Can't stop the cycling!

I have a gas, Weil EG-75, 300kbtu input (240k out) boiler living in a basement serving the floors above it as follows:

1st floor — retail, 4 large'ish radiators

2nd floor — 2 apartments, each with 4 radiators, plus a pipe through the bathrooms.

3rd floor — 2 apartments, each with 4 radiators, plus a pipe through the bathroom.

The boiler continues to short cycle and I've tried everything I know.

3rd floor have all brand new D size vents.

2nd floor have half #4 and half #5 size vents

1st floor has half #4 and half unknown size vents.

Basement has 3 brand new #2 vents and 1 #1 vent.

All pipes throughout the building are quite hot.

Changed from a simple programmable digital thermostat to a CK87 round which is not located in direct sunlight, or anywhere near a radiator, or open window, etc.

Thoroughly cleaned the piping to the pressuretrol (pigtail, etc. all clean). Pressuretrol set to 0.5 with differential now at 1.5.

I tested the pressuretrol as follows: When boiler shuts off, I push down on the rocker to make sure microswitch is not tripped but the boiler does not come back on. My conclusion: Boiler is not shutting because of pressuretrol.

Water looks clean to me. I don't see lights flashing on LWCO to indicate that is the problem.

It basically runs for 2-4 minutes, shuts off for 2 minutes, repeats.

That's about the extent of my knowledge and abilities.

Could it be a fauly thermostat? What am I missing?

Thank you!

Comments

-

You need a thermostat with lower heat cycle ..You want 3 cycle or lower per hour ..

There was an error rendering this rich post.

0 -

I believe you, but I got the CT87K1004 because it is supposed to be good for steam. It has dip switches to set it for steam (which I think they mean 1 CPH).

Could this tstat be the problem?

0 -

I doubt it. The thermostat, that is. But that's easy to check. Find the T-T terminals on your burner control and place a jumper across them. The boiler should fire — and keep firing. If it still cycles, it's something else. If not, it might be the thermostat.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

LOL — that's exactly what I'm doing right this second. I'm 15 minutes into it and it has not shut down. Going to give it another 10 minutes, which is longer than it's run without stopping in a long time.

Safe to say the problem is the tstat if it runs for 25 minutes (compared to 2-5 minutes on the tstat)?

0 -

Now that the boiler is running for 18 minutes, one (out of 4) of the main vents in the basement is releasing continuous air with some steam.

Is this a problem?

Now, after about 20 minutes, the boiler shut down and the water feeder went on (or at least did something) for 45 seconds, and then the boiler came back on.

Does this mean dirty water?

0 -

Follow up:

Boiler stops, green light solid and red light flashing on LWCO.

After 30-45 seconds, red light goes off and boiler starts up again.

Dirty LWCO? Dirty water? What's the easiest/quickest fix for now — going away for a week.

0 -

I must admit that it sounds like your thermostat is wonky. Modern gadgetry…

The LWCO may or may not be a problem. Probably not. It may be reallly and truly telling you that the water in the boiler is a little low — what you are describing sounds like slightly low water with slow returns. Check the water level in the sight glass when the boiler is cool.

Does the boiler lose water and require feeding from time to time? How often?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

I've been trying to piece this together from all yours and other's previous threads and help directly to me in the past.

I will replace the tstat, but I also had my doubts that the LWCO was a problem.

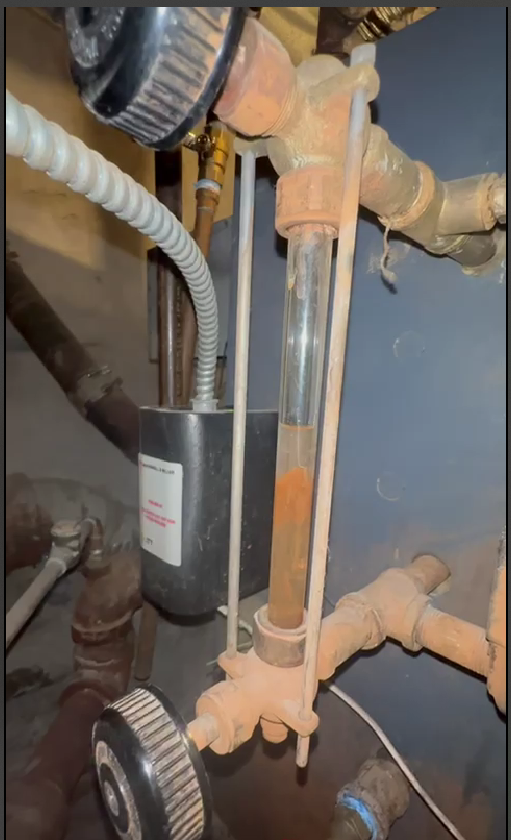

The sight glass was about 1/4 from the bottom with a hot boiler. I raised it to just over half and it's been running for 5 minutes. Water bounces between 1/2 and 2/3 high while boiler is running.

My hunch is that the main vent I mentioned earlier releasing air/steam is broken (I will replace that also), and that the water leaves the system through the stuck vent and leaves the boiler low. And, I have no idea if the autofill is filling with enough water, but it only goes on for about 30 seconds, so it might simply never get it high enough so that when the boiler gets good and hot the water level doesn't drop below the LWCO's threashold (sorry about the multipl negatives).

I'm heading out of town for a week tomorrow (of course!) so trying (on this Saturday afternoon) to make some progress.

Thanks again for everyone's help.

0 -

That vent may be the water level problem — but it may not be all of it. I have a sneaking suspicion that you may have other sources of water loss — and therefore that it is a Very Good Thing that you have an autofill if you are going to be out of town…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

It seems like a thermostat issue. If you set it for 1 cph and it's still short cycling. Something is wrong there. Could be user error.

Ive also seen similar issues when there is a draft coming through the wall penetration behind the thermostat (the hole for the thermostat wire). The thermostat may be sensing cold air (or hot air) intermittenly coming through the hole behind it and therefore causing these frequent cycles. Try sealing the wire penetration behind the thermostat.

0 -

This is a very confusing narrative. I would be most concerned about the LWCO activating. You have to determine if it is actually due to water loss, or if it's water getting pushed out of the boiler or thrown into the mains.

You reported that you tested the pressuretrol, but does this boiler have two of them? One this large usually would.

For a multi-residence with retail you should have a steam pro contracted to care for this boiler. There is too much liability for it to be DIY (and I love DIY but there are limits)

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I replaced the tstat with a new CK87 and replaced the stuck vent (the one that was letting lots of air/steam out) with a #1 (#2 would not fit), and filled the boiler to just above halfway up the sight glass.

The tstat does not have a specific CPH setting, but the dip switches are set for steam.

The boiler has a low pressure pressuretrol and a high pressure one. I haven't touched the high pressure one and have never needed to press its reset button.

I had a guy come in today who said he needed to rebuild the pressuretol (maybe both of them) with 3/4" piping because the small pipes get clogged and give it "a good cleaning" and that would fix it. I don't know if it's not allowed or improper etiquette here to talk about money, but between not being inspired to confidence with his quick analysis (didn't even want to hear what I've already done) or with his price, I passed.

I would love to understand what other ways water can be lost. I understand water being pushed out of the boiler (leaks or stuck open vents, right?), but I don't understand water "thrown into the mains." Does this mean water in the mains that does not fall back into the boiler?

0 -

You don't need to rebuild the pressuretrols. Just make sure that the pigtails are cleaned from time to time.

Water thrown into mains — which happens with bad water quality (oil on the water) or poor near boiler piping — can be a nuisance (and possibly cause water hammer or spitting main vents) but should all just drain back to the boiler.

There are any number of ways water can be lost from a steam system. Some of them are incurable — which is why you check the boiler water level from time to time — but most are not. The most common on one pipe systems is vents which don't quite close all the way. This may or may not be a problem — usually not, unless there is actual spitting. Another is leaking valve stems, which is dismayingly common on older system but can usually be fixed rather easily. Then there are just plain vanilla leaks in the piping, but these are rare, although wet returns, especially buried ones, can be a real problem. Then there are leaks in the boiler.

Now how much leaking or loss is worrisome? There's no really hard and fast answer than that, but many would say that anything over a gallon a week is a cause for real concern.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

What LWCO do you have ? Some intentionally periodically shut the burner off to test the water level.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

It's a mcdonnell and miller, but I'm not sure which model number.

0 -

OK I believe that LWCO does not periodically shut the burner off to test the water level.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I would venture to guess the single #1 main vent you added is quite insufficient on a system requiring (?) an EG-75 boiler.

0 -

Also , I would recommend a better thermostat .

There was an error rendering this rich post.

0 -

did yoh try the new thermostat and did.it help????

0 -

Update/clarification:

I replaced the tstast with a new CK87. It has dip switch settings (both ON) for steam.

I found 2 more stuck open vents and replaced them.

I added water until the sight glass is 3/4 high.

The system has 4 main vents consisting of three #2 and one #1.

After 48 hours, the sight glass shows 1/4 high, when boiler is very hot. I don't know if this is significant. That is, maybe all the water is in the form of steam throughout the building, or maybe it is solid evidence of a leak.

The ON portion of the cycles have lasted up to 20 minutes. But the OFF portion of the cycle is often as short as 1 minute.

I've been searching the entire building for leaks and have not found any. There is no white smoke from the chimney.

Is it just wishful thinking that the water feeder is simply not staying on long enough to feed enough water in to keep it at an acceptable level?

Is it okay to add cold water to a hot boiler when the sight glass shows 1/4 of the way up from the bottom?

0 -

can you post pictures of the return pipes to the back of the boiler? If any of them are beneath a floor slab they may be leaking underground.

0 -

Sorry for the very basic question: I have what I would call 4 mains each with a vent. Does that mean there are 4 return lines going down from near those main vents? Those areas (basically the corners of the building) in the basement are not visible, so i can't see.

What I'm getting at is: How to check the return lines if they are behind a finished area?

0 -

when the boiler stops firing, the water level rises to about 1/2 way up the sight glass.

This morning the pattern is ~20 minutes running, 1 minute off, ~20 minutes running, repeat.

Now I’m not sure if there’s a leak.

0 -

Unless the mains are counter-flow (pitched down toward the boiler) there are some sort of returns to bring the condensate back to the boiler. Maybe start at the boiler and trace out the returns (if any).

Pictures may help us.

That seems like a lot of water in a short time. Does it come back if you shut the boiler down for a while ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

is there a steam pipe running behind the t-stat or is it near a radiator?

did you compare the connected edr to the size of the boiler?

0 -

is the water level at 1/4 of the sight glass after the boiler has been off for say 10 minutes or so or is it just low while steaming?

0 -

water level rises when boiler stops firing.

there is some buried return lines.

Is the cycle of 20 minutes on then 1-4 minutes off a good indicator what’s going on?

tstat is no where near a radiator.0 -

There is about 14’ of return lines in concrete and another 24’ that are buried behind walls.

I don’t see or hear any evidence of leaks.0 -

I’m totally baffled: the water feeder adds water often, which points to a leak.

But then why is the boiler running nearly all the time?

0 -

when the boiler starts from cold. feel the mains and the returns as it heats. if the returns get hot before the mains the boiler is throwing liquid water up in to the mains. the returns really shouldn't get hot until the mains and emitters start heating and condensate starts flowing back to the boiler.

if the boiler is throwing liquid water in to the mains with/instead of the steam the boiler will heat that loop of water to steam hot before the boiler can start steaming

1 -

does that mean I have to turn off the boiler and let it completely cool down?

how would the returns get hot before the mains if the boiler is throwing liquid water into the mains? That is, wouldn’t it be hot water into the main and therefore the mains would be hot?

0 -

the water will just run along the bottom of the main, the top of the main and especially the runouts to the radiators won't heat from liquid water but the return should remain cool until after the mains are hot and the emitters are starting to get heat.

does the water line move up and down as it it steaming?

0 -

May I as a silly question? What's turning off the boiler for that 1 minute chut down? That almost sounds like a pretty well sized boiler cycling on pressure, which is just fine. Not a problem at all.

On the possible leak — the quickest and simplest test is does the water level recover when the boiler is off and allowed to cool down some? That is, you set it at some level — note what — and then come back later after it as cooled down again, where is the water? About the same? If it, no leak. Slow returns maybe, and quite possible — they can be flushed if needed — but no leak. You only have a leak if you have to add water to maintain level — more than a gallon or two a week.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

yes, when the boiler is running the water level in the sight glass moves up and down some.

0 -

I'd expect that. some boilers are pretty quiet, some bounce an inch or two. The question is — does it return to where it started eventually?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

this is THEE question!! Not remotely silly. Does the thermostat reach desired temp for that 1 minute? Seems unlikely but is possible.

0 -

With the boiler running that much 24 / 7 is it below zero degrees Fahrenheit outside where you are ? I would think the building would be quite hot unless the system as a whole it quite undersized for the building. How has the system preformed in past seasons ?

Where is the heat going ? If my boiler ran that much and it was 10 degrees outside it would easily be over 80 degrees in the house.

With a controlled test if you simply remove the thermostat and touch the R and W wires does the boiler still shut down for that short time then restart ?

You could use a multimeter to find what is actually interrupting the burner.

As far as a leak in the return piping somewhere, maybe do some inspecting with a thermal camera.

Also to test the heat exchanger for leaks, turn off the boiler, let the boiler cool a bit then intentionally over fill it just over the top of the boiler, see if any water leaks out of it.

Then restore the water to the normal water level to return it to service.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I will do the short-the-tstat test today.

I'm confused about how to do the water-level-returns-to-prior-level test. Can I start with a hot boiler?

It would make it a lot easier if I could start with a hot boiler, either firing or not (I could shut boiler for a short period of time, maybe 20-30 minutes to start test).

And, if it's 1-3 gallons/day leak, wouldn't i have to do this test over the course of quite of a bit of time to be able to determine loss by looking at the sight glass?

0 -

Bypassing the tstat (by shorting the tstat wires coming from the boiler), the boiler runs for 20 minutes, then stops for a minute, then starts up again.

Therefore, the cycling is not being caused by the tstat.

0 -

Honestly I will be mightily surprised if that one minute interruption in firing isn't the pressuretrol. Use your multimeter to find out if it's opening and cutting the burner.

Do you have an automatic water feeder? And, if so, does it have a counter? If it does, it will tell you how much water, more or less, it's feeding. If there is no counter, you may have to find out what's happening by simply turning off the water supply to the boiler and watching it over several cycles. Or longer. If it's leaking the water will not return to the original level in the sight glass.

As to when you check the sight glass. So long as you are looking at it at some consistent time after the end of a cycle, you can get a good idea of the trend in water level over time, from cycle to cycle.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements