No air scoop

Ther are no air scops or vents on my 98 year old heating system. Can I use these to remove air for my heating system?

508013A - Caleffi 508013A - 1/8" Automatic Hygroscopic Air Vent

I have cast iron radiators.

Comments

-

Show us your expansion tank.

0 -

Please. Some systems do not have air scoops because they can't use them… an old system like yours may very well be such a system.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Regardless if you have an air elimination or air management system (compression tank) That vent could be used in radiators in the manual mode only.

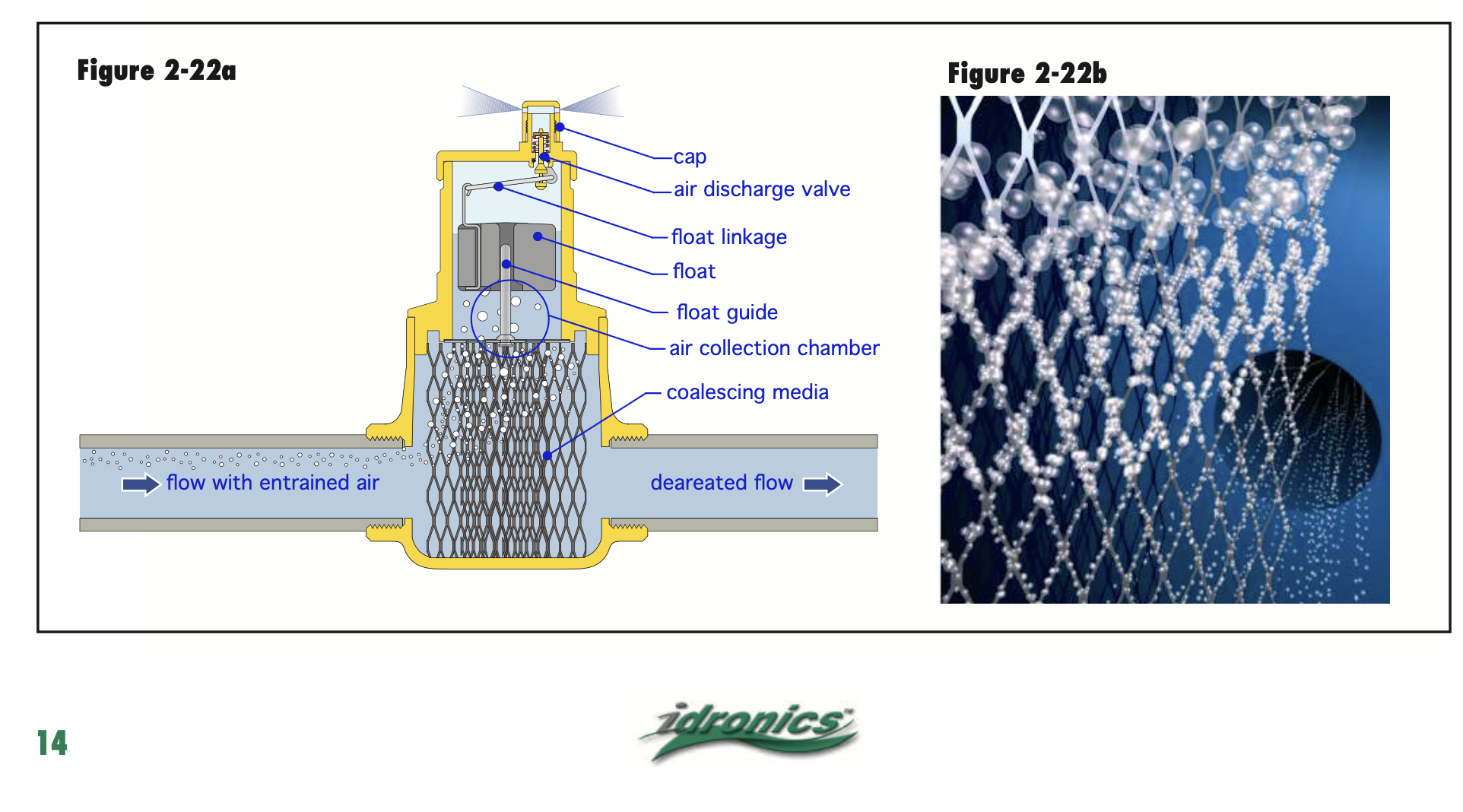

If you have a diaphragm type expansion tank, an air elimination type system, best option is an air purger at the boiler, in addition to a valve or vent on the radiators, the high point air eliminator. If you have a diaphragm tank those auto vents could be used in the automatic setting.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Why do you feel you need an air scoop?

As your system is 98 years old you may well have a gravity hot water system that uses the radiators as the point of no pressure change by holding an air charge in each radiator.

Please provide us with pictures of your entire heating system from the basement to the top floor and attic if you have an attic space.

Please take pictures of the boiler and all the boiler plumbing including the risers feeding ALL the radiators.

0 -

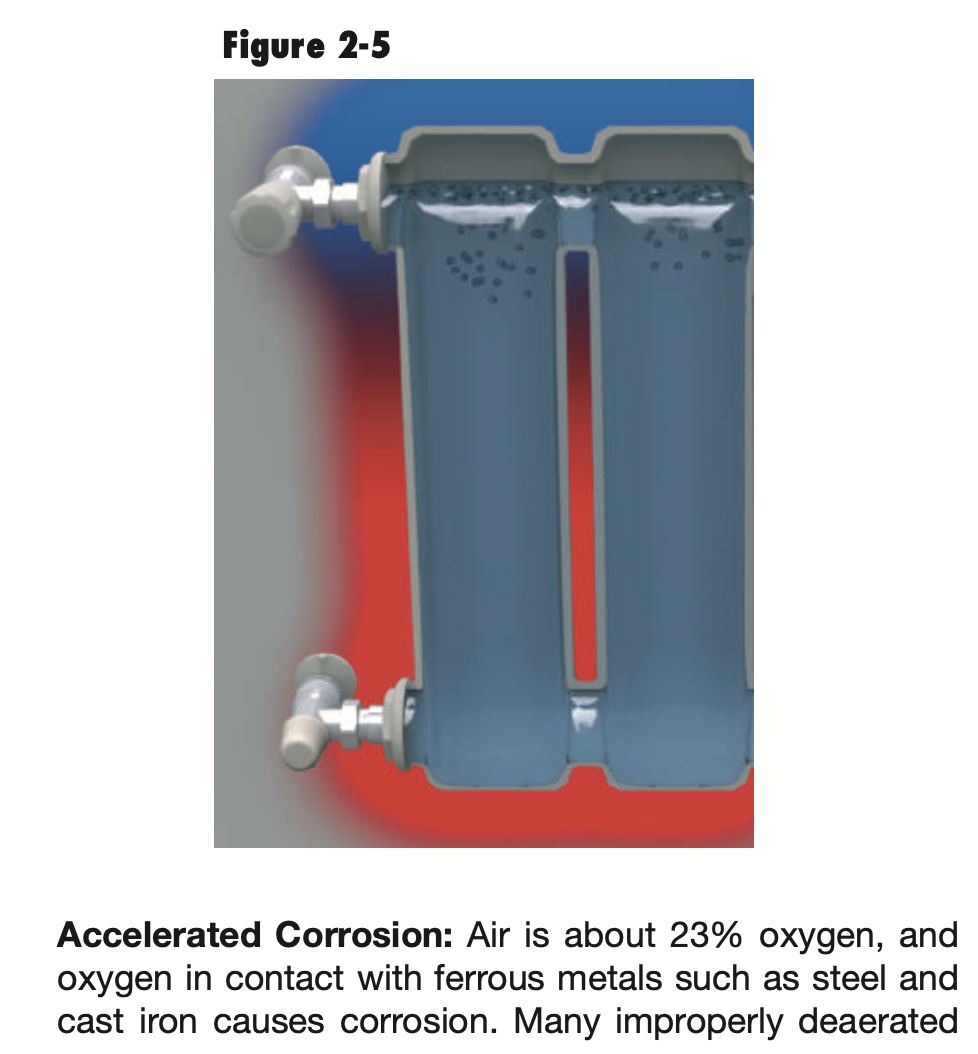

If it is a pumped system, even a converted gravity system and you hear air in the piping and boiler. An air elimination system is needed. Air in the piping, boiler, & radiation lessens the heat transfer, lowers efficiency, adds to corrosion potential. In some boiler designs it creates hot spots and shortens the boilers life expectancy.

Radiators in gravity systems acted as both air traps and the expansion space.

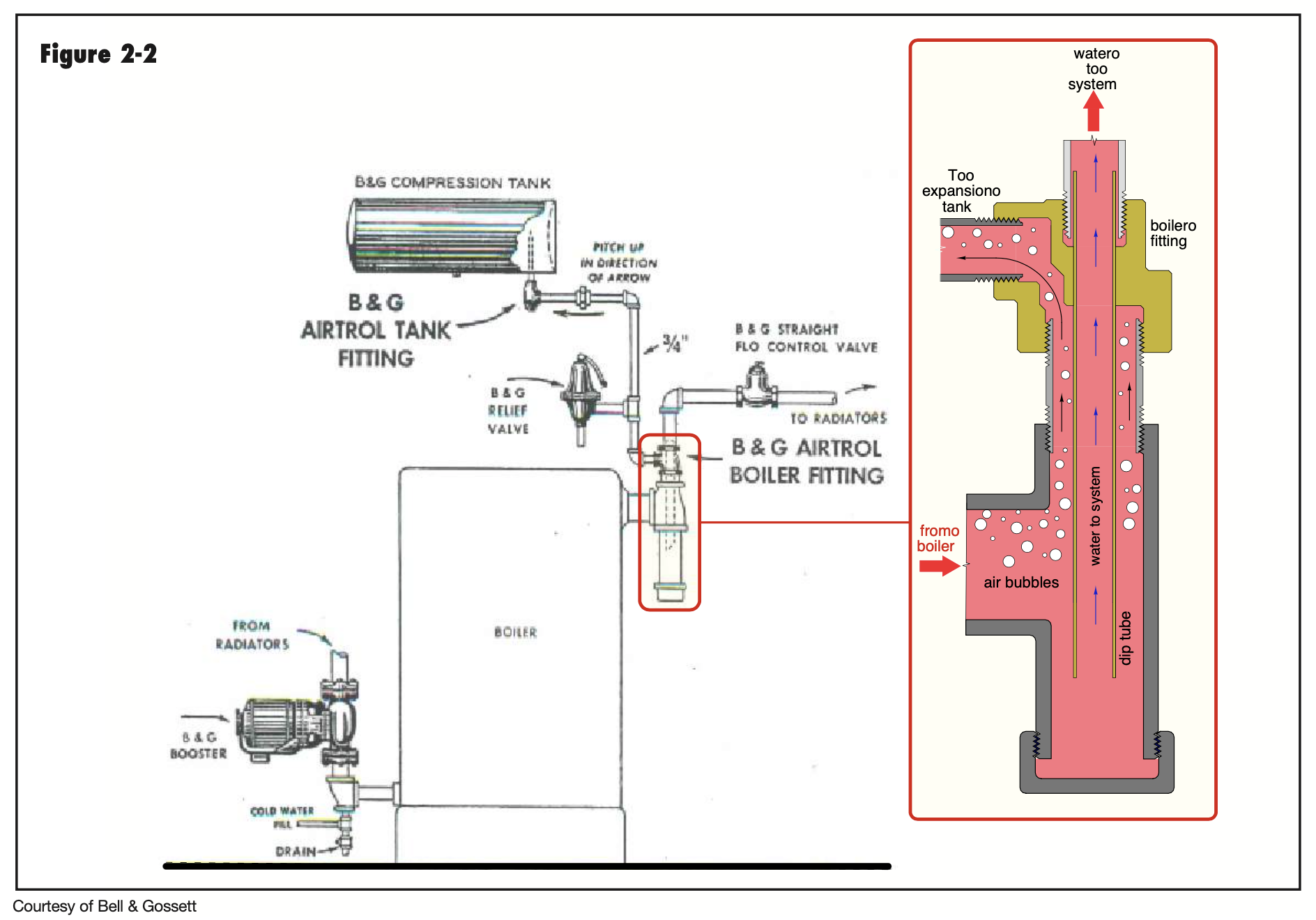

Often we see mis-applied compression tank systems that do not have the Airtrol™ fittings or equivalent installed. As such they are not doing a good job of air management and allow air in and out of solution.

Not all cast boilers have section designed to aid in air removal, certainly not the new "mini" cast boilers with 3 gallon volume. Those, probably all hydronic systems, IMO greatly benefit from a microbubble resorber type air separator.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

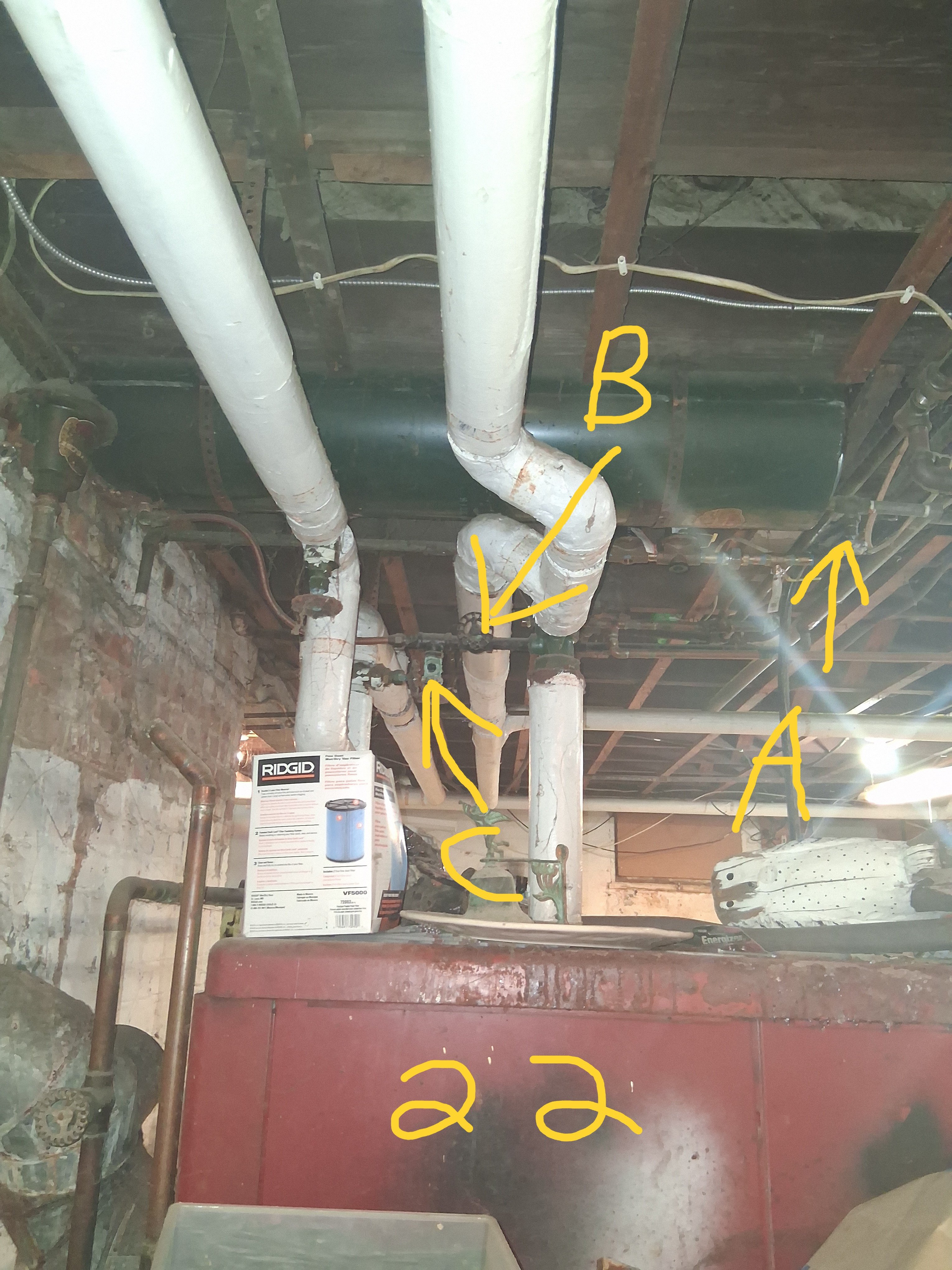

OK lets start with problem number one. Last winter i had to lower my aquastat to 170 because at 180 some scary things would happen like the pressure relief valve would open. My guess is the expansion tank is waterlogged. As you can see in the picture valve B will isolate the furnace water from the tank. If I open valves C and A I can drain any water in the tank. Now once all water is removed from the tank am i supposed to recharge the tank with air?

0 -

Problem number 2 is i always one radiator in my attic that would always need to be bleed and would not last the winter. That may be because my old pressure reducing was 100% plugged with rust because the strainer was never replaced in the 50 years I live in this house. I just replaced it. That may solve that problem but I am not going to know until I bleed the system. But I woul like to get past the expansion tank issue first.

0 -

Those "expansion" tanks (technically a compression tank) are incredibly simple and reliable. But it may well be waterlogged.

Which is easy to fix. As you say, close valve B. Open valves C and A and drain all the water out of the tank. Close them. Reopen valve B. Use you feed valve to bring the system pressure back to where you want it.

End of story. No need to add air to the tank….

Now it probably waterlogged as the connection to the rest of the system isn't really quite right. Ideally there would be a direct connection with an Airtrol fitting at the tank, but it is what it is. You just may have to drain the tank from time to time. Try to avid removing air by bleeding or whatever anywhere else — you want all the stray air in the system to end up in that tank if possible.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

This brass pipe on the relief valve should reach down to the floor. Very hot, boiler temperature water could discharge from this opening.

If you have a waterlogged expansion vessel, the odds of that happening increase.

Any metallic tube or pipe is fine, copper, black steel, galvanized pipe for example.

I'm wondering about the scorched jacketing on that boiler? Something overheated along the years.

You might start saving for a boiler replacement.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Please take more pictures of the near boiler plumbing as I need to know what the green colored device is near the foundation wall, please take a clear picture of the label on this device.

Now, the ball valve that is after the feed valve and the pressure regulator MUST BE SHUT OFF after the draining of the tank to eliminate the waterlogged condition.

Once you have drained the tank to eliminate the water logged condition you can open the feed valve slightly and add water back to the system BUT "only so much water/about half" as a water logged tank eliminates the point of no pressure change.

I cannot emphasize this strongly enough to you: "The ball valve must be shut off after you refill the steel compression tank to half full". YOU CAN ALSO shut the water feed valve off AND LEAVE IT OFF and drain ten gallons of water from the tank.

The reason your heating system is not working well is because it has no air charge in the steel compression tank which is required to allow the hot water in the system to (1) expand and (2) rise by convection and allow the heat generated by your boiler to rise naturally by convection.

If the ideal brand tank which I believe is a 30 gallon tank is drained of 10 gallons water it will eliminate the water logged condition and the heat in your home will start working more efficiently to provide you with low even heating again.

If you have a garden hose you can attach it to the valve labeled "C" and open the drain valve and fill a 5 gallon bucket twice and your heat will start working again BUT ONLY OF YOU SHUT THE FED VALVE OFF FIRST!!!!

0 -

and why shut off the pressure regulating valve and feed valve? I wouldn't… as long as the pressure regulating valve is working and set to the desired system pressure, it's just fine to leave them open. Safer too, unless there is a working low water cutoff…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Brother Jamie,

I suggested shutting off the ball valve this as a fool proof way of preventing the steel compression tank from becoming waterlogged after he drains half the water from the steel compression tank.

0 -

Fair enough — but it won't waterlog if he drains all the water, closes the drains, and then brings the system pressure up to where it belongs…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Brother Jamie,

I stopped trusting autofills when the one I had on my hand fed wood and coal boiler would lose all the

water pressure in my heating system a la clown plumbers.

That is why I suggested he shut the fill valve entirely at the ball valve before the fill valve and pressure

regulator as the pressure regulator is not really needed once the steel compression tank is drained of 10

gallons of water to create the balance needed for convection.

.

0 -

FYI. The green thing i was asked about it a circulator pump. I replaced the old one about 40 years ago. I would say my system was never gravity feed. Just a hunch.

0 -

I was asking you about the ideal valve next to the wall on the far left side of the image that is piped to the teel compression tank and has a copper riser below it.

=======================================================================================

EDIT: I was mistaken about the routing of this valve as it is connected to the regulator and fill valve, The above question is irrelevant.

0 -

Sorry but are you talking about the valve in front of the flue pipe or the valve in above the box marked rigid?

0 -

The green valve next to the wall is the one I am referring to.

It has a pipe connected to it at the bottom and it has a pipe coming out of the right side that is connected to the pressure regulator and fill valve; please take a high quality picture of the label on this valve that is painted green.

We seriously need to see pictures of all your radiators and all the piping connections. in the basement, all the radiators including the ones on upper floors and top floor to help you.

You have an "air management system" that does not require that Caleffi valve you just need to do some simple maintenance for your system not major surgery.

Help us to help us help you with your heating system, and you will have warm floors and walls once the issues are found and corrected before the weather gets worse.

Leon

0 -

Thanks. Should I drain the tank at normal operating temperature? I know I have two radiators that need to be bleed. I am thinking to leave valve b closed while bleeding the radiators and once full bring the system up to about 15 PSI. then open b after bleeding. Sound Good?

0 -

As Mr. Holohan has stated so well in the past "If you keep bleeding and all you get is water it ain't an air problem".

Please tell us where the circulator is located in your system???

Please shut the ball valve off with the white handle before you do anything; by shutting it off you guarantee the steel compression tank will not become waterlogged.

Please read brother Jamies comment from Nov. 2nd again.

Once you have the steel compression tank isolated drain 10 gallons of water from it and then shut the boiler drain off, the system will start working again AS LONG AS YOU KEEP THE WHITE HANDLED BALL VALVE SHUT OFF TO KEEP WATER FROM BEING FED BACK INTO THE SYSTEM.

Once the excess water is drained the air charge will create the point of no pressure change.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements