Water trickling sound in hydronic baseboards- please help

Hi everyone. I have a 10 year old Weil McClain ECO70 hydronic heating system, with one closed loop and a manual water feed. After having the system serviced over the summer, a sound of water trickling through the baseboards on the upper floor of my house has developed. I thing this might be due to trapped air in the system, but I don't know. I thought the brass valve on the top of my expansion tank (picture attached) was supposed to automatically vent excess air... but that doesn't seem to be happening.

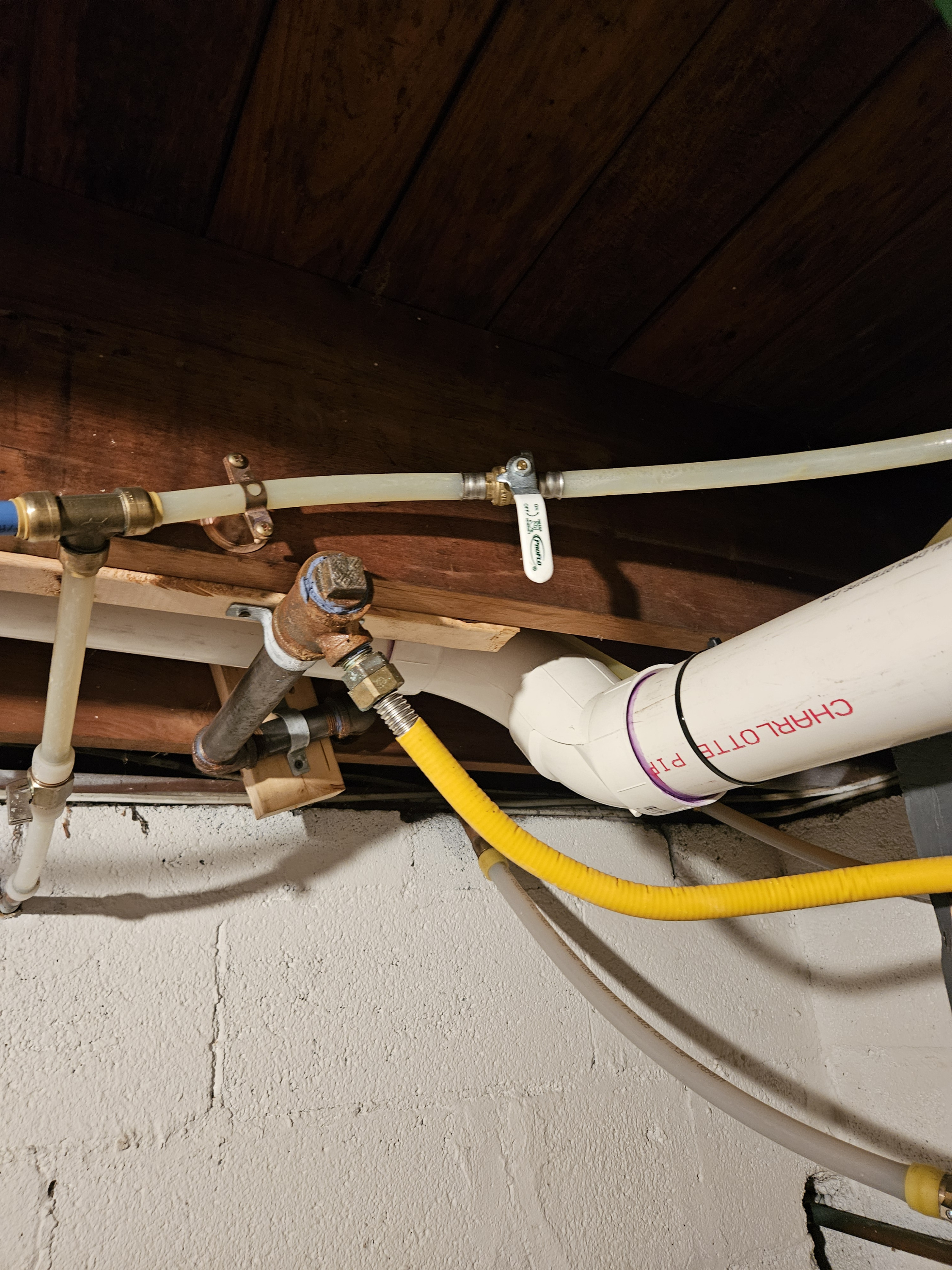

Also, the technician set the circulator pump to level 1, not 2 (where i think it was before) and im wondering if that is a factor. Pressure is abiut 14 or 15 psi when not running, 18 or 19 when running. Any suggestions? Should I open a bleeder valve on the 2nd floor?

Thanks for any help or suggestions you can offer!!

Comments

-

Pressure should be adequate — but opening a bleeder on the second floor to see if any air came out wouldn't be a bad idea at all.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Thanks for the advice. If air doesn't come out, any suggestions? Can I use that brass vent on top of the expansion tank somehow?

0 -

I would bump the pump to speed 3 for a hour or so. The newest Alphas have an air removal function "self venting" built in, basically taking the circ to full speed for a period of time.

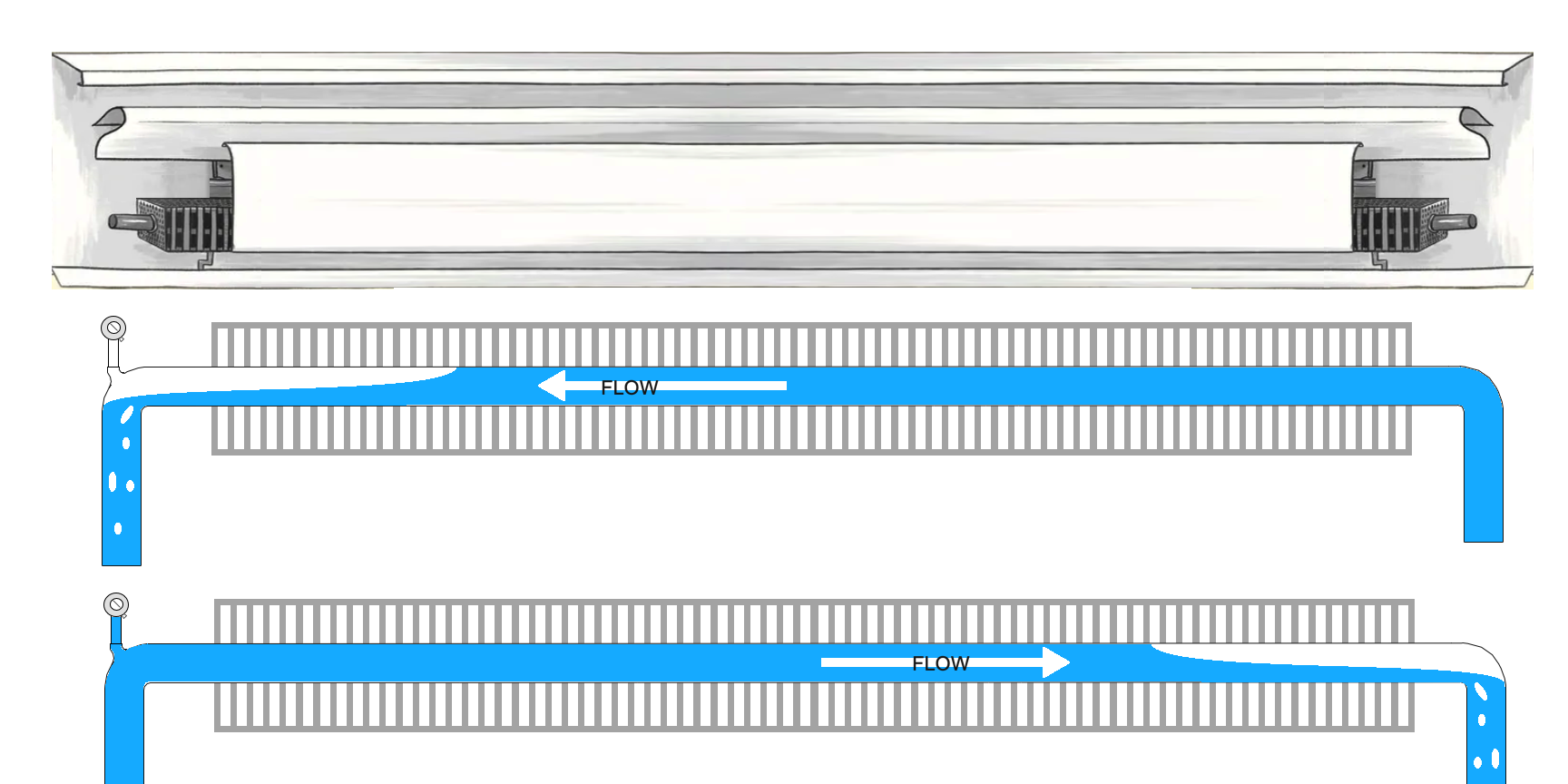

If you hear water trickling it must be moving, but not fast enough, above 2 fps to bring it down to the Spiro.

Pretty clean looking Spiro, usually you see some staining if they have discharged air. Could be the mfloat or valve is stuck.

That would take a disassembly to check.

No harm in opening that bleeder also, take a sponge with you :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

So increasing the flow rate (eg pump level 3) will push more water through the spiro, causing air to be vented? Will that work at around 18 psi? Or is that pressure too low?

0 -

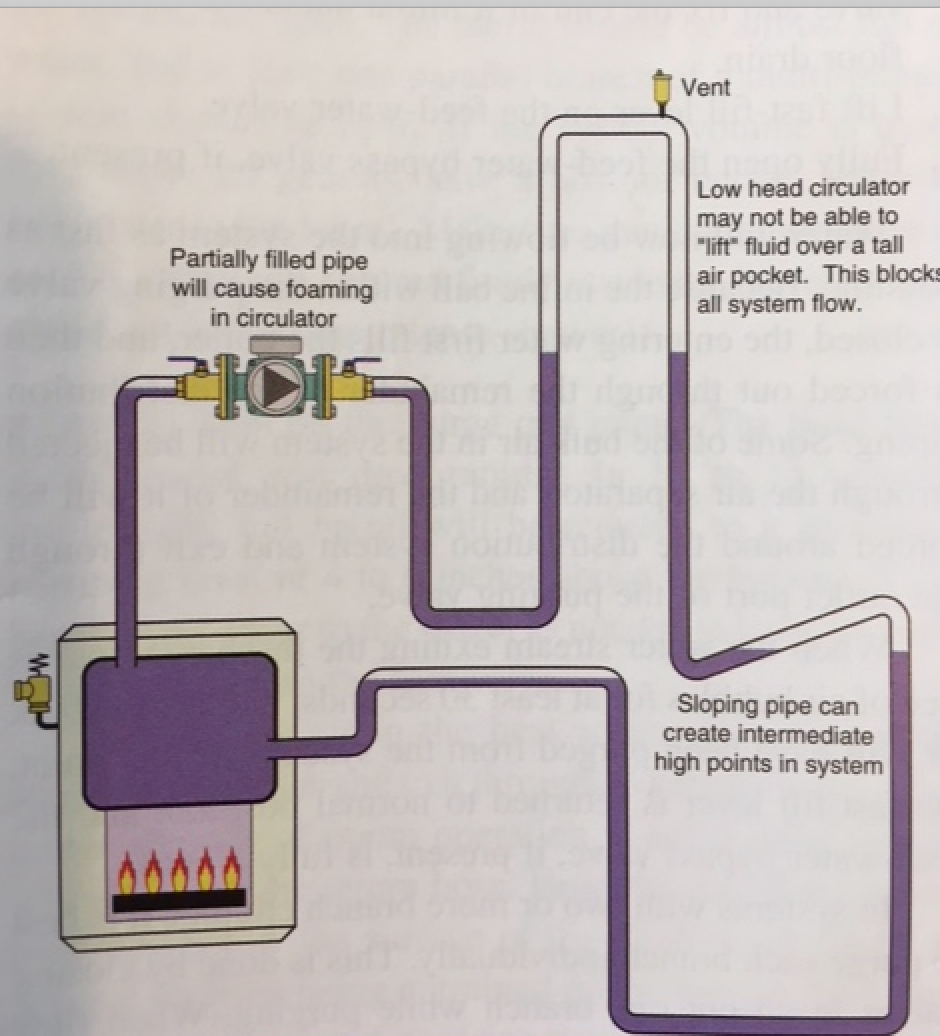

There is no automatic feed valve, correct? That means that as the air is vented (either by the Spirovent or by the coin air vent) there will be no water added automatically, to take the place of the leaving air. The manual valve must be opened to bring the static pressure (the pressure when no circulators are operating) up to say 12 or 15 PSI. If service was recently completed by a professional, and any water or air was removed for testing purposes, most systems with auto feed valves would put the water back in to replace the water or air that left during the test/maintenance call. The technician may have overlooked the fact that there is no auto feed and left the static pressure too low.

I would look at the pressure gauge and see if it is below 10 PSI. If so, add water to get it back to 15 PSI and see what happens after a day or so.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

If you gauge moves from 14- 19 that would indicate the gauge is working, a good thing. A bigger pic would show if a fill valve is connected somewhere else.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks for the replies. The static pressure is about 15 psi. So, should I bleed the 2nd floor valve and then manually add water to return static pressure to 15? Or, increase the circulator pump speed so that the Spiro is more likely to auto vent the air? ( also, as a side point, when the water heats up closer to 170 degrees, it seems like the trickling water sound diminishes). Manual fill valve is pictured below.

0 -

Do both. If you bleed a tiny amount out, no air for example at that bleeder, you probably do not need to add fill water. If you start bleeding a gallon or more to get all air purged out, then you may see a pressure drop, so add some fill.

The air, if in solution, may not all come out of that small bleeder. That is a "high point" bleeder, usually only needed at start up to catch air that rises to the high points in the system during a long off period, over the summer for example.

The Spiro really should clear 90% of ALL air within hours of all zones circulating.

Can you hear the air going across the Spiro? You shouldn't! That would indicate it is not removing the air. It does take a while to gather a big bubble in the Spiro, allowing the float to drop, then air should hiss for a few seconds or longer.

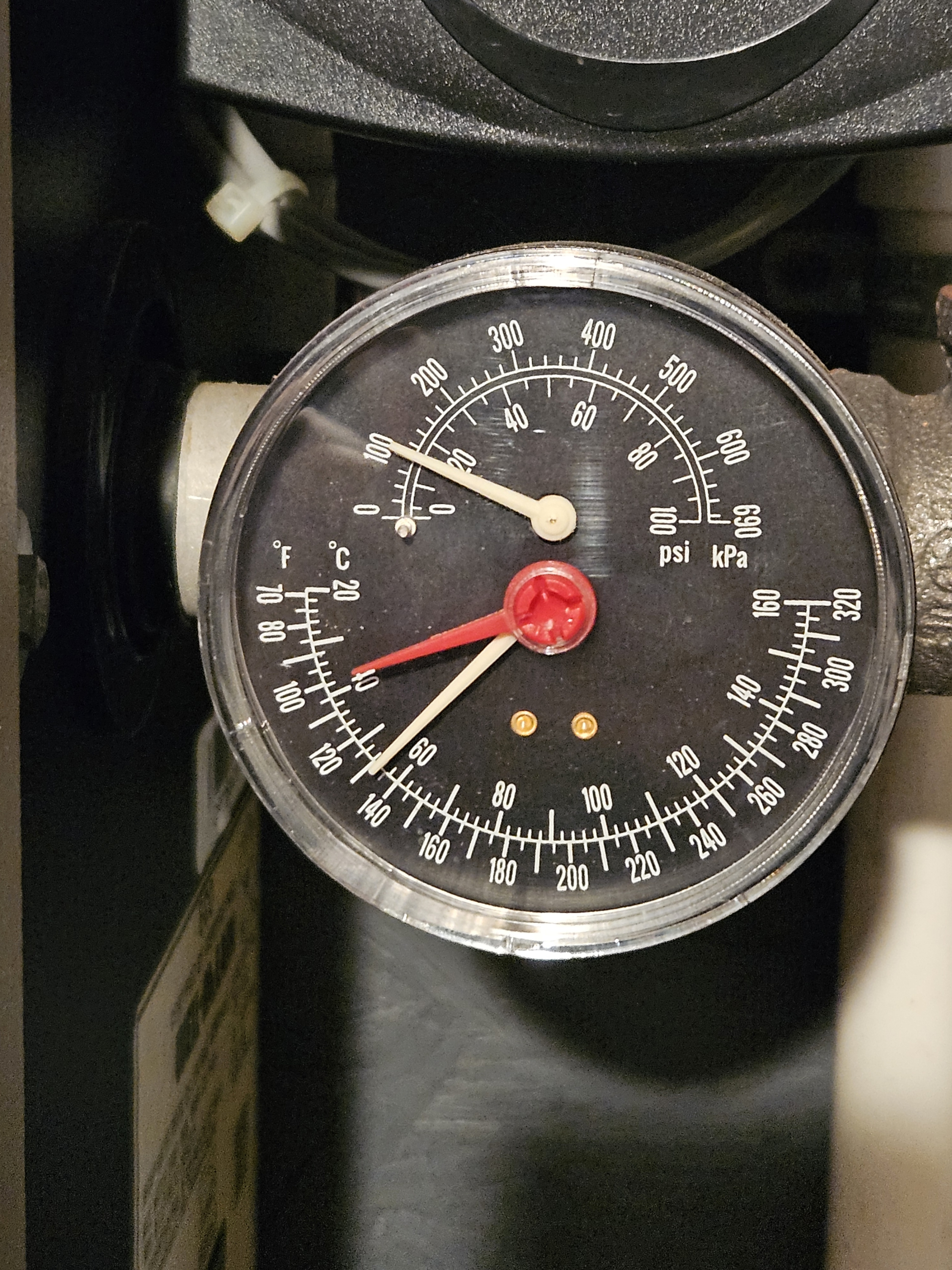

Another trick is to boost the boiler temperature for a few hours. The hotter the water the more it give up air.

It's about Henry Law, friends call him Hank :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

Keep in mind that if you open the coin vent and all you get is water it is not an air problem.

The other option would be to be sure the system is at 15 PSIG and simply turn your thermostat up and leave it alone for a few hours on speed one which works as well or better.

0 -

Yes, it is certainly above 15 psi. If it isn't air, what could it be? Also… and I know this is an amateur question, but should the heater be running/circulating or turned off when I open the bleeder valve upstairs?

0 -

A friend of mine had water hammer when his hot water baseboard system would come on so I helped him purge/flush that upstairs loop that was banging. The banging is gone but there is now a quiet trickling water sound from one of the baseboards. I assume there must be some air still in the the loop, but he doesn't have bleeder valves on his system so we just left it for now. I'm interested to see if you find a solution.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Is it possible since the system was worked on recently that some debris got into the piping?

What type of work was done ?

I had some small pebbles circulating in a system once, my fault, and they finally got stuck in the pump and broke the shaft

It was more like a light tapping sound, and it moved throughout the piping.

Sometimes you can increase the fill pressure for period of time to get problematic air out, maybe 20-22 psi

The higher pressure squeezes the air bubbles smaller so they go along with the flow better

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Usually the coin air vent at the top of the system will work if the pump is operating or if the pump is off. So you can try it either way. There are some instances where operating the pump is better and other instances where operating the pump is problematic. Every system is different. Example below:

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

The small air pocket could be elsewhere in the system, copper tube transmits noise very well

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements