Dual Element Smith HE2 Baseboards

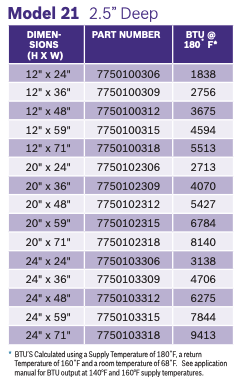

So I have hit a snag in my heating which In one area of my house I just dont have enough elements / BTU's to keep up.. I mean it eventually does, but not really. The area has some insulation and is the combination of a basement with 3 rooms, 2 - 6ft slant-fins and 1 - 2ftx12" Buderus radiator, and I really dont have any room to increase length. So 2 @570 x 6Ft = 6840BTU and the RAD at around 1838 BTU's or around 8678 in total with 180 degree water, and I really should have around 10-11K BTU of output. So I am looking for way to solve.

The first is easy, costly but easy, I can swap the 24x12 buderus (1838) with a 24x24 (3138) btus, so around a 1300 increase. Sorry now my question.

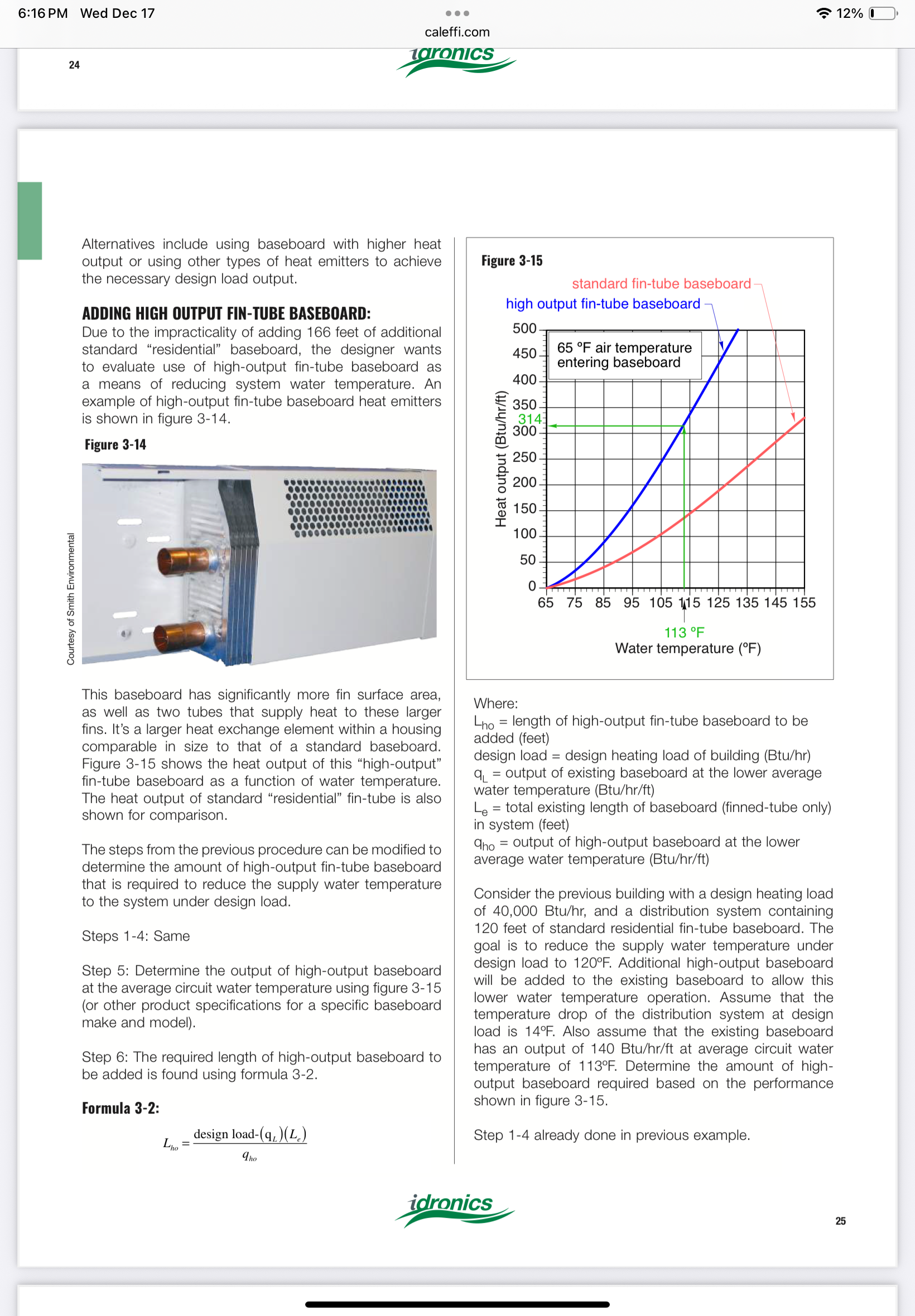

The smith HE2 baseboards have a dual element (pics enclosed)

Could I use the same single supply with a Tee and 90 as input, and then Tee and 90 on the output side to complete the connection? I think there is something about water collision or maybe the supply top element doesnt get enough flow, because of water path of least resistance?? Can someone please explain if this would work to increase the Output BTU's??

Or cause other issues.

Thank you.

Terri

Comments

-

Yes as long as the existing pipe will give you enough flow. To get the most heat out of it pipe the supplies to one end of each element and the return to both opposite ends.

But when you pipe it on the return end, put a tee on the lower element, bring the return line to the boiler into that tee to up to the upper element. At the upper element put another tee with a air vent on it.

On the supply end put the tee on the top element. Feed this from the boiler and continue it to the bottom element . This balances the flow between elements. Another tee on the lower element instead of an elbow to attach a drain valve if needed.

0 -

-

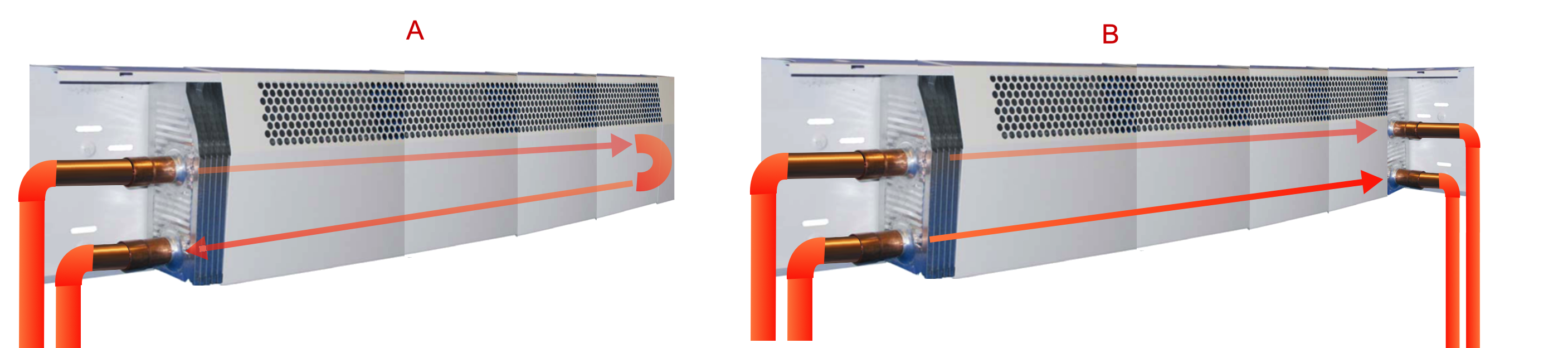

If piped direct to the supply and return like B there will be more heat than if you did the return loop like A.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

i think they want to go with option c and use a tee at each end

0 -

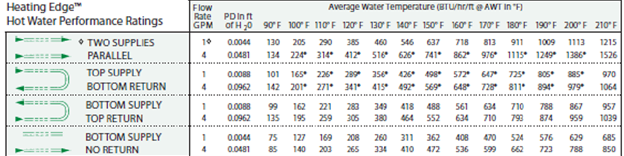

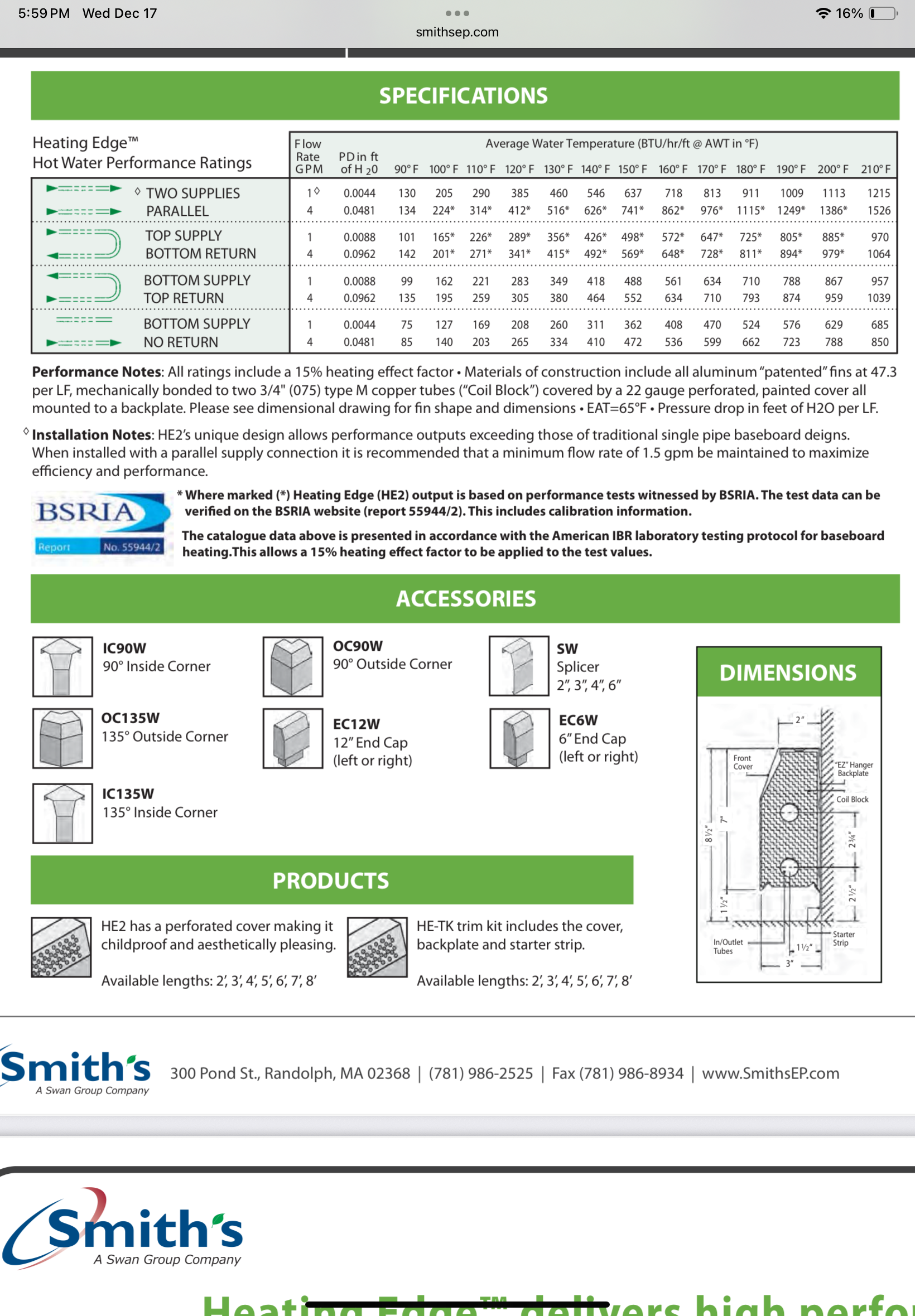

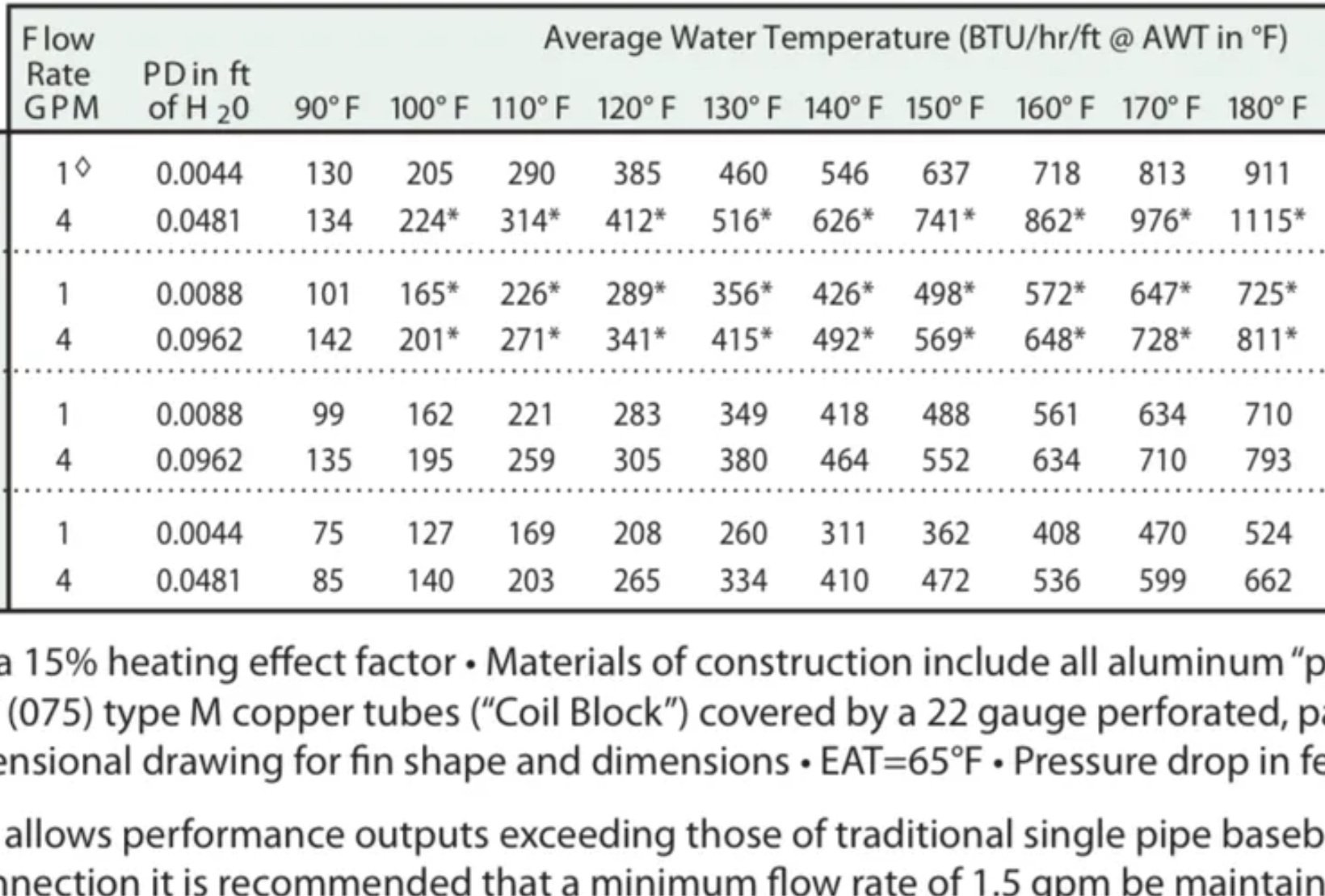

the output chart shows the difference in piping method and btu output.

Two parallel flows are the highest, the footnote indicates 1.5 GPM minimum to obtain that

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

-

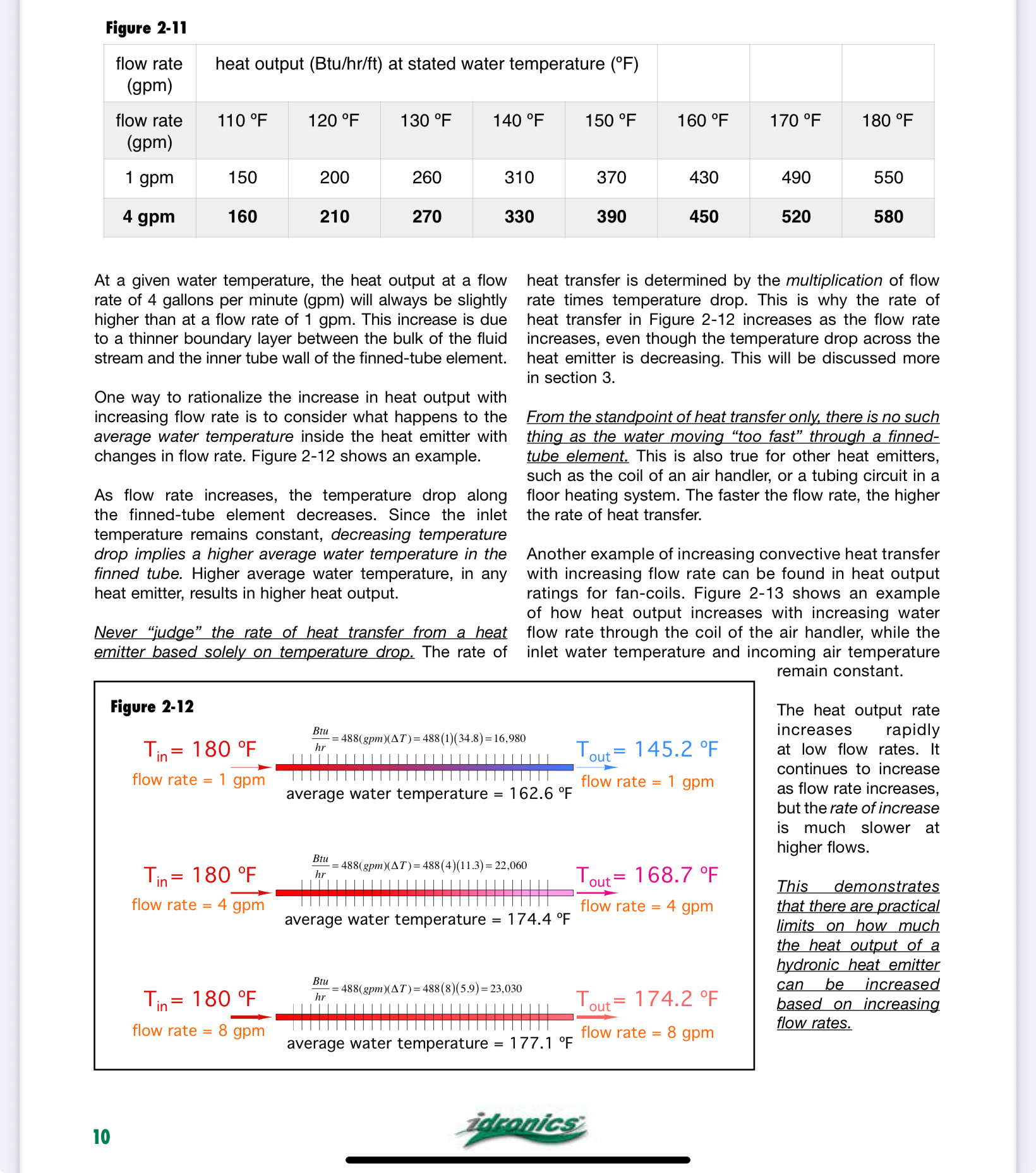

notice also the fin tube output charts show a higher flow rate performance. Higher flow gives you higher AWT and some additional performance fit. 2-11 shows output change fromm1-4 gpm.

Fig3-15 is more about output at lowered SWT, but does show standard fin vs high output curves.

If you are just a bit short you could increase pump speed/ flow and see if that covers you

Are the fin tubes on the same loop as the Buderus panels? How are they piped?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

if the table for the smith wants 1.5 gpm for the rated output, 3/4 can do 4 gpm if the rest of the system can get it there. it isn't clear in the footnote if 1.5 gpm is per tube or total. some specific heat math would probably tell you which.

0 -

-

-

1gpm is pushing it for a panel radiator. you'd need a bypass if they are in series

0 -

Wow, Thank you for all the replies. Lets see if I can answer everything asked.

First the Buderus panel is first in-line and has a Caleffi bypass valve feeding it. This way everything downstream should not be impacted or much…

The system itself has 2 - 007e pumps. and the 6ft fin is 2nd after the buderus. The path of easiest is to swap the 24x12 buderus to a 24x24, which keeps all the same connections and picks up around 1300 btus. I am not sure how to check my flow rates, so that is still an unknown.

My original question still stands but I think according to EBEBRATT-Ed if I reverse my Tee's on the supply/return sides, I might be able to force the water equal thru the HE2, or close to it, assuming my flow-rate is adequate . The question becomes, I am currently getting around 570BTUS give or take from the current fin, would swapping it out and spending the money on the HE2 give me enough extra BTU's. Meaning potentially 710 - 910 BTU's per FT would add between 840 - 2040 extra BTU's, if I get the full 2K, Im golden and money well spent, if its something less, then my BTU/Money was maybe not worth the work/time/money.

Now I am trying to figure out if I can make what EdTheHeaterMan work, since everything is currently 3/4 copper. Or if swapping the Tee's feed would provide enough flow.

As far as what if I spend all this money and it doesnt fix the issue, its not going to hurt but my bang for my buck might not payoff and then I just live with the issue…

Thanks

Terri

0 -

I think B would work fine.

Or reverse return it if there is room in the enclosure.

Reverse return makes both piping paths equal so they balance flow

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Another question, What if I went back into the wall on the Supply and return side and put this in, then run 2 pipes into both elements, Then come out as 2 pipes and back into 1 pipe?? Better/worse idea?

0 -

how you connect the ends is much less of an issue. the question is what is the pipe size and size of the path through that radiator fitting. is that fitting 1/2" or 3/4" and is the path through it a full 3/4" is it is?

also if they are in series there will be a temp drop through the panel radiator so you'll have to use a lower average temp when calculating the baseboard output.

0 -

From the documentation at least what I can read online, it looks like 3/4" straight thru pipe, and not that I understand pressure/flows, but I should not be creating any low/high pressure points except maybe at the actual return Y??

0 -

if the panel radiator is in series, i am concerned about that h fitting restricing flow

and having the panel radiator in series definitely will change which water temp column you use on the smith output chart

0 -

But is there room for them? And do they go with the decor?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

So the way the panel RAD thru the Caleffi fitting is setup only 35% goes into the Buderus, the other 65% is passed thru the bypass in the value.

0 -

and how much total goes through that fitting, and how much does the 35% that goes through the panel radiator reduce the temp of the mixed water?

0 -

I would actually go back into the wall maybe 12-24" and come out of the wall with 2 pipes, same on the return side.

0 -

So I do have a thermal pipe clamp I can tell you over the weekend and look at another buderus downstream or I have other fins I can check at and see. I know when I put the new boiler in 2 years ago, I was only seeing about a 5-7 degree drop between supply and return and that was even to my attic. But I will double check that again, maybe in the am I can check it.

0 -

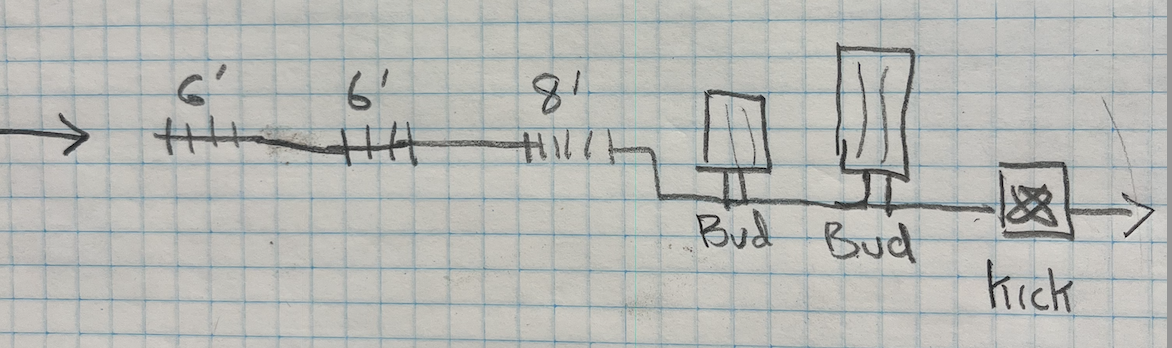

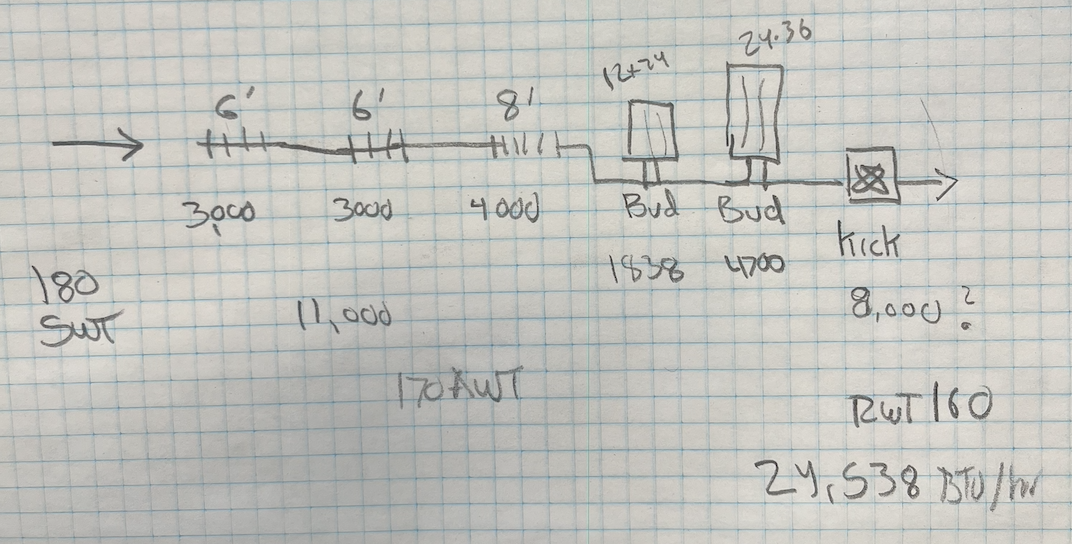

Maybe I should give you a little more info on this loop. There are 2 - 6FT fins, 1 - 8ft fin, 2 Buderus rad's one 12x24 and one 24x36 and one Kick under the kitchen sink. And right now, I have not seen a TEMP drop on the 2nd rad in series.

0 -

is this a single series loop or are these fed off of separate supply and return mains or manifolds?

0 -

Correct, 1.5" supply manifold, feeding 4 zones, single supply/return for each zone ending in a return 1.5" manifold.

0 -

Is it piped like this, everything in a series row?

The 1/2" H valves will be the flow restriction, as you try and get more output.

Knowing how much more BTU/hr would help determine what is possible.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Yes mostly, its actually, 3/4 Caleffi into small rad, then 3/4 into 6ft fin, Loop with 2 - 3/4 - 1/2" diverter tee's to push water into the Kick, then another Caleffi valve into the bigger RAD, then into the 8ft fin and the 6ft fin and then back to the boiler, all feed by 3/4 copper.

0 -

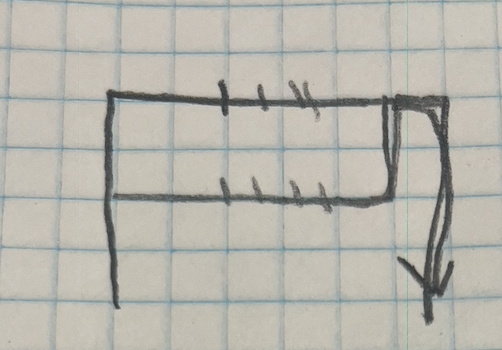

I don't really agree with the reverse return sketch. The bottom element has flow through the branches of two tees. The top element flows through 2 tee runs and 1 90 deg ell.

I was thinking like this

0 -

My numbers look like this, depending on what the kick is rated at?

You mentioned a 7 ∆, so if you are flowing 2 gpm. \

so 500 X 2 gpm X 7°= 31,000 BTU/hr from all the emitters

If you have more accurate numbers plug them in. 2 gpm may be a bit high through those H valves

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I agree with your numbers, but this is where who ever plumbed my house back in the 40's probably, they didnt pipe it all by floor, they piped it, Attic, in 1 loop, 2nd floor in a 1" feed loop, then the 1st floor and basement, front of the house, back of the house. So the problem I am trying to help/fix is the back of the house, but specifically the basement which has a bedroom with 1 6ft emitter, bathroom 1 6ft emitter and common area with just the 24x12 rad. The front half of the basement has more emitters.

So my thinking was increase the rad to 24x24 and try to increase the bathroom fin to something like the HE2 to increase those total BTU's, since the doors are all open I was hoping it would all mix together and bring the temperature up by 1-2 degrees which is what I think I am missing. The kitchen and dining room are okay temperature wise with the rad and kick. the 8ft is in the dining room and okay.

0 -

So the "couple of used CI radiators" that @mattmia2 mentioned is an option? Then I would do that. Or are you answering a different query with your statements about moving 12 to 24" and come out the wall with 2 pipes?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

No not an option. I the bathroom is only have about 3" wide x 6ft and in the other area 24" is my max width by 24 high and 2.5 in deep.

So I think given what everyone has stated i can y the feeds on supply and return and probably be okay. Since I am early in this loop feed. I am still going to check my water temp at first rad and last fin in the series but I think as long as I stay within 10 degrees I am good.

Thanks

1 -

when you check for the operating delta in a loop it needs to run for a bit to stabilize

Hydraulic equilibrium is when the supply and return temperature have stabilized, not moving up or down. At that condition check the delta.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

You made a statement and I missed it, so could you please clarify, because even thou you went over my knowledge in some of the calculations, with SWT, AWT and RWT, it was this statement.

You mentioned a 7 ∆, so if you are flowing 2 gpm. \

so 500 X 2 gpm X 7°= 31,000 BTU/hr from all the emitters

If you have more accurate numbers plug them in. 2 gpm may be a bit high through those H valves

Are you saying the 007e pumps are pumping at 2GPM thru my system? Or is there a way to really know this number? And not saying this is right, but for the past 3 years the bigger 24x36 Buderus, also has the H valve and working without issue and its only the 2nd year for the 24x12. I should have bought the 24x24 to start, but I figured adding the 1838Btu's from 0, would be enough, where 3138 would have been a better starting point. So when you say a bit high for those valve, in what way is that a bad thing?

Thank you…..

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements