Strange events

I have lived in my house for thirty years, and have been tuning up my 1969 Williamson fuel oil furnace for 29 of those years. I've never had a problem with the furnace, until this year.

I put in new igniter tips in the fall of 2024 and had the transformer checked. it was at only 80% of strength, so I ordered a replacement and installed it this fall, along with a new injector tip (85 degree, W code, where as usually I use and A or B code). I also installed two new filters in the fuel line. I reset the points to spec and the furnace ran fine, for two or three cycles. and then the reset button popped.

resetting the button had no effect. the furnace refused to fire. I am getting fuel oil, because if I open the inspection door I can see and smell the fine oil mist. I also know the CAD sensor works because does shut down the system when it doesn't fire. The fuel pump will run, but the ignitors will not fire.

I have checked all the wiring between the internal junction box and the pump motor and the transformer. All wires have been cut off, stripped and reconnected.

What will get the furnace to fire is if I loosen the two screws near the firebox on the transformer, flop the transformer back and push down on the contacts, push up on the contacts and reseat the transformer, feeling the spring pressure from the contacts. When I push down the reset button the furnace will fire 95% of the time. Occasionally i have had to perform the procedure twice, but rarely.

I ordered a new transformer from the same company and installed it, thinking that is where the issue lies. I still have the same problem.

First thing in the morning I have to restart the furnace, and it usually lasts through three or four cycles, and needs to be reset in the early afternoon.

I thought about the box between the thermostat and the transformer being bad, but it will consistently fire the pump, but not the transformer, although both are wired together to the box.

I have been dealing with this since the season started.

I know the three tings required: Fuel, air and ignition. I don't believe handling the transformer affects the fuel or the air, but I am out of ideas.

Any suggestions?

Comments

-

Assuming your transformer is ok I can think of a few things:

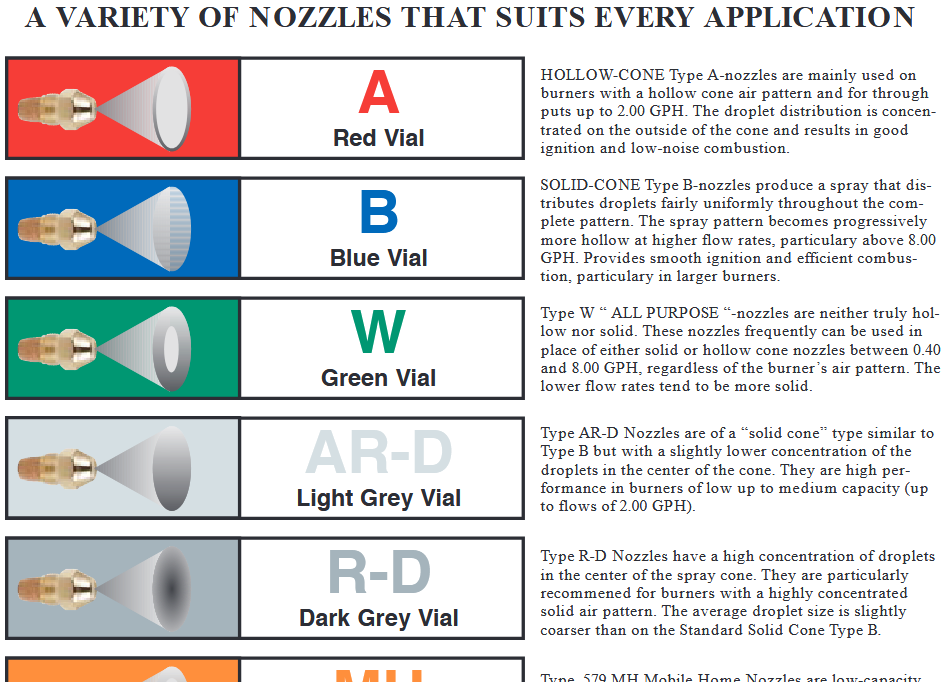

I never herd of an 85 degree nozzle. 60,70, 80 degree are common. Your problem seem to start when you substituted a different nozzle. That may or may not be the issue. But I would find out what the correct nozzle is and go back to that.

Seems to be a problem with the transformer or the connections to the buss bars.

Try this. Shut the burner off, disconnect the motor wire so only the transformer is powered when you turn it on. You should here the electrodes spark at the electrode tips. It could intermittently be sparking elswhere due to electrode not adjusted right, electrodes sparking off the burner head or nozzle or the transformer connectors not contacting the buss bars or cracks in the electrode porcelain.

You could also have improper air adjustment.

The burner should be combustion tested.

0 -

^^^^^^^^^^ This ^^^^^^^^^^ AND

If this intermittent problem persists, replace the motor. It probably has a dead spot in the windings,

0 -

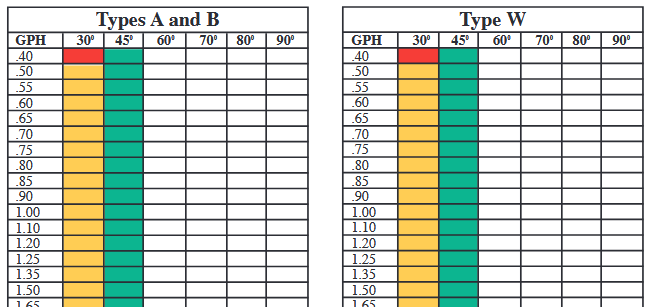

Ed, First; thanks for your help! I have had 85 degree nozzles since day one. It was the letter suffix that I was unsure of. Do they have a meaning that you are are of?

As far as the transformer, since I have had two do the exact same thing, I am pretty certain the transformer is not the issue.

Here is my big question- why does moving the transformer allow the furnace to start? What does that action fix? If I can figure that out, I can fix the issue.

Does allow an 'Air Shot' that starts the combustion? I don't think this is the issue, as it would need this action every start. Combustion is good, as the flames are a bright orange.

Does it realign the Igniters, although I don't touch them? i also make sure there is a 'spring pressure' against the buss bars by the transformer before i tighten it down.

I have checked the igniter points for proper distance (1/4" apart, 1/4" out and 1/2" up).

Why will it start normally 3-4 times before needing a reset? If the points were wrong, it would not start at all, would it, right? why would it start sometimes and not others?

I have never had an issue like this. The system is simple and has always worked perfectly, until this fall.

0 -

Sure you don't have any cracked insulators? Or something almost but not quite touching a high voltage contact that shouldn't be?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I will take a look tomorrow to be sure, but they are only about a year old, and looked good when i cleaned them about 6 weeks ago.

I am also going to clean my old nozzle with some brake clean and reinstall it.

I am just flat out of ideas.

Thanks Again!

0 -

Delevan nozzles:

"A" is a hollow spray nozzle

"B" is a solid spray nozzle

"W" is a semi solid spray which is a mix of hollow and solid and is considered the "all purpose nozzle"

1/4" gap on the electrodes is too big. Should be 1/8"-3/16 usually.

Transformer springs just sit on the bussbars.

0 -

Can you take a picture of this 85 degree nozzle? Never seen one, only 80's & 90's

0 -

https://www.sidharvey.com/documents/30609-7.pdf

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

changing the pattern without doing a combustion analysis sounds like asking for weird intermittent issues.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements