Controls Upgrade (1960's AmStan GPM boiler)

Looking to upgrade controls on subject unit:

-Single zone gas fired boiler supplying cast iron radiators (no domestic HW);

Goal: replace existing transformer and basic aquastat with a reliable unit that will allow proper thermostatic (2-wire) and circulator control.

Thanks in advance for your time to search memory banks ;)

Comments

-

Post a few pics of what's there now.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

-

What is unreliable about it now? If it is a pre total shut off system there could be some upgrades that are possible, if it is already a total shut off system it should be about what a modern system would be.

0 -

mattmia2 - I am sure there is good information in your post, however I am not clear with terminology: Total shut of vs Pre-total shut off?

Looking forward to better understanding…

0 -

total shut off: the pilot is controlled by a combination gas valve or a separate thermocouple controlled valve so if the pilot goes out the pilot gas is shut off.

pre total shut off or "wild pilot": The pilot gas is only controlled by a manual valve, if the pilot goes out the pilot gas stays on but there is some sort of safety to keep the main valve from opening. Since the amount of pilot gas is small and methane is lighter than air the pilot gas just dissipates if the pilot goes out.

0 -

great insight…thanks.

I lifted this pic from the web. Gas valve, transformer, relay all the same with the exception of the aquastat. The aquastat was changed out with a similar type only with 3 terminals…R W B (common, circulator and burner). I am not savy enough to troubleshoot but can't help to think that an upgrade to a self contained unit might geve a fresh start.

0 -

That's a modern system with a combination valve, the main valve, regulator and pilot control and safety are all bult in to that one valve.

0 -

Incredibly good of you to share your knowledge mattmia2.

With the gas feed defined; do you think the unit would benefit from more modern controls.

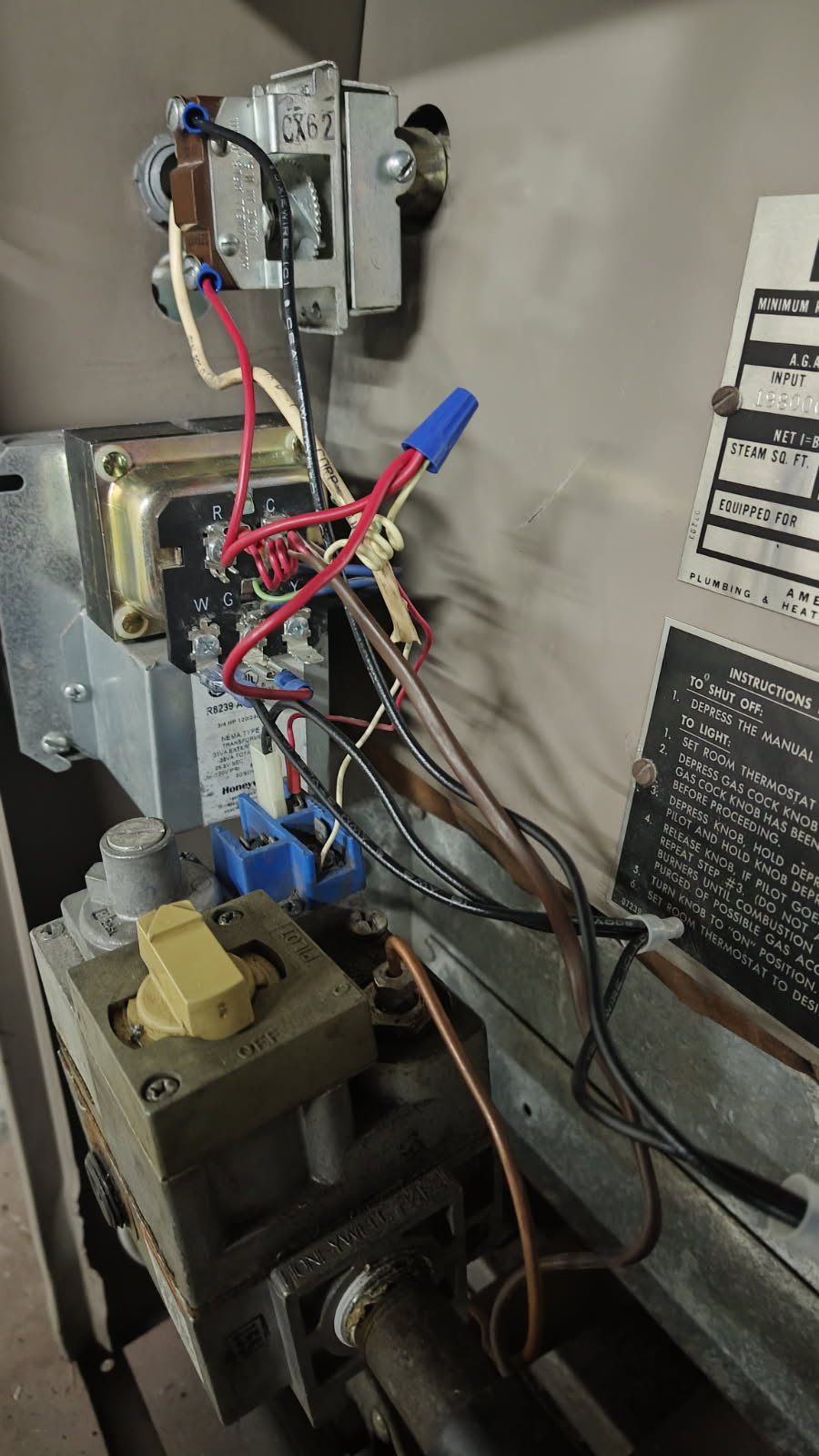

The controls interface (fan center to aquastat to thermostat) were modified from original. Terminal definition is not clear and do not necessarily follow convention, even though Honeywell components. No "clear" identifiers for thermostat (T) or circulator (C). I am not good enough to troubleshoot, but however can grasp concepts and wire to defined terminals. This would give me a fresh start so to speak ?

0 -

Because they use a fan center to isolate the boiler controls from the thermostat, g is the control wire to the relay because g is the fan terminal on a furnace. That is pretty common with boilers. If the fan center was original there is usually a schematic inside of one of the covers showing where the thermostat should connect. C is usually common, the side of the transformer connected to the unswitched side of the devices being controlled.

0 -

an outdoor reset control might be what you are thinking? It changes/ regulates the boiler supply temperature based on out door temperature it can save fuel dollars and increase comfort.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

TY hot_rod. Funny you reference outdoor temp control. Before any awareness of such, I thought these systems should have some outside temp interface; little did I know that such existed. My situation is such that my home was build in the 40's, very little insulation and in a time when coal was common. I am certain that the piping and associated hardware is not properly matched, sized, etc. Trying to make the best of what I have. My guess that outside interface is likely not an option with such. Trying to nail the basics by making sure that the existing control is at least at baseline. Thanks again!

0 -

This NORA video does a nice job of explaining boiler control and ODR add-on

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

if the system is cast iron radiators it very likely will do well with outdoor rest, however that boiler must heat to a minimum temp to keep from condensing so it isn't as well suited to outdoor reset.

0 -

A 4 way with actuator, properly installed and configured will protect the boiler from extended cold return..That is the beauty of a 4 way with actuator. The valve has two mixing points so it can do both tasks.

If the system was designed for, or needs to run 180 on design days, you could get 30 degree of temperature reduction with the ODR. That is well worth chasing for comfort and fuel efficiency

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

mattmia2, steamhead, hot_rod, and EBEBRATT.

Thank you all for your generous sharing of knowledge. I treat this as a special gift and remain very grateful.

I was able to restore the boiler control to baseline function by removing the three terminal aquastat and replace with a simple high limit aquastat. I was able to gain enough knowledge from your posts to wire all components: thermostat, aqua, pump and burner. As we all acknowledge…the unit is quite old. For now I need to be satisfied that it remains functional !

Thanks to all !!!

0 -

Gentlemen/Pros, I need your continued support in regard to my AmStan GPM 1BJ1 boiler and control.

I have achieved baseline. You may recall that I was struggling with control function. I was able to achieve baseline operation by removing the three terminal aquastat (that appeared to be a replacement) and installing a limit (L4080D 1010) that was original to the unit. I have also been able to neaten-up wiring allowing for thermostatic control and syncronized function of burner and circulator.

HOWEVER heating function (temperature) and cycling are not what they should be:

-Outdoor temp 40 with indoor thermostat set to 71;

-Boiler fires…runs 5min…produces only moderately warm water 130 and shuts off (somehow the stat appears to be satisfied?)…cast iron baseboard only warm.

? The L4080D was used (in a box in boiler room)…specs are 180 upper limit; appears to have NO differential.

??Do I have a bad aquastat?? How do i ensure that the boiler produces a reasonable temperature in spec with boiler requirements and adequate heat in the house?

Thanks all in advance!

0 -

-

Yes…that makes sense.

Does this add a puzzle piece? Wall thermostat set to 71…on an outside day with temp 40…house with little insulation. Boiler fires and runs for only 5 mins producing only marginally warm water…unit shuts down and stat reads 71

I only know enough to be confused about this…

0 -

you need to measure the ac voltage across the various controls to figure out which one is open. if the control is closed the voltage will be more or less 0. my bet is on the thermostat having a very wrong heat anticipator setting. after it shuts off, does it fire again in 5-10 minutes? with a standing pilot i don't see much else that could do this other than an unusual defect in the wring or the contacts of a control. if it had electronic ignition i could see a couple other ways what you're describing could happen.

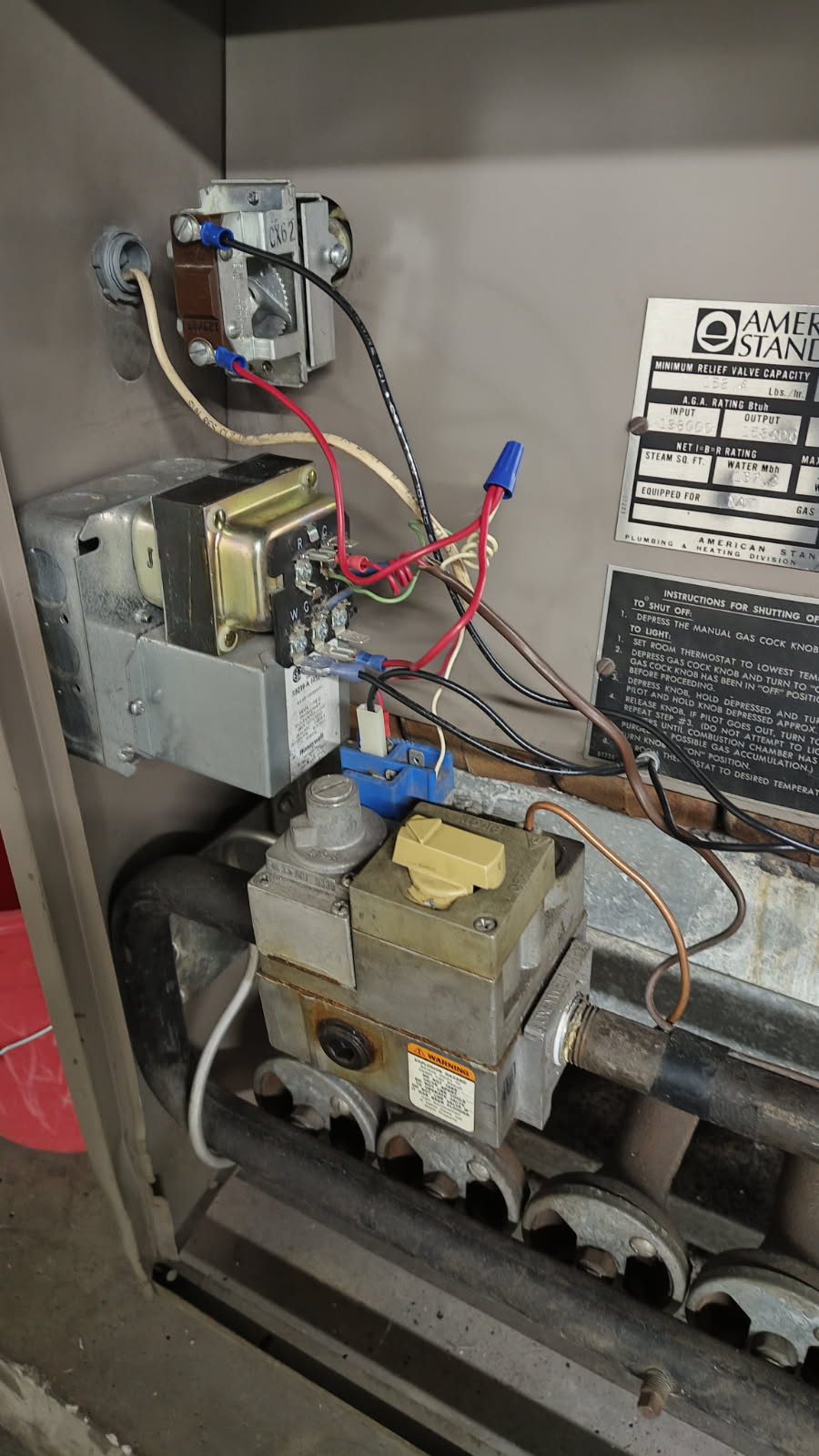

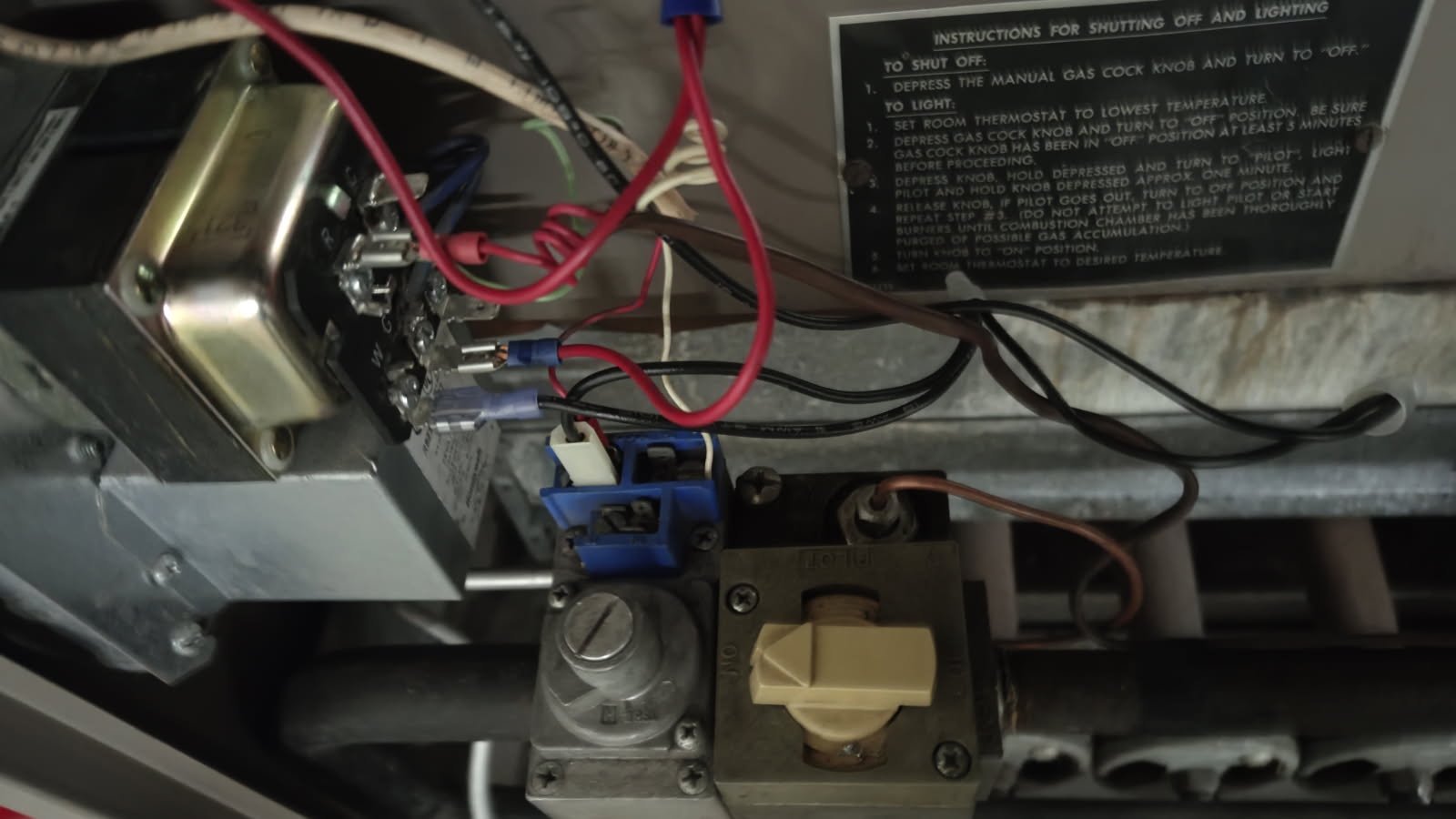

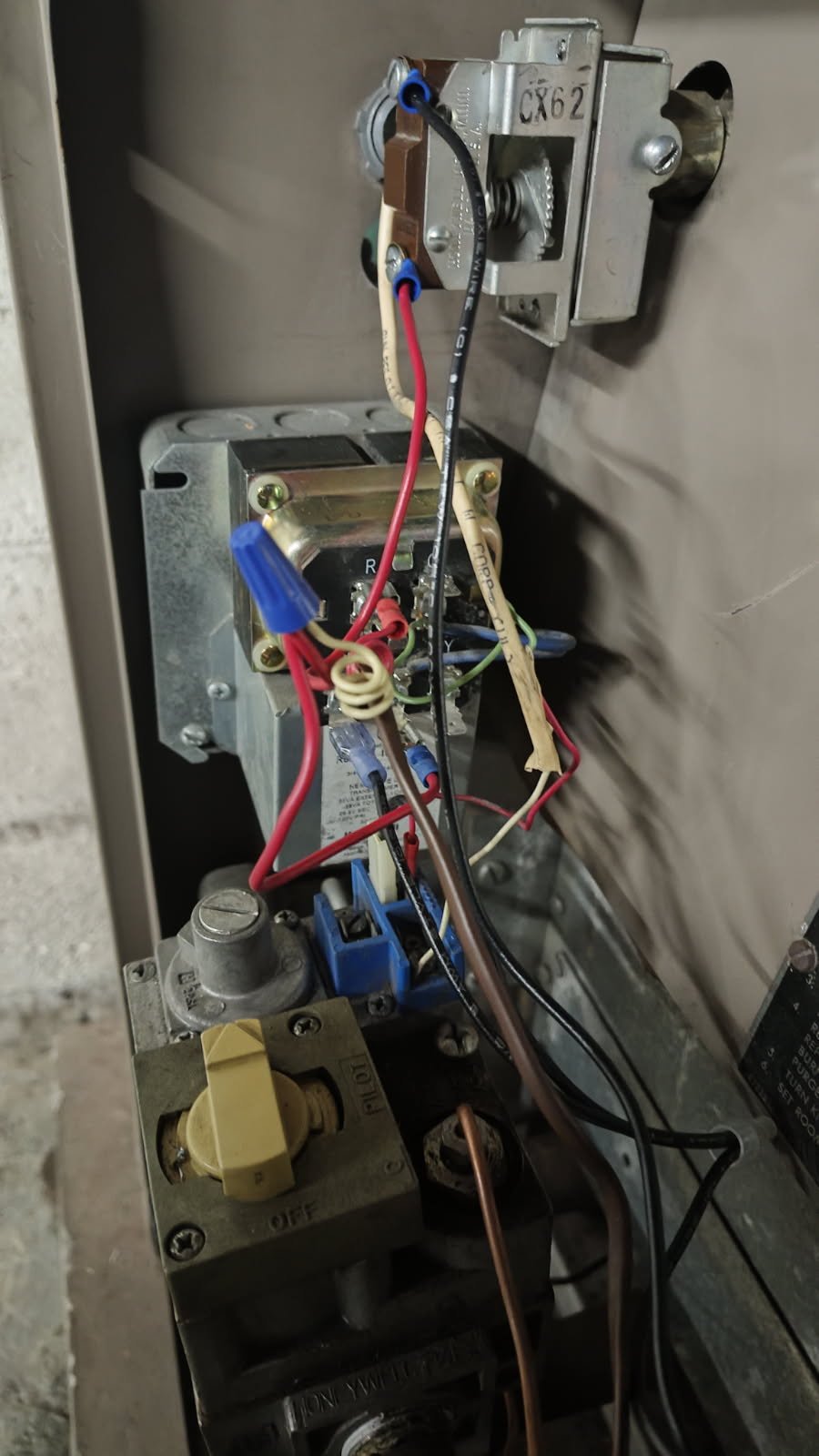

can we see a picture of your actual controls, especially the gas train, not just some random picture off the internet that you think is the same?

0 -

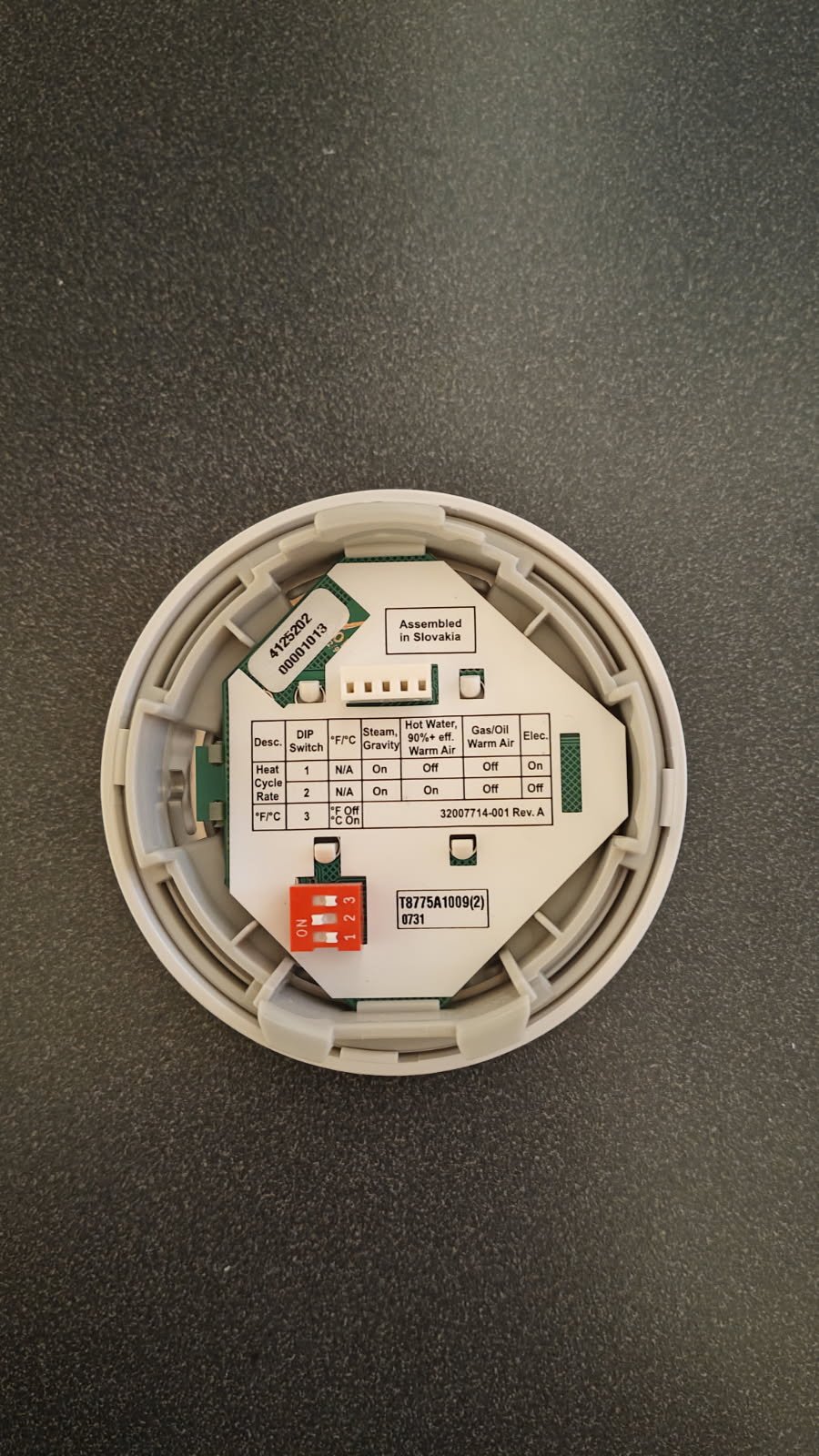

Matt - i am working on uploading pics. I think you are spot-on in regard to the anticipator. I will inc a pic of the stat as well. Current stat is honeywell, round digital. T8775A1009. (I also tried with an old honeywell with traditional mercury switch…behaved same). will hopefully have photos soon…

0 -

0

-

Gas Valve wiring. I forgot to mention that there is a power vent wired into the gas valve. This is the control wiring that you see. Works as intended.

0 -

the proving switch on the powered vent is highly suspect here, possibly bad but more likely doing its job.

an electronic t-stat won't short cycle in the way i was thinking.

0 -

The older Honeywell stat's had issues.

0 -

sounds like priority 1 is to fix the "suspect" proving switch. If you can provide me with reference I will follow-up.

In regard to boiler plumbing…should I refer back to your comments on boiler bypass?

TY

0 -

In regard to the thermostat…I too was thinking of relocating it

0 -

is this a converted gravity system or a newer system with ci radiators and smaller piping?

if it fires for an extended period if you turn the t-stat up a couple degrees it is something about where the t-stat is located or how it is configured or possibly that the system is massively oversized.

0 -

Matt…I think it is all of the above.

The house is old and originally heated with coal. Piping is cast Iron large in diameter (I am obviously not a plumber), (copper adapted from boiler to connect with existing ci) I would guess 2" necked down to service cast baseboard and cast free standing radiators to what looks to be 1". In regard to gravity system…I would guess so considering it was early 1940's and coal. The gas upgrade included a B&G circulating pump.

I read you on the T-stat location and will give relocation a try…not clear on "configuration" (I manipulated dip switches in all combinations and it produces the same results)

Finally…oversize…that is a devil and quite possible. Looking more and more like conditions that I can't correct.

(you once referenced bypass…if that is an option, i can investigate/research. Know you can't spoon-feed me and you have been more than generous with your time) Thanks

0 -

a bypass wouldn't stop the short cycles but it would let the boiler get up to temp. it might have been doing that for decades without damage though.

the radiators being just lukewarm might match the heat loss of the house when it is 40 out.

dip switch 1 and 2 on would be the correct setting for your system.

0 -

Did the easy thing for now Matt. Flipped dip switches per your suggestion. Love my old house but not the inefficiencies…

Will let you know what the revised stat settings produce.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements