Counterflow steam system

I think I may have found my solution with the help of posts here, Dans book and his and other videos I’ve watched. Also why changing my header and all the other things I’ve done and checked didn’t change anything.

Here it is….

my system is two pipe COUNTERFLOW.

it was originally a coal fired system, and the mains are always warm with that system so when it called for heat there would be little to no steam condensate when the steam down through the mains

… now it’s gas fired and mains are cold between cycles. The water in my mains are just from the condensate from the beginning of the cycle . I know this because once I purge / drain out that water in the main heats as it should.

also there is no water hammer so I know it’s not pooling cold water . The water is the condensate from the cold main. Also why if I shut it down near the start of the mains heating up, let it set for a time and fire it back up problem is for the most part gone.

So this would mean I need to add the previously mentioned by some, DRIPS to the HL near the boiler header to both of my mains so that condensate in the mains at start up can drain back.

Thoughts ?

Comments

-

Well you need the drips. It kind of sounds to me that when the boiler is heating (steaming) you are pooling water and when the boiler shuts off the pipes drain.

The bottom line is this. Steam changes to water when it cools. If the water can't get out you going to have problems. The water can't be allowed to remain in the system. It can't wait for the end of the cycle. The water has to be drained as fast as condensate is formed.

Never seen counterflow 2 pipe myself but that doesn't mean it won't work or doesn't exist.

Pretend you are water inside the pipe how does the water drain out. It can't go up hill.

Maybe someone raised some pipes or messed it up or knuckleheaded it before you bought it.

1 -

There are some inaccuracies in your statements of facts in your first post in this thread, @JoshP

A hot main still creates condensate, even an insulated one. Yes it will create more condensate when it is cold, but the point remains. What @EBEBRATT-Ed said is exactly right of course. If the water can't get out, something has been messed up in this system.

I know this because once I purge / drain out that water in the main heats as it should.

This is a sign that water is not running back to the boiler like it needs to. It's not because the system used to be coal. When it was coal, rest assured, it was designed to let water return to the boiler. Coal fires were allowed to go out during warm spells, no doubt, and I'm sure sometimes coal fires went cold or at least not hot enough to create steam at various times during the winter. There's no way those residents back then were draining their main with a shop vac.

I saw a system where a plumber decided it could easily be converted from parallel flow to counterflow because "wet returns are obsolete". He was wrong.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I would love to see this thing but it's too far for me. @Mad Dog_2 could help you out.

0 -

i think it is the combination of the missing drips and the header pitched toward the steam riser.

the coal boiler had a huge area above the water line that could better deal with some condensate running back in to it although the near boiler piping might have been just significantly rearranged when the coal boiler was removed. might have had some vapor specialties too.

0 -

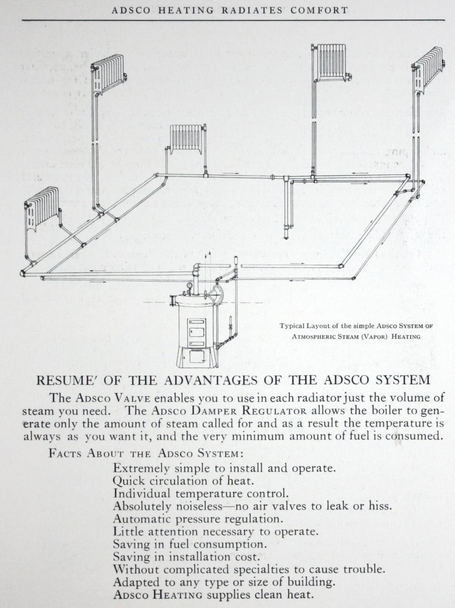

it’s an ADSCO vapor system

0 -

Look like it should be parallel flow to me. Since it is not, plan B, or C or D.

https://archive.org/details/AmericanDistrictSteamCo/page/n7/mode/2up

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I’ve read that and have that ADSCO brochure . My system has the ADSCO valves but it’s counter flow , no wet loop at the ends of the mains and the no connection / tie in of the mains to anything but take offs to the rads. Just two parallel counter flow mains to rads and dry returns back.

Also no evidence of any pipes being modified or changed other than at the boiler when it was replaced 50+ years ago. All the asbestos insulation was still untouched when I moved in.0 -

As I just said elsewhere, residential steam is incurably forgiving. There's no reason why counterflow mains won't work — but here's the gotca: they must have drips at the boiler.

At least as important, they must have main venting at the ends of the steam mains, whether counterflow or not. This could be crossover traps, which are often preferable, or it could be main vents. But they have to be there.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

I added big mouth vents near the end of each main. I guess my next step is to add drips for each main near the boiler, Reducing main pressure and allowing the condensate a place to go other than near the end of the mains.

0 -

allowing the condensate a place to go other than near the end of the mains.

Forgive me if you answered this in the past, but this is sounding a lot like the system i saw where a plumber just decided he could remove the wet return…so let me ask it plainly here:

If your system is counterflow, then what is the condensate doing near the end of the mains? Are the mains in fact pitched away from the boiler?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

The condensate is sitting and surging near the take off piping to the second floor causing those rads to heat half as fast . It’s not draining back to the boiler. No drips at the boiler.

Both mains are pitched back to the boiler . Lowest point if the mains are at the boiler header . All rads tied into a Dry return all pitched back to the boiler with return venting at the point where both returns come together and drop to the HL.0 -

You say the mains are pitched back to the boiler, but some part of them must not be. So either the mains have settled at the ends (very possible), or this piece from the diagram that @109A_5 posted has been removed by someone (or both).

You indicate your system has a dry return so how could it be counterflow? What would the point be to a dry return (I know Jamie doesn't like this term) in a counterflow design?

Lowest point if (of) the mains are at the boiler header

Maybe so, but that's not enough for counterflow to work. Every part of the main must be higher than the part that precedes it.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Keep asking everywhere, it can't hurt! 😉

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

I have seen one CF 2 pipe system, it took awhile to figure this out.

You never mentioned rad traps, are they working OK?

If not closing then steam may enter the returns and close other traps.

Remember the main steam pipe has to only return the cond produced as the steam flows to the rads. The return line has the main job for cond return.

The system I speak of has only 1 main and 1 return with a single air vent on the return above the HL. I don't recall the main having a drip. However it has a "steam drum" at the boiler which may collect that condensate.

I see the advantage to this system as both pipes are at the same elevation around the basement to give max head room at the ends. Of course the boiler is the low point for both pipes.

You said your 2 returns are tied together above the water line. If you have any steam in the returns this could create problems.

0 -

no problem here! I like digging for the truth. You have had a lot of good advice here to consider though!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

I replaced all the trap bellows. Hoffman 8c. Returns are not getting hot.

0 -

-

-

Oh dear. Several points here. I have no objection to the term "dry return" — provided it is used correctly. In a two pipe system, the dry return carries — or should carry — only condensate and air. That condensate will be from the radiators, but in the case of parallel flow mains it may also be from the mains. The air will be from the radiators, but may also be from the mains if crossover traps are used rather than main events (and note carefully: many vapour systems have pressure differential control devices which will NOT work if main vents on the mains are used).

Since dry returns carry only air and condensate, they can, and again in many vapour systems, MUST be connected above the water line and must be provided with ample main venting at that location.

And by the way — in a properly operating two pipe system with dry returns, those main vents at the boiler will never see steam or close…

Where the problem arises is that in many systems — either one of two pipe — the steam main, which will be parallel flow, continues on beyond the last radiator takeoff and returns to near the boiler, at which point it terminates. THIS IS NOT A DRY RETURN. This is a steam main, even if it is a smaller diameter, and must be treated as such — and if there are two or more of them, as is common, they must NOT be connected above the water line, but dripped and vented separately.

All of this applies whether the mains — and dry returns, if they exist — are parallel flow or counterflow.

Now in @JoshP 's situation, it would appear that there may be a low spot in the main near where he mentions water — condensate — pooling or surging. Lots of possible reasons for that — but the most common is that the line has sagged. It may be hard to believe, but even fairly large diameter pipe can, and does, sag. It may also be that someone did some remodelling and removed a drip or water seal which was meant to be at that location.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

there are no drains for the mains. Which is why I think drips need to be added .

Mains have take offs for rads . The take off for the second floor rad is essentially the last take off and on the end of the main .

Video of system. If you need to see something else let me know. Pics really don’t work well to see the big picture.

0 -

-

the vent at the boiler is how the radiators vent. there should be no steam in the returns. if the equalizer does have to equalize the supply and return you want that to happen near the return vent so it can close the vent without filling the returns with steam.

0 -

correct

0 -

are there any connections between the mains and returns anywhere other than at the equalizer?

0 -

i think at this point the only part of this system that is a vapor system is the metering valves on the radiators.

0 -

Correct. Mains go to rads. Returns from rads go to the boiler and are vented . No connections between the two otherwise.

0 -

that stub could be partly filled with water and be more mass to condense steam in the main too, exacerbating the lack of drip problem.

oh, and it could have been a drip for the original boiler.

0 -

it was next on my list to get the cap off see if water is pooling in it and either cap it right at the tee or now possibly use it for a drip return for that east side main

0 -

-

two pipe counterflow .. drip on main, which mine lacks. That’s the fix.

0 -

If the pitch on everything out in the system is correct the drips should help.

0 -

If the header slopes to the equalizer, then the east (right) main slopes downhill to start, so maybe there is water pooling there.

A new swing joint and a new drain T at the top of the east riser might help.

Dennis

Dennis0 -

I’m missing the stub Matt; which photo?

Thanks

0 -

there was maybe A half once of water in the header when I split the unions to adjust pitch and check if water was pooling inside.

I prob should have done swing joints on the mains. I may add that too. Thanks0 -

it is in the other post i think and there was more allusion to it than a picture. i think there might have been one picture and a diagram and some questions about it. it looks like it was maybe a connection to one of the missing vapor specialties or to the equalizer or maybe even the out let of the original boiler.

1 -

Sorry. Been mixing this system up with some other thread of a "2 pipe" that had radiator vents and no traps on the radiator outlet pipe…

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements