Water meter accuracy and pipe size

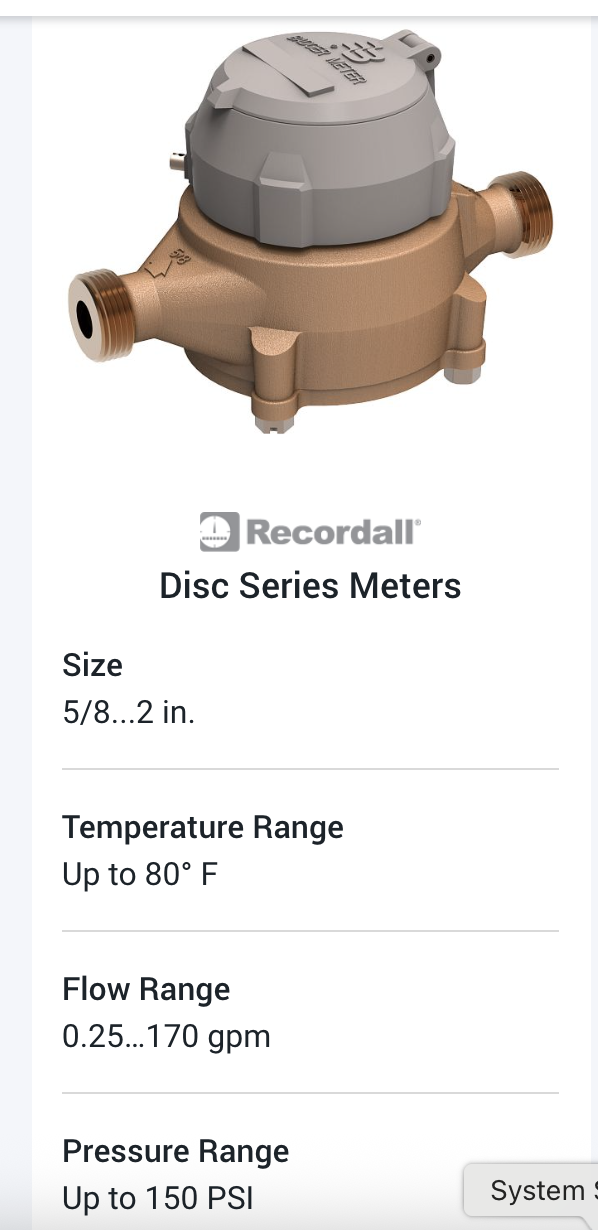

Hi. I'm about to add a meter to keep track of makeup water on a steam boiler. I like the idea of a digital unit that can installed in-line vertically and be easily reset. This unit:

Ticks all the boxes and the price is right but it's sized for 3/4" and my feed is 1/2" copper. My understanding is that pipe diameter is critical to accuracy but the 1" model ships with optional bushings to adapt to 3/4". If I adapt this to 1/2", will it read accurately?

Thanks in advance.

Comments

-

-

depending on how much flow your fill system provides? You want a meter that reads low flow rates maybe .5 gpm or less? I have a plastic version of that meter and it seems to take 1 gpm or so to get it booted up and spinning.

A typical Badger disc meter reads low flows, plastic versions are inexpensive.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Why would pipe size matter at all?

The meter I have from the city seems to move even with the tiniest leak. I can't imagine if you have a 1" service getting free water if you run the faucet slow enough?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Wait a second here. How big is this boiler to which we are adding water? And how often are you adding? Most residential sized heating steam boilers should not add more than a gallon a week — some may be a little more, but not much, and some may be a lot less.

If it's controlled by an automatic feeder, most of those feed a more or less fixed amount per activation, so a simple counter (which the more advanced ones have anyway) would be fine.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

It's a 10 section Weil Mclain 80 series. Installed last year. Auto feed on the feed tank is wired to a float switch, I don't know exactly how it's configured. The guy who installed it was in agreement that an in line meter would be the easiest way to monitor makeup water. Fresh water killed the old boiler when a failed pump on a remote condensate tank failed and nobody noticed for (possibly) years 🤯. That's not going to happen again but there are alot of old returns in places where a leak would go unnoticed.

0 -

Chris J.

I don't know from fluid dynamics but something about the turbine hall effect sensor meters seems to make sizing the meter to the line important I think? The fact that their 1" meter can be bushed down to 3/4" seems to indicate otherwise though.

0 -

That's true but I'm looking for an accurate baseline to compare to as well.

0 -

The pipe sizing example is probably more for the ability to get full flow condition, gpm reading.

If you are looking for below 5 gpm flow a 1/2" copper will easily move that through the meter.

The meter will see the same gpm regardless of a 1, 3/4 or 1/2" pipe feeding it.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

-

Thanks Jamie. Good to have a figure to shoot for.

0 -

Ok that makes sense. Thanks.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements