Collapsing steam in main radiator slow to heat

Comments

-

Yes I’ll go back and check header pipe pitch and adjust if needed.

0 -

I agree with @Jamie Hall gotta get the water out one way or the other.

I agree that the two returns connected above the water line are not an issue with correctly working traps, but no one had asked for radiator pictures before. so we didn't know if it had traps or not.

I see a few choices because re pitching the main is probably not possible with the amount of radiation connected to it.

Take the elbow off the end of the main and install a tee then:

put a trap on it and get it to the boiler or to any return that is lower than that tee or

come out of the tee and drop down to the floor and make a water seal. Rise back up and ty into any return lower than the tee.

I agree with @ChrisJ that the new header has a slight pitch problem but is not the issue.

I also think that if you compare the pictures of the old header and the new header that with the old tee you can clearly see that the main coming out on the left was counterflow with no drip and the end of that pipe had to be cut with a "drunken" or "****" thread to get that pitch. The one on the right is less obvious

0 -

now i want to know what swear word or slur was used to describe an intentionally out of square thread to provide an offset of a pipe to a fitting.

in the pictures the main looks like it has downward pitch. i would check that with a level and look for reducers that make a lip that keeps the condensate from draining. if i don't find any of that I would take off that vent tree and put a hose thread adapter there and hook up a hose there and flush that main back to the boiler in case there is some mound of sediment that has somehow ended up in that main.

i also winder if there is a piece of teflon tape stretched over the end of one of those fittings making a dam in the pipe.

0 -

A similar issue was present before I redid the header . It’s actually a lot better with the drop header and repipe. That rad would barely even heat two or three sections of the radiator sometimes after a full cycle. It get hot but It’s about half as fast as the rest as I described. I’m confident there isn’t any tape causing a dam. It’s something else.

I can try flushing the main back . when I repiped near the vent, that section anyway was clean.0 -

It seems you are missing the point…

" It’s something else. "

" I just opened up that valve I added by main vent and dumped out about a quart of water in a bucket which seemed just about all that was in the main and then that radiator heated right up fast and as quiet. "

You have a huge puddle of water at the end of your steam main. Where water is steam is not. Probably a pipe pitch issue. It needs to drain back to the boiler, continuously. There are various ways to correct this issue, but until you do the puddle will just come back.

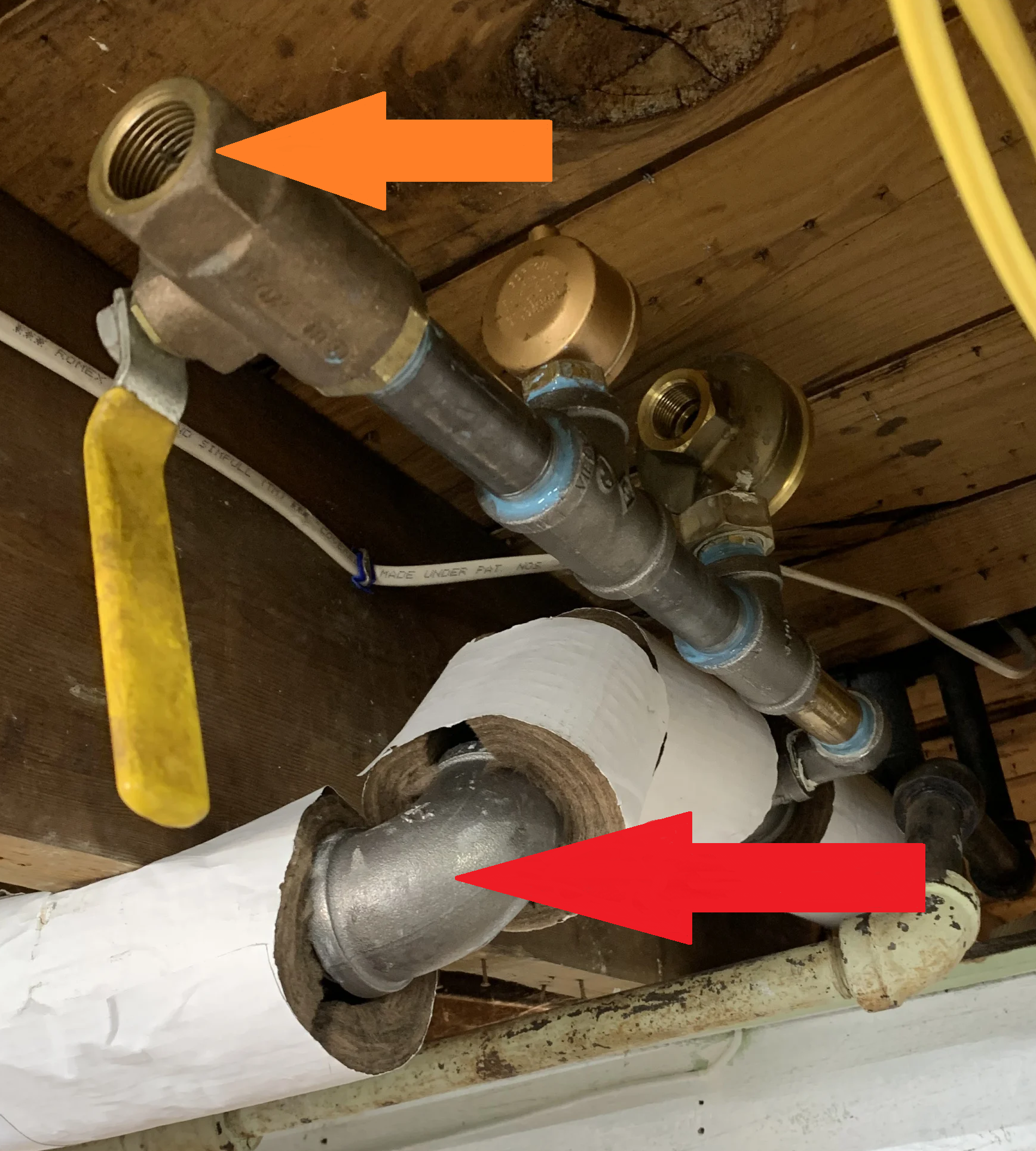

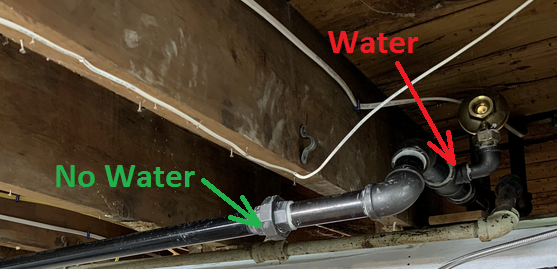

If your are getting significant water at the Orange arrow when you open the valve (should be almost none), the Main at the Red arrow is flooded (it should not be), preventing normal steam flow. There is a pipe pitch issue.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

a string along the main and a level is good for seeing if it has proper pitch.

reducing fittings that cause a dam are also a possibility

can you show us that main all the way back to the boiler?

that valve is pretty far up hill from the main itself. the picture is inconclusive but i would put a level on that lateral that has the vents in the side of it and make sure it has pitch toward the main. i would also make sure that tree of vents has pitch toward the tapping on the lateral. if it pitches toward the valve it could hold water and keep the main from venting.

0 -

between the pipe insulation and my shelving in my basement it will be tough to any good pics of the main that you can see much. I’ll probably pull the insulation off and see what’s going on. It’s got asbestos with fiberglass wrapped on top. Eyeballing it as is I don’t see and thing that stands out.

0 -

if you break this union, does water come out?

0 -

I’m not disagreeing with you. I’m going to pull insulation off the main and see what it really looks like. I’d rather not have to fix it with more piping if I don’t have to. I’d rather correct the cause of the problem. And I appreciate the help.

Im just making sure it’s not something else contributing. Anything I’ve read states incorrect near boiler piping and too high water lever also can cause water in mains.

You don’t think this piping at the boiler , which is also adding to the amount of water in the boiler (since it would be full up to the sight glass level ) is causing any issues?0 -

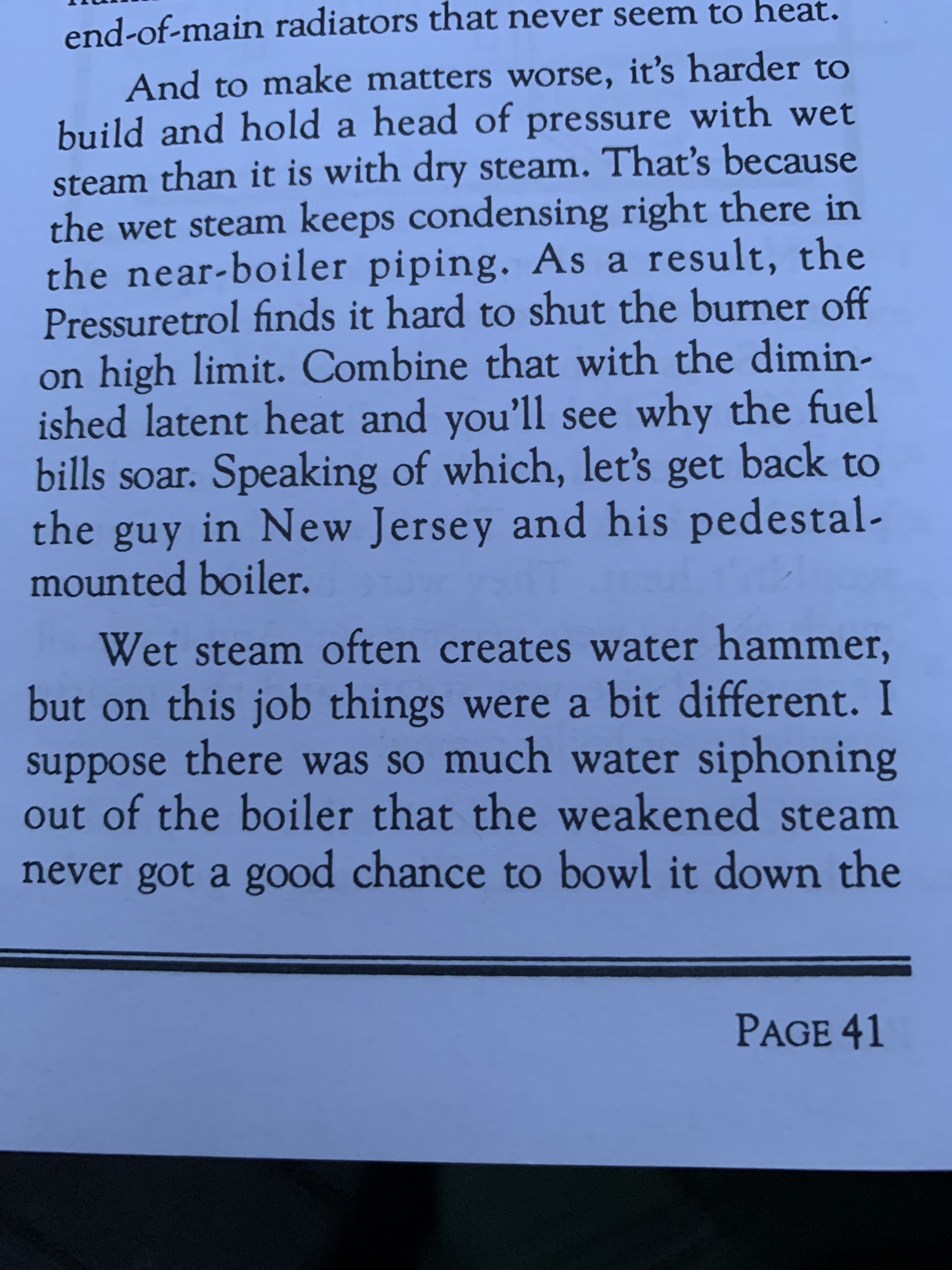

the water in the mains from incorrect near boiler piping would only be while the boiler is steaming. the incorrect piping would cause the boiler to throw liquid water up in to the mains and that water would drain back to the boiler when it stops firing. usually when that happens the returns get hot before the mains from that water flowing back through the returns

if you have water in the mains after the system has been shut down for a few minutes then there isn't a path for the water that condenses in the piping to get back to the boiler. it is an issue with the system piping or a clogged steam trap or something like that, not the near boiler piping.

0 -

What @mattmia and @109A_5 said.

If the piping at the boiler was causing the issue you would be getting pounding and banging.

You will always have some water (condensate) in the system pipe when the boiler is on.

When the boiler is off the pipes have to be pitched so every drop of water (within reason) drains back to the boiler and the returns below the water line.

The condensate also has to be able to drain while the boiler is running so it does not accumulate in the pipe.

You system for whatever reason is accumulating water in the pipe at the end of the main.

- Something is not pitched right. Weather it never was, or something changed a pipe hanger dropped, the piping sagged none of that matters now. It is what it is.

- You can find the pitch problem with a level or a laser. Or you can pipe a drip to the end of the main

I would not remove any insulation until you find the bad pitch. You can check the pipe size/look for the reducer by taking a piece of wire (coat hanger) and poke the pipe through the insulation. Measure the od of the insulation, not the circumference poke it with the coat hanger till you hit the pipe. That gives you the insulation thickness

Deduct twice the thickness from the od and that measurement will be the approx. pipe OD

1 1/4 is about 1 1/2" od

1 1/2" is about 2" od

2" is 2 3/8" od

You might be able to take the nipple out at the end of the main between the 90 and the 45 and put one in 1/2" shorter will give you some pitch back. You would need about 3/4" between the top of the pipe and the joist to do this.

If the pitch can't be easily fixed then I would get some 3/4" copper tubing and run a return back to the boiler or into another lower return

0 -

This problem may have preexisted before you moved in.

Why were these pipes replaced ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I’m sure it persisted. It was a neglected steam system (and house ) when we purchased the house.

That section of pipes were replaced because I was convinced by someone that the problem there was because there was a reducing tee from 1 1/4 “ to 1” and a 90 elbow attached and the that’s what was causing the problem. So I changed it so its the same 1 1/4” (see second pic with arrow ) over to the main vent (which I also added because the system didn’t have any main vents)0 -

Just curious.

What happens if you start the system, and just as the radiators start to heat, shut it down, wait 5 minutes and try again? Will it heat completely normal and fast?

I know close to nothing about 2 pipe setups, but I'm curious why your main has much water in it at all to begin with. Other than heating the piping initially would cause some. Also, I didn't think two pipe systems had main vents on the mains themselves? I thought they were after the traps on the return?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-- drop header at boiler MUST be pitched towards equalizer

-- main pipes on your system MUST be pitched towards boiler

if the above factors are checked, you might have the issue i had: one of my rada made the loud sounds of steam collapsing into water. the culpirt turned out to be a supply pipe very close to an uninsulated wall and a heavy draft around it. the section of the pipe never had a chance, it was constantly cooled by the outside air. this caused the steam insude to constantly collapse. generous insulation through the inspection hole solved this problem.

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog0 -

-

Some two pipe systems have vents on the steam mains, @ChrisJ . Some don't — or don't seem to. The ones that don't, however, have another means for venting air: crossover traps. These are just like radiator traps (often are, in fact!) but set above the steam main and related dry return — and allow air to go from the steam main to the dry return (let's not talk about F&Ts… different application and principle) and the dry return takes the air back to the main vents at the boiler.

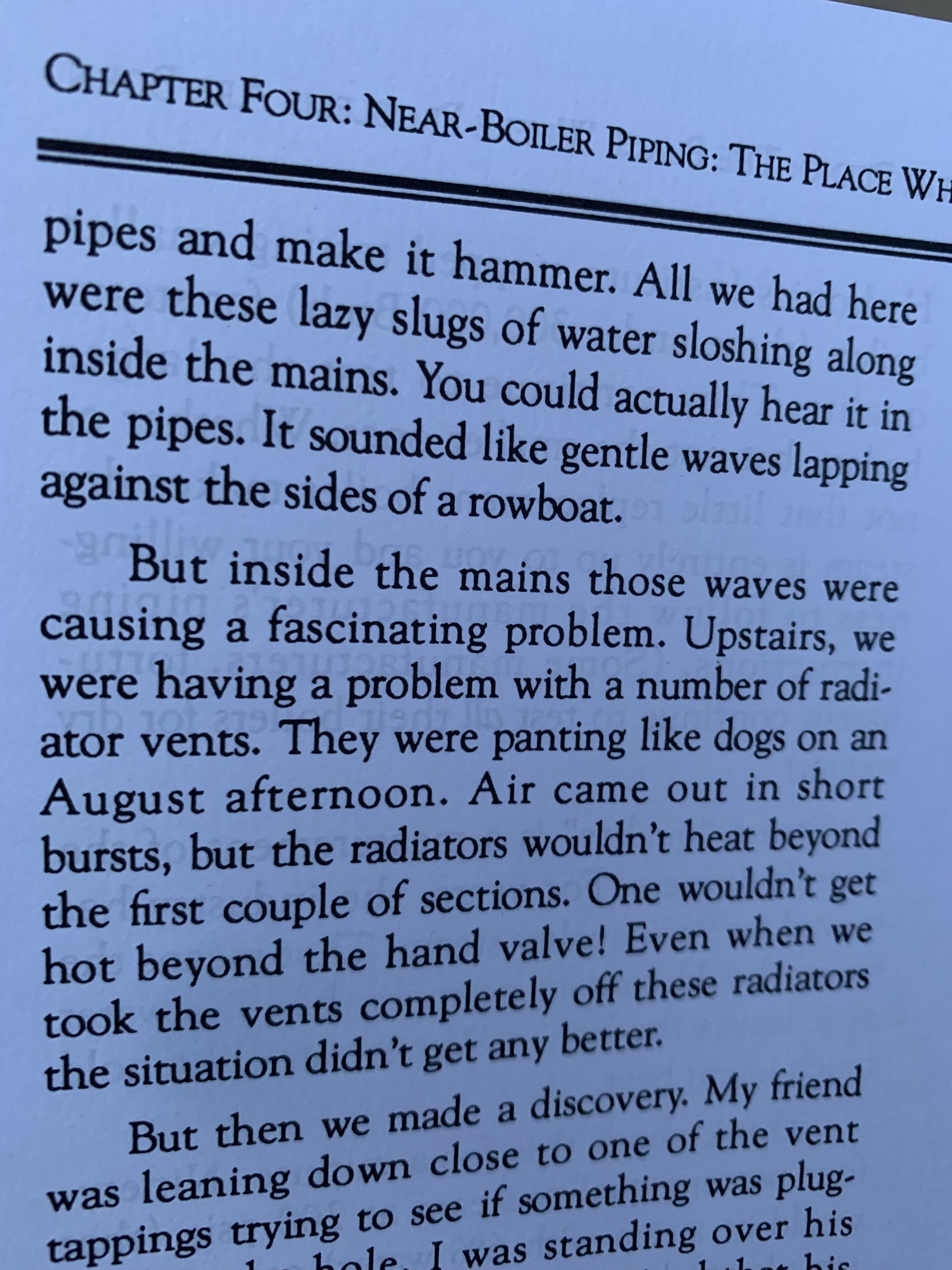

Now water is another problem. Any main carrying steam will have condensation in it, and that has to drain by gravity somewhere. The problem is that if it can't drain, or can't drain adequately, it will severely slow the passage of steam by the puddle, since until that whole puddle is up to steam temperature steam will just condense and add to the puddle, rather than going by.

(For the mathematically inclined, the condensate volume is somewhere around a half cup of water per square foot of EDR per hour).

Now if you take a nice long main and put an elbow going up at the end of it, and the end of it is even as little as half a pipe diameter low rather than high enough to drain back to the boiler, the condensate is going to make it to that elbow and… sit there. And the amount of condensate on startup is quite enough to block the steam flow (worse, in our OP's case, it also tends to block air flow to those lovely vents, so not only is steam condensing to add to the puddle, it's flow is partly blocked by air…).

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

This isn't a tough problem to fix. Its either re-pitch or add a drip. This isn't magic. You can't deny the law of physics.

It reminds me of a large air handler we had in a paper mfg plant a new system. The engineer wanted spray nozzles for humidification, so they were installed in accordance with his drawing and spec. The nozzles discharged the water against the air flow as designed.

Downstream of the nozzles they had baffles that were supposed to catch any water that was not absorbed into the air.

They were getting water carrying over into the fan section past the baffles which obviously not good for the fan or the motor.

I was sent to look at this, and I measured the air velocity which was like 800fpm.

It was obvious to me that this was the issue. Chilled water coils have to be kept below 500fpm so you don't pull the water off it. Standard stuff. Its the same with DX coils

It was Carrier AHU and they insisted it would work. It didn't

Being a non-Engineer I was ignored

They struggled with this thing for 6 months and the water caused all kinds of issues . They finally slowed the air flow and got it to work

Same job had 2 steam preheat coils side by side9Huge air handler. The contractor that piped this connected the condensate connections from each coil together then one common pipe into the steam trap. Never going to work in 1000 years. I found this during start up in September.

I said you going to freeze a coil, not going to work. Every coil needs its own trap. They ignored me again and froze the coil. Guess who got sent to temporally patch the frozen coil?

0 -

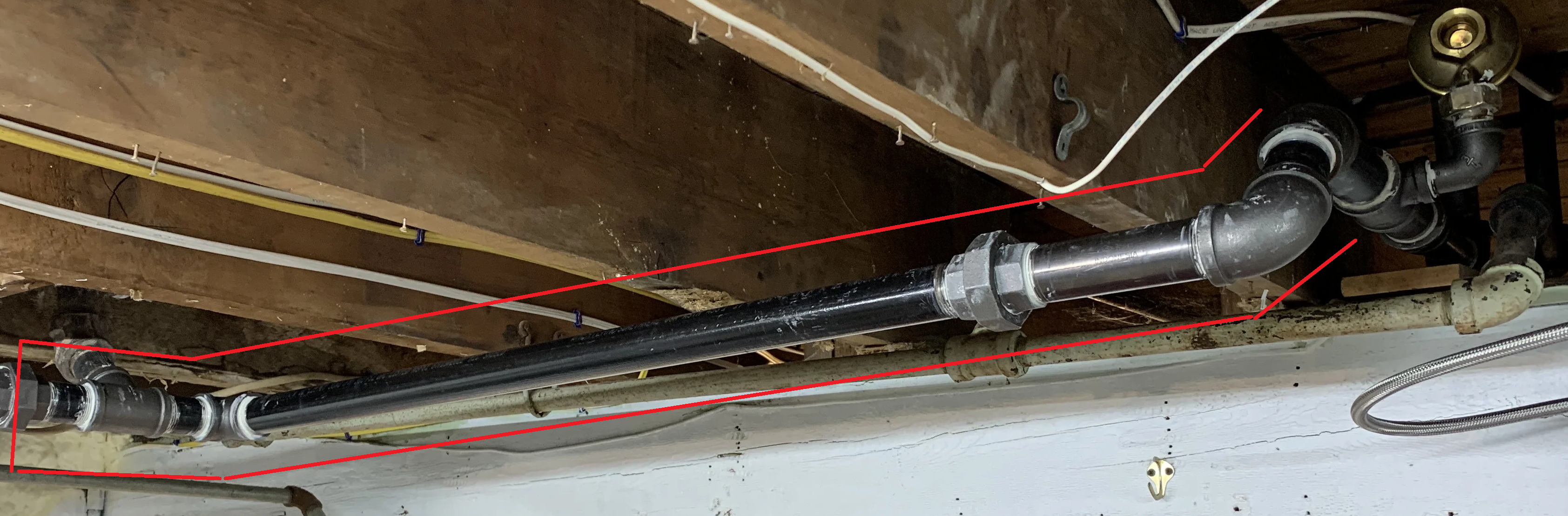

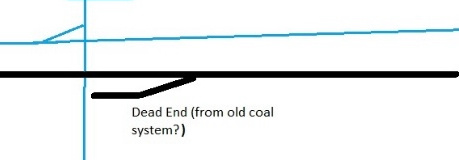

I can’t get a good pic of it so here is a rough sketch .. near the boiler header is a dead end off the main. I think it was left there from when it was converted from a coal to a gas boiler . It’s about 2’ before the verticals take off from the header. Could condensate from the main be running back into this pipe and sitting there, then get pushed back up the main during the heat cycle ? It’s on the stain side with the problem I’m addressing.

0 -

No. There's nothing to "push" the water in that dead end out.

Look. As @EBEBRATT-Ed said, and I've said… this isn't rocket science. Either repitch that pipe so it drains to a drain, if you can, or add a drip so the water can leave…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

if that area has water I say open the unions and see how far back toward the boiler you have trapped water, that will tell you which direction of the union to look in. if the union closest the radiator has no water then that runnout and offset has something going on. if it it all the way at the first section of new pipe then look further toward the boiler.

how do you get from the existing pipe to that new 1.25" pipe?

if you find it is in the asbestos covered section then maybe you put a drip at the connection to the first section of new pipe instead of getting that abated to find out what someone did 60 years ago.

0 -

@ChrisJ furthermore, there are different types of 2 pipe systems. vapor systems frequently need to have a single vent point in the entire system because many have some sort of device that lets steam in to the returns to equalize the pressure between the mains and returns (usually a loop of some sort but there are other designs). the main vent needs to be near this device so that the steam will reach the main vent and close it and allow the return to equalize without the steam going all over the returns trying to find the vent. there is usually a check valve on the return that prevents the boiler pressure from pushing out in to the return directly.

0 -

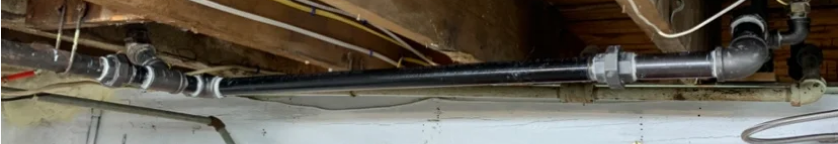

separated union at runout. No water . Took elbow off end of main. Tan scope camera 8’ down main, no water . Took vent off and ran scope inside that section. No water.

The end I of the main is 1.25. Somewhere from the boiler to that point it reduces to 1.25 Wherever that is is covered in insulation and I can’t see it unless I pull insulation off.0 -

but water comes out when you open that ball valve teed past the vents?

0 -

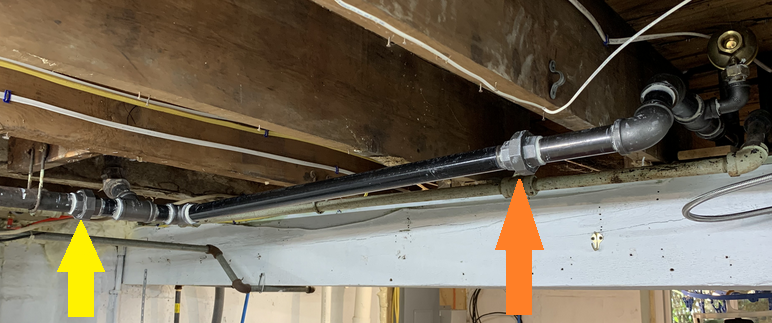

Which union did you open up, Orange or Yellow ? If you had significant water coming out at the valve near the vent and there was no water at the Orange arrow, that seems odd, unless it drains away slowly over time.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Which way does this pipe pitch ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I split the orange union and took off the 90 elbow off end of main (over by the yellow one). I ran my scope camera 8 feet into the main and didn’t see any water.

0 -

I have that leg with the main vent pitched back to the vent / main

0 -

That is correct. I can hear the water in the main there just before and just after the vent. If I pull the trap cap off at the radiator you can see it spitting/pushing the water through during the heat cycle . If I open the valve and let it push the water out it’s fine and works as should. I’ve used my scope camera and pushed it 8 feet in the end of the main and see no water. At least not there.

0 -

wait, let me get this clear. the water comes out if you open the valve after the cycle is over, or does it only come out during the cycle?

0 -

So its like this ? Is there a rag or something in the pipe between the Green and Red arrows ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Water spits out during heat cycle. Nothing comes out when open after it shuts off.

0 -

All The pipes in the picture you can hear the sloshing in.

I upsized those pipes , they are all new. No blockages. The problem was there before I upsized the pipe.0 -

we were under the impression that it happened when the boiler was off. if it happens only when the boiler is on, water is getting thrown up there from the boiler or possibly from an old header from an old boiler that wasn't removed

0 -

is there a drip connected to that main anywhere? the water line in that boiler looks really low so there might be something that was below the water line with the old boiler that isn't now.

0 -

Regarding piping there is a tee in the main near the boiler with a dead end section of 2” pipe . It’s about 2 feet in total length. Maybe part of an old header?

0 -

-

Maybe the wrong pipe is being blamed. 2 pipe systems often vent the air from radiators through the return pipes (dry return). If the return pipe is not pitched correctly and the water puddles blocking or reducing the air flow the steam flow into the radiator will suffer. I kind of wonder about the pipe behind the new pipe in the picture, maybe it's just the camera angle or the pipes are actually not parallel. It looks lower on the Right end.

Are there other vents near the boiler ? How are the rest of the radiators vented ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

it’s a capped dead end leg. Possibly for the old coal boiler. If water drains back into it , it can’t drain out.

0 -

seems like my problem described. But changing header didn’t help much. It helped but not solve it. So what am I missing ?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements