24 Volt transformer blowing

I've got a question as to why my customers transformer keeps letting out the factory smoke.Customer called about his 16 year old Burnham Alpine 150. Display screen black, no power light on Sage control, and blower just running full out. Tested the transformer and had no 24 volts, I did have 122 on the line voltage side. So I decided the x-former just gave up the ghost after so many years. Not uncommon given its age. Replaced the x-former with an OEM Burnham one and it immediately blew it, no 24v again. Spoke with my rep and with tech support and it was agreed that there must be a short in the Sage board. Was advised to replace board and display panel because old displays are not always compatible with new controls, and if course a new x-former. After the swap I powered the boiler, fan came on as it should, and then plugged in the 24 v side of the x-former (the boiler service switch is at the top of the basement stairs and none at the boiler, I wanted to be at the boiler when low voltage was applied) There was no display and no power light on the board so I immediately unplugged the 24 v side to put my meter probes into the molex to check it. Now this is weird AFTER I unplugged it and before I got my test leads in I hear POP and the x-former smoked! I got my rep coming out Mondayorning but ant input? 122 volts into the x-former, 122 from black to white, 122 from black to ground, nothing from white to ground (in case I was getting stray voltage on neutral) nothing back feeding from the Taco relay end switch. I'm perplexed! Anyone?

Comments

-

Theres a low voltage short somewhere.

0 -

-

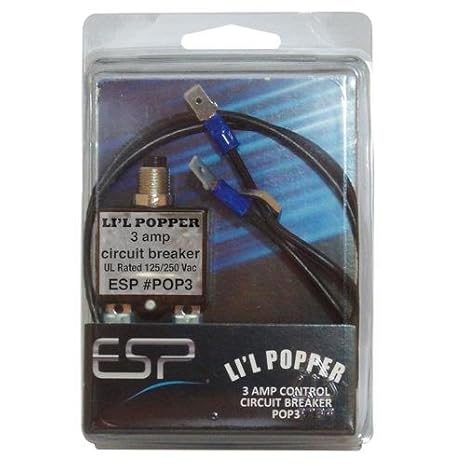

Or 5 amp circuit breaker with leads — try the auo parts store.

There's a short somewhere — but not necessarily in the board.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

another trick is to put a 24v lamp in series with the xfrmr secondary, it will limit the current so you can look for the short without blowing the fuse.

0 -

The simple Pro Short Tool works well for this.

0 -

Transformers aren't cheap. Try this: Should be in everyone's toolbox.

2 -

-

-

can you explain the sequence and the process for using these to find low voltage shorts? Totally unfamiliar. Thanks.

0 -

-

Or a fuse can be wired across a control to work as a tattle tale. Just make sure the fuse is rated a lot lower than the amp draw on the circuit or you will be jumping out a control

0 -

There are many techniques to find a short circuit. Focusing on mostly one here. IMO the best way is not to accumulate burned up transformers and/or blown fuses if the circuit has a fuse or if a fuse has been added.

I would find the Li'L Popper very annoying, since it requires constant resetting, it is just an appropriately sized circuit breaker with convenient wires and wire terminations added. But it is better than accumulating burned up transformers and blown fuses. I have not used the LED device so I have no comment about it.

The oldest but probably most forgotten method is to put an incandescent lamp (tungsten filament) in series with one side of the transformer's secondary wires (a lamp on the transformer's primary side may work too but you have the transformer's properties that may muddy up the technique a bit.)

The incandescent lamp technique, commonly called a Dim Lamp test or Dim Bulb test (look on YouTube) has to be set up correctly to be most effective. And this means the incandescent lamp(s) need to be sized correctly. The lamp need to be the same voltage as the circuit under test. Also the load current of the lamp should be in the ball park of what the transformer can safely source.

So for example if the 24 VAC transformer is rated at 40 VA the lamp should be in the 40 Watt ballpark or a bit less. The lamp provides a maximum safe load for the transformer and any fuses in the circuit. So no more burned up transformers or blown fuses. Two 12 volt lamps in series can be used too.

The benefits: No more burned up transformers, blown fuses, it is self resetting, provides good visual indication of the circuit status providing diagnostic information.

The down sides: 24 Volt lamps are more rare, incandescent lamps are more fragile, you would probably have to build the tester.

Using this technique I have founds shorts in seconds where others have failed using other methods (the looks on their faces were priceless).

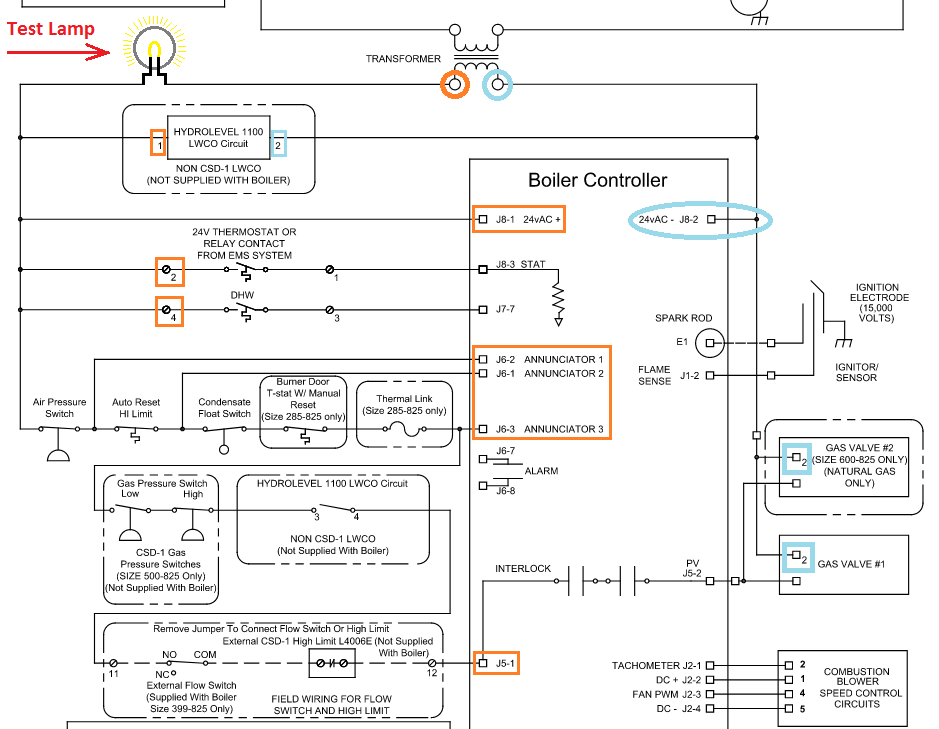

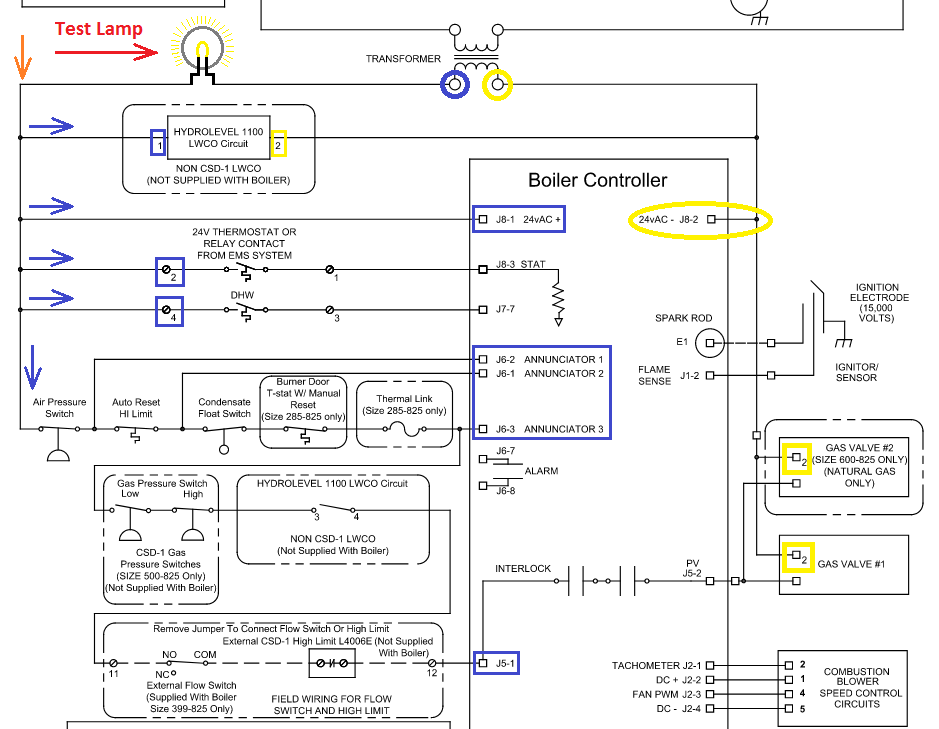

In this situation it appears the Orange and Blue annotations are shorted together somewhere. With the test lamp in circuit it will be bright until the short is removed, then it will get dim. Often the circuit will actually work with the dim lamp in circuit (the short has been repaired obviously). In this case the Orange or Blue annotations can be disconnected one at a time to locate the part of the circuit that is defective. Also if there are crushed or chaffed wires the lamp may help identify where they are with the self resetting ability and the good visual indication. Also although not shown here one side if the transformer's secondary may be bonded to ground and/or the jacket of the heating equipment.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Sure Doctor!

Low voltage shorts with Pro Short Tool:https://www.youtube.com/@dennismitchell9689 (3 videos)

Testing for LIne Voltage Shorts:

Or, if you have an old edison based fused box, you can screw a 100 watt light bulb right into it, then work your way (carefully) disconnecting wires until the light goes out. If you have breakers, you can put a bulb on a pig tail in series right off the breaker, then work the wires.

The light comes on because you have a short, the 100 watts is current limiting the breaker from tripping.

But you are working on live wires with 1 amp in the circuit. The video method for line voltage is 'safer'-ish because you are using your meter and not handling live wires, as much.1 -

I hope @BruceSteinberg looks at this discussion before he buys anymore transformers.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

So do I. If you want some videos of two real pros playing with test lights, go watch South Main Auto or Pine Hollow Auto Diagnostics. If you think the stuff we play with here gets complicated, watch trying to find a misbehaving circuit in a modern car…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England3 -

-

Picked up a resettable Circuit breaker like a Lil popper but let me see if I got this. I put a 24V light in line, series if you will, on the red coming out of the x-former. Since there is a short it'll bring common side back to the light but not blow the x-former because power is being consumed by the light. Start disconnecting whatever is using 24V and reconnect if the light stays on but if the light goes out I've found my short? Anything else I need to consider?

0 -

more or less. it will be more difficult if it is intermittent or if it is something that gets switched on at some point in the cycle. the light limits the current to less than the rating of the fuse. if you chose a light that is close to the va rating of the transformer the system will probably still operate if it needs to get part way in the cycle to turn on whatever is shorted.

0 -

That sounds like you understand the process.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

That's about it. However " because power is being consumed by the light ", the light limits the power that can be drawn from the transformer to a safe amount even though the original circuit has a short circuit.

The short circuit defect creates significant excessive current flow way exceeding the transformers rating so the transformer fails (it burns up). The lamp limits the current.

This technique leverages the difference between the Hot and Cold resistance of a tungsten filament.

Also keep in mind even with disconnecting one part of the circuit that part may branch out down stream into multiple paths and only one of those branches may be shorted. (The wiring diagram often helps) That is where the self resetting and visual indication is so beneficial. All you have to do is explore the circuit and not mess with resetting the test equipment with every test.

If you use the lamp and the Li'L Popper the Li'L Popper should never trip.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Use a popper like suggested so you can reset it. You could just leave it in the system added feature to your repair. start with using your amp meter, disconnect thermostat and wire. jumper the boiler with out them in the system. if you don't trip the popper. Then your problem is the wire ( which I've seen a lot) or tstat. That's were I start when It is not obvious. If those are good start taking low voltage components out of the equation, till you find the culprit. People remodel and hit tstat wires in the wall. They run the tstat wire over metal straps or housings that wear out the wire coating.

0 -

Use the popper, by breaking the 24v common to transformer. put it in line there and again I would just leave it for future issue. And save transformers and 3 amp fuses.

0 -

Well if your are going to leave a circuit breaker behind as @coby suggests I'd buy then from a vendor like Digikey or Mouser a lot less expensive.

I still say when wiggling wires I'd rather be looking at what I am doing than messing with an ammeter (that I can't see from across the room) or resetting circuit breakers. To me with using circuit breakers as a troubleshooting aid the logic is backwards and cumbersome.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Pro Short Tool (and others), from what I can find on-line, it seems usable there are a few different versions. The lack of published specifications does not help my enthusiasm. One thing I don't like is they seem slow, one states 5 to10 seconds to reset. Personally I like the fact you can see an incandescent lamp flicker and they are bright (with a short) not a little LED.

Pro Short Tool (and others) not sure what the current is limited to, with an incandescent lamp there is enough current that it can be traced with a clamp on Ammeter.

I guess what it comes down to is what you like and understand.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

the circuit breaker and the ballast lamp are for different types of shorts. the ballast lamp is for something you can reproduce ant possibly doesn't require proper operation of the circuit. the breaker is for more elusive problems where you might need to try different sequences of operation or force certain operating modes or possibly just wait and see what happens over time.

0 -

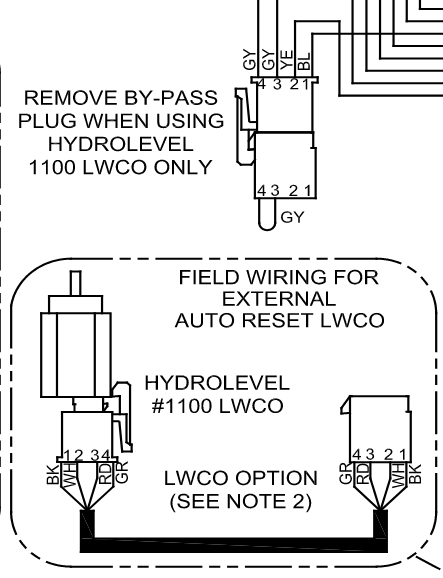

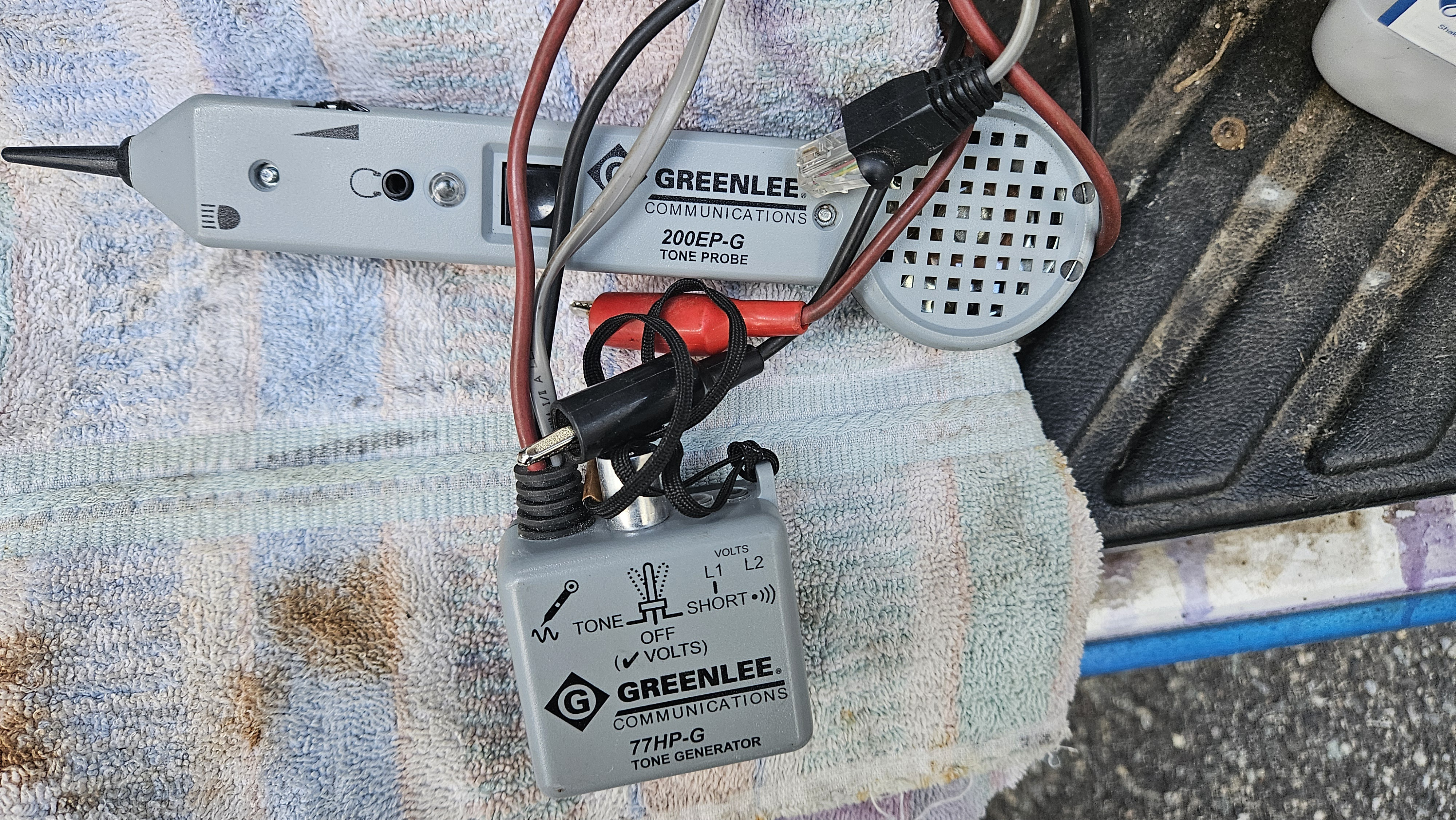

So here's what has transpiredup to this point. I was able to clget an inline resettable circuit breaker like the LittlePopper. And had it all set to go but then remembered that my tone generator has a short circuit setting on the transmitter box. Met the Burnham rep on the job, attached the short tester to the 24v plug on the boiler, blue and yellow on the molex, and sure enough beeeep, short somewhere. Not unexpected. We went over every inch of wiring, unplugged every sensor, control, device on the boiler and still short tone. I remembered from looking at the wiring diagram that the yellow, which is the common from the x-former has a connection to case ground. Snipped that wire and VOILA, no more beeeep. Now I test blue to case ground and beep again. Though not obvious anywhere there must be a broken insulation spot on the blue wire that is shorting to the case. Ordered new harnesses, both line and low voltage and will change them out. Unfortunately they're not a stock item anywhere and they factory told my supplier that it'll take up to 2 weeks! I told supplier to next day air it but Burnham factory is known to be super slow. 2 weeks is a long time to go without heat and hot water! I'll let you guys know the outcome. Thanks for all your input.

0 -

" Also although not shown here one side if the transformer's secondary may be bonded to ground and/or the jacket of the heating equipment. "

I did mention that.

If possible I never cut wires, since then you have to repair them, more work.

Lamp technique, I've never had to replace a whole harness in Anything, Ever. It simply may be a crushed, chafed wire to ground. The defect may not be in the harness either, thermostat wire crushed to ground, etc. And keep in mind the ground bonding may be through the Boiler Controller and the Boiler Controller may not be the problem just part of the path that connects ground to the low side of the transformer.

Just curious " tone generator has a short circuit setting " what is this piece of test equipment ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

As an example of a Beep Test (continuity test) with my work's Fluke 117 the beep test will activate up to about 68 Ohms and once activated it will not cease until the resistance rises to at least the 140 Ohms ballpark. In my opinion not the mode of that tool to be using to find a short that is burning up transformers. Way too much possibility of false positives.

Personally I don't like the wholesale change out of something like a wiring harness, too many variables, If you are not lucky you will have other issues when its done.

" We went over every inch of wiring, unplugged every sensor, control, device on the boiler and still short tone. " This seems impossible, unless you were getting false positives.

I hate asking this, you did disconnect the transformer's secondary from the wiring harness ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

See how this is taking way too long and now you want to change the harness. What if it is actually not the harness ?

There is 5 places to disconnect to give you troubleshooting direction, the 5 Blue arrows, one at a time. If the short still exists with all 5 places disconnected it is a defect with the wire from the transformer into the harness Orange arrow, a defect like that should be obvious with inspection. There is nothing else left, unless some one tapped into the system with some other device.

Once the path to the short is identified move on down that branch. This process is not hard or time consuming, but it has to be logical, strategic and methodical, using the correct test equipment helps too. Ambiguous testing leads to ambiguous results. Keep in mind disconnecting J8-1 also disconnects J8-3, so the thermostat wire (screw terminal 2) should be disconnected first to avoid confusion.

LWCO ? Could someone have put the connector together wrong shorting out the 24 VAC ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Transformer is not connected at all. All sensors and safety devices disconnected. LWCO 120V and the jumper was removed during testing procedures.

0 -

-

I hope your diagnosis works out for you, however I remain skeptical since in my mind you did not find the actual defect. I would think if you " went over every inch of wiring " the defect of a crushed, chafed or melted wire would be obvious.

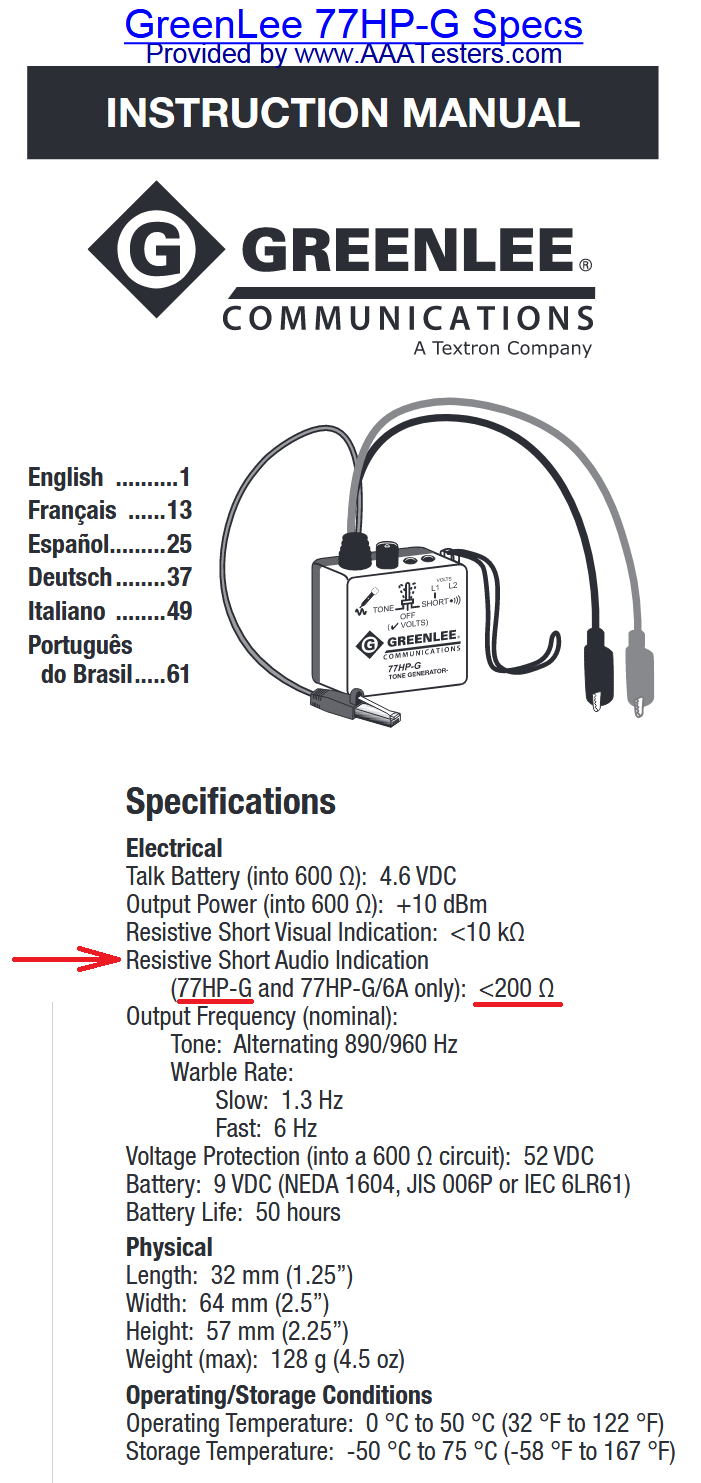

Thanks, got the picture of the " tone generator has a short circuit setting ". I figured that is what it was, just wanted to be sure. Here is my issue with that type of tester. Some manufactures call that functionality a continuity tester, yours and others call it a short tester. The intent (at least the original intent) of that type of equipment was to trace out and verify phone lines, not to help troubleshoot burning up transformers.

When you look at the specifications of that short tester it will alert with any continuity under 200 Ohms (see the image below). Well, for example if you have a 24 VAC 40 VA transformer at full load the load resistance would be about 14.4 Ohms. Since in this case the transformer immediately dies I suspect the fault load resistance is much lower.

The issue the way I see it is using that short tester it may be prone to false positives, since you can't tell the difference between 180 Ohm load, 14.4 Ohm load or a 1 Ohm load. False positives will have you replacing things that are not defective.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements