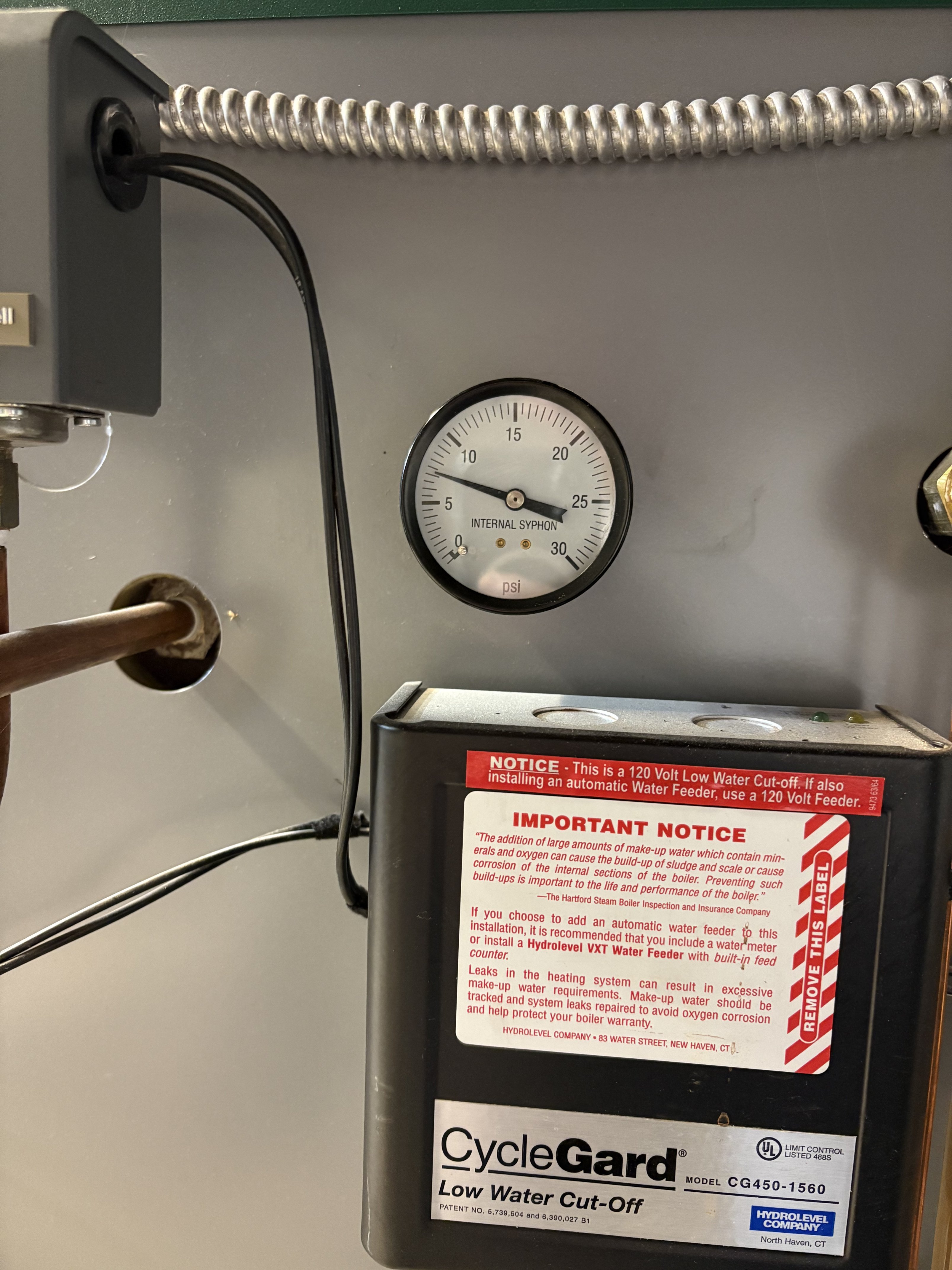

2 Pipe Steam Boiler Pressure Reading 8psi

So the gauge on the boiler gets all the way up to the 7.5 to 8 psi point. Pressure -trol set to the lowest setting. Out in the house every scenario is going on. Some max hot all the way across, some hot about 1/3 across, these are the supper long ones in living room, some hot up to the valve on the radiator and that’s it, nothing into the radiator at all. Boiler seems to go off when thermostat is satisfied.

New main vent installed on one side and two on the other side are fairly new.

Suggestions?

Comments

-

oh…the pressure reads at 1.5 psi before the call for heat.

0 -

Good heavens. Where to begin.

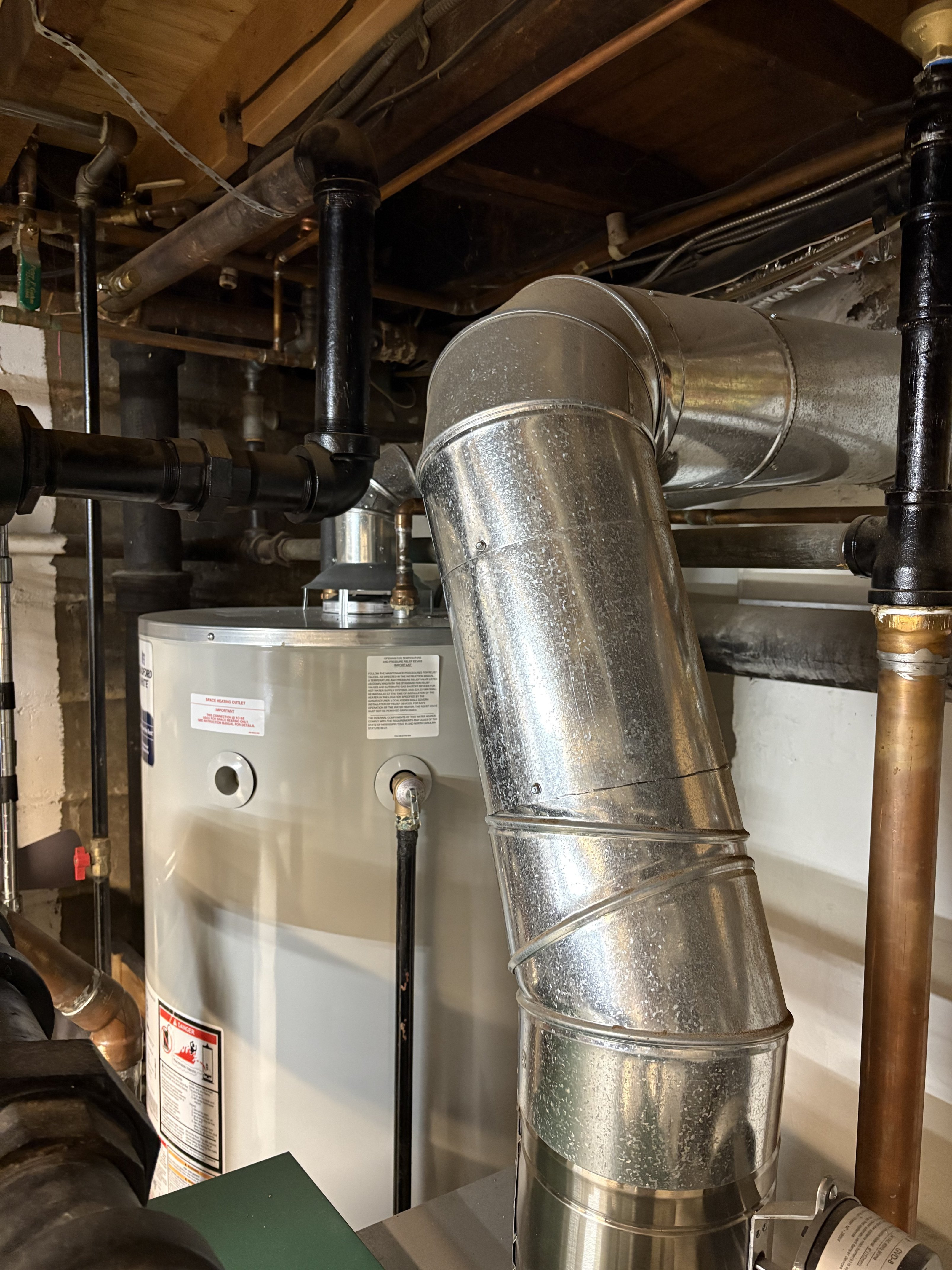

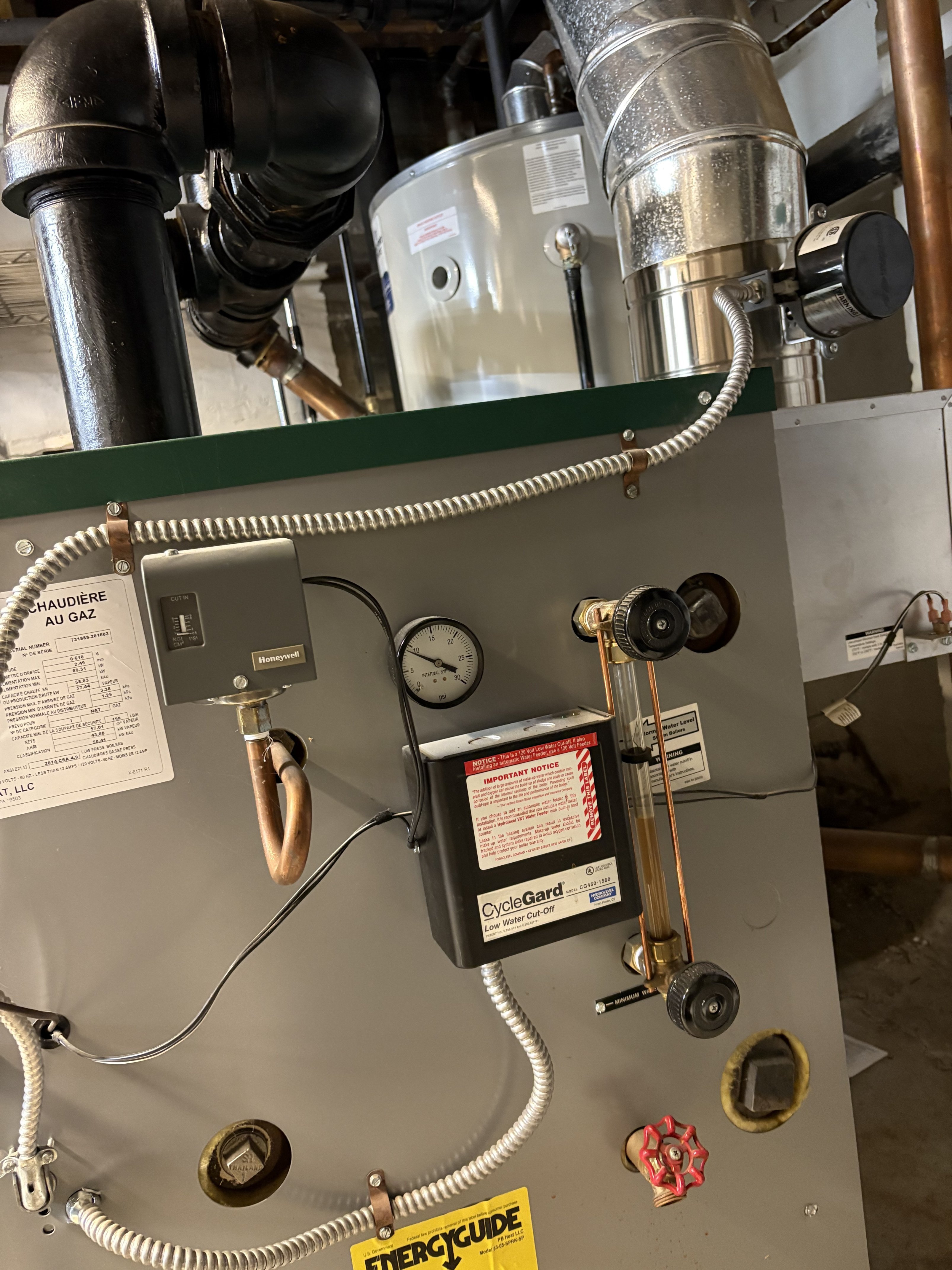

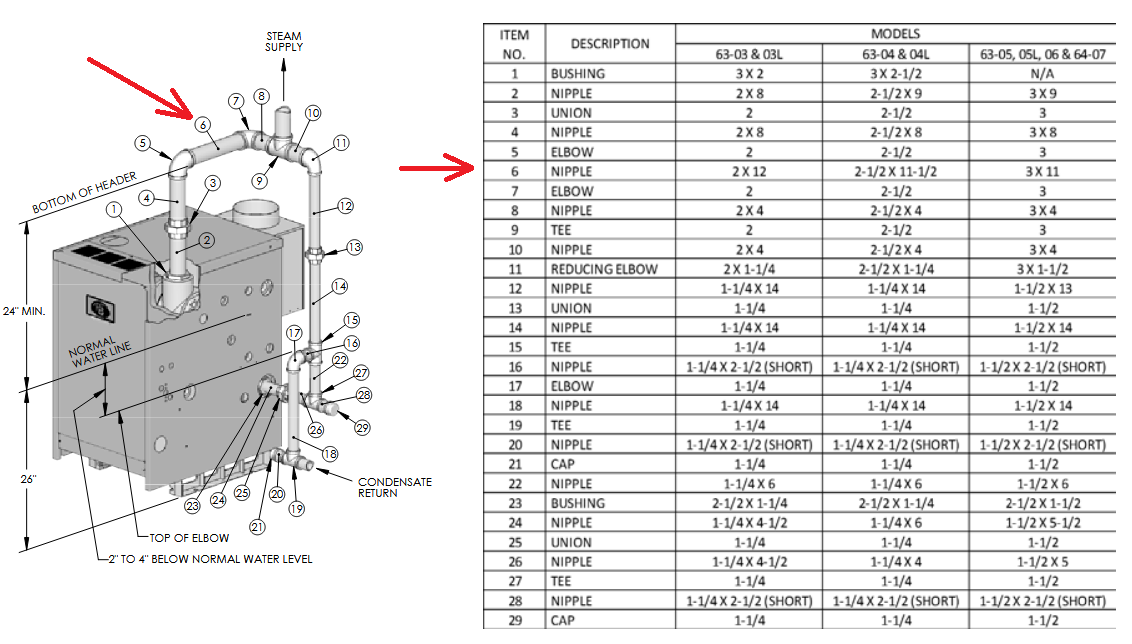

Well, the good news. The boiler seems to be piped correctly. Header might be a bit low, but it's OK.

Except I don't see where the dry returns tie in or how they are vented.

Now.

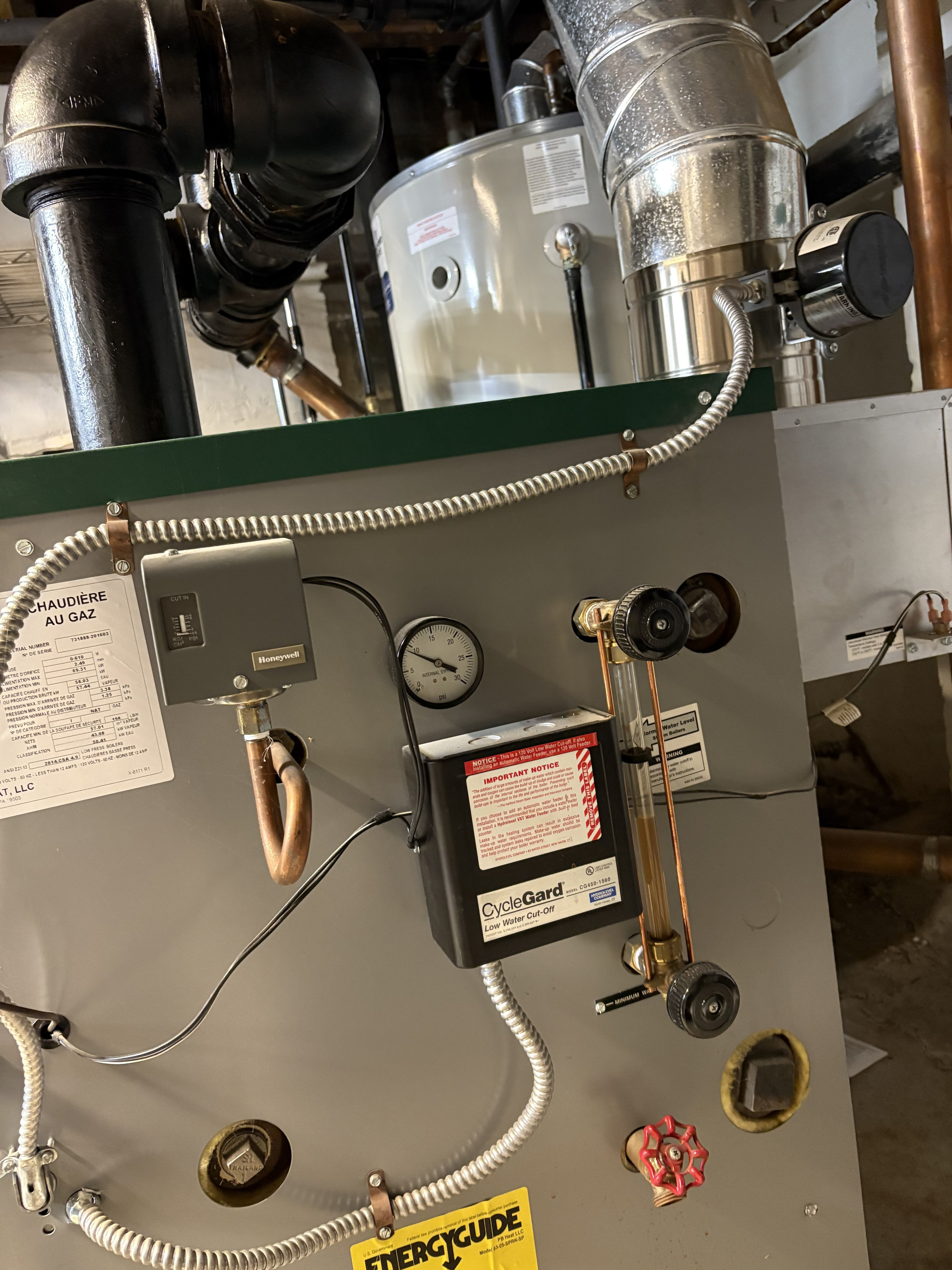

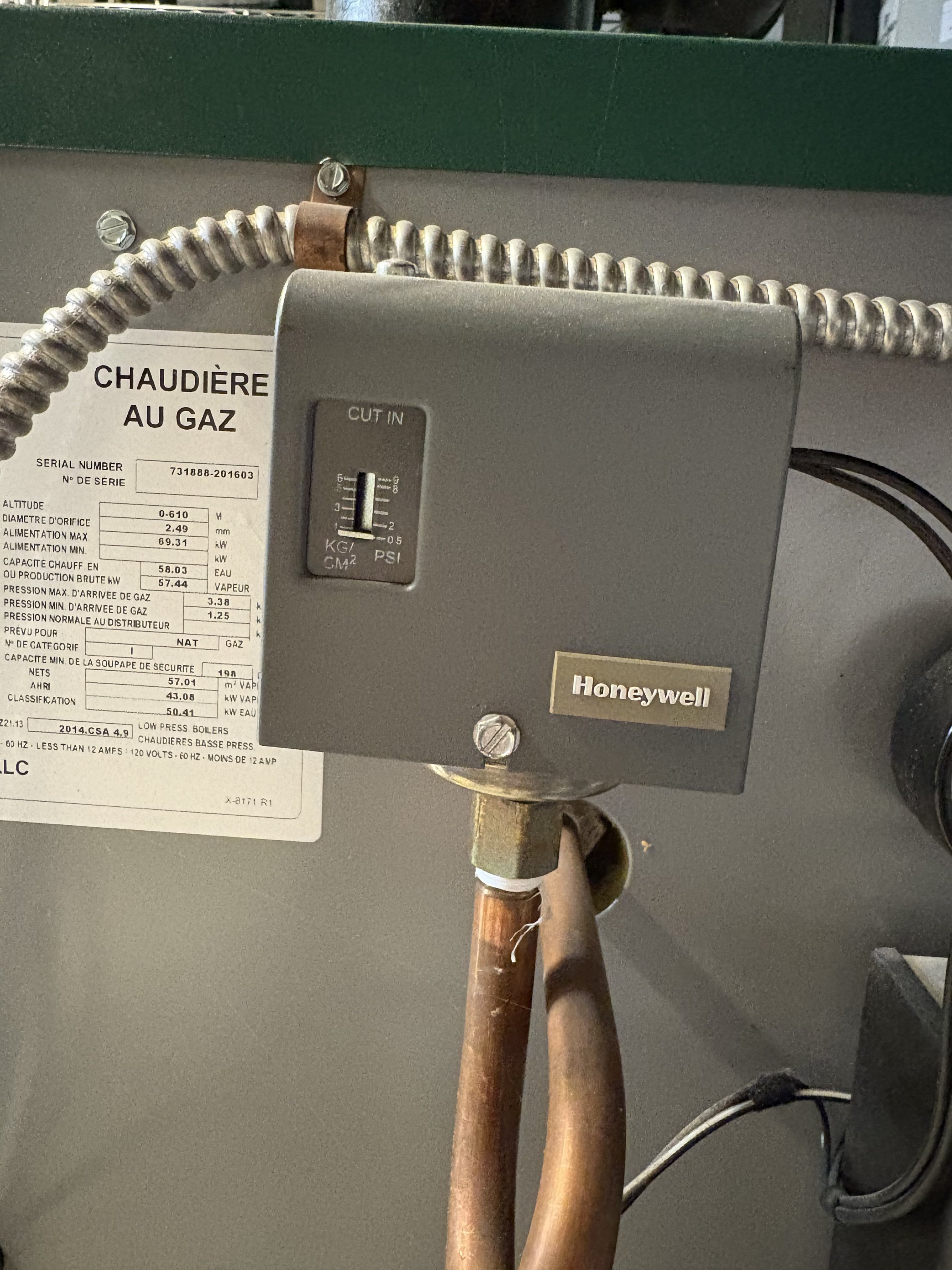

Pressure. Those standard gauges are known to be inaccurate, so I have to ask: what does it read with the boiler cold? It's unlikely to be that inaccurate, however, so the pressure is way too high — at least 5 times what it sh9uld be. Which brings up the pressure control, which I presume is the grey box just out of the picture showing the pressure gauge. What is it set at? That looks like a standard additve type, so the pressure setting on the front should be around 0.6 or so, and the differential wheel inside. If that is the case — and you say it is set at the lowest setting, which is what that would be — it is likely that the pigtail connection to the boiler is clogged. Check the pigtail. If that is not the case — try resetting it correctly.

Now the bad news. If the pressure is anything like what you see, the odds are good that all the radiator traps are damaged and will need new elements. The ones that are hot up to the valve and not beyond — the valve is shut. See if you can open the valves. If not…

That's for starters…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

You could just have a bad gauge. Pictures will help.

I would suggest the first step would be to shut the boiler down and take the pressure gauge and pigtail and pressure control(s) off the boiler and inspect and clean them (especially the pigtail) and all the pipe and nipples connecting those parts and into the boiler. Replace gauge if needed then reassemble.

1 -

Those radiators that stop with the heat right at the valve are definitely twisted to the max opening….maybe the valve is not opening? The radiators getting hot only partially across are bad traps we figure?

Also after cycle is done , and the pressure is at 7psi, should the pressure relief valve if manually opened relieve the pressure?

0 -

-

The radiator trap elements are going to be in the out flow 90?

0 -

-

I would suspect a bad pressure gauge. But the pigtail on the pressure control should be checked.

0 -

Since it appear there are no thermostatic radiator traps on the return side, maybe there is an orifice in there or in the supply side of the radiator or the valve type is the limiting factor. The radiators that heat all the way across are probably letting steam into the returns closing the vents trapping air in the system, so the other radiators don't heat or heat poorly.

The risers #2 & #4 probably should be taller. More of an issue with two risers, and probably won't fix anything obvious but #6 is way too short reducing the flex in the header assembly.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

FWIW……….I appear to have the same boiler, or a model close to the one you have. Going back a few months, my gauge was reading (ironically) 8 psi. System worked fine, except for the high pressure reading showing on the 0-30 gauge.

Turns out the gauge was stuck in that position, and the pigtail was clogged. I put in a new pigtail for the 0-30 PSI gauge and a new 0-30 gauge, and added in an additional pigtail at a secondary port with a 0-5 PSI gauge. Everything appears to be functioning properly now.

My guess is your gauge is stuck, and the pigtail may also be clogged.

0 -

I should probably clarify my response……..I ended up putting a pigtail on the outlet port where the 0-30 PSI gauge was directly mounted to the boiler (as you have yours currently mounted). 0-30 PSI gauge is now mounted to a pigtail.

I also replaced what was a clogged pigtail to the pressure sensing mechanism. At the same time I branched off that pigtail and added in a 0-5 PSI gauge.

0 -

To clarify, gauge starts at 1.5psi. When call for heat starts up the boiler and steam is created and with in a minute the pressure starts increasing and settling in around 8psi. Pressurtrol is set at the lowest setting but is not working clearly, as the boiler keeps the fire going until the thermostat is statisfied. So…yes, cleaning the pigtail amd piping to the pressurtrol is top priority. But question remains, why the build up of pressure? Radiator valves broken closed a possibility? Brand new steam main vents. There are no steam traps at the radiators. Only steam valves on the supply and union 90s on the return. Both directions on the main supply have some radiators with heat all the way across, others with no heat getting passed what looks like and twisted like an open supply valve, others with heat only 1/3 the way across. And these scenarios are on any of the three floors.

0 -

But question remains, why the build up of pressure?

More steam is being produced than is being condensed back to water. Oversized boiler is the typical reason.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

What main vents do you have on this thing? I know they are new, but what are they? And where are they?

How are the dry returns separated from the steam mains? Is there any connection at all?

Are the dry returns vented?

Do the dry returns get steam hot? Warm?

Those may — or may not — be plain vanilla elbows. Some vapour systems used special elbows which did a pretty decent job of letting air and condensate out, but not steam.

And… I'm beginning to think that may be a vapour steam system which has many problems… which will take some effort to disentangle. I presume that you have a copy to The Lost Art of Steam Heating? If not, you need one…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Just put another gauge on the boiler to test the one you have befor you go crazy loking for problems. You start troubleshooting by checking the easiest things first not shooting the parts cannon.

To clarify, gauge starts at 1.5psi. When call for heat starts up the boiler and steam is created and with in a minute the pressure starts increasing and settling in around 8psi

Building pressure in a minute doesn't make sense. How long to get to 8 psi???

0 -

From when it sounds like the boiler has started steaming, about 8-10 min to get to 8psi.

0 -

Ah. I misunderstood. That sounds suspiciously like inadequate main venting — though i still think you have other problems as well.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I am thinking what I called main vents are the dry return vents. See pictures. Picture with the copper pipes are self explanatory. The boiler pressure gauge does eventually go back to 1.5psi, but after about two hours. ???NEW QUESTION: SHOULD THE P&T RELIEF VALVE WHEN MANUALLY OPENED RELEASE BOILER PRESSURE????

The dry returns don’t get warm. The dry returns are connected at the end of the steam mains at the bottom of a drop along the wall below the water level. See pictures.

0 -

Forward progress! Those dry return vents belong — they are what actually vent the radiators. What may be missing is a way to vent the mains. In many low pressure systems, the mains vented into the dry returns with crossover traps, but I don't see those in the photos (they might be there anyway) — so you may need to add main vents on the mains. Without looking at the whole system, I wouldn't care to say for sure — nor be able to suggest where they might go.

This is also suggested by your observation that the pressure takes a while to drop when boiler shuts off. No venting to speak of.

In answer to your bold question — yes, lifting the pressure relief valve should release boiler pressure.

And your pressure is still much too high in any case.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

did you check, clean, and clear the pigtail yet? and blow thru it back into the boiler? it needs to be free breathing,

remove the gage and see that its port is open and clear to inside also,

known to beat dead horses0 -

The main steam vent pipe at the end going down the wall and connecting to the dry vent below the water line in the boiler….what is that supposed to do?

0 -

that deep, condensate filled, loop should be stopping steam in the main from getting into the dry return,

but 8 psi may be blowing it thru,

concentrate on the gage, and if you have that pressure or not

known to beat dead horses0 -

differential loop would be my guess, it is there to equalize the mains and the returns and keep a maximum pressure differential set by the depth of that loop. I can't see anything else it would do unless there was a wet return that was removed.

0 -

Those loops filled with condensate — the water sat at the level of the dry return on that side, and was pushed down by the pressure of the steam on the steam side. Worked just fine — so long as the pressure wasn't too high.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Jamie Hall, if the condensate side filled with water on these deep loops, where is the air going that was in the steam main? The pressure of the steam behind the air would force just enough water down to let the air process down the dry return main toward the boiler?

0 -

Nelic- same question. The deep loop would be filled with condensate by now. But would the air trying to get out of the way be stopped by the water too?

0 -

air or steam would be held back at that loop, at low pressure,

but if you're running up to 8psi, you're likely blowing the condensate out of the loop

seem's you need a vent, or @Jamie Hall 's crossover trap there,

known to beat dead horses0 -

You need venting on the steam side of the loop

0 -

Indeed the air would not get out but… in many vapour systems, which used the water seals, there was a crossover trap as part of the game. This was a pretty standard radiator trap, but was mounted Above the main — typicaly a short nipple up, then a 90 and a nipple over to the inlet of the trap. The trap was usually directly above the return, and the outlet connected to the return with an appropriate nipple.

Presto. Until steam got there, trap was wide open and acted like a very big vent (the Barnes & Jones Big Mouth is, in fact, a radiator trap modified). When steam hit the trap it closed. Thus the trap vented the main.

The beauty of all this was that the only vents needed could be placed at the boiler, where the dry returns came together before dropping to the boiler inlet — and, in many vapour systems which controlled the differentia pressure between the mains and the returns those vents were part of that.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

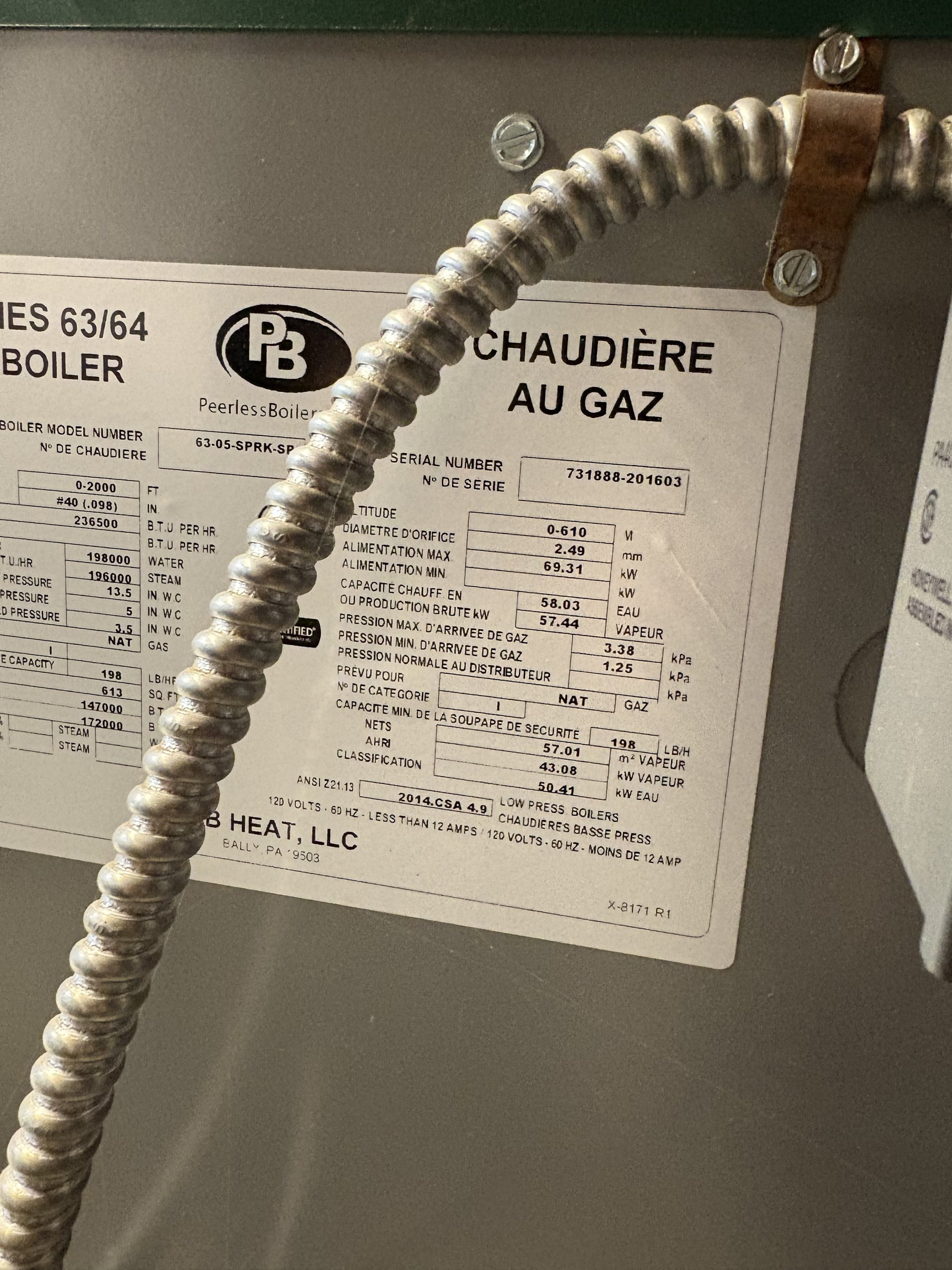

Given that everything looks pretty shiny new, I'm going to guess a new boiler? If so, or even if not, you could be suffering from bad water driven carryover. My previously docile system went nuts with the new Peerless boiler. I would strongly suggest a dose of Hercules Boiler Cleaner. It claims to stop priming and surging and sure worked for me. Nothing short of miraculous. And if it doesn't fix your woes, at least she'll be cleaner than before.

Steward to 1923 Spanish revival near Chicago - 2 pipe steam 650 EDR shiny new Peerless 63-06

0 -

Off topic but your floors looks identical to mine. Century house in PA.

0 -

Your main gauge is broken. Change it.

Check the pigtail to your pressuretrol, if not cloged it could be the ptrol

Preasuretrols often are badly calibrated at the factory. Look up "Silent Steam Heat" on youtube - he has plenty of videos that show how to fix it.

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements