Water hammer - novice question

Comments

-

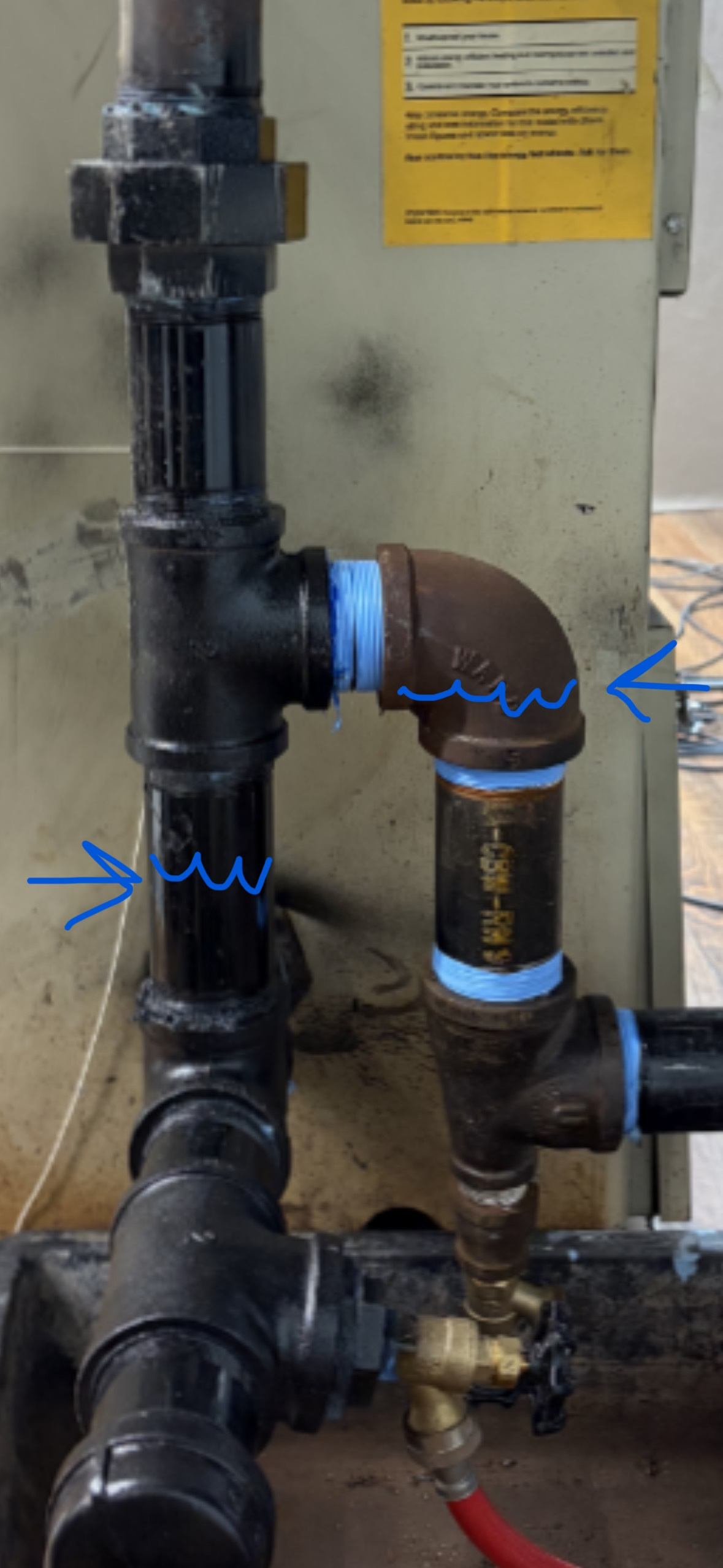

Regarding Jamie Hall's question about other horizontal pipes near the water level… the only one I see is below the return trap where there is a check valve. This is just about exactly at the nominal boiler water level height.

0 -

that whole wet return and trap was well below the water line of the coal boiler. that check valve was likely a misguided attempt to fix the new boiler's water line being too low half a century or more ago.

if there is much of any pressure differential between the mains and the returns that will push the water out of the wet return and allow steam to follow those drips and the wet return between parts of the system that should be isolated by the wet return

0 -

the cracking pressure of that check valve could also be causing condensate to stack up somewhere it shouldn't be

or it could have been part of the original vapor specialties

0 -

I truly appreciate everyone's prompt input on my newbie questions. I'm presuming the water hammer, besides being annoying, 1) contributes to premature pipe/joint wear and 2) makes the system less efficient. Or have I missed something important.

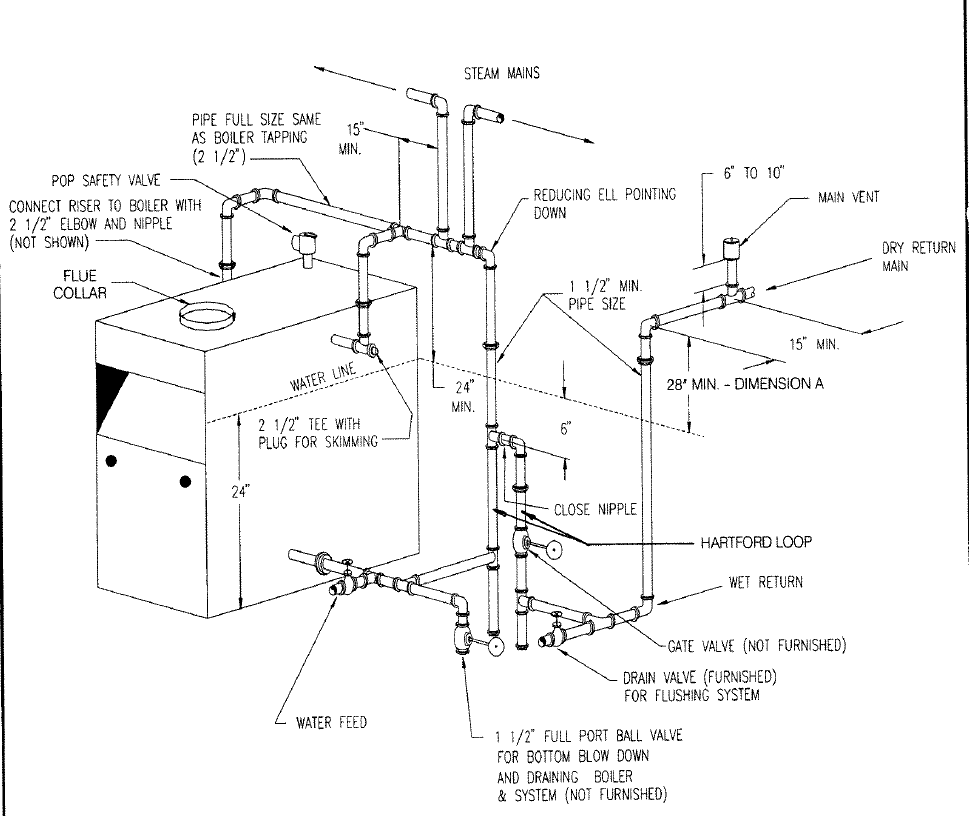

I'm thinking to get some contractors over to see what it takes to make it like it should be. The diagram below is pulled from the Dunkirk PSB manual, so I would say "make it like that". Make sense? It won't be cheap, I'm sure, and the boiler is already 32 years old. Neither of the techs who have been over have raised concerns about the boiler itself (they said it was in very good condition), though neither of them said anything about the piping arrangement being screwy, so not sure how much weight to give their opinions.

Someone mentioned checking the steam trap in vs out temps with an IR thermometer. Good idea, thanks, I just have to get one.

0 -

if there are wet returns that are right at the water line you should add a false water line to that I think but those that know vapor systems very well may have some comments about the implications of that.

if you have a wet return that is right at the water line, pressure in the boiler (and thus the mains)could be pushing water up the drips. that might be the mystery of your changing water line.

0 -

Sorry, not following what a false water line is…

OK, now I am adding a few random observations, which may or may not mean a #$%#% thing…

- Having failed to acquire an IR thermometer so far, I am checking radiator steam traps by feel. All the radiators seem to be giving off uniform heat across the entire radiator. Several traps are warm on both side of the trap (at or approaching the temp of the feed line). Some are cool to the touch on both sides of the trap. One or two seem to be cooler on one side of the trap vs the other. One or two overhead return lines in the basement are noticeably warm as well, while most are cool to the touch. The hot traps seem to be mostly, but not exclusively, on the first floor.

2. There are a couple of pressure gauges above the pigtail. They seem always to be more or less near zero, so I am not really sure what their purpose is. One of them is today showing me a slight vacuum of almost -4 inches of mercury (burner is off). When I have paid attention to it before it has been close to 0. The smaller one is always stubbornly pegged at 0.

What are the references (books/websites) I should have in order to understand these systems as much as possible and avoid silly questions? I am coming from the perspective of a reasonably intelligent human having no prior experience with steam heat.

0 -

-

Good afternoon and Happy New Year…

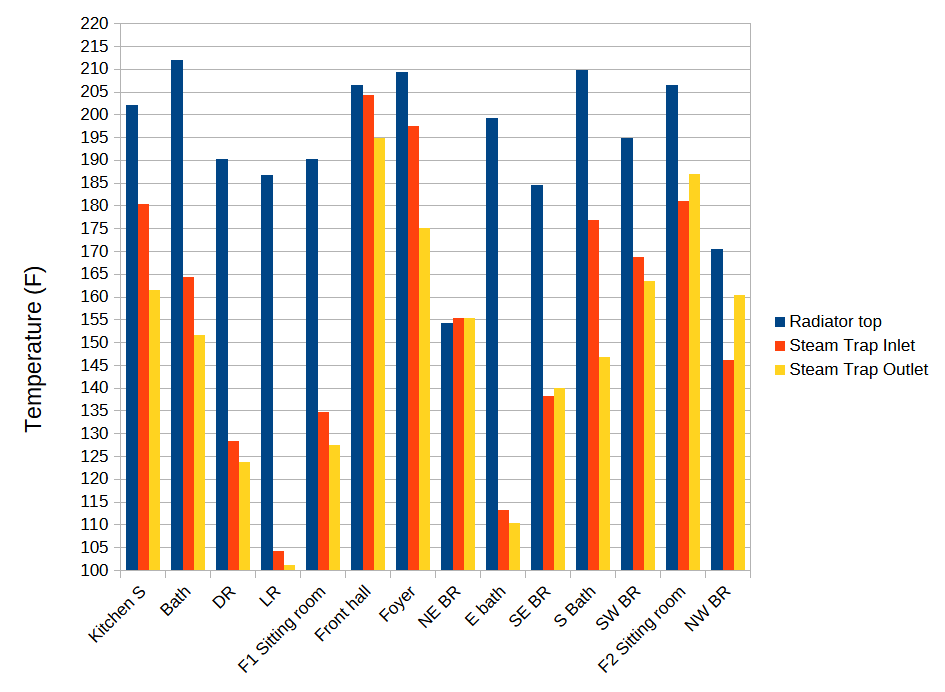

Got around to checking steam trap temp differentials using IR thermometer. From this chart below I presume that the ones with 0 or negative temp differential (inlet temp - outlet temp) need new steam traps. I'm a bit puzzled as to why some of them are hotter on the outlet than the inlet side. I measured these after turning the heat up and letting all the radiators get warm all the way across. The tops of the radiators range from about 155 F to 212 F. Steam trap inlet temps range from 104 F to 204 F, outlet temps range from 101 F to 187 F. Is the diagnosis as simple as going by these temp differentials?

Steam trap inlet-outlet delta (F)

-1

19

13

5

3

7

9

23

0

3

-2

30

5

-6

-14

1 -

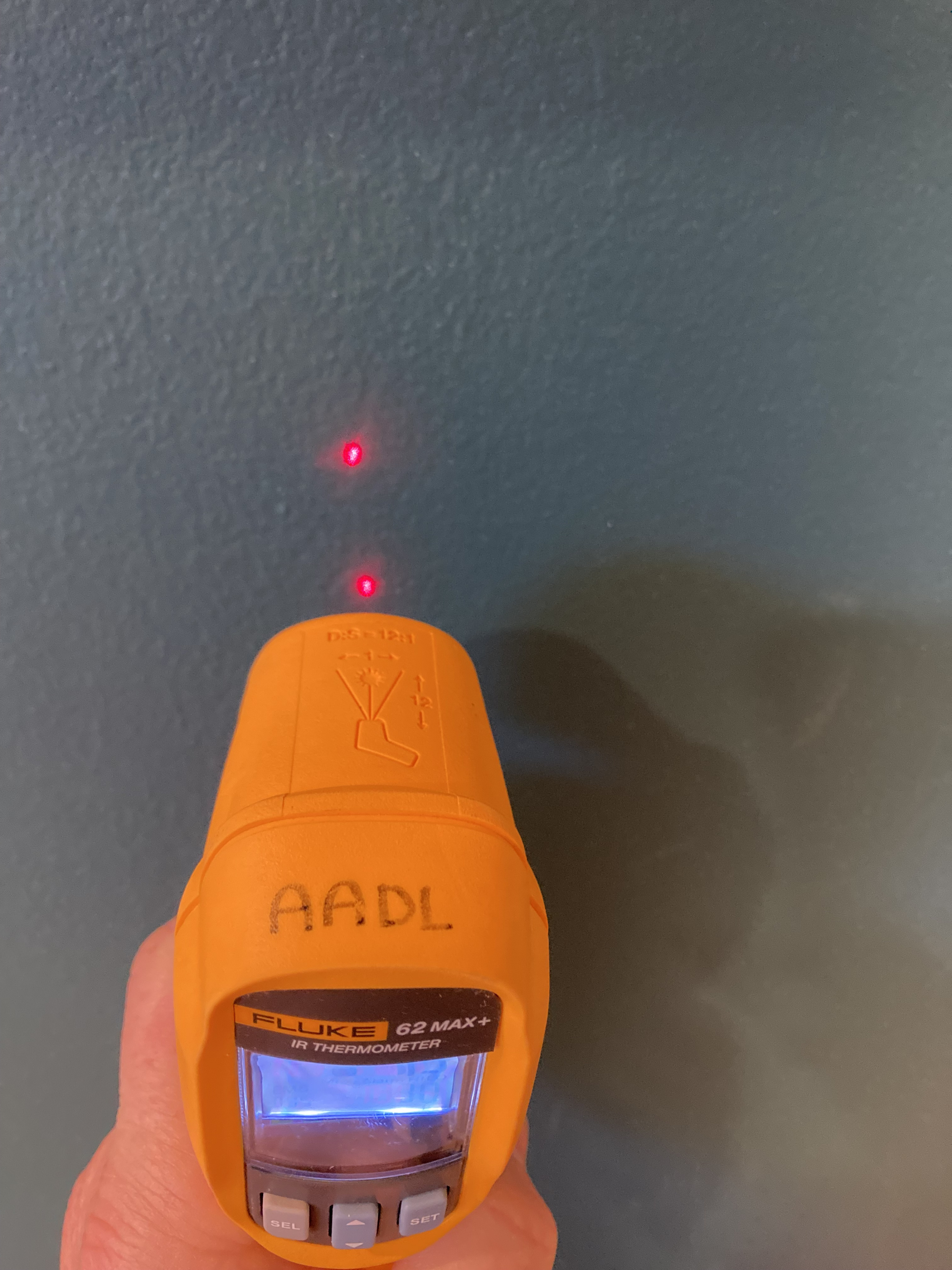

Maybe. Not a helpful answer! There is a problem with IR thermometers, and I think you may have run into it — unwittingly. The quality of the surface finish which the thermometer is aimed at makes a huge difference, and there is also the risk of sensing more than one thinks one is.

With the sensing — it's important to be as close to the object as is reasonable. That handy dandy red dot is the center of a circle which is being measured — but that circle get bigger the farther from the object you are. The diameter may be as much as the distance to the object, though for more expensive thermometers it will be more like half to a third of the distance. It's quite possible, for instance, if you are a few inches from a pipe, to be getting a reading more from the wall behind the pipe than the pipe itself!

So that is one source of variation.

The other is the nature of the surface. Shiny metal, for instance, will read low. Sometimes very low. Most paints are pretty even — if they are clean — but a few,, such as metallics, read low. So it is very necessary that the surfaces of the material are comparable if the readings are to be compared.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

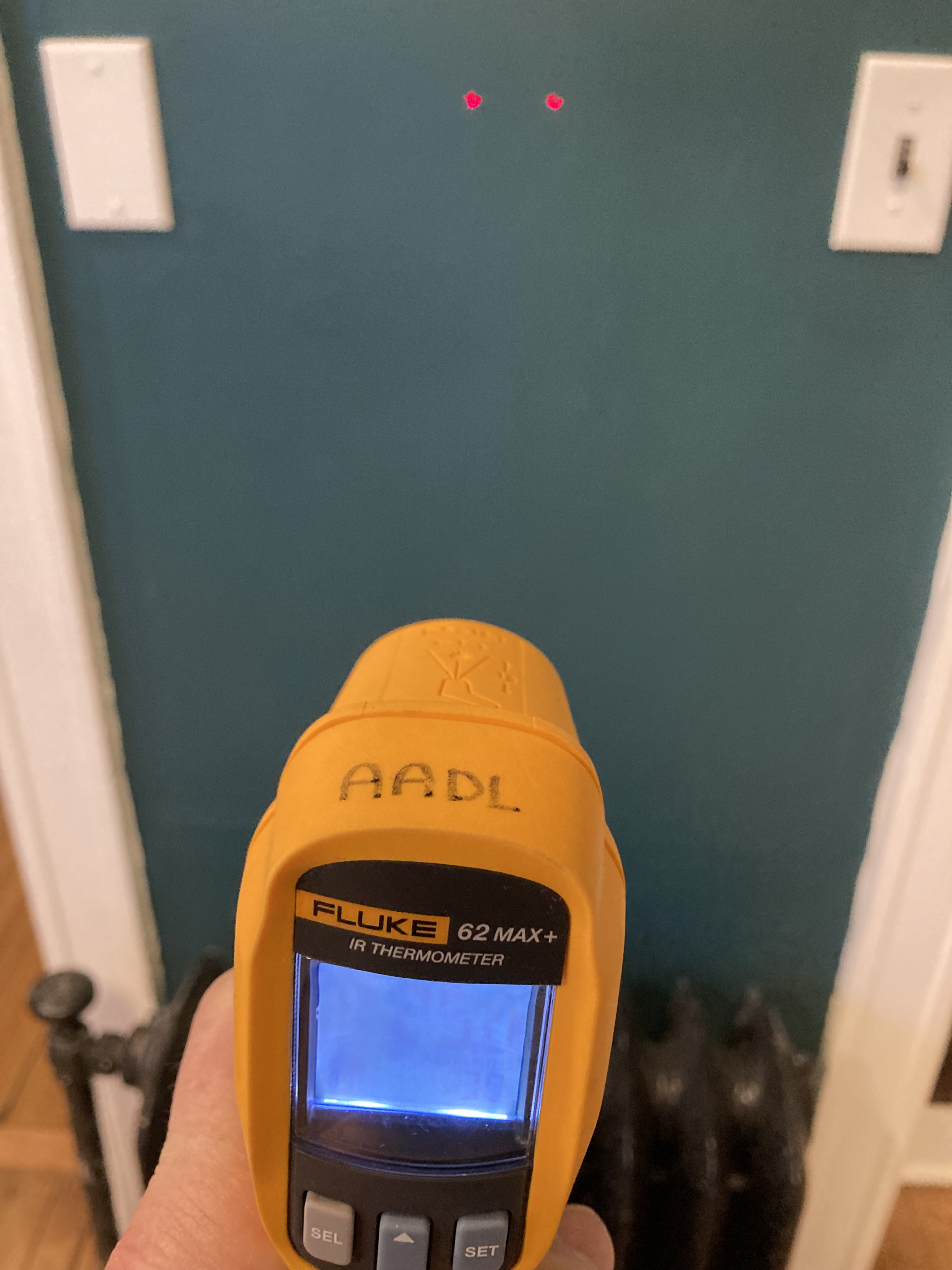

Hmmm… it's always more complicated than I want it to be!… Most of these traps are painted though there are a few newer-looking ones which aren't. The IR thermometer is a Fluke 62 Max+, which has 2 dots. I'm trying to get as close as I can and line up both dots on the inlet side or the outlet side. Actually I just noticed what I think is an aiming/locating feature for this unit, though I don't have any instructions for it - 2 or 3 feet away from the object the laser dots are horizontal, and as you get within a few inches they gradually rotate to being vertical. I did a similar set of measurements last week and today's numbers seem fairly consistent with those. So I feel reasonably confident about the numbers.

0 -

Those Fluke meters are nice, and the dots help you figure out what is actually being measured. Definitely a plus. But…the closer you are the better.

Bare metal like that union nut in your picture tends to read low. Sometimes just a wrap of electrical tape and shooting on that will give more reliable readings.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Manual;

https://www.fluke-direct.ca/pdfs/cache/www.fluke-direct.ca/fluke/thermometer/62max/manual/fluke_62max_thermometer_manual.pdf

" From this chart below I presume that the ones with 0 or negative temp differential (inlet temp - outlet temp) need new steam traps. "

I would think the actual temperatures and the differential would need to be considered to get a better understanding of what is actually going on with the system.

So a chart of trap inlet and outlet temperatures per radiator would be more meaningful.

" I'm a bit puzzled as to why some of them are hotter on the outlet than the inlet side. "

Steam is probably on the wrong side of the trap, probably from another trap leaking steam through.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Example;

Radiator, Inlet, Outlet, Differential

A, 180, 180, 0 Inconclusive, may not be hot enough to close the trap.

B, 111, 111, 0 Maybe a bad trap, steam traveling through.

C, 111, 100, 11 Maybe OK, temperature drop across the trap.

D, 100, 111, 11 Maybe OK, but steam is on the outlet side, probably from a defective trap elsewhere.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

If it makes a difference, the boiler is on the W side of the basement, so the radiators furthest away from it are NE BR, E bath and SE BR. Don't seem to have any cold areas.

0 -

Well IMO there is nothing there that screams bad trap(s). And all radiators seem reasonably hot. So no trapped air causing cold radiators. To me there are some curiosities. As you said the F2 Sitting room and NW BR have hotter outlets. As a curiosity I would measure the F2 Sitting room and NW BR return pipes in the basement if the Inlet / Outlet temperatures are consistently odd.

Maybe there is a spot in the basement where the steam can sneak through (due to water line issues) and it is not obvious in the pictures. Maybe snoop around the basement returns with the IR thermometer. See if any of the returns are oddly hot.

If the hammer is still the basic issue I'd get the Hartford Loop corrected to eliminate that as a possible issue.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Thanks, I had to give up the IR thermometer but will be searching out those return pipes to at least get a subjective feel for them compared to the others.

0 -

use a clamp type thermometer. can't really make any inferences using delta, but if it is steam hot after the trap and not before the trap steam is getting in the return somewhere else.

if it is steam hot in to the trap and not in the return the trap is at least not failed open.

if it is steam hot on both sides of the trap either the trap is failed open or another trap is letting steam in to the return.

0 -

-

Looks like they used the same pipes and just rearranged them, easy. Maybe the blue tape helped too.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Well, as long as it works……………..

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

-

Why? Because you still believe that steam doesn't enter the equalizer due to air being there?

@stevesorenson Please report again in a week or two, on whether the water hammer was solved for sure by this rework. Nice job.

PS: Keep an eye on your sight glass levels relative to the height of the close nipple. Amazed that your Dunkirk manual says a whopping 6 in. from CL of close nipple to NWL. That's the most I've ever seen a mfg. say to do it.

0 -

As seems to happen quite a bit when I ask a question that is difficult to answer and still believe in various long-accepted but apparently never-proven ideas in this industry, a question I asked about this before was ignored, so I’ll try again.

Let’s assume steam does manage to fill the equalizer despite Dan telling us that steam and air don’t mix and that air must escape for steam to take its place. We know that condensate return water does not create steam, right?

But with steam in the equalizer after the above assumption, what exactly would the difference in system behavior be in these three scenarios below of three different water lines? I can’t think of any.

actually, the above water level would usually be more like below, but the question remains:

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Gentlemen, this isn't theoretical. I have seen Hartford Loops bang when they are improperly installed. The cure was either to shorten the nipple between the tee and the elbow, or lower the tee, or both. Maybe someone can build a Loop from Pyrex piping at some point so we can see what's happening, but it doesn't change the fact that an improperly-installed Loop can bang.

Listen to the Dead Men, via @DanHolohan .

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting3 -

-

-

No, because what is lacking in the drip is a horizontal section of pipe where steam can get trapped between waves and condense/implode and also Dan's statement @DanHolohan that steam bubbles are rising up from below, through the water towards the steam/water interface.

0 -

-

But will it make a bang? There is a reason why the manufacturers prefer a Wye instead of a close nipple or a street Ell, but apparently the latter two suffice.

0 -

in the equalizer pipe you have a bunch of powerful forces fighting with one another: steam, warm/hot air, hot water, coldish pipes etc. as those forces comingle intersting things start to happen that define simplified explanation: steam doesnt mix with air. i belive at some point the hot air finds its way out of the equalizer (despite lack of air vents) thtough all sort of currents and vortexes. as such what you have left in there are steam and hot water.

i believe, in reference to Paul's question, in the second picture if the nipple is long enough there is possibility of water hammer. on my system slightly badly pitche 1ft horizontal pipe is enough to cause water hammer from time to time.

(notice my use of the word "believe" rather than "know")

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog1 -

on my system slightly badly pitche 1ft horizontal pipe is enough to cause water hammer from time to time.

yes because water gets trapped there, then cools off, then steam comes into contact with it at the next call for heat.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements