Help with recommendation of Gorton steam cast iron radiator vents sizes?

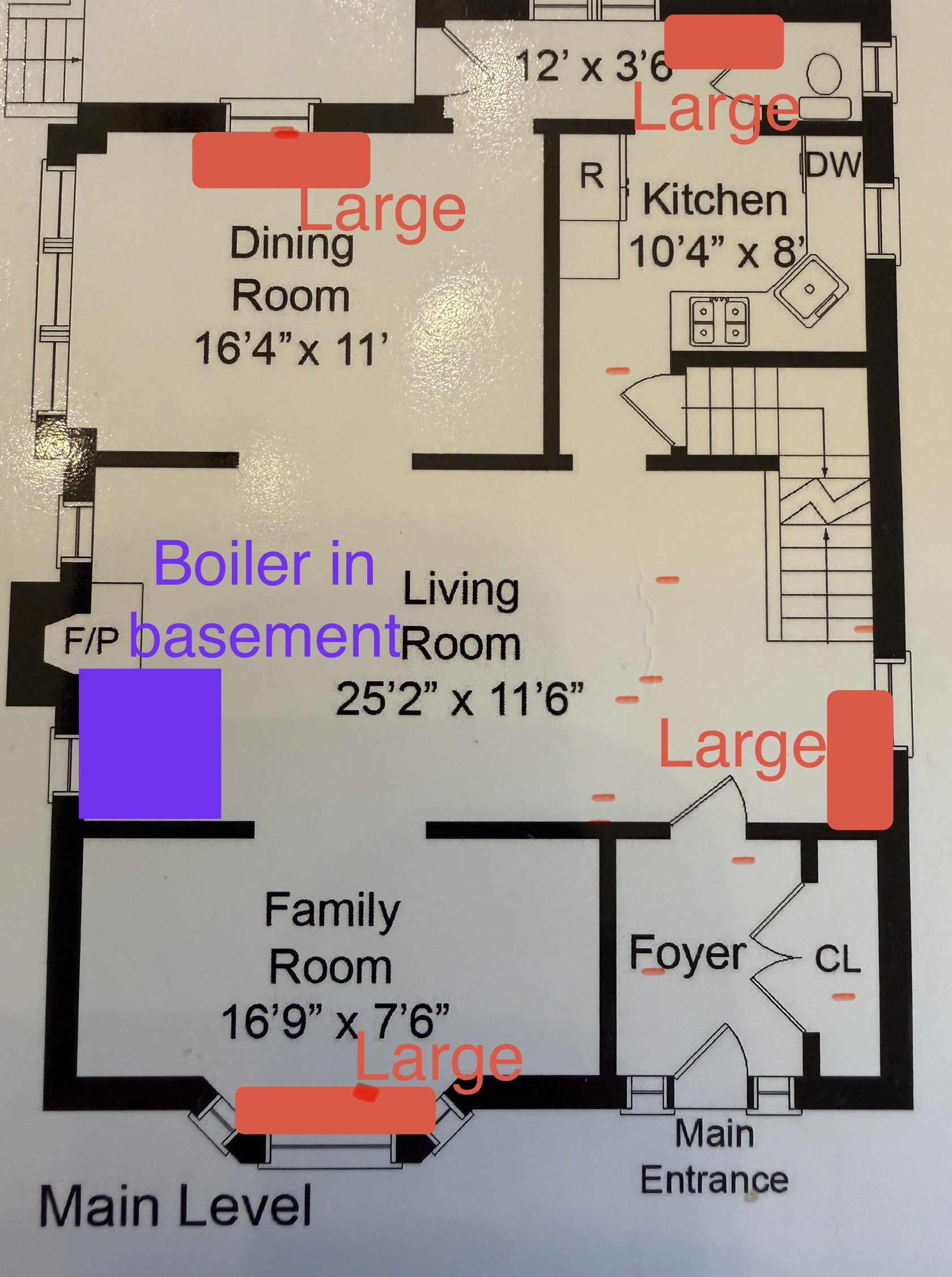

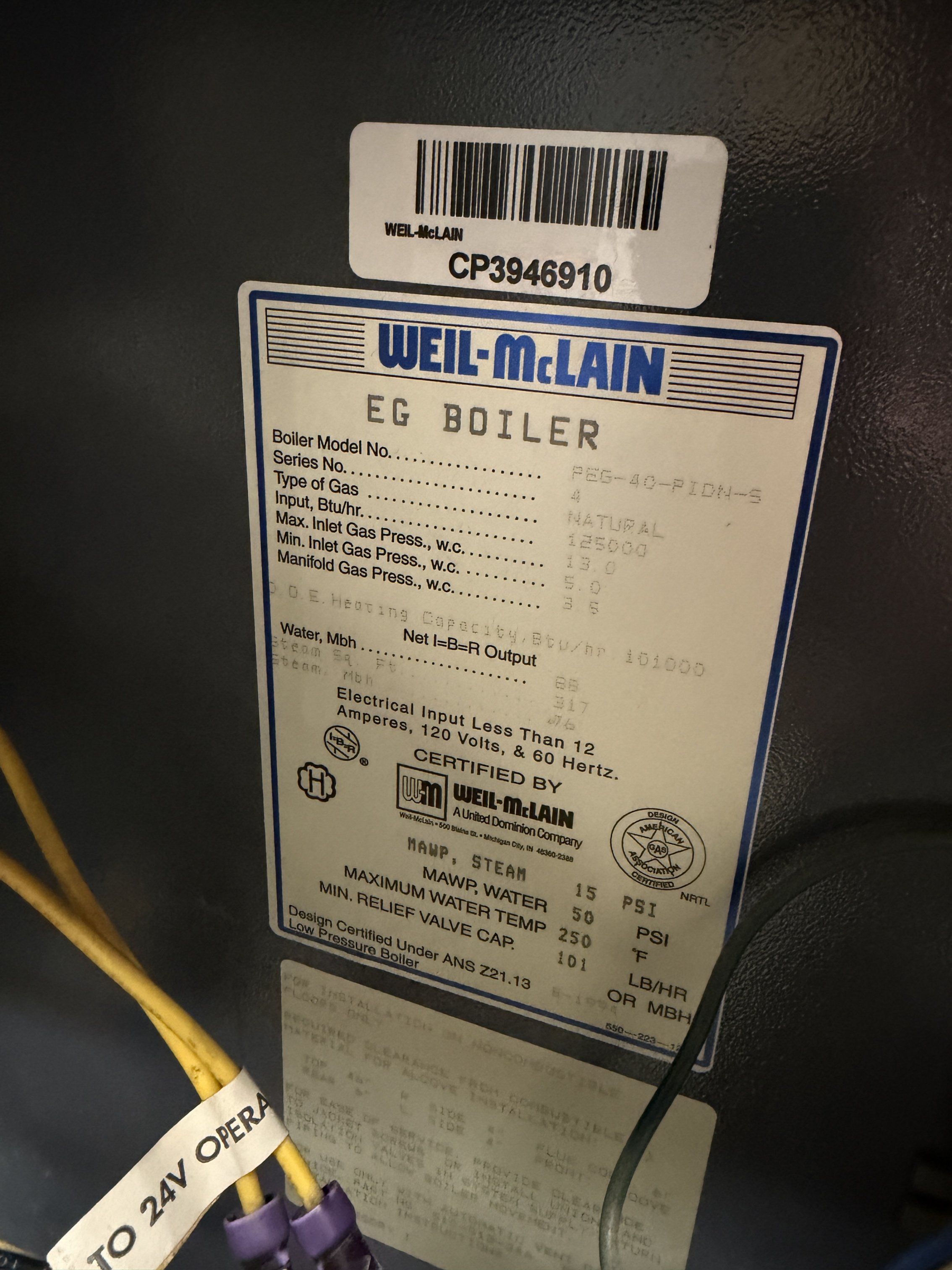

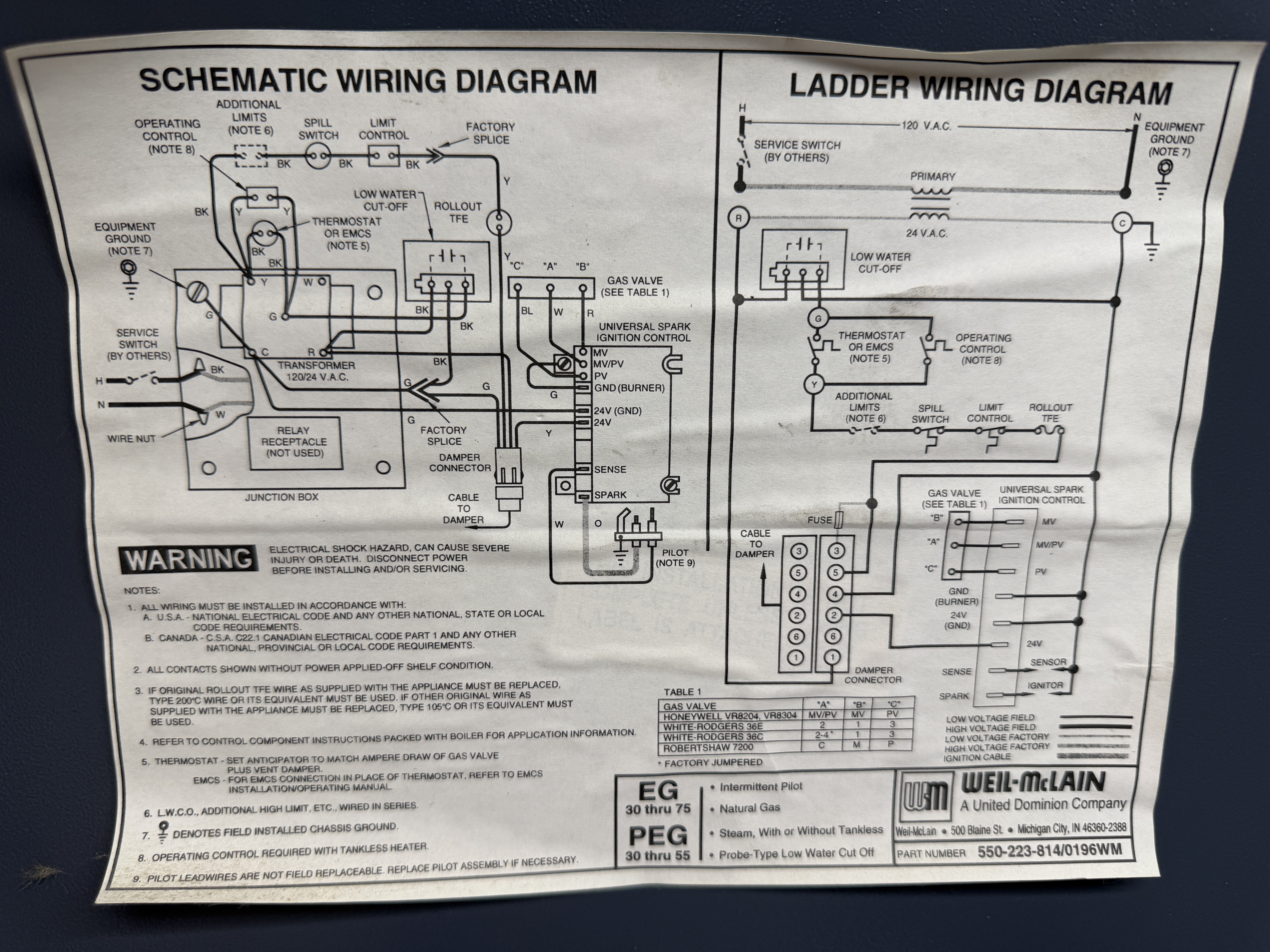

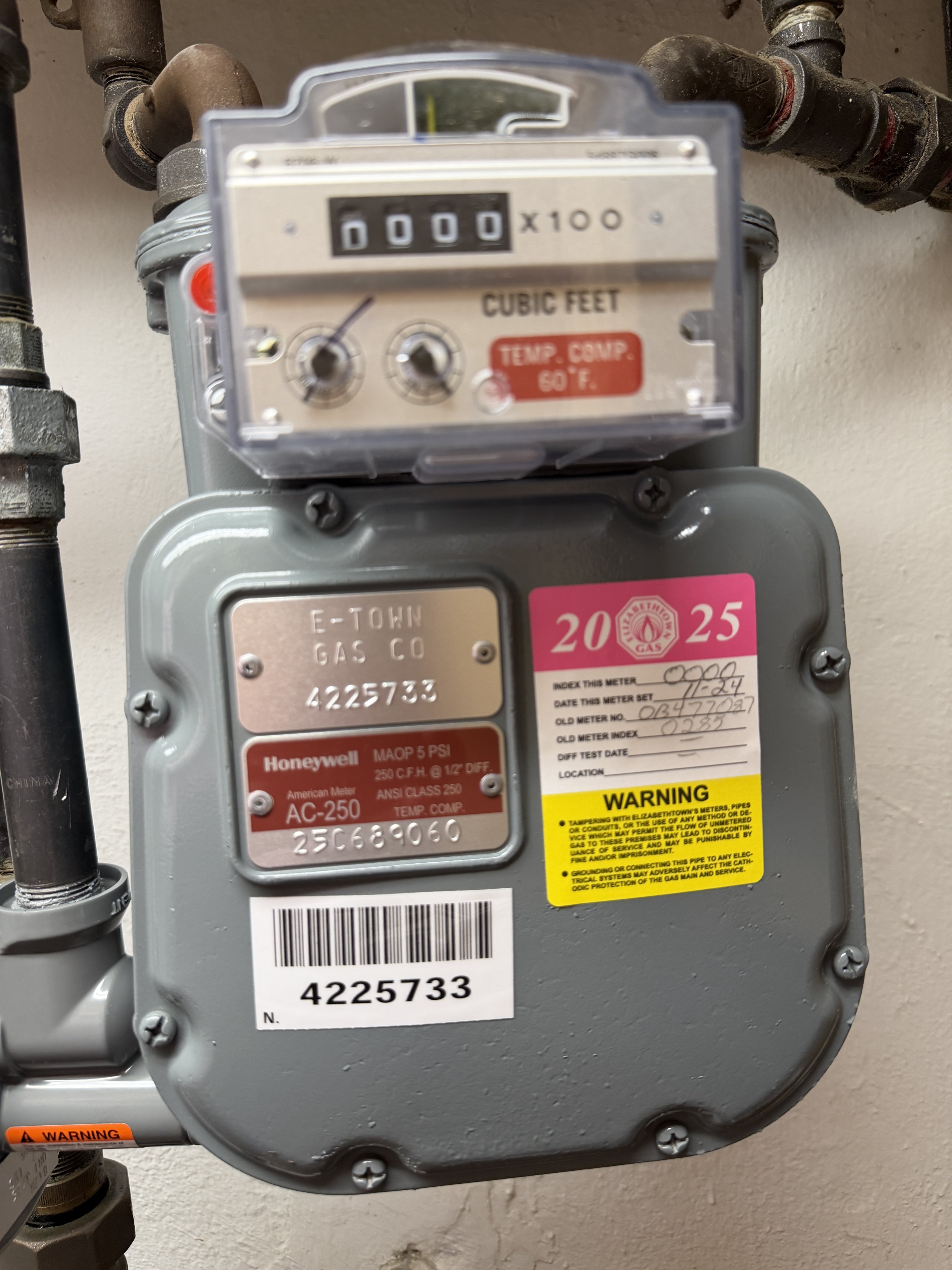

Hi, I am the owner of a 100 year old home with a single pipe steam boiler system (a DIY homeowner) and live in northern NJ near Newark Airport. I have owned the home for 10 years now, with a natural gas powered Weil McClain boiler is 16 years and well maintained with cast iron single pipe radiators. This year during the annual PM before the heating season it was discovered the natural gas water column only showed 3.8 (without any other natural gas pulling in the house). So we had the Natural gas company come out, they changed the regulator and meter, now its 6.5 water column and with everything natural gas powered on in the house on high, its 5.8. So that is resolved. **There is 3rd floor in the house but no radiators up there, on the 3rd floor we have a mini split that does heat in the winter.

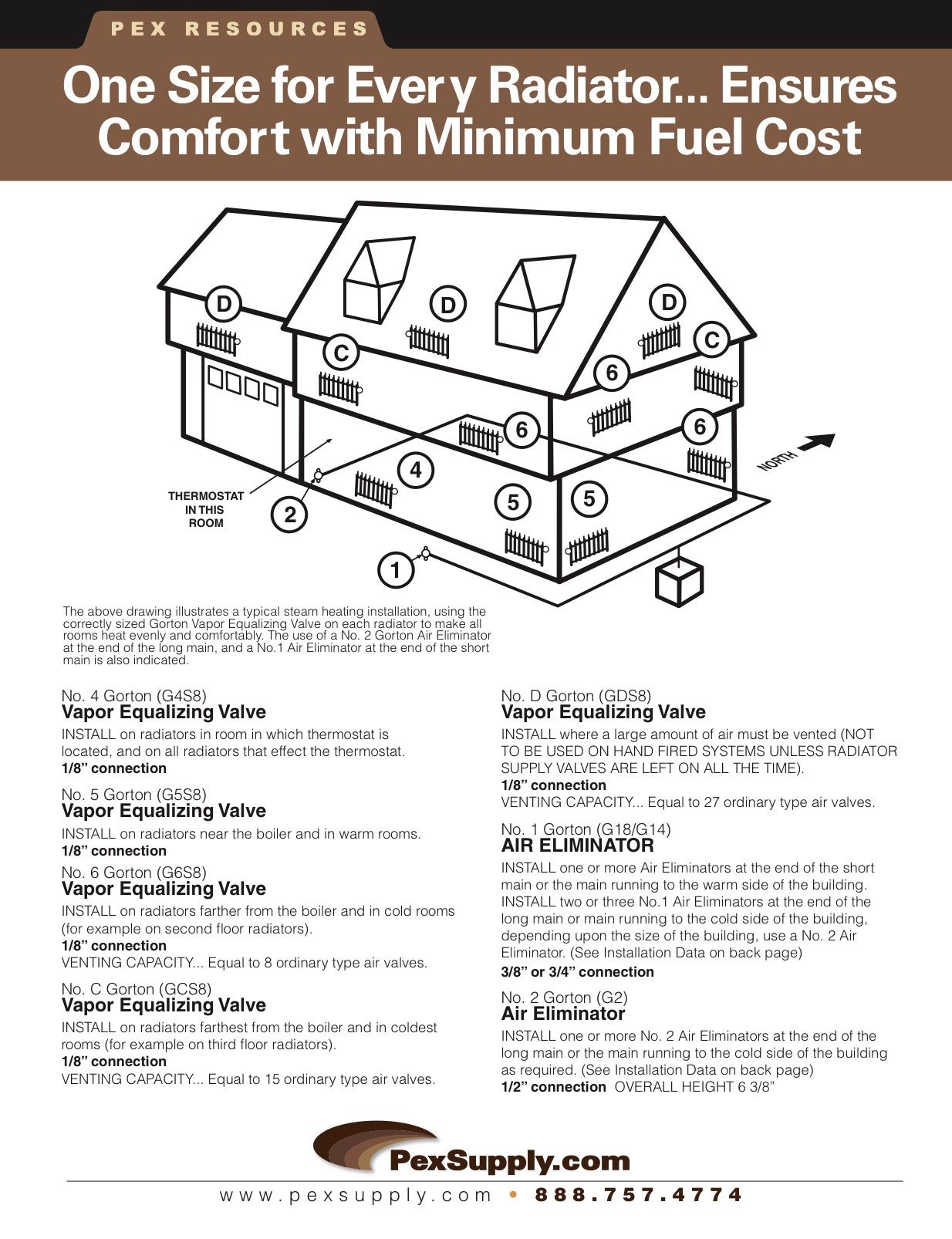

The steam pipes are all insulated in the basement but the walls of the house are not insulated except a couple of the rooms. Right now the heating runs pretty well in the house, I am overall happy. But I want to dial it in a little more, I have all the radiators pitched properly, and all very clean, but I want to focus now on changing the air vents on all them. Right now they are a mix of Gorton, Hoffman 1A adjustable and 1 maid-o-mist. I want to change them all to the Gorton, either 4, 5, 6, C, or D.

Also there is one large Gorton main steam valve in the basement, I have had two HVAC techs here this season, they said everything is looking and running good.

But the Hoffman's make some noise, after reading and researching this for the most part is 'normal' for a lot of folks. I am just looking to dial in the heat some more and get the heat as even as possible throughout the house.

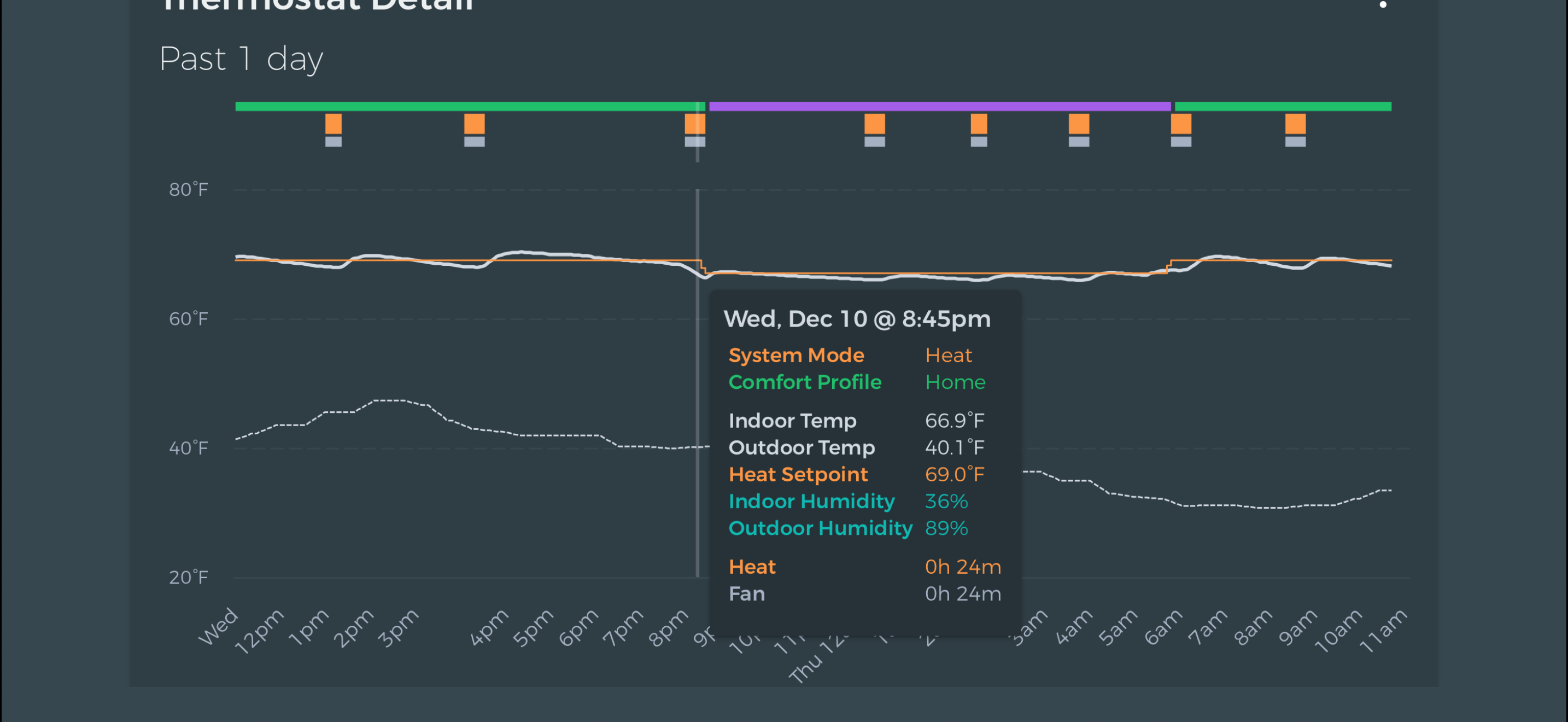

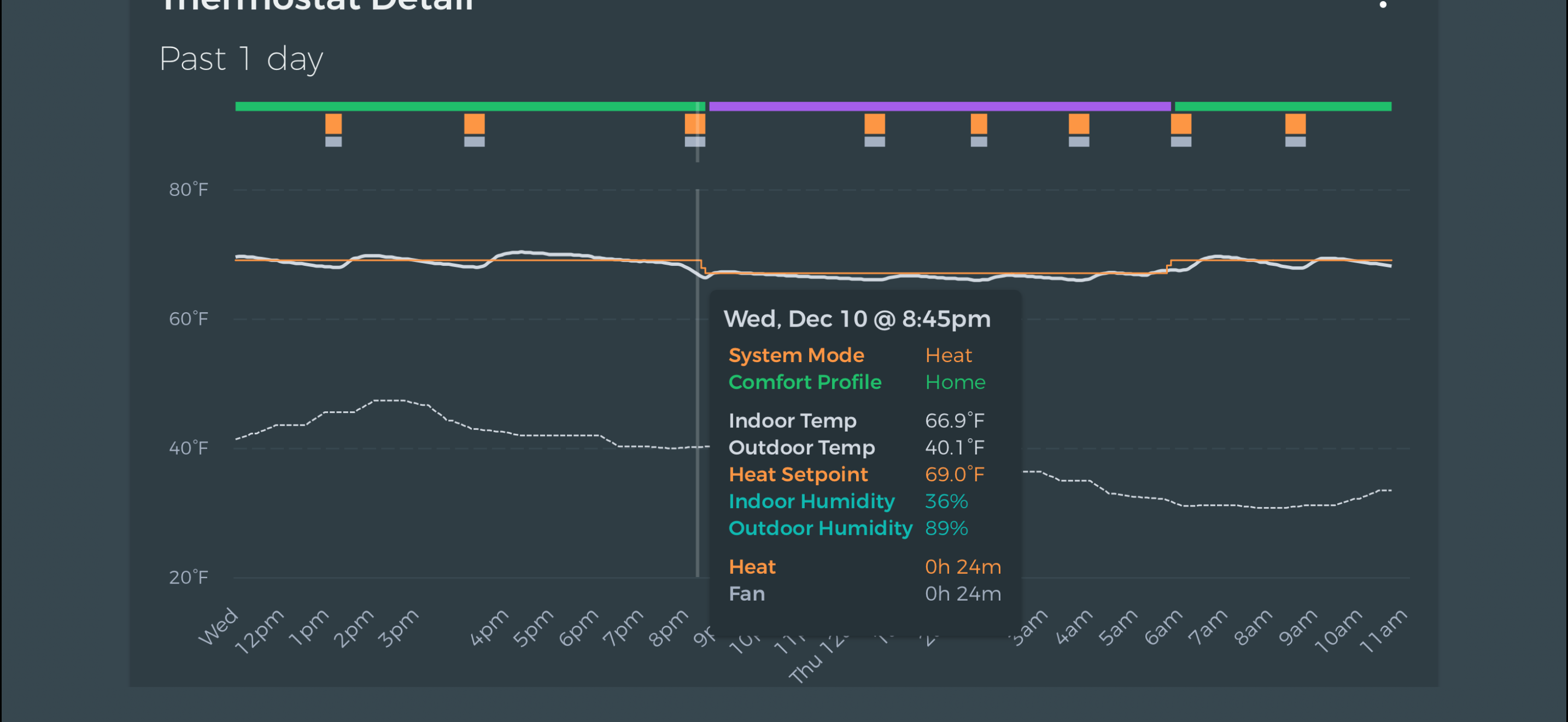

I have a Ecobee premium thermostat with it configured and knowing I have a steam boiler, with it set with a 1 degree temp differential. I have it set to 69 degrees during the day (and I have 5 remote temp sensors (1 in each room) on 1st floor). At night, I have it set to 67, and I have 3 remote temp sensors (1 in each bedroom) on the 2nd floor).

I am attaching the floor plans for my house with the location and size of my radiators and where the boiler is in the basement in relative to the rooms/floors and a few other photos.

Please let me know if I can answer anything else or if I missed anything or was not clear in any of the explanations.

My goal of this post, is to get all of my radiators onto Gorton air vents, from what I read, I have a good idea already

of what # size Gorton vents I want to use on each radiator but I am looking for the experts here to help and see what you all suggest since you know better than me.

thanks in advance!!

Jonathan

Comments

-

Remember that in one pipe steam systems, the size of the vent on a radiator really controls how much heat the radiator will produce, within a remarkably broad range.

Therefore… I would start by determining whether there are some spaces which are warmer than you would like, or some that are cooler. If you find that in general the balance isn't too bad, simply replace the existing vent with a Gorton of roughly the same size. @gerry gill produced a remarkably useful document to help with that — it compares the venting capacity of quite a range of vents.

( @gerry gill I hope you don't mind my uploading my copy here!)

Check the vent you have on a radiator to find its capacity, then select the nearest Gorton.

Now. Having done that, go back and think about what rooms are too warm — if any. On those, try dropping the vent one size. But do this only one room at a time, and let at least a day go by, as any change in one vent will affect all the others in the house!

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

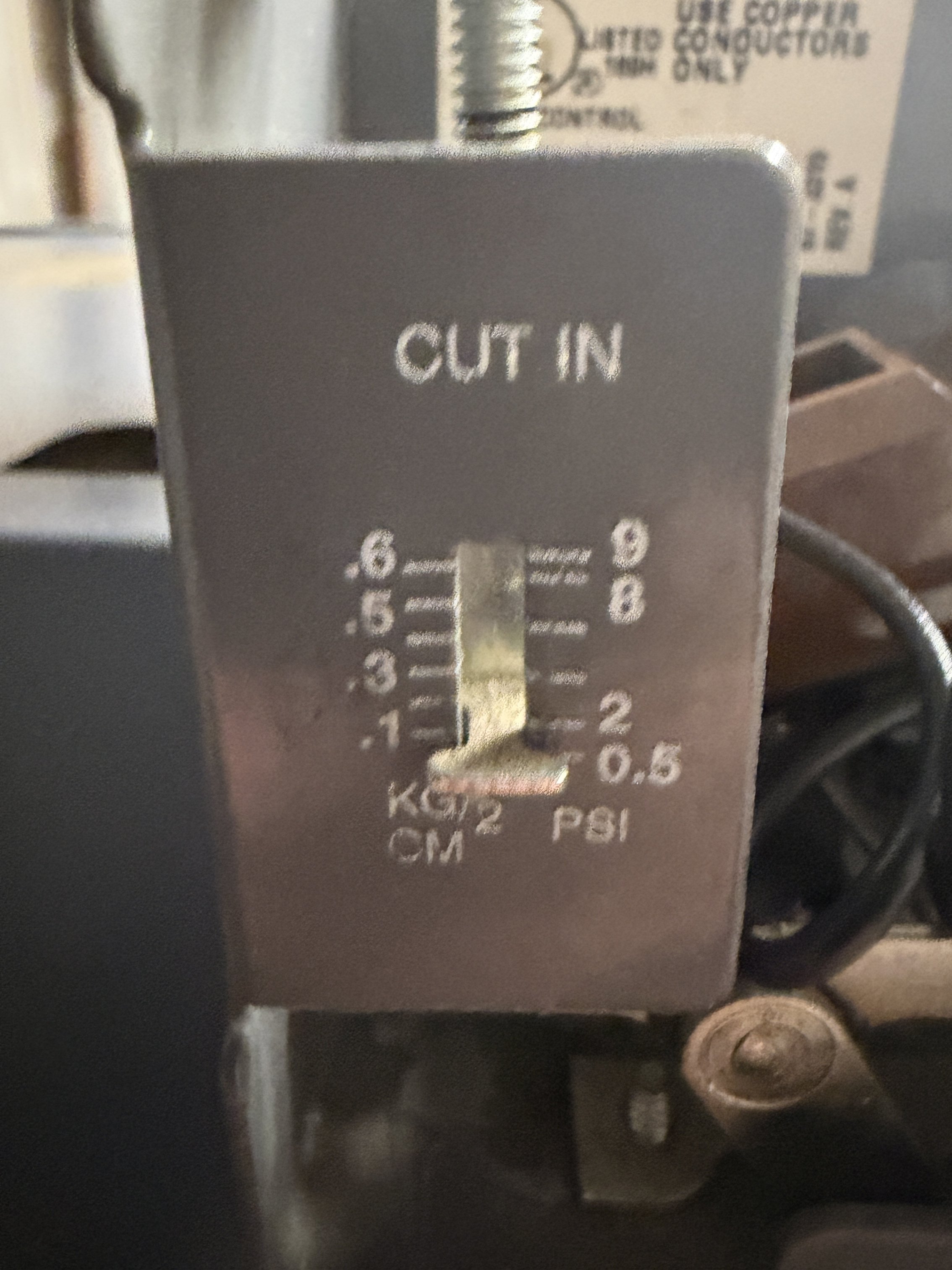

post a picture of your pressuretrol

0 -

here you go, thanks!

0 -

is the pigtail serviced?

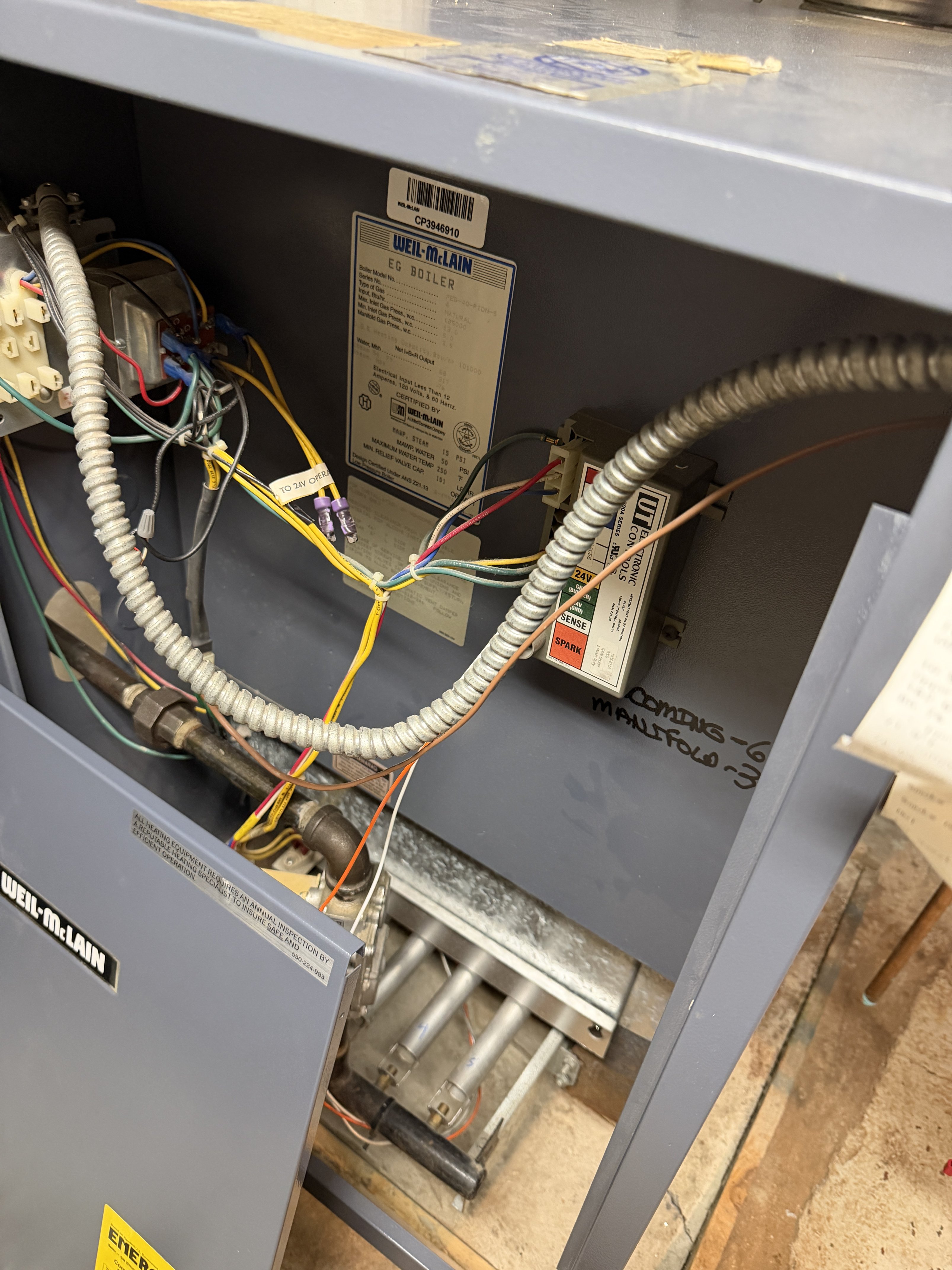

can we see one picture of the controls side of the boiler, all in one

known to beat dead horses0 -

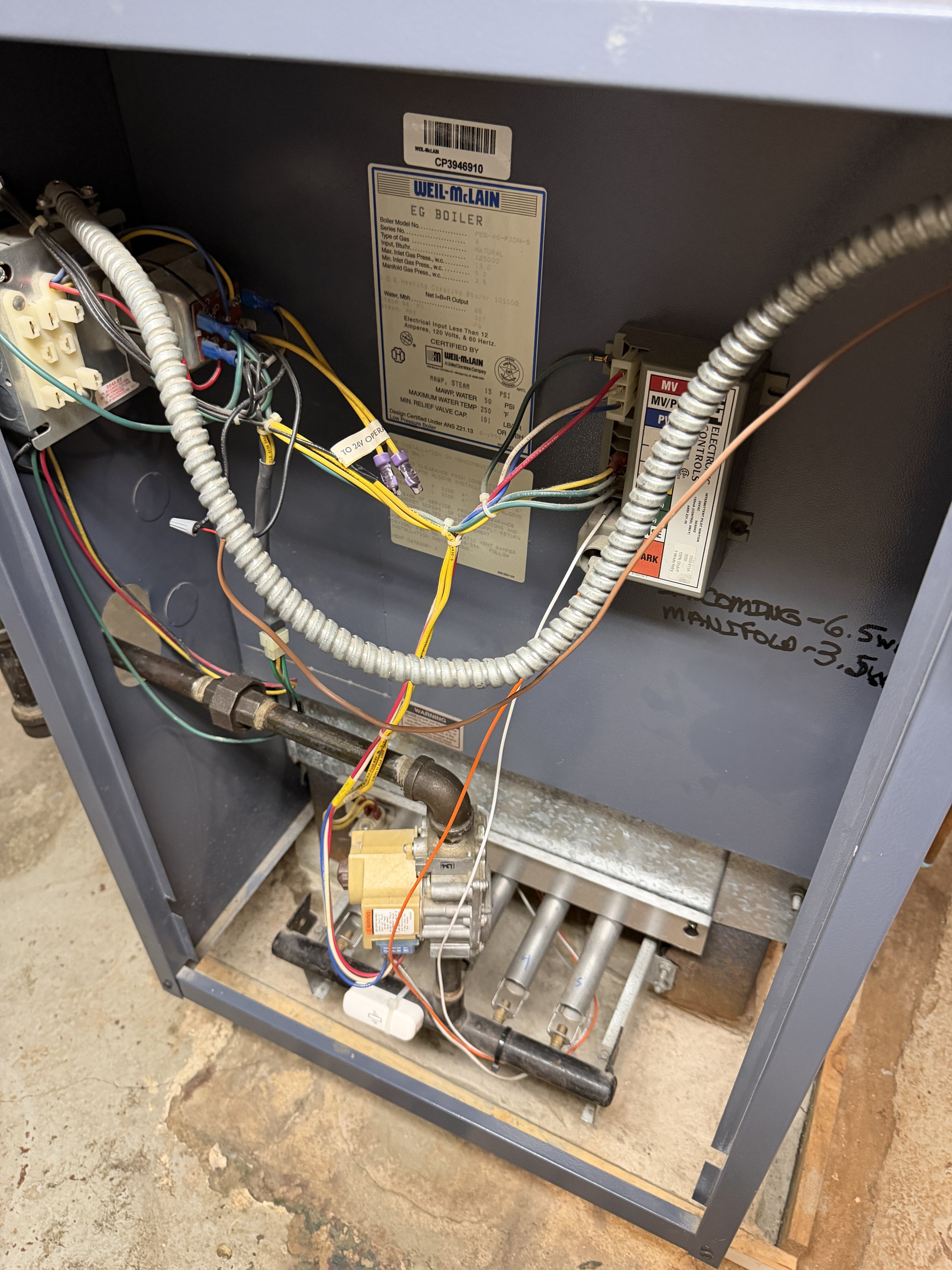

yes, it was checked and cleaned in Sept and November actually. Here is the control side (I believe this is what you are asking for).

0 -

no, we wanna see the Ptrol, siteglass, gage while running, LWCO, all in one,

what pressure do you see when you're making steam?

known to beat dead horses0 -

Sorry, here is that picture, I need to look, I have no paid attention to see what pressure shows when boiler makes steam. The next time it runs, I will check and advise. thanks!

Here's the right pic.

0 -

It looks like the differential on that pressure trol (the white wheel inside) is set too high. "1" should face the front.

—

Bburd0 -

What does the 2 mean versus the 1?, only curious.

just fyi, it was the way the last boiler tech set it that way in September when he was here.

0 -

I was gonna ask for a closeup on the siteglass, but I see that above, and the 8way also, @ethicalpaul may correct me, but that isn't your best treatment, and may be adding to your wet steam, consider draining the treated water, and refilling with fresh water only,

hard to tell but still looks like you have an oily top of glass, and I don't see that your skim port has been unplugged, nippled, and skimmed, how about a head on close up of that siteglass,

known to beat dead horses0 -

The umbrrs measure the differential between burner cut out and burner cut in in pounds per square inch of steam pressure. For that type of control on an ordinary low pressure steam heating system, the differential should generally be set to 1 and the main scale on the outside set to achieve a maximum cut out pressure of 1.5 psi.

—

Bburd1 -

Sorry, that is an old overall picture of boiler, I have not put any treatment in there for 4-5 years. Only fresh water. Here is 2 close up photos of site glass. No oily top that I can see.

and I did drain some of the water out of the boiler last weekend until the LWCO kicked on, then filled with fresh water.

thanks!

0 -

thanks i can change it and turn it down to 1. Just curious only, what’s the difference to the boiler and the steam going to the radiators to heat them up? I’m still totally learning and want to understand, it very much interests me.

0 -

I did just buy this book yesterday, 'The Lost Art of Steam Heating Revisited", did I buy the wrong one? :(

0 -

-

thank you!!! I just ordered that book!

0 -

-

thanks. I just ordered ‘we got heat’! Appreciate it!

0 -

Hi, I did order the book because I definitely want to continue to learn more. But in the meantime, would you please be so kind to explain what are benefits/ differences of changing that wheel from 2 down to 1? Thank you very much for all your time and wisdom so far! -Jonathan

0 -

Um… folks…. what does all this about the boiler have to do with vent sizes on individual radiators? @n1976jmk asked a perfectly straightforward question on vent sizing, and we're fussing about the boiler?

Am I missing something?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

thank you Jamie, it does seem to buy running well overall, each time the thermostat calls for heat, depending how cold it is outside, it runs for about 18 to 25 minutes.

And for the most part the heat is even through the rooms, I’d just like to use nicer vents. And everything I read is Gorton seems to be the overall best.

Thanks Jamie!

0 -

-

thank you, Jamie!

0 -

That guide is very interesting! I hadnt come across a recommendation to add a main vent to the 3rd floor. How would one even go about doing that in an existing system?

0 -

The pressuretrol setting with 0.5psi curing and differential wheel set to 1psi theoretically will tell the boiler to turn off if pressure reaches 1.5psi and turn back on after it falls to 0.5psi. If the wheel were at 2psi with the same setting on the slider scale those numbers would be 2.5 and 2.0 respectively. This normally only comes in play if you run a long enough cycle to 100% fill the radiators and it is nice if you are controlling so you don't have to do that much. As pressure rises you are using energy just compressing steam which can be called inefficient. Should be able to run the boiler most of the time less than 0.5psi. If you want to see what your real pressures are add a 0-3psi or 0-5 and make sure your pigtail is clean.

Sounds like you are not having significant balance problems, nevertheless 1st step in balancing is normally making sure your main venting is adequate. That is normally determined by the length and pipe sizes of your steam main/s. With that info and photo of your current main vent we could recommend a main vent size.

As far as radiator venting @Jamie pretty much said it, however, another option to consider is Maid-oMist vents which I and many others have found to be as decent as quality as anything with the advantages of being more economical and having the ability to adjust just with swap out of the orifice caps.

The only true rule on balancing is that every room meets your temperature expectations which may or may not be 100% even. As a homeowner myself I like venting adjustability during and after the balancing endeavor.

1 -

thanks for this thorough explanation. One question about adjustable radiator vents. I read about adjustable vents, Hoffman 1A, maid o mist, vent rite. In everything I read, it seems the vent rite are the #1 choice. What’s your thoughts on that? Thank you again!

0 -

I don't have a clear cut recommendation for you. I have all three of those adjustable varieties in my home. I can say that the Ventrite #1 seems to be a very good vent and probably quieter than the others, however, that may be largely in part to the fact that the Ventrite #1 is a relatively slow vent (reference the Gerry Gill table mentioned earlier). I use in on a bedroom radiator I want to vent slowly and it works great. Most of my vents are Hoffman 1a's which were there when I bought the house 23 years ago. The adjustment on the Hoffmans is pretty sloppy. To get them where I want sometimes I have to take the top off and manually position the cap to cover the vent hole as I wish and hod it in place while screwing the top nut back on. They will make a clicking noise if steam and pressure reaches them but for me this is rarely an issue since I rarely get the radiators completely filled. I have replaced a couple of them with MoM vents including a radiator that does fill more often than the others because I purposely vent it faster. They seem to work well and are comparatively economical. I have 13 radiators and haven't had to replace any of the vents in the last 15 years due to failure. Two by choice and two Hoffmans due to failure in the early years when I didn't know squat about my system.

1 -

Jacobus also makes an adjustable single cap for their vents that I haven't tried but might just out of curiosity:

https://www.supplyhouse.com/Jacobus-Maid-O-Mist-JAC-ADJ-Adjustable-All-in-One-Orifice

There are also the packs of caps available (one of each size):

https://www.supplyhouse.com/Jacobus-Maid-O-Mist-JAC-ORIPAK-Orifices-for-Retrofit-Pack-of-5

…or you could use a drill

1 -

thank you dabrakeman! appreciate it!

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements