Minimum temperature of a hydronics boiler

Hello, My name is Marty and I just joined. I have a 1940 home with a 1992 Peerless Hydronic System. I have two zone valves for the entire home. I also have a temp gauge on the copper pipe that is going back into the boiler. It is set at around 160 degrees. I notice, however, that when I turn my thermostat down or lock the zone valve to "on", that the boiler does not kick in at all. I checked the temp gauge wire on the incoming pipe, and found that it is totally disconnected. One of the guys that came and checked my furnace did that. So, the tank actually just keeps getting colder and colder, until i turn the thermostat back up. Shouldn't the tank keep at least some warm temp, while the thermostat is not up? Also, as soon as the thermostat clicks back off, the zone valve closes, so NO water flows to the radiators anymore, even if the water is still really hot on the other side of the zone valve… This seems like a waste of nice hot water to me. But I don't know much about it yet. I ordered the book, "Classic Hydronics". : ) Do I need to get that temp gauge hooked back up, and where would I attach the wires? Thanks so much!! Marty

Comments

-

I am thinking that what you are calling a temperature gauge is not a gauge but a Aquastat if there are wires going to it. The tank is actually your boiler.

So you don't need the maintain a minimum temperature in the boiler unless the boiler also makes your domestic hot water by way of a tankless coil. Do you have a separate water heater?

You are describing a cold start boiler and that is a normal way to set up a boiler. there is no reason the burn fuel all year long just on the chance that you might want heat in the radiators on July 5th or September 22 or even February 14. The thermostat in the room will let the burner know if it needs to heat the water so your radiators can heat your home. You can have a cold start boiler.

What you don't want is to operate the boiler so the return water is below 135° for hours of operation. You want that return water to get to 135° within a few minutes of operation. (like maybe 10 minutes)

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

There are someb thermal purge options, but the heat that is left in the boiler goes into the space where the boiler is located. A portion goes up the flue, a vent damper can limit that flue loss if it has one

What type of heat emitters? Copper fin tube or cast radiators?

Copper fin tube doesn’t need a boiler temperature protection valve

Cast iron radiators may if the boiler doesn’t warm up within 10 minutes or so.

Depending on the type of zone valve, some will trigger the boiler on when manually pushed to open, others do not

A pic of the boiler piping and valves would explain more

If it has been running since 1992?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

it would seem it must have had a tankless coil or indirect or hot water zone or something like that at some point if someone went to the trouble of installing a low limit aquastat.

0 -

Thanks so much, Edward, for your feedback and great info!

My water heater is separate from this boiler, so it looks like i don't need that temp gauge hooked up. So, I must have a cold start boiler, that you mentioned.

I have run the boiler and it took about 15 to 20 minutes to get to 135 degrees. Does that work?

Thanks again!

Marty

0 -

Thanks, Bob, for your input!

My thought on the heat loss is, what if i got the boiler up to around 140, and let the home heat up nice, and then turn it down to our regular "61" degrees, (since our gas company tells us that we are using more gas than most neighbors), and then run downstairs and open the zone valve manually, so that it still circulates the hot water for awhile. Would that keep the pipes hotter longer? Just a thought…

I have cast iron radiators in all of the home except fins aboive and below the floor in the kitchen, (it was added on to the home around the 70s)

The boiler took like 20 minutes to get to 135.

When my Honeywell zone valves click on, they open the water flow and also start the boiler.

Here are some pics I just took, if that helps. And yes, it has been running since 92.

0 -

It looks like someone has added a temperature control on the return piping? See below pic. But is has been disconnected inside?

I suspect that added control maybe kept the pump off if the return temperature dropped below 130? That is one method for boiler protection.

The general rule of thumb is for the boiler return temperature to rise above 130F within 10 minutes of run time. But your 20 minute in not a deal breaker, if that is measured at the return, not the boiler temperature gauge?

The building, lifestyle, and your desired ambient temperature is what drives the fuel bill. It not so easy to compare neighbor houses.

Also you want to look at fuel consumption over the years, your fuel provider may have that available online? Fuel costs have been going up, as such the monthly bill goes up.

You do not have a vent damper on that boiler, so a portion of the heat energy you paid for is going up the flue, when the boiler is off. I don't know if that could be added, a question for Peerless. I would rather that then a purge system.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hi Bob,

No, the added temp control on the return piping is NOT connected.

At this point, I do not have a temp gauge for the boiler return temp. All I have is the boiler temp gauge on the tank, so that is the gauge that took 20 min to get to 135 degrees. Do I need to install a temp gauge in the incoming pipe, just before the tank?

As far as our lifestyle, my wife suffers a bit… LOL I can live in a house that is around 63 or 64 degrees all the time, but she wears a few layers of clothes. We do that because we are told that we use the most gas in our neighborhood.

I am not sure of how much gas I used over the years, but this is at least the cost of the highest month each year:

02/27/2025

$199.18

02/27/2024

$175.91

02/28/2023

$206.95

02/25/2022

$194.67

03/01/2021

$153.68

02/27/2020

$128.10

Would a vent damper be worth installing? I am not completely sure how to purge the system. I have drained air out of some of the iron radiators, but that's about it.

Thanks much!!

Marty

0 -

Several things can cause excessive gas usage. An Oversized boiler. Excessive leakage. On and On.

1st thing id do is get a blower door test performed and find out where the heat is going. These can run $250 - $500. Some utilities will pay all or part of this. Find and Fix the leaks.

Then get the boiler sized properly.

0 -

unless some upgrades have been made, a 1940 home may not be well insulated ar sealed

An energy audit that included a blower door and an infrared scan would show all that. In some cases the gas company may have an audit program

Www.dsireusa.org may show programs offered to audit the home

it is always the home that dictates most of the heating costs.

The important number is the amount of gas you get for that monthly bill, how much you pay per therm and if there are additional costs

I would not suspect the boiler is grossly oversized if it runs long cycles to heat up?

Getting rid of the tankless coil will help, contact Peerless or their rep in the area about a damper addition

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hi Bob,

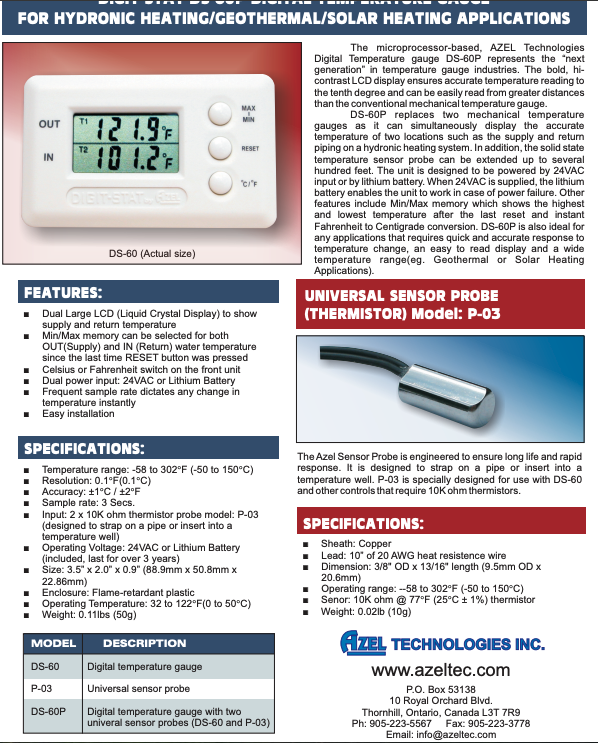

What model is a good, cheap temp gauge for the boiler return pipe?

I wasn't aware that I have a tankless coil in the boiler. Do you see that in a picture?

I will check on a damper for the flu.

Thanks

Marty

0 -

I have four of these clip-on pipe thermometers mounted on the supply and return pipes of our two boilers, and they are accurate enough for your purposes. I have checked calibration with an infrared "gun" type thermometer.

For best results, get some thermal conductive paste and smear it on the contact surface of the thermometer. That ensures good contact with the pipe and better accuracy.

Tell us how many square feet your house is, and if it has any thermal upgrades like double-pane windows, more insulation, etc. You said it was circa 1940, so if it has original windows and insulation, it's probably fairly leaky. I think I saw a boiler service label that said Boyertown PA, which tells us where your house is and what assumptions to make about the local climate for heating calculations.

1 -

-

-

It would be interesting to know how many BTU you actually "scavenge" by post purging the block? A BTU meter or data with flow and differential temperatures could be used to calculate that.

The water in the block and heat in the cast iron mass is what you are trying to harvest.

In your case it seems the short cycles elimination are more of the quest?

With a well insulated buffer tank, thermos bottle, you store those additional BTU to use as needed.

This eliminates room temperature over-shooting, which increases room heat loss, that you noted, or dropping ambient too low before the next heat available cycle.

It's more of a piping or mechanical fix compared to your custom control approach.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

As for post purging the boiler, I'll mention that I've been running a one-year experiment with post purging our two WGO-5 boilers in a gravity conversion heating system from a typical end-of-burn water temp of 140 degrees or so down to 90 degrees, and I haven't been able to measure a statistically meaningful effect on fuel consumption.

I'm doubtful it's helping much since we would normally get continued gravity circulation after boiler shutdown, and the post purge is simply adding some additional force to the gravity flow, thereby speeding up the process somewhat. When I proposed trying the post purge last year, some pros here were skeptical that the juice would be worth the squeeze, and the data so far suggests they were probably right. If there is a fuel savings in our application, it's so small as to be swamped by the noise in the data.

2 -

@jesmed1 - I think for a post-purge to meaningfully help, you need all of the following to be true:

- Boiler that is not located such that heat given off by it meaningfully heats the conditioned space (i.e. those BTUs are 'wasted')

- Large fraction of BTUs stored in the boiler and its surroundings vs the distribution system located in the conditioned space (so high mass boiler with low-mass distribution system like fin-tube)

- Short calls for heat (so very high heat output vs actual heat loss), such that only a small fraction of injected heat is actually required to satisfy the call for heat.

2 -

Wow, there is some great wisdom here. But most of this info just goes over my head. I just don't enough about these things yet to understand some of this. I will try to answer each person in order of when they gave the info. Here goes:

To Jesned1 - I put those two things in my Amazon list to buy, and will try them on my incoming pipe. Thanks for that info.

Our home is 2000 sq foot. Some windows have been upgraded upstairs, but it was before we moved here 14 years ago, so not sure how good they are. I doubt that there is much good insulation in the walls now. We upgraded the kitchen 2 years ago, and I put insulation in one side then. We want to re-side the home and put better insulation in then. We live in Rockford, MI, near Grand Rapids.

0 -

Ed, I like your idea of bypassing the circ relay, although not sure how to do this. Once I physically kept the zone valve on, to see if it would circulate the heated water for awhile, before the boiler would come back on, but not sure if that is what you mean. We are located in SW Michigan.

Bob: You have been so helpful so far, with so many great ideas. However, this last message was completely beyond my understanding:

It would be interesting to know how many BTU you actually "scavenge" by post purging the block? A BTU meter or data with flow and differential temperatures could be used to calculate that.

How do I post purge a block, other than letting air out at the cast iron radiators? I am going to view this video to maybe learn some about this: https://www.youtube.com/watch?v=voS7Url50M4&t=166s

The water in the block and heat in the cast iron mass is what you are trying to harvest.

In your case it seems the short cycles elimination are more of the quest?

With a well insulated buffer tank, thermos bottle, you store those additional BTU to use as needed.

This eliminates room temperature over-shooting, which increases room heat loss, that you noted, or dropping ambient too low before the next heat available cycle.

It's more of a piping or mechanical fix compared to your custom control approach.

I am starting to wonder now if I am just too ignorant yet to be able to really understand much. LOL. I guess I just need to do some study for awhile before actually asking questions in here. I don't want to waste your time and effort. I recently bought "Classic Hydronics", so I will read that before asking more. Maybe i can hire someone to tell me exactly what needs work on the boiler, and then go from there. Thanks so much!

0 -

Eventually… probably next summer, i want to learn how to start another "zone" for the upstairs. Right now, we only have 2 zones, one for the kitchen, which was added years later, and one for the rest of the 2000 sq ft home, both upstairs and down. So, when we try to keep the bedroom at least at 60 to 62 upstairs, the rest of the home downstairs is like 66, which seems like I am wasting fuel at night, so we generally leave it down, so upstairs is around 58 and downstairs is around 62.

I also have no idea how much water pressure that my fill valve is at, or if it is on or off. I need to add a water pressure gauge, or get a fill valve with that included.

0 -

For a 1940's house with some window upgrades near Grand Rapids, I'm guesstimating the heat loss at 20 BTU/hr/sq ft. For 2000 sq ft, that's 40,000 BTU/hr.

From that heat loss, we can estimate your total annual heating energy use as about 65 million BTU's using 7000 heating degree day, a Cd of 0.63, and a delta T of 65 since you keep your thermostat set low.

To get 65 million useful BTU's out of a conventional gas boiler running at 60% system efficiency, you need to burn 108 million BTU's, or 1,080 therms. AI says natural gas costs in Michigan average $1.00 to $1.20 per therm now, so let's assume $1.00 per therm (check your gas bill to find your actual rate). At that rate, you'd be paying around $1080 per year to heat your house with gas.

Here in Boston, I find that we use about 20% of our heating oil in the coldest month. For you, that would cost you 0.2 x $1080, or $216. You said your actual gas cost last February was close to $200, so we're in the right ballpark.

You haven't said where your domestic hot water comes from, but if it's also from a natural gas water heater, some of your gas cost will be from hot water production. So your house's heat loss could be less than the 20 BTU/hr/sq ft I guesstimated. And that's not bad. As a point of reference, the heat loss in our old 1924 multi-family in the Boston area is also around 20 BTU/hr/sq ft, with upgraded windows and attic insulation (but little or no wall insulation).

Many people here in New England would love to have gas bills of only $200 in February. Around here, your $200 gas bill from last February would have been $500, if that makes you feel any better.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements