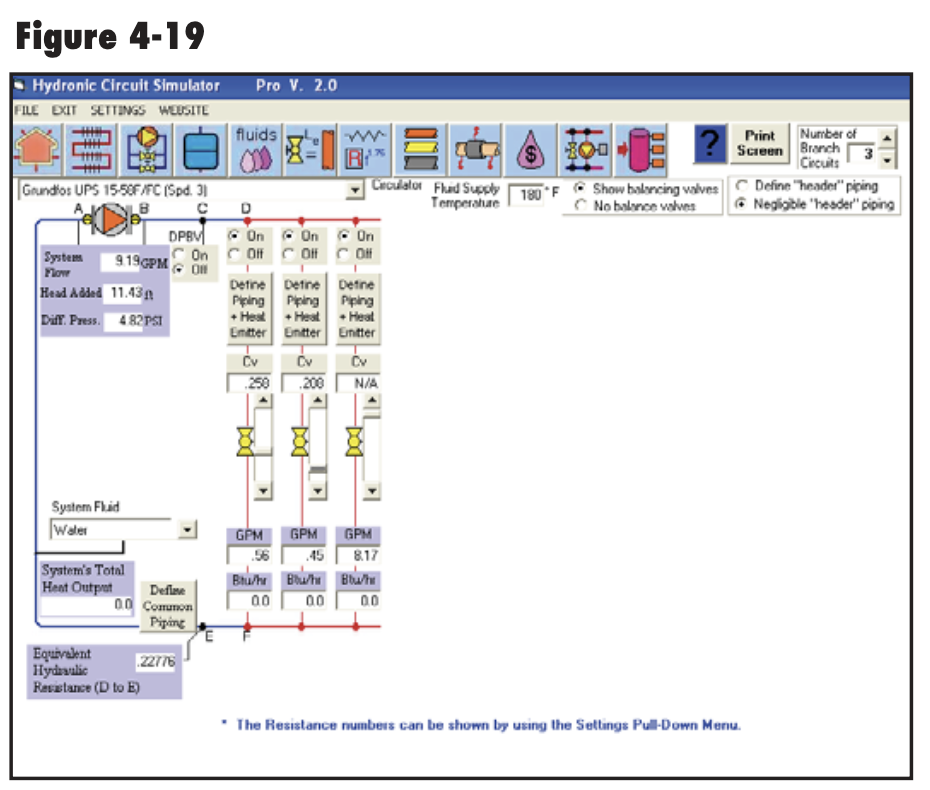

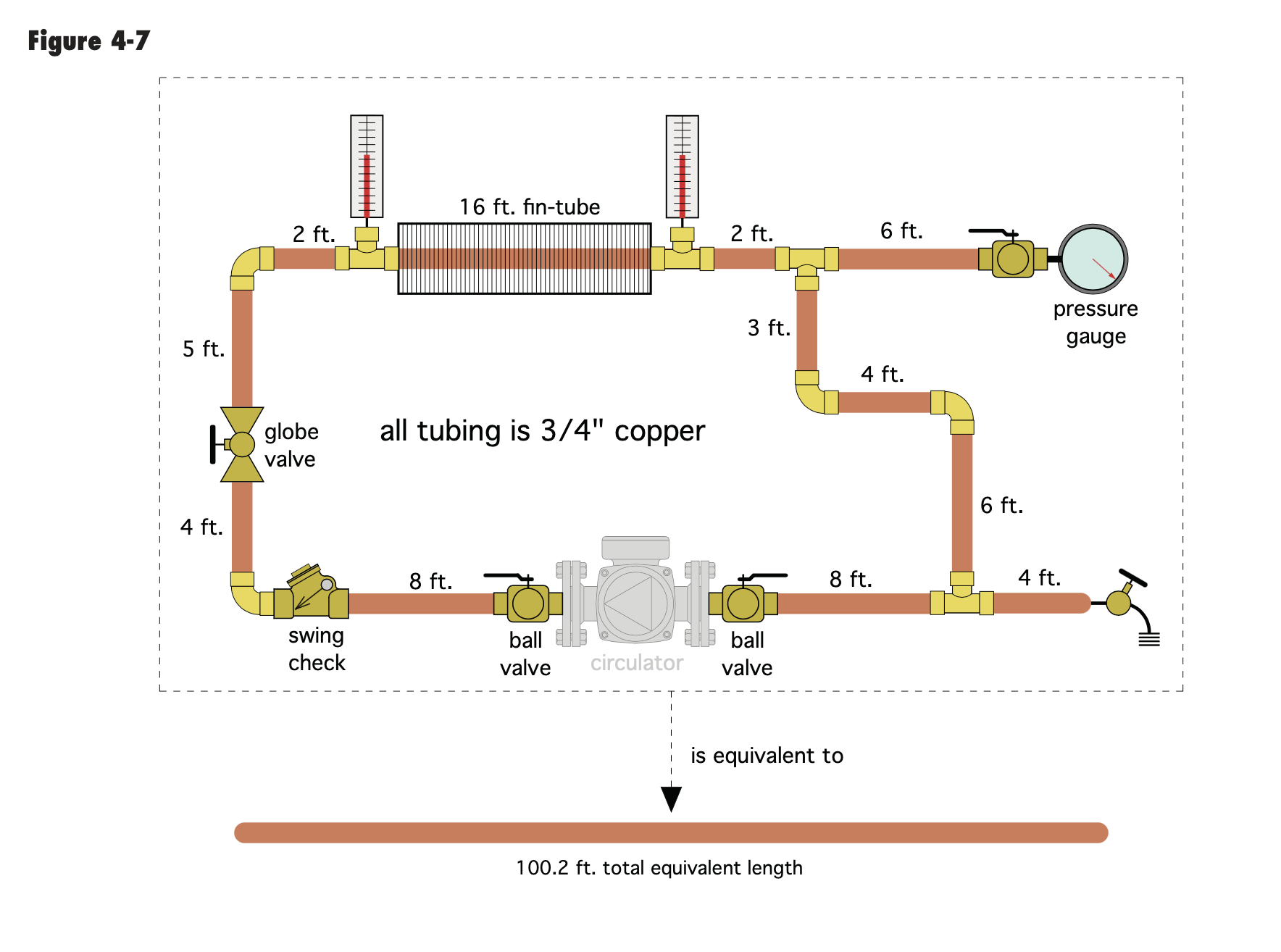

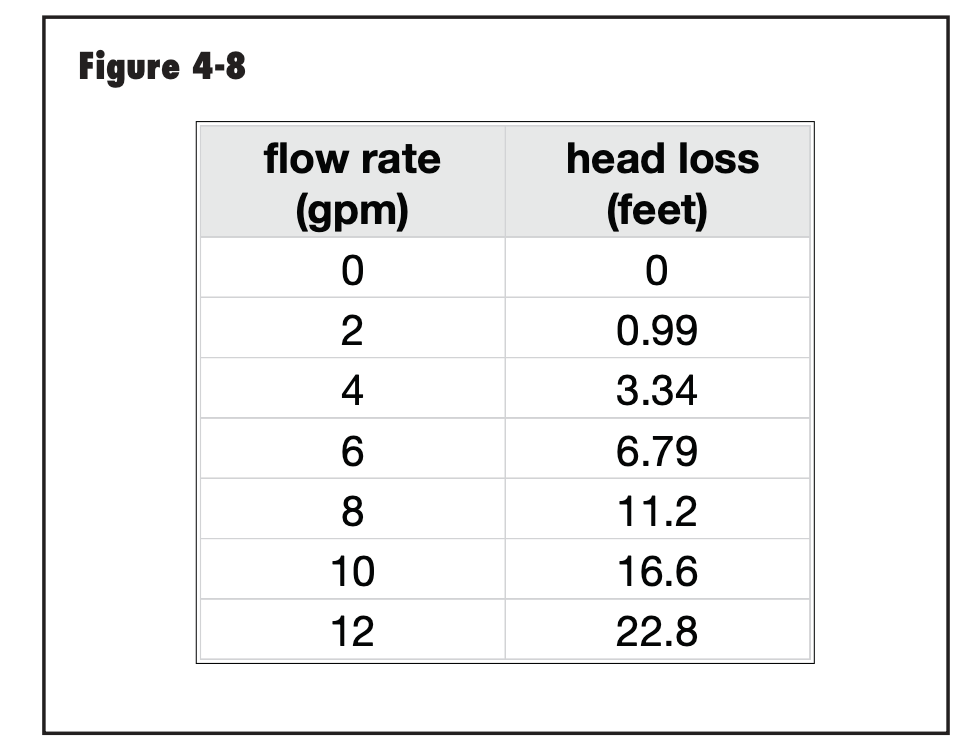

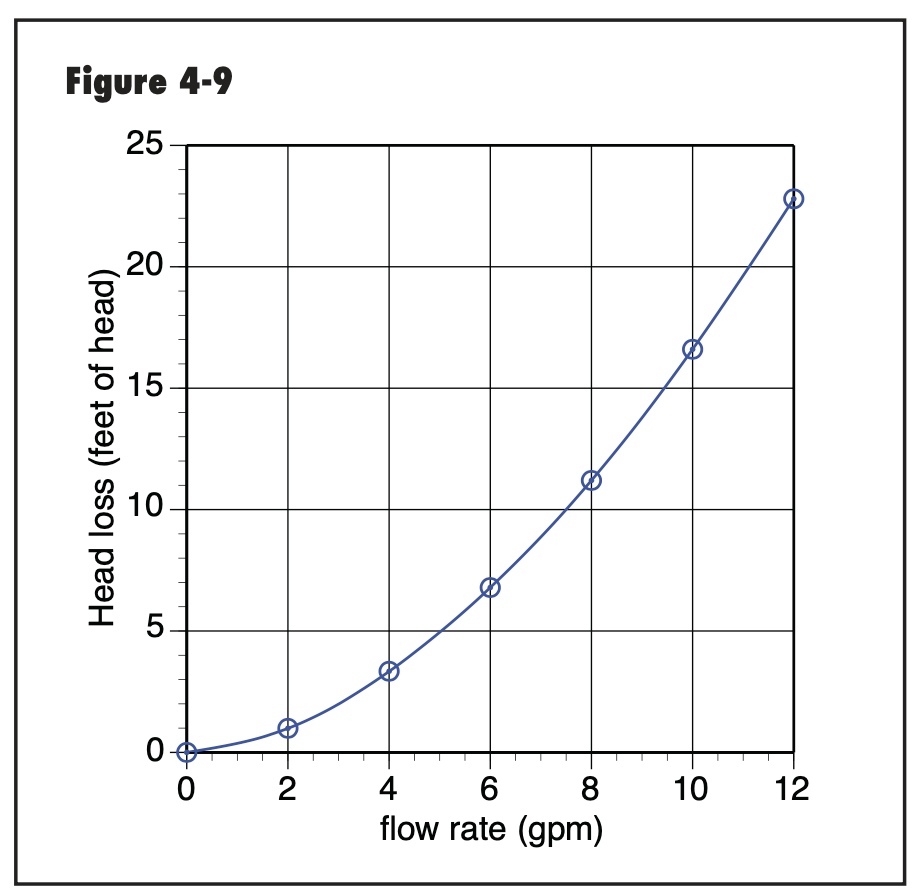

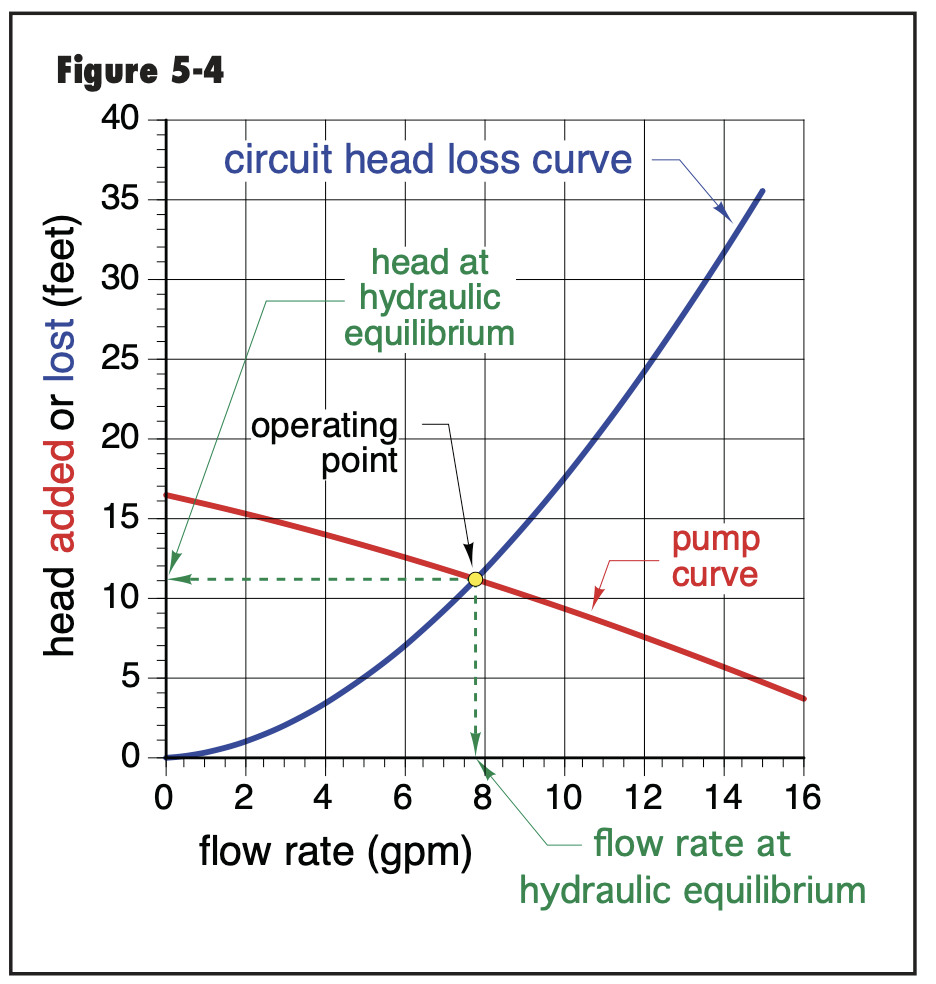

You would calculate or measure the pressure drop of the circuits or various circuits. Then on graph paper plot a curve with a series of various flow rates. Take that curve and lay it over the top of the pump curve you are considering.

Where the two lines cross is the OP operating point.

Pics below of the steps. From Caleffi Idronics 16

This is where the the pump actually operates on your system.

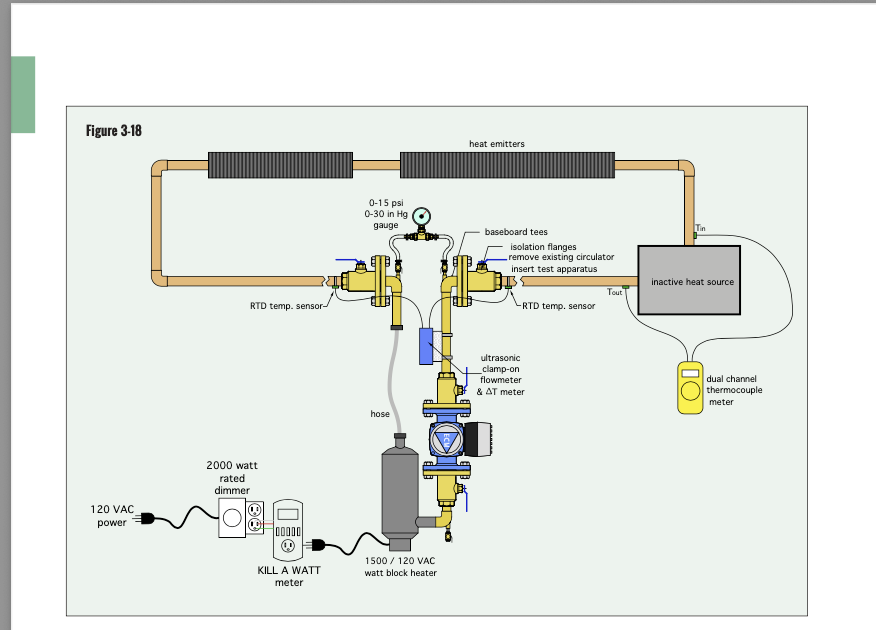

Idronics 35 has other options for evaluating a circuit, but it is quite involved to build one of these setups. We did a demo of this in my shop for a Coffee with Caleffi webinar.

Ideally you would want to be in the middle 1/3 of the pump curve. That give you the best efficiency, quiet operation and pump longevity.

With your troubleshooting method it is sort of a hit and miss method, trying different things until you get the end result you want.

If you are 100% sure the system is air free, you have lowered operating temperature, increased system pressure, throttled flow, there is not much more you can do to change the system dynamics.

I would think the 0015E would have been a good match, perhaps not enough time was allowed for it to get the system air free? before a switch was made.

While better component positioning may help, converting to pumping away, it may not be the final answer either.

You are 100% positive the noise isn't coming from the boiler as it gets hot? A scaled boiler can make similar sounds as it heats up.

I suppose the easy answer is go back to the series 100, if you are convinced that is the only fix.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements