Water hammer - novice question

Hi all,

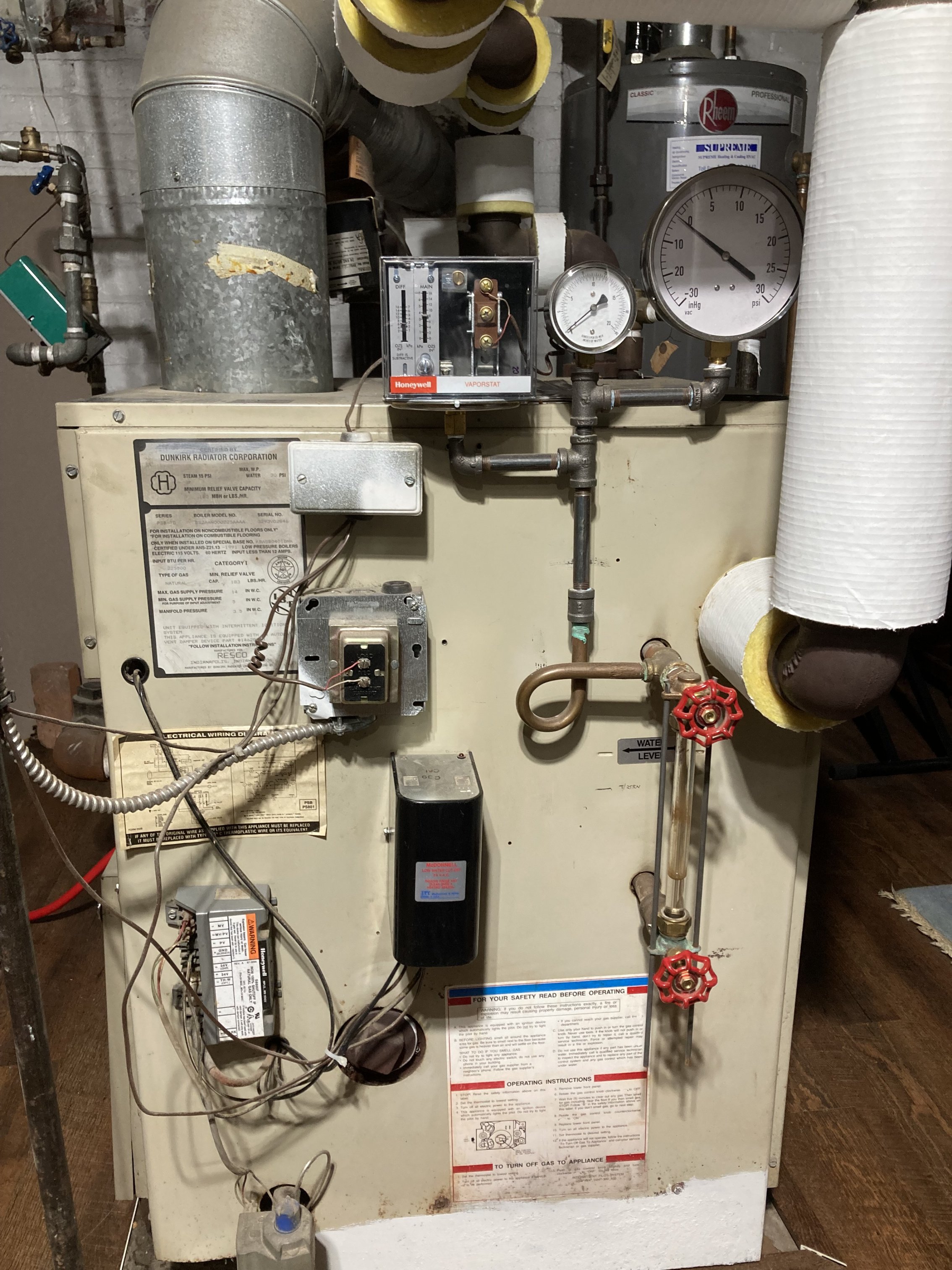

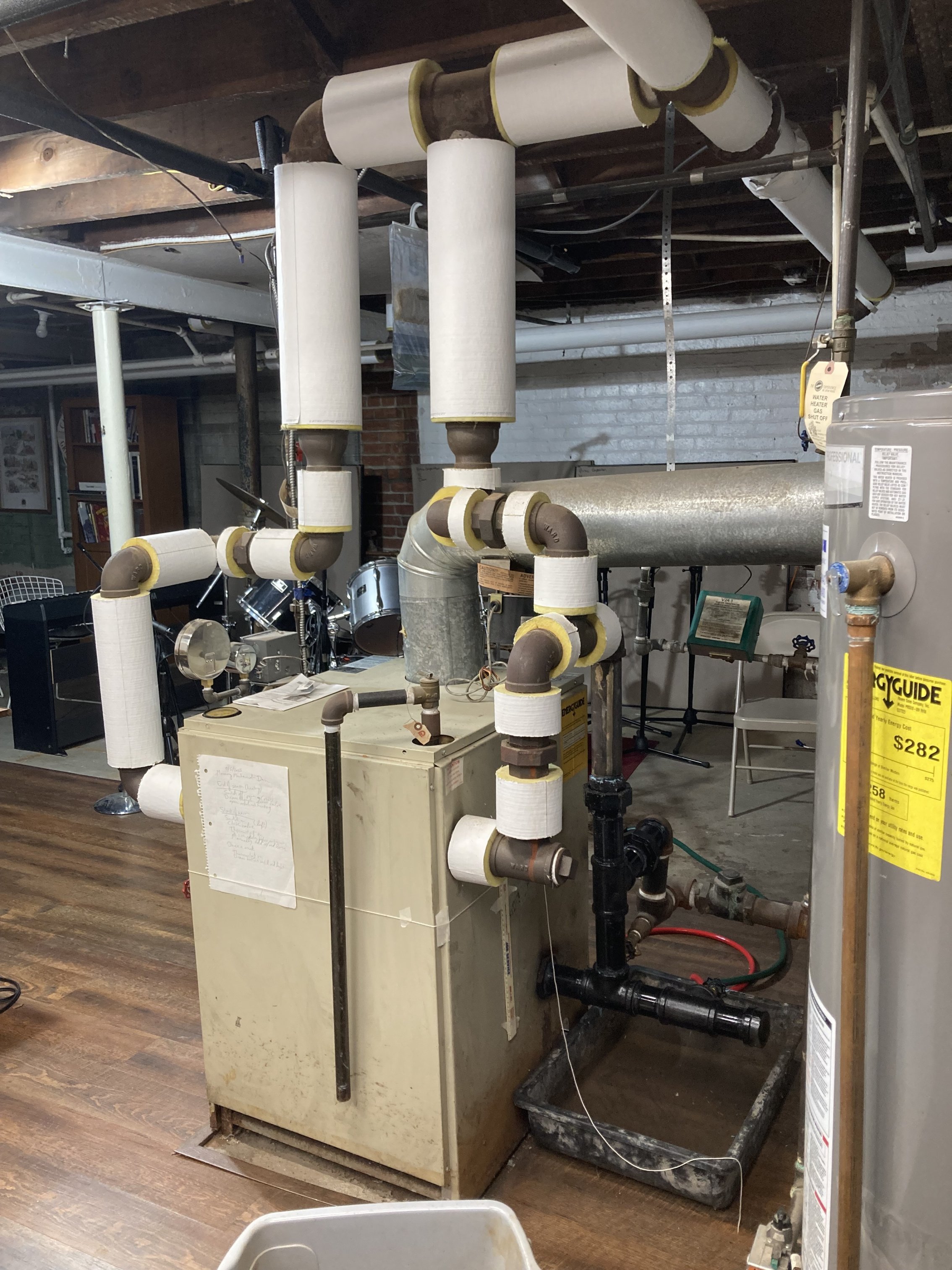

I am new to steam heat as of this year. This is a 2-pipe system with a vaporstat. Heating throughout the house seems to be pretty even. Recently had some near-boiler pipes replaced when they started to leak several weeks into the heating season. Both before and after this pipe replacement I have had some water hammer. Though I can hear it in many areas of the house, it seems loudest and most localized right next to the boiler. To eliminate this I drain some water from the boiler (not enough to activate the low water cutoff) until the hammer stops, then close the drain valve. Then I'm OK for a few days until the hammer starts up again.

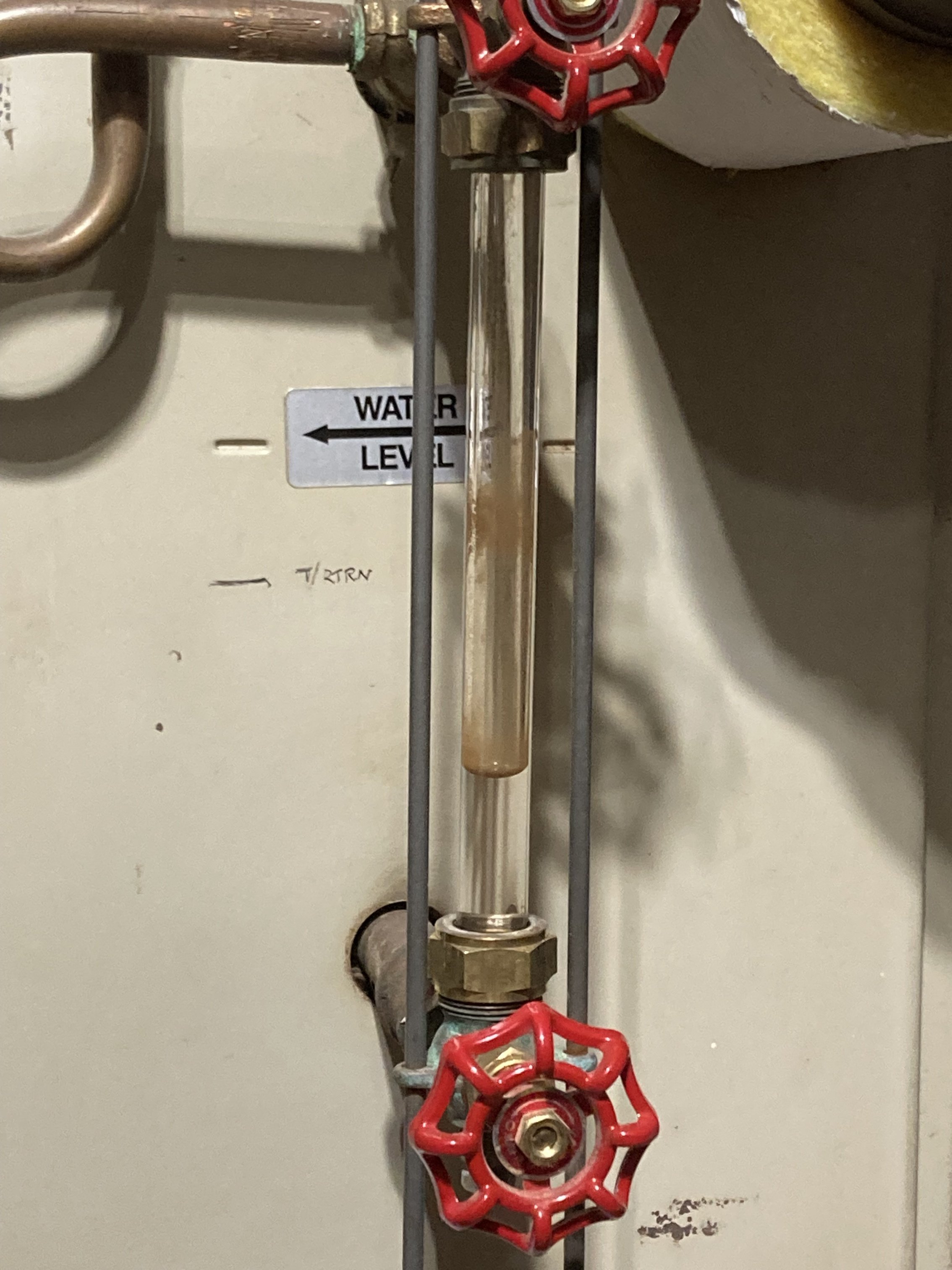

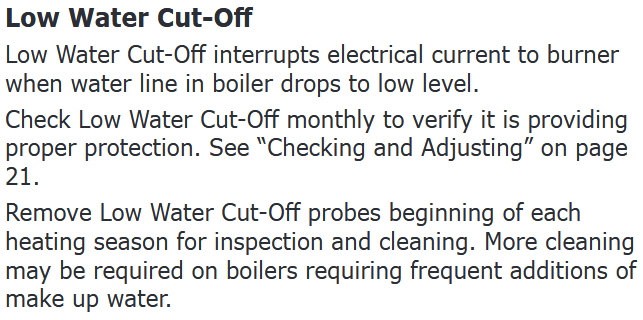

The water level in the sight glass does not look too high when I am getting hammer. There are times when the water level is substantially higher than the indicator line on the side of the boiler enclosure, but these are not times when I am getting water hammer. I also do the weekly drain of the boiler, with the system calling for heat, until the low water cutoff activates.

So I am trying to figure out what might be causing this and what I should be doing about it.

Thanks!

Comments

-

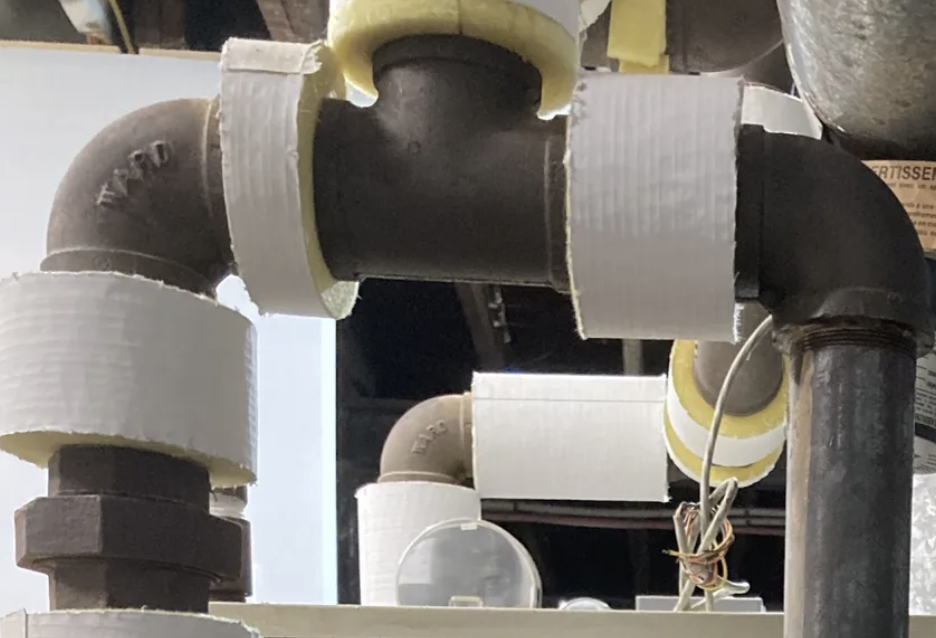

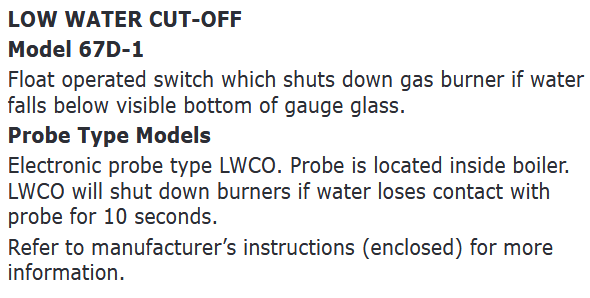

use a level and extend your normal water line around the boiler to the hartford loop, then post that new pipe picture again, loop connection should be 2 inches below normal water line,

then in the manual, note the loop connection should be as short as possible, a close nipple, not the foot that you have there,

has it been skimmed since the work? a few times? the oils from the fresh work make the boil more violent, water in the glass bouncing? how much does it drop from burner off to end of burner run?

known to beat dead horses0 -

and post a picture of the controls side, show the Ptrol settings, and siteglass water,

known to beat dead horses0 -

Thanks, here are some pics. I do not know if the tech did any skimming at installation. I will have to pay attention to water level at start vs end of cycle. Photo below is between heating cycles (i.e., burner off)

0 -

Pressure control is set to high. Does the boiler build pressure on a call for heat?

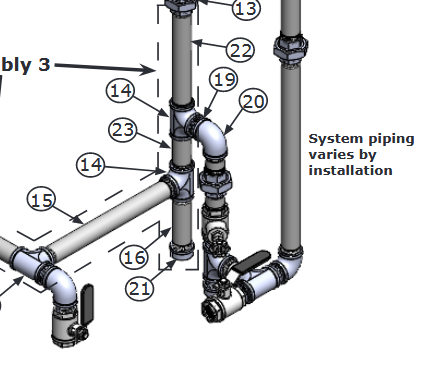

Check the things @neilc asked about. The Hartford loop nipple is too long. Is that where you here the water hammer?

Can you post some pictures of the piping above the boiler.

0 -

-

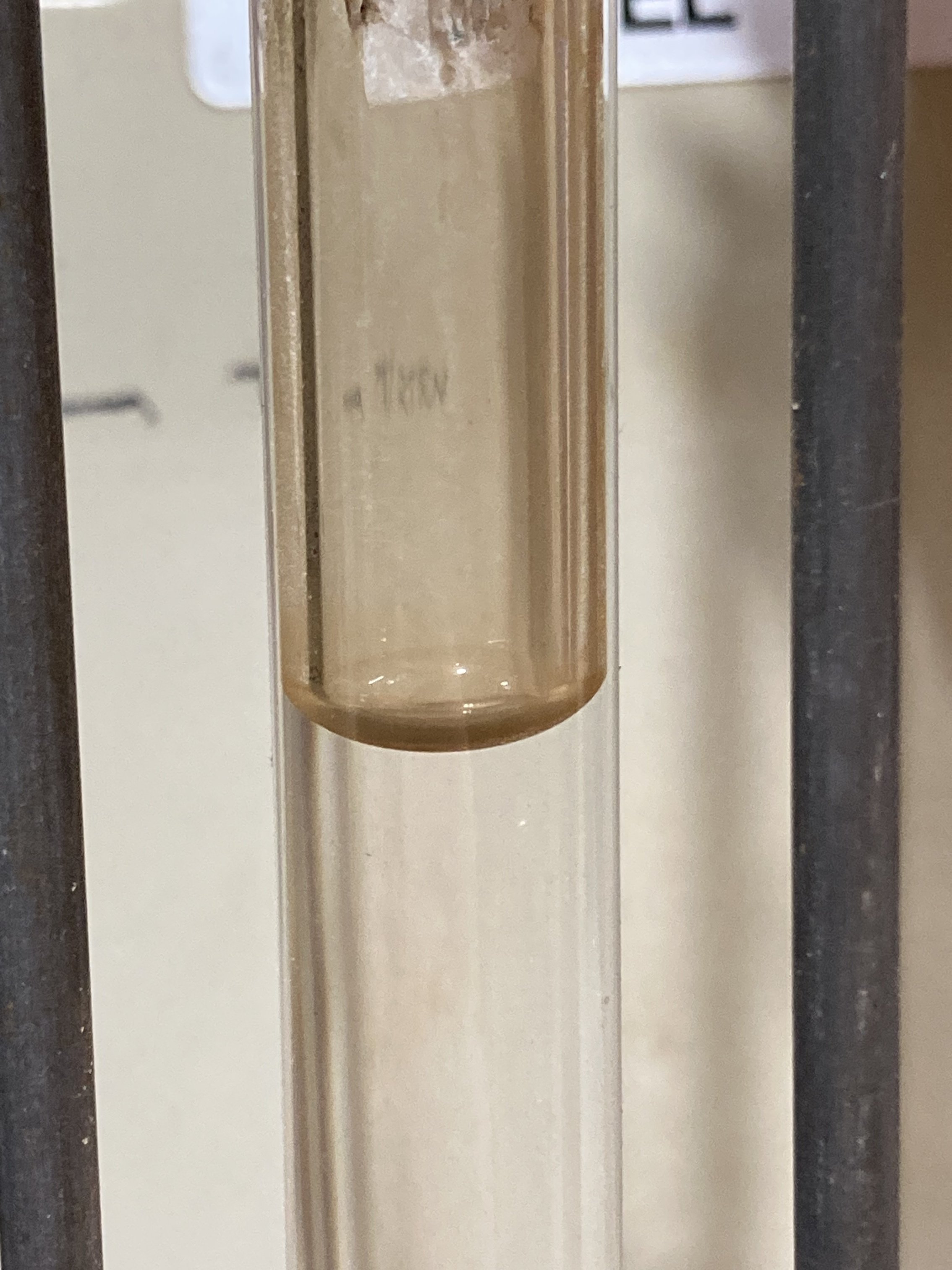

we see oil in the gauge glass. It needs to be skimmed and probably repeatedly

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

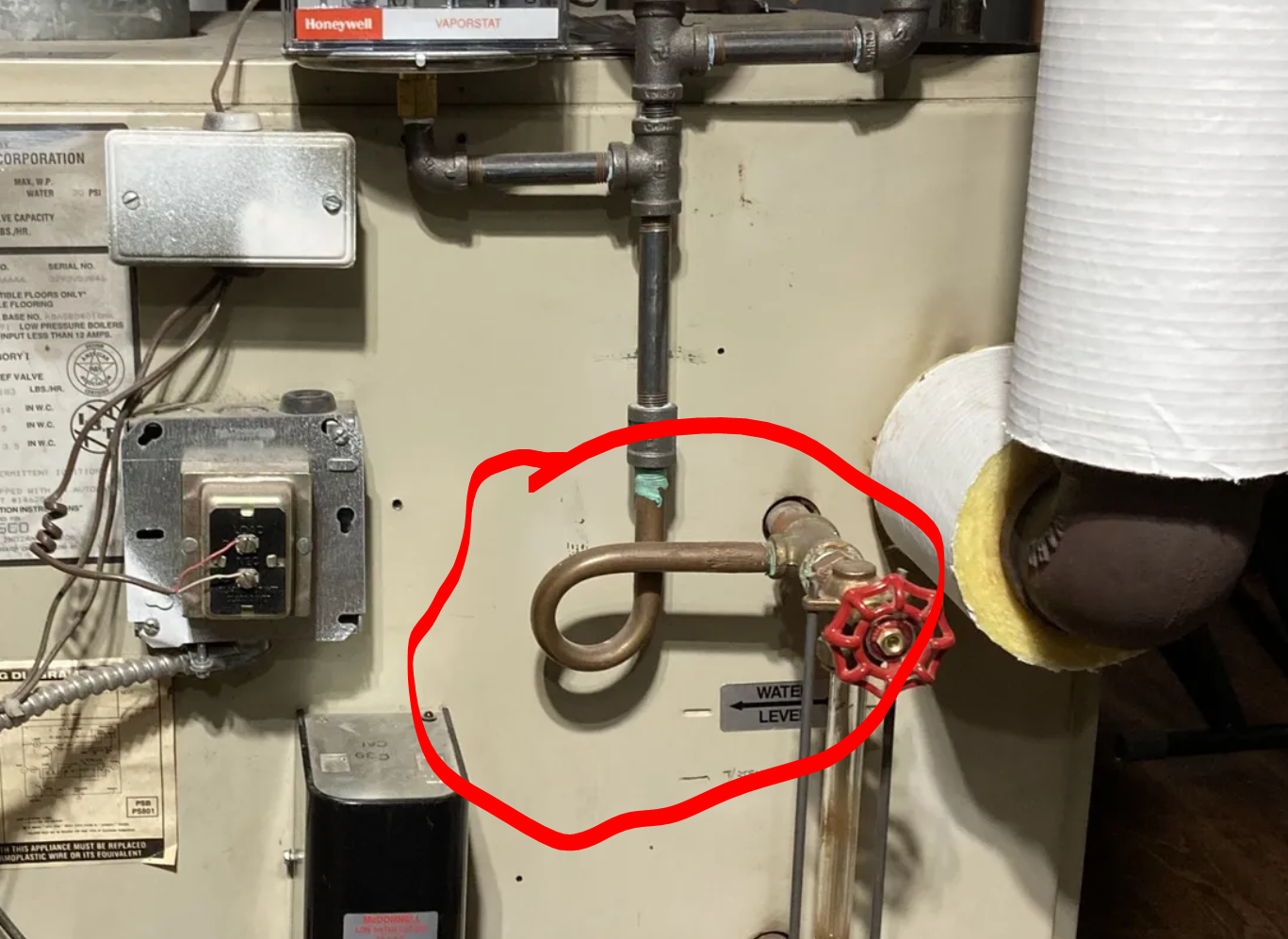

I can get back so far until I hit the wall. 2nd pic has the upper piping.

Oil in the gauge glass? I see rust stains on the glass and the water level. Here is a closeup.0 -

There's a lot to unpack here but I'll chime in with the strange stuff I read:

The water level in the sight glass does not look too high when I am getting hammer.

This is strangely written. I can't tell if the water level is high or low when you are getting hammer. I assume the water level drops when you have hammer. This would be due to "carryover" or "surging" which is caused by the oil that is in your water. That's what's staining your gauge glass, not rust. Your boiler needs to be skimmed.

Edit: I saw your closeup picture of the gauge glass but the other picture is where I see oil. Every time it surges, the oil is getting put into your pipes, then it drains back down over time where it causes surging and water hammer. This is somewhat conjecture because I'm not there, but that's what your facts as I understand them tell me.

I also do the weekly drain of the boiler, with the system calling for heat, until the low water cutoff activates.

What is this? Who told you to do this. Do not do this. You have a probe type LWCO that does not need this and the fresh water will rot out your boiler.

I will have to pay attention to water level at start vs end of cycle.

Definitely do this! And stop draining and adding water please

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Thanks for the commentary…

Regarding water level "does not look too high" - I was trying to say it is not above the water level mark on the side of the boiler enclosure when the hammering occurs. During the non-heating cycle the level typically is somewhat below this line by several inches (like the pic above where you are seeing evidence of oil), though several times I have seen it resting above the water level mark. During heating the level fluctuates less than one inch a couple of times or so per second. It doesn't appear to me to be violent fluctuation (i.e., no water splashing in the gauge) but I am a novice at this. My boiler tech told me it is to be expected during heating. This behavior is very similar now as it was with the old piping. Boiler is early '90s, though I can't vouch for how the earlier owners took care of it.

Drain cycle: 2 different boiler techs have told me a weekly drain until the low water switch activates is a good thing, and I have also read it is a good thing. However I have also read about dangers of too much fresh water addition. Reading more carefully I see a probe-type switch mainly needs a yearly cleaning, and this McDonnell switch seems to be just that. So I will have to interrogate the tech about that next time I talk to him.

Best regards, Steve

1 -

You can interrogate him if you like, but usually they don't want to learn, they only want to tell you "I've been doing this for 30 years"

OK, if the water level is only varying an inch during firing then that does sound OK. I had the impression the water level was all over the place.

though several times I have seen it resting above the water level mark.

this is currently a mystery to me. I assumed the level was changing because of your weekly drain and fill operation. It could be that your makeup water valve is leaking by and raising your water level over time. If the level is too high, water will carry over into your very bizarre near boiler piping that seems to have 1.5 headers.

I also have to say, I hope you didn't pay by the hour for this rather humorous insulation installation. I'm not trying to slag on you or your installer, but this is like wearing gloves that are rings of leather on your fingers with space between them and I find it charming if not actually insulative:

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

If the hammer sounds like it is coming from this horizontal pipe it should be a lot shorter, like #19 in the factory example shown below.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

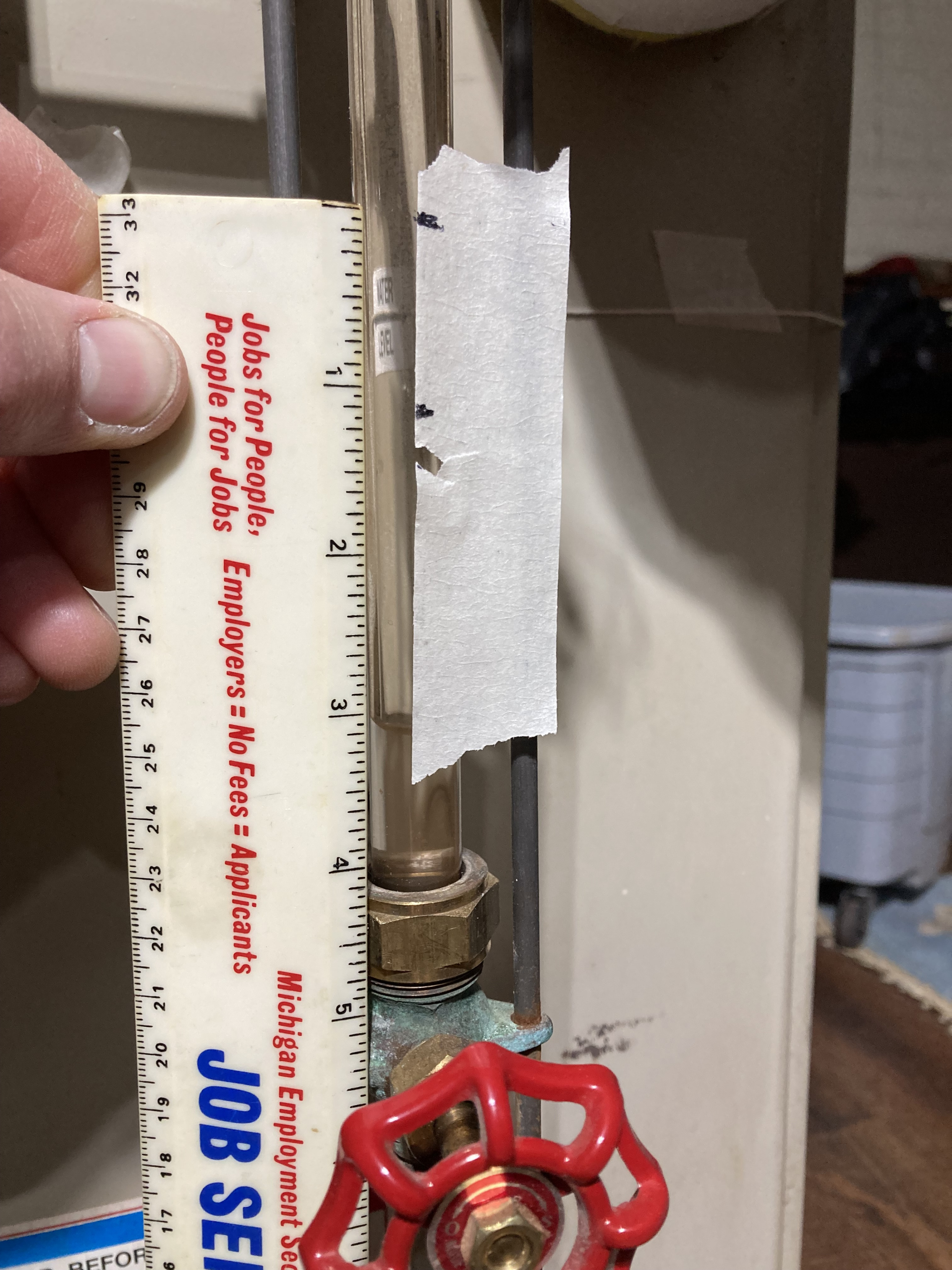

It appears with the PSB boiler, regardless of LWCO type (Float or Probe) this is Dunkirk's recommendation or they defer to the LWCO's manufacture's instructions.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Ahh, the insulation…. It was like that when I moved in this past summer. I am speculating it used to have asbestos wrap and after remediation they replaced with fiberglass on the straight sections only.

No hammering the past several days so I’ll see if I can localize it more next time it happens.

FWIW this is the only photo I have of the leaky pipe layout prior to their replacement.1 -

Well if the painted black pipe was what was replaced, they had an opportunity to correct the Hartford loop and did not take it. Probably did not know any better.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

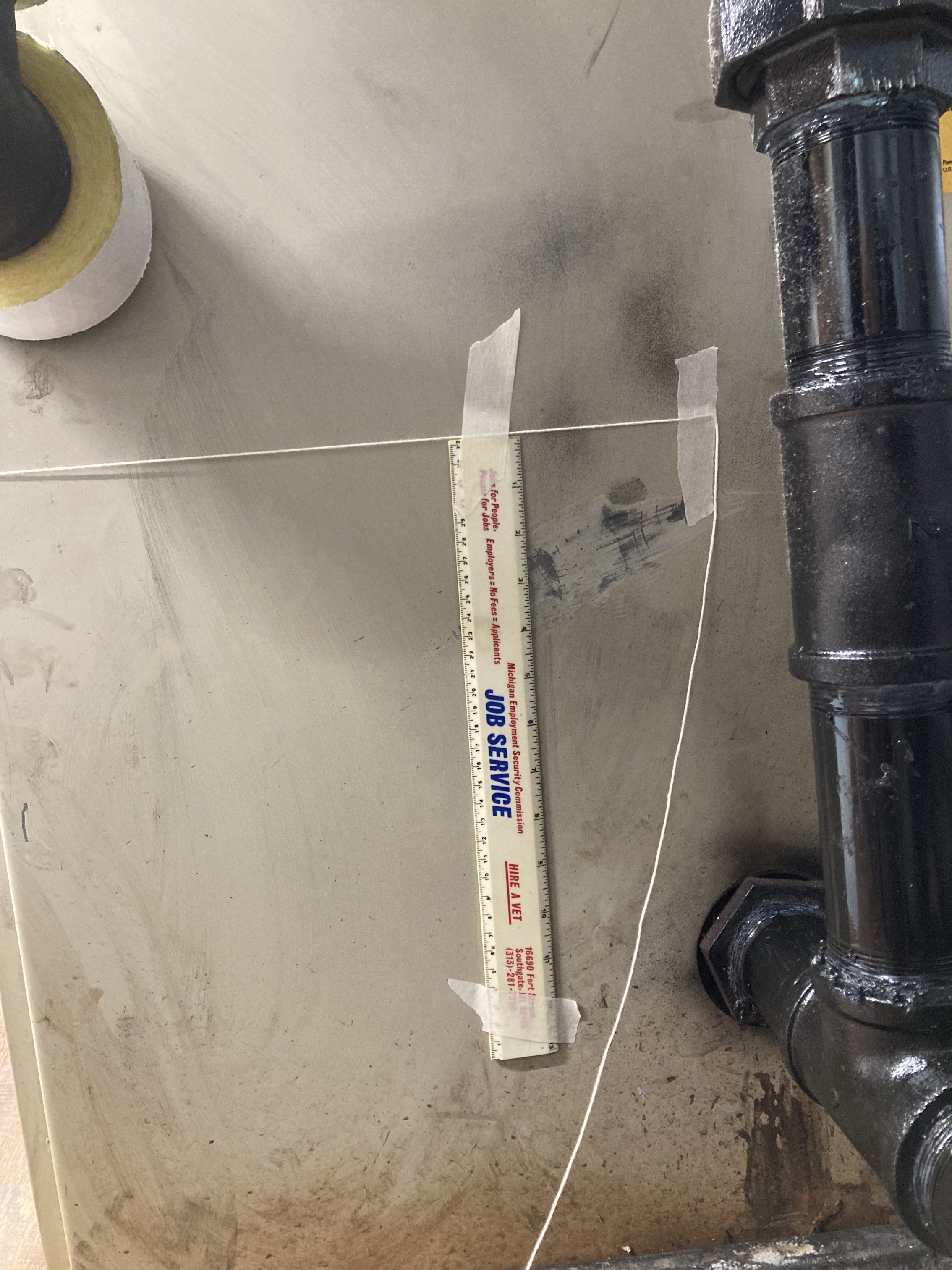

OK here is the other requested info, water level change from start to end of a heating cycle. I don’t know how typical this is. The top mark (0”) is the reference water level mark on the boiler enclosure. The black mark at 1-1/4” is where the water level was at when the heating cycle started. You can see the water level is at about 3” after the cycle is done.

0 -

Seems a bit excessive but it could be normal for your system. How long does it take to return to the level it was at before the heating cycle ? It may be slow returns or that check valve (probably not needed) is clogged up and may be a restriction. Steam and condensate out in the system is water that is not in the boiler any more.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I have to find time to sit with the system during and between heating cycles to see what the levels are. However, today, after about 5 days of no water hammer, it came back. Though I can hear it in many rooms, it is strongest in the red area circled above. Water level was an inch or two below the water level mark on the enclosure. I drained a bit of water and it went away. So what I am wondering… Is draining a little water an acceptable way to treat the symptom? Is the basic problem that the horizontal pipe is too long? Is there any reasonable countermeasure to reduce or eliminate the hammer short of replacing the pipes with a much shorter horizontal connection (max length = ?)? And what is the risk of not addressing it, beyond the basic annoyance?

0 -

As the others have mentioned the Hartford loop nipple is way too long. It may or may not cause hammer but if you get hammering in that location it will certainly make it much worse. That needs changing.

I still don't get a clear picture of your water level issue. If you put water into the boiler while it is idle? If it does how long for the water to come back. to bring it to the MFG recommended water level. Then turn the boiler on and leave it cycle for a few times does the water level return to the MFG water level when the boiler is off

0 -

The water hammer may have been a contributing factor to the premature dilapidation of the pipes that needed replacing. Basically you should be able to run the boiler at any level in the sight glass water hammer free. That being said I would run it at the recommended level or a bit higher.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

OK, I finally made time to sit with my friend Dunkirk during a heating cycle. Total length of this burner cycle is 25 minutes.

Start level of water is almost exactly at the water level reference mark on the boiler enclosure.

Soon after the start the water level increases and is bouncing between ref. mark and ref. mark + 1".

Then it gradually drops until, at the time the burner goes off, it is 2-1/4" below the start level.

25 minutes after the burner stops the water level is back to the original level. After another 20 minutes it is about 1/2" above the original start level.

And one odd thing I was seeing while looking at the sight gauge glass… There is what looks like a rusty dirt deposit on the inside of the glass. However, I saw this dirt deposit going up and down with the bouncing of the water during the burner cycle. I don't seem to be able to post a video on this site but I took a couple of screenshots. A little difficult to tell but the dirt on the inside of the glass on the left side is changing pattern as the water level below it rises. Maybe this is just a trivial observation, but does that mean anything? Oil? There doesn't seem to be any change in light refraction through the glass compared with near the top of the glass.

0 -

Don't know why when the water level finally settles after shutting down it is higher than when you started.

It seems to me it is taking a long time for the water to come back to the boiler. If it was me I would ditch the check valve in the return line and depending on what you see in the return line flush or replace the returns and fix the Hartford loop nipple.

0 -

It is possible the water at the start of the burner cycle wasn’t fully restored from the previous cycle. I got tired of waiting for the cycle to start so I just bumped the thermostat a touch to get it going.

By “replace the returns” you mean all the lines at the lowest level running around the perimeter of the basement?0 -

that type of lwco doesn't need a weekly blowdown, you are just adding oxygen and minerals to the boiler by doing that. testing it once or twice a year isn't a bad idea.

skimming is the first thing to try although if there wasn't work on the system before this started then it is probably something else.

since it is a vapor system there are a number of things that could have gone wrong from pipes sagging to crossover traps that have failed if it has them to metering valves somehow being opened too far or being replaced with incorrect valves.

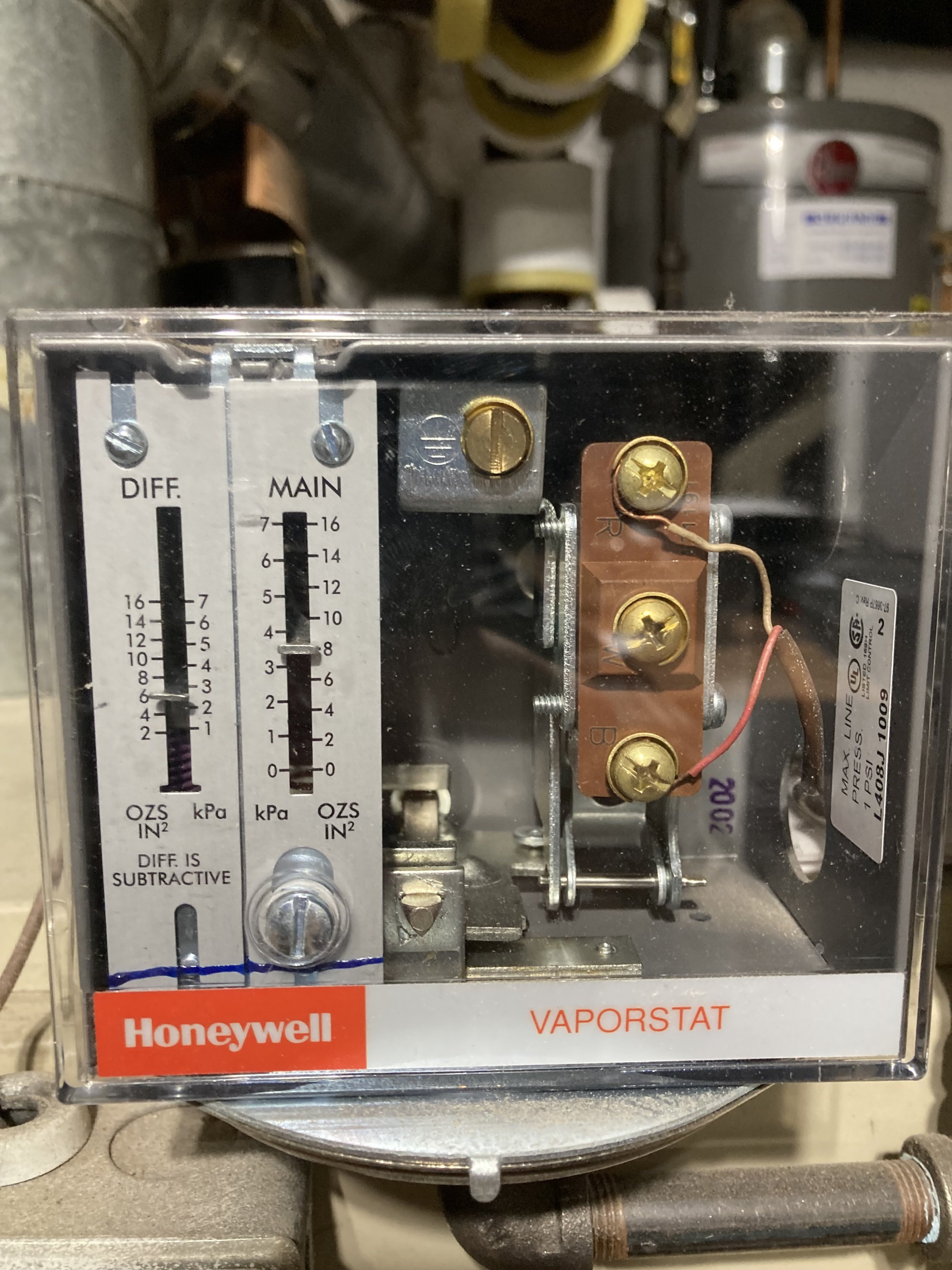

8 oz/in^2 looks just right for a vapor system. make sure the pigtail is clear. does it cycle on pressure? did it in the past?

if the water level is too low it could uncover water seals and let steam get places it shouldn't so bringing it up to the marked level is another thing to try.

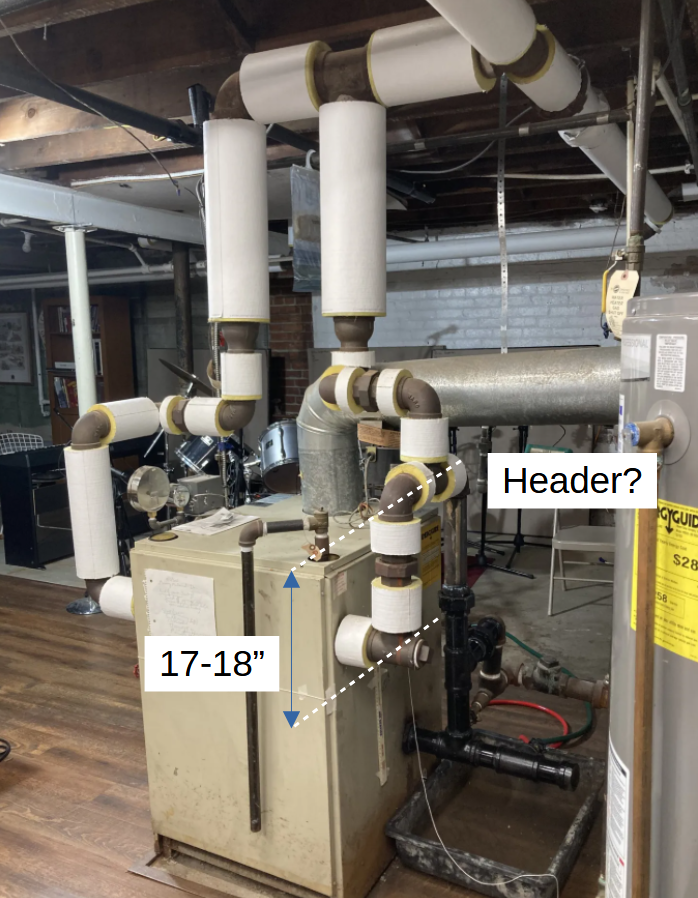

near boiler piping is very wrong, both outlets should collect in to a single header then that header should connect to the steam mains individually, then the header should connect to the equalizer. you have that happening on half then another main connected randomly to the other tapping.

the check valve should work with a boiler return trap to equalize pressure in the returns to allow the water to return to the boiler. There probably is some level of water that has to stack up in the returns to open that check valve to allow water to return to the boiler.

we need to know if the boiler return trap is still in place to know if the check valve is doing anything or not.

the hammering appears to be happening when a differential develops between the mains and the return and the equalizer has to equalize them, allowing steam to push down through the equalizer and giving it access to the pool of water in that way too long nipple in the hartford loop. If the water level is higher the differential probably can't push through the water. if the water level is below that nipple then there isn't a pool of water for the steam to hit.

the stuff moving in the sight glass is probably little drops of dirty oil being moved around by the water. the oil in black iron pipe and fittings is usually very thick and dark and dirty, almost like axle grease.

setting up a phone camera on a tripod or other stand can capture the cycle without you having to sit there the whole time.

1 -

(i assume that this is 2 pipe vapor from the check valve and the vaporstat, can you show us the trim on a radiator?)

0 -

Lots to figure out, and thank you all for the help…

This is 2-pipe system, here is a typical radiator.

I don't think I understand the pigtail question. Also this whole system is new to me as of this year (bought the house over the summer), so I have little knowledge of its history, or steam heat in general.

The boiler return trap is sort of integrated with the air vent…

And there is another check valve you can see down at the bottom of one of the pics.

0 -

you have steam traps at least on that radiator so much of the vapor stuff is less important though to much pressure may push steam from the mains to the returns.

this is the pigtail. if it is clogged the pressuretrol won't see the pressure in the boiler:

0 -

Did the water hammer start before or after you had your Hartford loop redone?

0 -

All the radiators have steam traps. Functioning? Not sure how to confirm if an individual one is working properly.

Is there any way to directly check the pigtail? There are a couple of pressure gauges above it which are always at around 0.

Regarding water hammer, I also noticed it a few times prior to the re-pipe.

0 -

should be disassembled and cleaned once a year or so

0 -

OK I will schedule that after the heating season.

When I do get the water hammer, I can make it stop by draining some of the water from the system, though not enough to activate the water cutoff switch. Does that provide any useful clue?

And as I look at the system along with the comments here, I am a bit mystified as to why one outlet is plumbed into the equalizer/Hartford loop/header then up to the main supply line, and the other boiler outlet goes directly up to join the main supply line. What I am calling the header is where the RH boiler outlet below connects to the equalizer/loop plumbing, if all my terminology is correct. I suspect it was installed this way in the early '90s when the boiler went in. Maybe this is OK? I would think you want both outlets to meet at the header.

And if I identified the header correctly, I also read that it should be 24" above the waterline. This one is about 18" above the water reference mark. Problem?

0 -

First off, what is that vapourstat set at? I can't quite read it, but I have a sense that it may be higher than it needs to be for the system to run well.

Second, checking a trap isn't all that hard. With the system running long enough so that all the radiators are nice an full, check the temperature of the outlet of the trap (an IR thermometer is really handy). If it is even as little as even 5 or 6 degrees cooler on the outlet pipe than on the inlet, the trap is working. However, if there is little or no temperature difference, the trap is stuck open — and, of course, if it is stuck closed the radiator itself will be only partly warm, if at all.

You can make a real fast first pass in the basement. The dry returns should be warm, perhaps, but never even close to steam hot. If you find one that is really hot, start looking for bad traps on the connected radiators.

The near boiler piping is miserable. What you are labelling as a header is… sort of, though much too low. Worse, the other outlet isn't hooked into it at all. In a sense the short horizontal pipe up high, which both risers hook into, might be called a header — but it has no good way for carryover to get back to the boiler. One has to wonder why it was piped that way… it would have been so easy to do it right.

On the water hammer which stops when you drain a little water. Wander away from the boiler room, and see if there are any horizontal or near horizontal pipes which are at or very near the present waterline of the boiler. This is not uncommon — the new boiler may well have been installed without regard to the old water line elevation, but just plopped on the floor — but will give you water hammer problems (it may also give a number of other problems as well).

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

lowering the water level probably stops the water hammer because it gives the water and steam more space to separate in the boiler. that is supposed to happen in the header but since your boiler only has sort of half a header, it can't happen for the main that is connected directly to a boiler outlet. side outlet boilers are especially prone to carryover and piping the near boiler piping correctly is more important to their function than with a top outlet boiler.

if the near boiler piping is repiped correctly the hammer will likely go away.

skimming the boiler if it wasn't done after the piping was replaced and raising the ph of the water a bit might help until it can be piped properly

0 -

Vaporstat: main 8 oz, differential 6 oz

0 -

-

Right, presuming this is the piping dating to the boiler installation it has been this way for 30-35 years. Seems to work without hammering most of the time. The black pipes replaced were expensive enough. So I am wondering if it makes sense (both financially and functionally) to carry on with this arrangement until the boiler needs replacing. Because I think the right arrangement for this boiler can’t just be grafted onto a different boiler, yes?

Going part way, such as just making an actual close nipple connection where I hear the hammering loud and clear - worth doing without correcting the rest of it?

0 -

i doubt that the close nipple is most of your problem. if it hasn't been skimmed a few times using the plug in the tee in the outlet since the piping was replaced, oil on the water is probably making the essentially nonexistent header worse.

0 -

Looks like the short horizontal pipe (up high) was the former boiler's header. The new risers were just connected to the old risers. The lower header was just added to accommodate the equalzer pipe. They had an opportunity to make it a lot better, they did not take it.

Remove the large gauge (probably the easiest) and blow into the pipe to verify the pigtail is not plugged. next time the pigtail is cleaned out put a union on both sides of it for easier future service.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

If it were my boiler and I found the hammer annoying I would start by fixing the Hartford loop. Since I can do that work myself the only expense would be the pipes and the time. Skimming won't hurt and it just takes time.

Curious, lowering the water level stops the hammering, what about raising it to maybe 3/4 of the sight glass.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

i didn't pay a lot of attention to what was going on at the ceiling until now. that is some very…unique…piping. they halfa$$ reused some previous header which was also wrong.

my guess is that the hammer caused by the wrong piping is making the water in the equalizer bounce and letting steam get down in the equalizer where it finds the surface of the water in the hartford loop and causes more hammer. hot water from the boiler should be in the equalizer and return but steam generally shouldn't be unless the differential pressure between the supply and return pushes it there. that shouldn't happen if the vaporstat is keeping the pressure very low. that is why i was asking if the pigtail was clear.

any carryover or condensate in that "header" has to flow back to the boiler which is likely to collapse at least some of the steam coming out of the boiler.

0 -

watch @ethicalpaul 's video. your boiler is missing the header to do the separation that his boiler has

2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements