Modulating low pressure steam…

vaporstat would work for the on-off part but I am stymied trying to find a modulating control that operates on ounces.

3 million btu, two pipe vacuum system in 100+ year old building. Thanks for the time,

Jim

Comments

-

You have two things you are trying to control — or should be trying to control, with a vacuum system — which I presume is a two pipe system? One is the differential pressure between the dry returns and the steam mains. That is an essential control parameter, and one which is usually overlooked as in most two pipe systems the returns are at 0 gauge pressure (atmospheric). That diffeerential governs the operation, including balance and condensate return, of the entire system.

The other is the gauge pressure of either the steam mains or the dry returns (and in the case of a vacuum system, it would be the returns). That determines the boiling point and hence the power output of the radiation.

Vapourstats — and indeed most available pressure controls — are gauge pressure sensitive.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I might add — which of the two parameters — differential pressure oy system gauge — are you tryiing to control, and what device or devices (vacuum pump/level or boiler input power) are you controlling?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Thanks J Hall.

You are correct the first control turns it off at around 2 psi. I have a second control that feeds burner a 0-135 modulation signal. The issue there is I can’t set the modulation control accurate enough to keep boiler from cycling off since it’s a psi control.

If I was controlling to ounces which seems like it’s going to be a spendy control I could keep the boiler in equilibrium and not short cycle.

0 -

If your talking about a Honeywell series 90 modulating control the lowest setting is 0-15 psi. It is a series L91 control. They do not make them for vapor stat type pressures.

Best you could do is make the motor work as a two-position motor low fire or high fire easily done by wiring the motor through a vapor stat.

You would need 2 vapor stats. 1 to drive the motor from low to high and 1 set a bit higher to shut the burner down as a high limit. Be sure to keep any 0-15 psi control in the circuit to act as back up limits.

There are probably other ways you could modulate the mod motor by using a din process control and a pressure transducer. Would require more wiring and cost.

0 -

A minor correction to my previous remarks — it's absolute pressure, not gauge pressure, which determines the boiling point. Sorry…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

thanks again Jamie Hall. That would work as once the building is warm, low fire is a million BTU and should carry load. I could pull the R leg from the Modulating control with a second stat. The building hasn’t had steam for years so it’s a bit of a learning curve.

0 -

I would not pull the Red wire. If you do that the motor will not move. If you open the white wire from the modulating control the burner will drive to low fire but will still be able to go open and closed damper when the primary control drives it for purging.

0 -

Thanks, I meant the modulation part of the circuits “Red” wire. Still get purge etc…

0 -

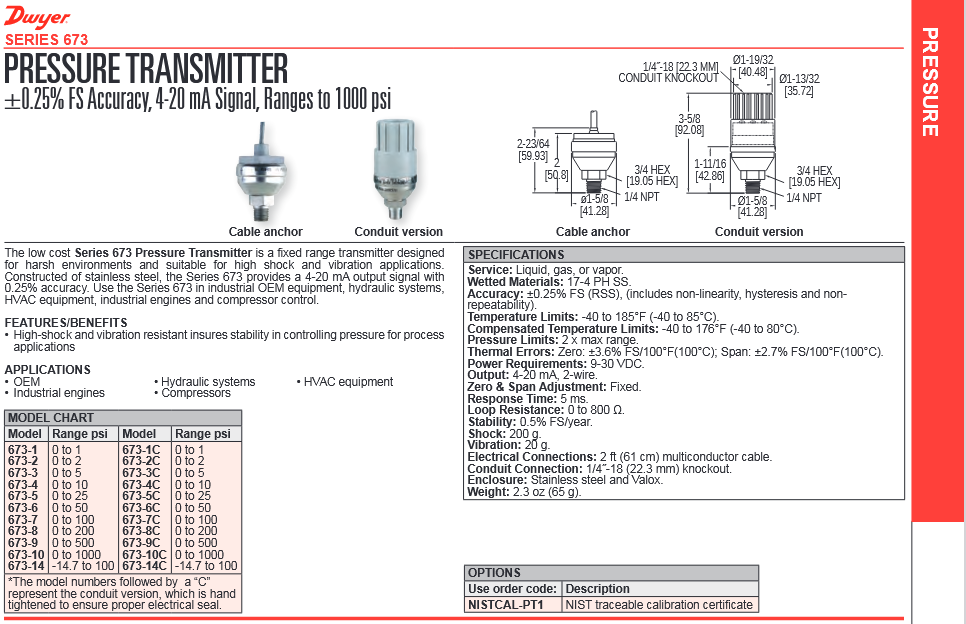

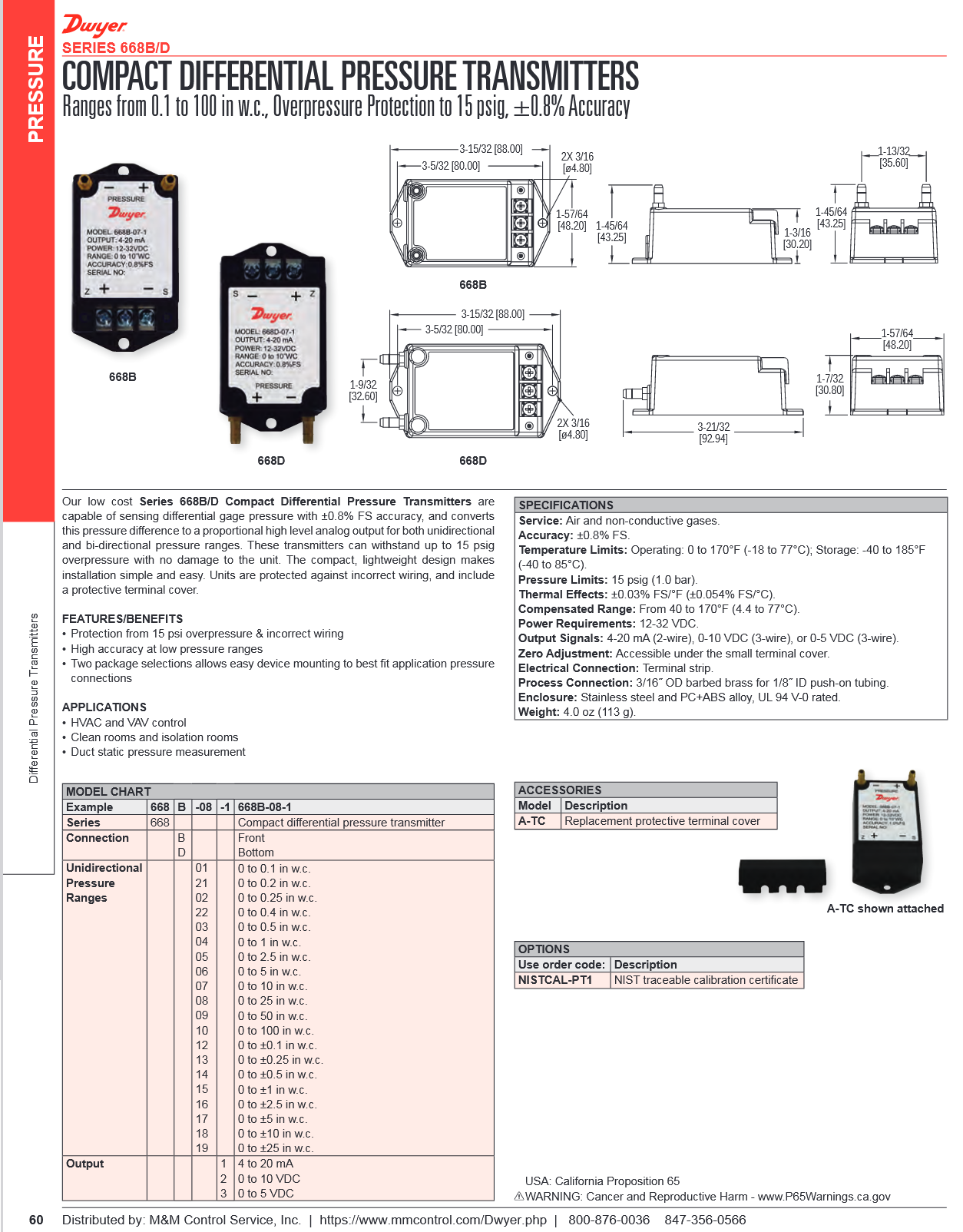

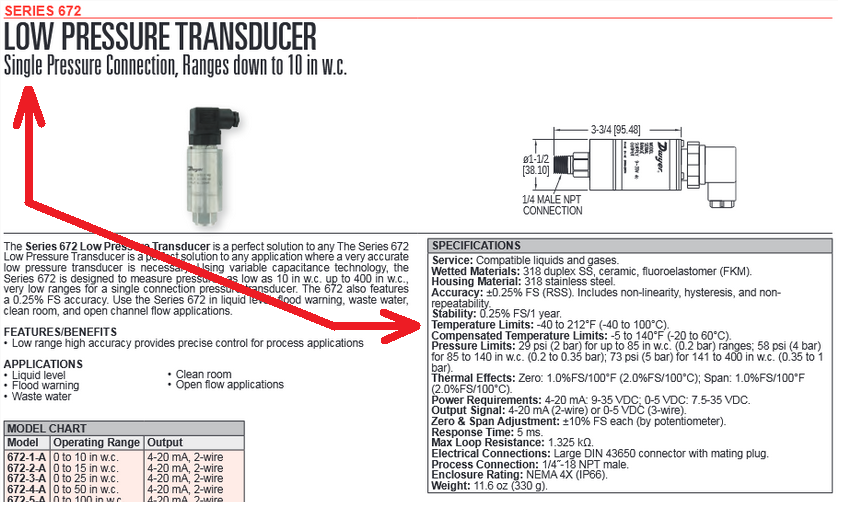

What about a low pressure sensor transducer that has an 4-20mA output then connect it to a Tekmar 005 or an ACI DRN3.1 or DRN4 to convert it to the 0-135 Ohms control ? The ACI products look like they have relay isolation to the output resistor network.

ACI DRN3.1 or DRN4:

PWM/Analog/Floating Point to Resistance Output, 0 to 135 Ohm Resistance Network, Plastic Enclosure

Tekmar 005:

The 0 - 135 ohm Converter 005 is designed to convert a 4 - 20 mA modulating signal from a control to a 0 - 135 ohm resistance signal. It can be used in applications where a modulating boiler control is used to operate a boiler that requires a 0 - 135 ohm signal.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Look to the Dwyer 1823 series of low pressure switches. You can easily wire one of these into a timer relay module so that when the desired max pressure is hit, it shuts down the boiler for a time specified by you.

Mine is set up to trigger at about 8 inches of water column to shut down for 10 minutes

I get all my Dwyer stuff from ebay because it's very cheap and so well-built that used or open-box is fine:

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Is this really modulating or just high/low 2 stage?

0 -

FYI the ACI units on eBay that I looked at appeared not to have the resistor network installed.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

3 million input it could be lo-high fire or full modulation. That is why I asked but never got a clear answer.

at 3 million I would guess full modulation which would be a Honeywell series 90 135 ohm R<W>B potentometer.

Honeywell makes the L91 controls but they are 0-15 psi (or higher) not lower. that is why I mantioned another type of controller but that is $$.

You could make it lo-high fire with just a vaporstat

0 -

sorry on a different Job today and WestCoast to boot.

Boiler is full modulation but old school with a 0-135 Mod. Signal. Not I high turndown burner, slightly better than 3-1.

1095A_5 had some good info, but I think the sensor might not like 210+ degrees.

My first idea was to find a 4-20 sensor and use a RWF55, but Siemens versions lowest is 0-15 psi.

The conversion module is also a great idea if I can find a low range sensor maybe 0-5 since we still don’t know where the sweet spot for the building is.

the timers are also a good idea as once all the radiators are hot you could set an on delay.Right now they have traps blowing by and dirty water so I have some time to ponder.

Thanks Guys for all you do”….

0 -

you could make it low and medium fire by putting a pot on the second vaporstat. it maybe never needs high fire or only needs it for the first couple minutes until the boiler gets hot

0 -

" but I think the sensor might not like 210+ degrees. "

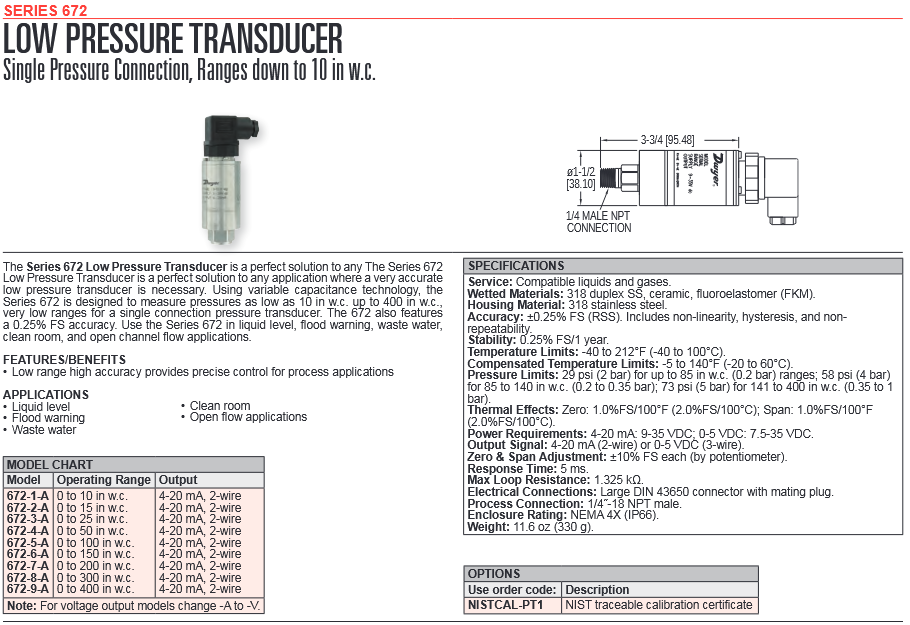

The sensor is for pressure, not steam temperature. Why would it have to be exposed to 210+ degrees ??? Although the Series 672 tops out at 212F, why would you do it that way ?

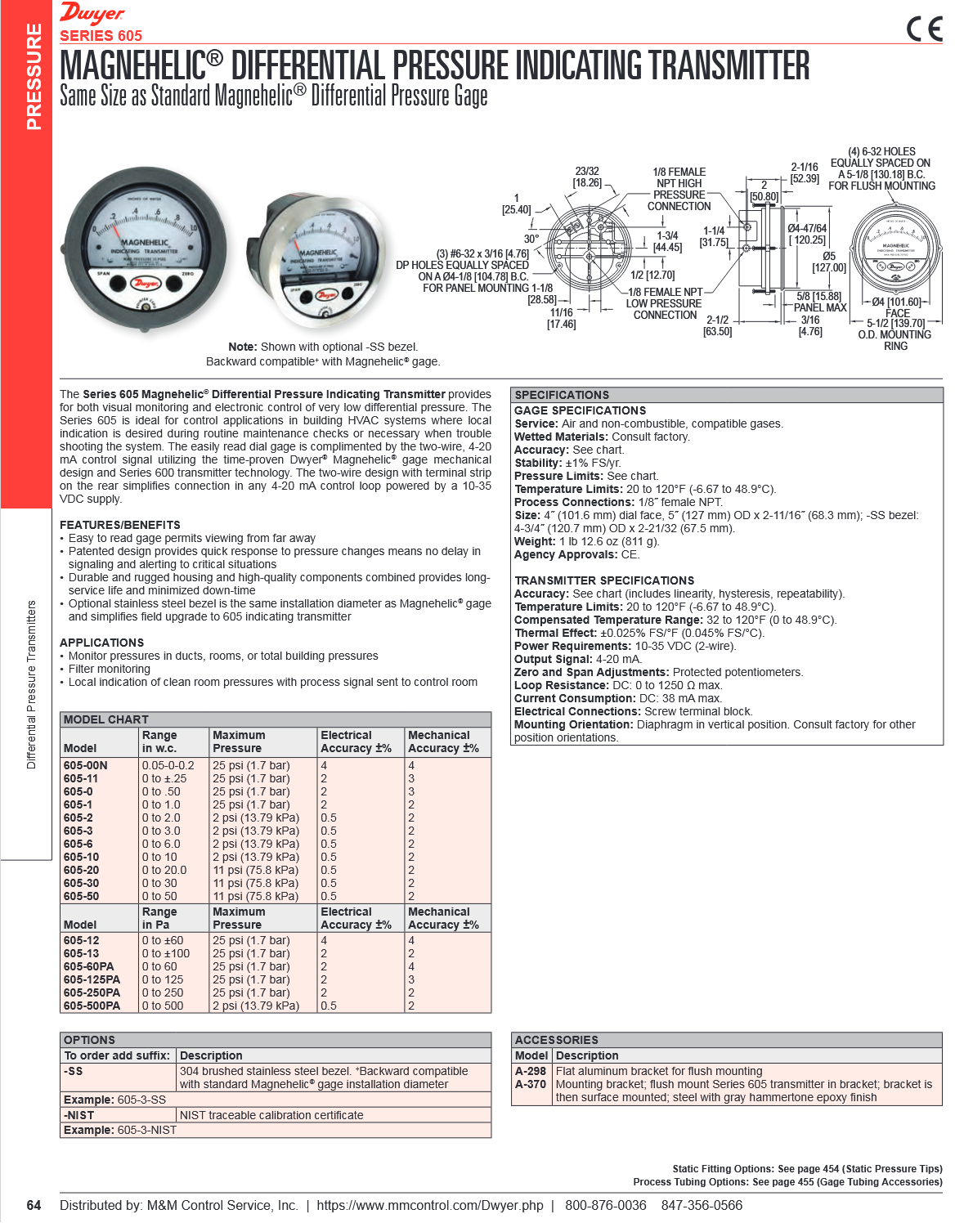

My Magnehelics are at room temperature.

The beauty of 4-20mA is it is easy to measure and generate, you could connect a manual variable 4-20mA generator to find the sweet spot.

" low range sensor maybe 0-5 since we still don’t know where the sweet spot for the building is. "

0-5 what ??? PSI, inches of water column, Oz ? The sensors above have plenty of range, but you need to pick the correct one.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Thanks again, your right about the sensor, it will be on a pigtail so that will not see the temperature of the steam.

I want to control on the ounces side to get long cycles.

0 -

So 0 to 5 Oz which would be 0 to 8.65 Inches of Water Column.

Many of the low pressure sensors are rated in Inches of Water Column so it helps to think in Inches of Water Column instead of other units of measure.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements