Additional Low Water Cutoff

I have a Weil-McLain EG-40, which has one probe type LWCO.

Dan’s book recommends installing an extra LWCO.

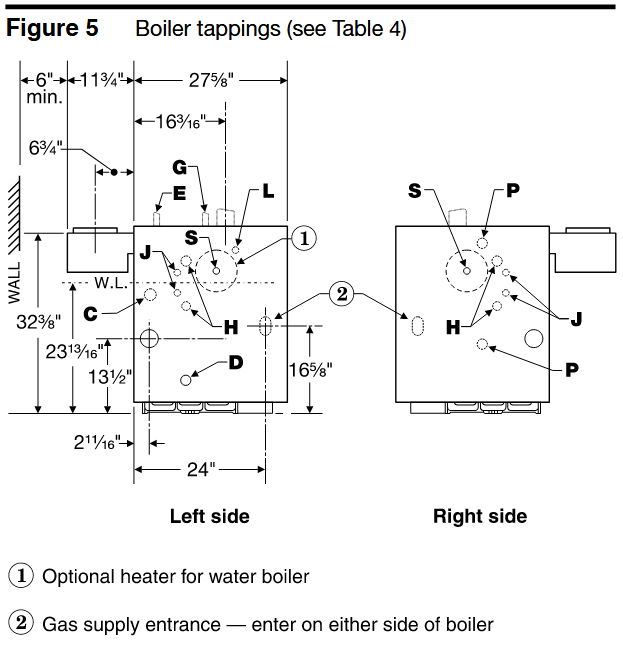

How can an extra LWCO be installed if there’s only 1 hole on the side of the boiler for the probe ?

Am just a homeowner, and not sure if there are other probe holes available .

Comments

-

I don't recall seeing that recommendation, but I could have missed or forgotten it. Can you site the page number?

In my opinion, and apparently in the opinion of all the residential steam boiler manufacturers, one probe-style LWCO is sufficiently able to protect your home.

Now I would strongly recommend to have a look at the boiler at least weekly during the heating season to keep the water level topped up and to be aware of the water usage over time or any other anomalies, but I can say for sure my LWCO is not my first line of defense…my eyes are.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I bought this book :

Pages 130 to 131 says this :

When it comes to steam, I’m a belt-and-suspenders kind of guy. And although it’s not required by code, I think that every steam boiler should have two low-water cutoffs, preferably a float-type and a probe-type. They should be in different places on your boiler. This doubles your protection, and since low-water cutoffs are much cheaper than boilers, it makes sense. They can also save your life. Besides, the cost of that second low-water cutoff disappears in the price of the job when you’re replacing your old boiler. Please consider it.

3 -

I think most residential boilers today probably don't have the additional tappings for a float type LWCO to be added, or if they do maybe they are hidden under the jacket somewhere. The really good installers who post their installs here and on youtube don't seem to be adding a second LWCO.

I think there might be a float-style LWCO that you can add to the gauge glass tappings if you really really want to, but to reiterate, I wouldn't see the need for that.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Not required for smaller residential boilers. I'm not sure what the firing rate cutoff is to require a second LWCO. A very common setup is a float type connected to the sight glass — not a big deal — which also trips the autofeeder if you have one, and a second, probe type, set at the "that really is too low" level — which, on a commercial boiler, is a manual reset type.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Many EG/EGH boilers have "try-cock" tappings next to the sight glass. We've used the lower try-cock tapping for the primary LWCO, and the "usual" tapping for the secondary.

I don't favor float-type LWCOs since folks don't blow them down.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

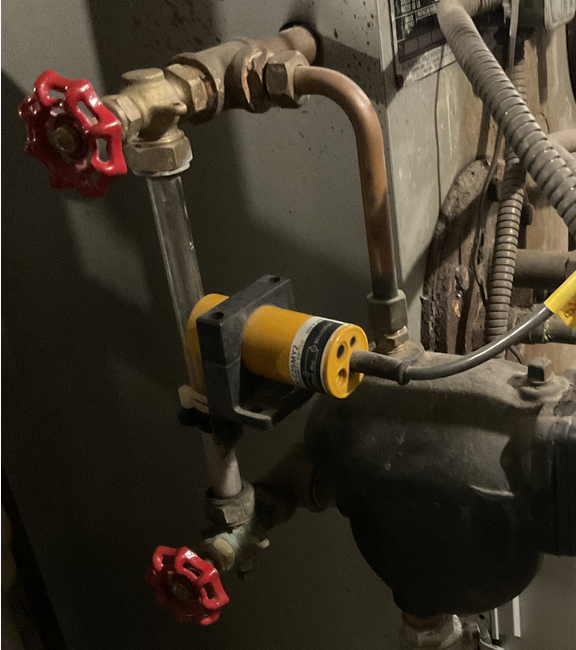

Any steam boiler can use a MM #67 which comes with the fittings needed to put it on a gauge glass.

Or you can add a probe type cutoff. Hydrolevel makes a probe type with fittings to mount on a gauge glass as well if no other tapping's are available

I am with @ethicalpaul on this. I think 1 cut off is ok with the HO checking the water level every few days and looking for leaks and having an idea about how much water is being added.

2 cutoffs may be a good idea for an apartment building or home without anyone to regularly check the boiler and the water level along with a water feeder.

In some areas two low water cutoffs may be required for a commercial building or any boiler above 200,000 btu input but local codes can vary. Usually, one is auto reset and 1 is manual reset.

1 -

Here’s 2

0 -

I would have used the tapping below the gauge/pressuretrol manifold for one of them. Less piping and you don't have to blow it down.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

Kind of pricey. If you are really interested.

https://www.supplyhouse.com/Mcdonnell-Miller-149400-67-Float-Type-Low-Water-Cut-off-Steam

https://www.supplyhouse.com/Mcdonnell-Miller-149400-67-Float-Type-Low-Water-Cut-off-Steam

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I would approach this from another view: This reference below is from a prior posting on HeatingHelp.com

Q: What happens if I don’t use a Hartford Loop?

A: Nowadays, your low-water cutoff should protect the boiler against a sudden loss of water, but if you have a gravity-return system, you really should also have a Hartford Loop. A Hartford Loop is the cheapest insurance you can buy to back up that low-water cutoff should a return rupture and water suddenly leave the boiler. Low-water cutoffs are great, but believe it or not, there are a few out there that don’t get blown-down once a week. Really!

Here is link to entire article that is self evident'

Regards

RTW

0 -

The XYLEM/Bell and Gossett information I have recommends using 2 LWCO's-The McDonnell and Miller RB-RB-122-E for systems of 400,000 BTU or greater.

In my case and my small coal stoker boiler being 120,000 BTU the second RB-122-E will also be wired in series as the first and second defense to protect the hot water boiler. A longer run of 2 BX cables would need to be run from the first low water cut off to the second low water cut off with two BX cable elbows and then back to my Honeywell L8124L Triple Aquastat.

The RB-122-E is a very small self cleaning probe type low water cut off that spins to clean itself with an LED bulb and manual reset test button.

Adding a second self cleaning RB-122-E is on the to do list for my stoker boiler this year as well as buying a spare blower and Intermatic timer motor and installing a domestic. hot water bladder tank to protect the hot water piping.

I have a spare tapping on the flue breech end of the kaa-4-1 coal stoker I will use to wire in the second RB-122-E low water cut off in series to be the first and second method to completely cut the 110 volt power to the boiler.

Perhaps I am speaking out of turn here; but if the Hartford loop piping is large enough a T could be added below the safe water level of the steam boiler to accept the RB-122-E probe type of low water cut off in the Hartford loop to offer a second low water cut off protection system if a blow down type low water cut off is not used?

If an RB-122-E is used they want you to use sealing tape on the threads.

0 -

When I have a client whose boiler dry-fired, they always go for the back up LWCO. Mad Dog

1 -

A Hartford Loop is the cheapest insurance you can buy to back up that low-water cutoff should a return rupture and water suddenly leave the boiler.

I don't know about insurance, but it's the cheapest 1 hour delay between the return rupture and the boiler boiling all remaining water out. In short, it is next to useless.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

It was the best they had in the early 20th century, and still has value today. Besides, manufacturers and Codes require it.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

I’m just saying don’t count on it, and be aware of how little it does for you. There are lots of obsolete laws and codes out there, I would guess. Just because it’s mandated by some codes doesn’t make it save anyone.

Honestly I have a hard time understanding how it helped anyone ever.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

0

-

Here is an article specific to the Hartford Loop, while not perfect, it did buy time to discover any leaks and fix issues before a boiler meltdown

By Dan Holohan

Regards,

RTW

1 -

If it saves one boiler from dry firing, splitting and possibly setting a house on fire 🔥, its done its job. Mad Dog

1 -

-

Some will say the HL does nothing.

But don't forget this was in the days of coal firing, no low water cutoffs, no burner to shut off, no pressure controls.

All you had was your eyes and ears, a safety valve and a fusible plug to melt and a HL

0 -

Just to add a result-oriented insight to Dan's article and comment from the esteemed Mad Dog 2 :

Significantly reduced the number of explosions

Did Boilers have less explosions after the invention of the hartford loop

The invention of the Hartford Loop in 1919 significantly reduced the number of explosions and cracked boilers in the steam boiler industry. This safety feature allowed condensate to re-enter the boiler but prevented complete loss of steam boiler water should a leak develop elsewhere in the condensate return line. The Hartford Loop was mandated by the Hartford Steam Boiler Insurance Company to ensure boiler safety and prevent catastrophic failure associated with a dry-fire scenario. The Loop's design helped maintain pressure balance between steam feed to radiators and return feed of condensation to the boiler, thus reducing the risk of boiler instability and explosion. InspectAPedia+5

Source: InspectApedia

Regards,

RTW

P.S. I may as well add Ben Franklin's so called "lighting rods" that he chose not to patent were installed ubiquitously throughout European cities and reduced frequency of fires caused by lighting that had proliferated prior to the invention

2 -

-

The Hartford Loop is a Simple Dam..with no moving parts. The Deadmen were no dummies. They didn't do anything willy nilly...they thought deeply about things. Insurance companies were always about minimizing their exposure and keep those premiums rolling in...that hasnt changed. Mad Dog

1 -

-

-

Sorry guys but there is no data here, that's OK, I'm not going to convince anyone, but the fact is that the Hartford Loop doesn't do anything other than possibly postpone a dry fire by however long it takes the boiler to steam out its water. No one can argue against that fact.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I agree with some of what you are saying but in the late 1800s there were no LWCO. They didn't come about until the oil burner was invented which was around 1920 it was put into common use. You had 0 protection against a low water condition and they blew up a lot of boilers.

The operators' eyes and ears and the HL and fusible plug to melt and dump water on the coal fire as a last resort

0 -

How did they blow up? Why were so many returns spontaneously catastrophically falling apart?

Every return I have seen leaking (admittedly only a handful) is weeping, not gushing.

This history sounds very implausible to me, sorry!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Not sure if steam heating is taught much in trade schools today, but a good assignment for students would be to research and write a paper on the development and the effectiveness of the Hartford Loop that is still required by code today. Then, report back to this web site with links to the results, but may be wishful thinking

Regards,

RTW

0 -

Humans are experts at making bad things happen. They sunk the Titanic, didn't they claim it was unsinkable ? It did not take long to fact check that claim.

And what average homeowner with a boiler checks the water daily ? If it was not for the modern LWCO, there probably would be many more issues.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I don't think anyone from 1920 is around to tell us what went on. So the only thing we have to go on is what we have been told.

Look, its easy to do.

Today I cooked a turkey among my other many talents. I had a pot of gravy on the stove (hate electric stoves) I needed to boil it and it wasn't boiling, I waited and still not go. Put the heat to it and turned away for less than a min and it boiled over and I had a mess to clean up. I may be outed from the kitchen forever!!!!

Inattention, lack of a Hartford loop, no low water controls and Murphy's law.

Back in the 70s I worked at an oil company. i went to this elderly ladies' house to do the yearly maintenance. A steam snowman oil fired with no low water cutoff. It's only been about 20 years since a LWCO became required on a HW boiler.

0 -

Yes, the LWCO I agree is a valuable, necessary item on a steam boiler. It prevents fires and dry fires without question.

Back in the 70s I worked at an oil company. i went to this elderly ladies' house to do the yearly maintenance. A steam snowman oil fired with no low water cutoff. It's only been about 20 years since a LWCO became required on a HW boiler.

Was she checking the water level regularly, I have to assume? And in all those years, her wet return didn't disintegrate one day and cause her boiler to explode? 😉

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

How Common Are Boiler Explosions Today?

- 19 December 2025

A boiler explosion is defined as the abrupt structural failure of a pressure vessel, typically caused by excessive internal pressure or material degradation. This failure results in the rapid release of high-energy steam and hot water, which expands violently upon rupture with immense force. The stored thermal and pressure energy is instantly converted into destructive explosive power, capable of causing significant damage. Fortunately, due to technological advancements and rigorous manufacturing requirements, the risk of a catastrophic boiler explosion in a modern residential setting is extremely low.

The Historical Reality Versus Today’s Statistics

The frequency of boiler explosions has seen a dramatic decrease from the industrial era to the present day. During the 19th and early 20th centuries, these incidents were a common hazard, largely due to poor material quality, lack of standardized manufacturing practices, and absent regulation. North America saw a peak where steam boiler explosions occurred at a rate of approximately one per day, claiming about two lives daily in the early 1900s. The sheer number of devastating accidents necessitated the empirical investigation and subsequent establishment of engineering safety codes.

Today, the statistics reflect a profoundly safer reality, though incidents still occur almost exclusively in industrial or commercial settings. The United States sees an estimated 20 to 30 boiler explosions annually, with residential units rarely involved. Many reported incidents are not catastrophic shell ruptures but rather contained system failures or fuel-related combustion events within the firebox. While the destructive potential remains real, the low probability is a direct result of comprehensive safety measures designed into every modern pressure vessel.

Primary Causes of Modern Boiler Failure

When a modern boiler does fail violently, the mechanism is usually traced back to one of three specific technical lapses that compromise the vessel’s integrity. The most frequent cause of structural failure is a low water condition, where the water level drops below the minimum safe threshold. This exposes the boiler’s steel shell or heating surfaces to the intense heat of the burner, causing the metal to overheat rapidly and weaken. If cooler water is then suddenly introduced to the superheated components, it flashes instantly into a massive volume of steam, creating a pressure surge that the already compromised vessel cannot contain.

A second major factor involves the failure of the pressure relief valve, which is designed as the last line of defense against over-pressurization. If the relief valve is blocked, damaged, or malfunctions, it cannot vent the building pressure when it exceeds the safe operating limit. This allows the internal force to climb unchecked until it surpasses the vessel’s design strength, leading to a rupture. A third contributing element is the long-term degradation of the boiler’s material structure, primarily through corrosion and fatigue.

Corrosion, such as oxygen corrosion or graphitic corrosion, systematically weakens the metal components of the boiler over time. Water impurities, including chlorides and dissolved oxygen, contribute to this material thinning, often leading to holes at the waterline where the metal is constantly exposed to air and water. This sustained degradation reduces the wall thickness, making the pressure vessel highly susceptible to failure even under normal operating pressures.

Safety Standards and Preventative Maintenance

The current high level of boiler safety is maintained by strict external controls and required user actions. Organizations like the American Society of Mechanical Engineers (ASME) develop comprehensive standards for the design and manufacturing of pressure vessels. The ASME Boiler and Pressure Vessel Code (BPVC) provides detailed rules, such as those found in Section IV for the construction of heating boilers, which ensure that units are built to withstand far greater forces than they will encounter in normal operation.

These codes also mandate the proper function of safety devices and set the framework for mandatory inspections, especially for larger commercial and industrial units. For homeowners, the most effective safety measure is a program of preventative maintenance, ensuring the longevity of the unit and the reliability of its safety components. Annual servicing by a qualified technician is recommended to inspect for signs of corrosion, check water levels, and verify that the burner management system and safety interlocks are functioning correctly.

0 -

This is a rather entertaining discussion — but not simply because of the debate on the effectiveness or otherwise of the Hartford Loop. Rather, it reflects — to my mind anyway — an overall cultural shift from relying on designs and equipment which, while not inherently safe necessarily, were very simple to designs and equipment which is much more sophisticated, perhaps, and more efficient (almost always) but which contains inherent failure modes which, while rare, are catastrophic — resulting in, at best, replacement of equipment at considerable cost and, at worst, property destruction and fatalities.

I'll happily grant that some modern machinery simply can't be controlled without very sophisticated computer assistance — some modern aircraft, for instance — and some can be made much safer with sophisticated computer assistance — the modern passenger car is a good example.

Don't try to fly an Airbus when the computers don't work. Don't try to get into a Tesla when the battery is dead. Don't try to stop a modern car when the ABS is toast (the e-brake won't work). …

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

YUP, and if you buy a coal stoker boiler sell the hydrostat and order a honeywell L8124L from Supplyhouse.

0 -

A few days ago, I was reading about the "Waymo" self-driving cars. (first time I heard of Waymo) in San Francisco.

They had a power failure and all the traffic lights went out. When the Waymo got to a traffic light that was out it stopped dead in its tracks as it was programmed to do. All the Waymo's stopped dead. Massive traffic jamb

1 -

Bad programming… A traffic light that is out should be considered a stop sign for all roads entering the intersection. But even Humans get that wrong and blaze through them. So now you have the other way, just sit there until the power is restored, nice.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Hydrolevel is releasing a gauge glass mounted LWCO in 2026

sales sheet

0 -

They've had those components for some time now, but this is the first time they've sold them as a kit. Still need to blow it down though, but it does away with the 67's moving parts………………

Edit- found the link, this is the two-probe version:

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Looks like they probably ripped off this guys idea, he probably did not patent it.

EDIT: Just looked at it, it does not connect to the gauge glass, it connects to the gauge glass pipes.

https://forum.heatinghelp.com/discussion/190480/a-question-about-steam-heat

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements