Settings/Wiring for two pressuretrols on a one pipe system steam boiler

I have a single pipe steam boiler that has two new pressuretrols . They have their own pigtails connected by a T into the boiler. Both are set at 0.5 cut in w/ a 1 differential . The burner cuts off at a gauge read pressure just shy of 2 lbs. I believe they should be wired in series , but should the cut in &/or cut out settings be different ? Thanks for setting me straight !

Comments

-

Pictures would help:

Why two controls? Is one manual reset (with a push button) and the other auto reset?

Does 1 control for lo-high fire control

If they are both High limit controls it would be better to have the controls piped to the boiler in individual tapping's if possible. my not be a code requirement, however.

Need more info to help.

Your pressure settings are about right. The pressure setting scale on the controls is usually a little bit off from the actual pressure.

0 -

-

If you have a millivolt gas valve (with 100% shutoff), they should not be wired in series, and they should not be set the same.

If it is such a millivolt system, one pressuretrol will be set as yours are to cycle the boiler on pressure. The other is set a pound or more higher to turn the gas and pilot off completely in case the other pressuretrol fails and pressure starts to build. (You'll then need to relight the pilot to operate the boiler.)

0 -

True, if sslightly misleading. They still shouldn't be wired in parallel. Rather they need to be, as iss implied, on completely different circuits. One for the millivolt gas valve. The other (it can be on the 120 volt side, perhaps) to shut the boiler down completely — all gas off, all fans, whatever — in the event of an overpressure. AND that one should be a manual reset.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I didn't mean to imply they should be wired in parallel. (And never heard of a 120 volt side to a millivolt gas valve on a residential boiler.)

The ones I am familiar with are all millivolt. And there is no need for a manual reset on the pressuretrol that shuts down the boiler and pilot since the boiler can't be restarted without lighting the pilot.

0 -

and no one will ever figure out that is why the pilot keeps going out. maybe about 10% will figure it out if it happens in front of them.

0 -

I don't think you find a millivolt system with dual pressuretrols , Resistance issues ..

There was an error rendering this rich post.

0 -

-

Two pressuretrols are code in MA for residential millivolt systems, not that many people have millivolt systems anymore since you can't buy them new.

Here is a picture of one of my 40+ year old Burnham boilers (taken some years ago) with the two pressuretrols in their original configuration. The upper one is for the total shutdown.

0 -

Both pressuretrols are automatic reset and no low-high fire regulation . They are wired in series and cannot be adjusted to a 1 psi cut-out pressure. I have read that it's possible to lower the cut-off pressure by turning the 0.05 " hex screw under the pivot arm CW ,which I have yet to attempt. Both are covered by a tamper proofing blue glue. It is a fuel oil burner ( so no millivolt gas valve ).

0 -

Don't attempt to lower the cutout. There's no point to that. 1.6 or 1.7 psig is low enough for any conventional system, and if you have a vapour system requiring lower pressure, you need a vapourstat.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I don't understand the "millivolt shut down comments" at all.

There is normally no 120-volt power to a millivolt system. The one time I did this I had a MM #67 LWCO and added a feeder to it. The top two terminals broke the millivolt system to shut down the burner.

The bottom two terminals ran the feeder on 120 volt.

If you have a straight millivolt system all the power is generated by the powerpile. There is no other circuit to break to shut the boiler down. Power pile current runs up through the pressure control on off switch (if you have one), low water cutoff and thermostat.

0 -

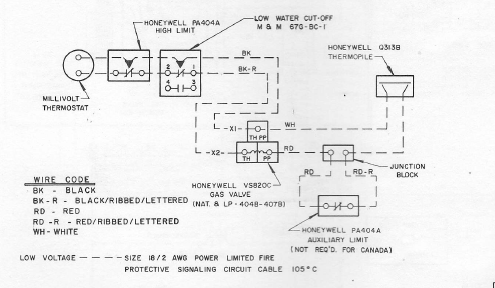

@EBEBRATT-Ed , if this diagram (or the attached pdf) is legible, you'll see the second pressuretrol ("auxiliary limit") wired between the powerpile and gas valve. If that trips, it shuts off both the gas flow to the burners and the pilot. That shuts down the boiler, and it won't run again until the pilot is relit even if the pressure returns to atmospheric.

0 -

Thanks never seen that done.

0 -

This is my V35 Burnham boiler with the two pressuretrols highlighted. Because the controls are set at the same cut in and cut out pressures, I won't be able to determine if one of the controls fails. The burner was coming on at 0.5 psi and cutting out at just before 2 psi. The differential for both is set at 1. If one of the two controls is a safety shouldn't it have a different cut out pressure ?

0 -

yeah…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

So would I set up my control pressuretrol cut in @ 0.5 and cut out @ 1.5 psi (using 1 as differential even though my gauge is reading close to 2 psi in operation) ? And my safety pressuretrol cut in @ 2 psi and cut out @ 3 psi (using 1 as the differential ) ?

0 -

The safety pressuretrol needs to be a manual-reset type. It will only trip when something is wrong, like the operating control has failed closed. If it's automatic reset, you'll just switch over to using it as an operating control.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements