Big mouth vent installed horizontally — wrong?

Hello all. I just had an old Hoffman vent replaced with a Barnes and Jones “big mouth” BJ-B3M. The plumber who installed it moved it about 12” from where the Hoffman was, and also put it on a T. The T comes up from the steam pipe about 8”, then the vent is pointing out horizontally from there. Looking at the spec sheet (https://s3.amazonaws.com/s3.supplyhouse.com/product_files/Barnes-&-Jones-BJ-3BM-Submittal-Sheet.pdf) it looks like only their crossover trap should be installed horizontally; main vents should be installed vertically. Will the horizontal position impact its function or performance? It’s on the dry return about 8” above the pipe. It’s the only vent in the system. 2 pipe steam.

Thanks.

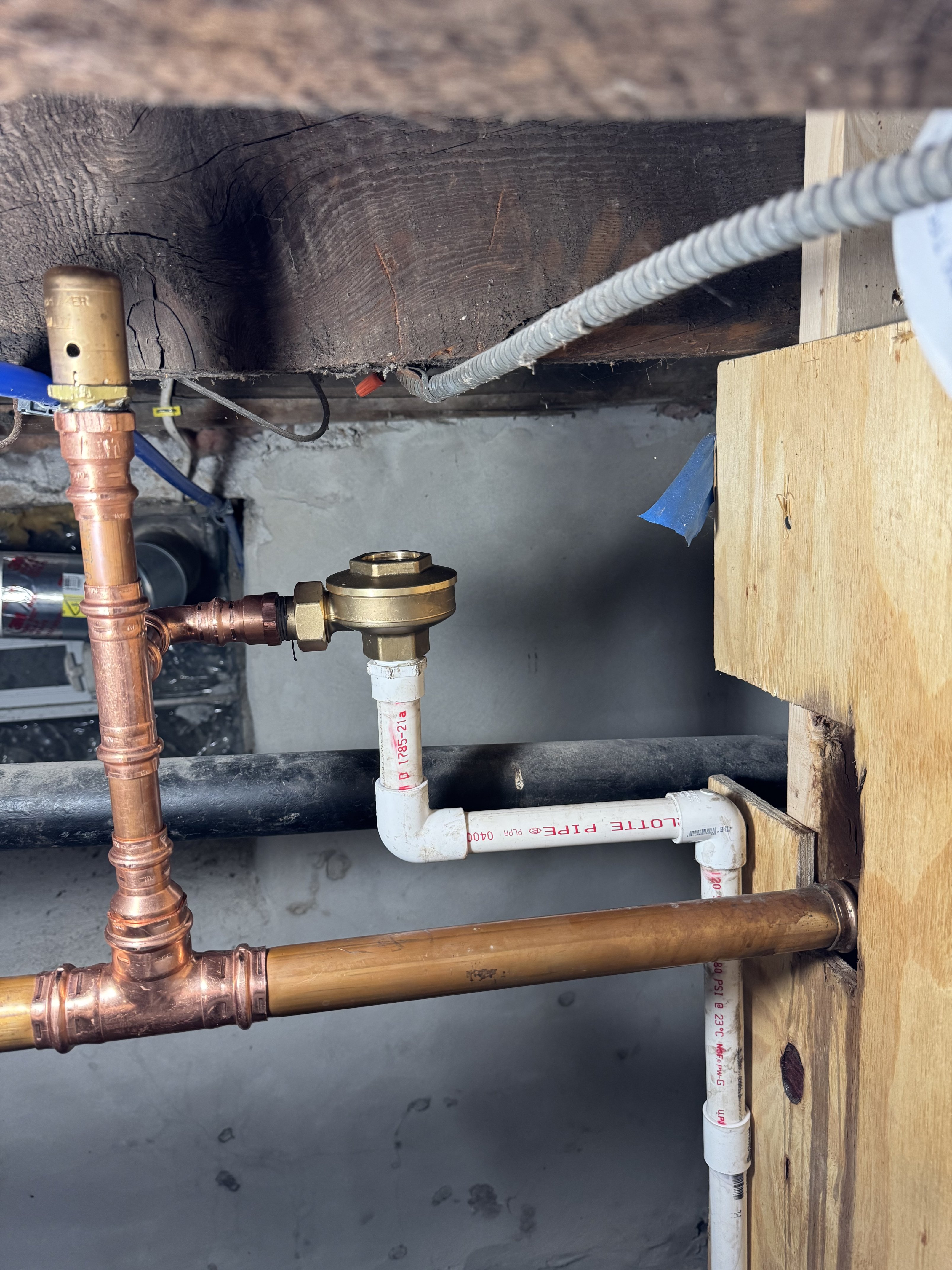

Edit to add picture. The white PVC is open at the bottom leading to a bucket. The gizmo at the very top is a vacuum breaker.

Comments

-

It's on a dry return? Then it shouldn't be a problem — since it should never close anyway.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

-

Quite true. A Big Mouth will not close against water…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Can you post some pictures?

0 -

I have a big mouth, oriented correctly very near the end of the main on a 1 pipe system. So it sees steam every boiler cycle. The spec sheet orientation is so the condensation from the steam that closes the valve drains back into the system, minimizing system water loss.

Your system being a 2 pipe system, if your big mouth never sees steam, probably not a big deal.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

if the big mouth never sees steam, then it should just be an open pipe. That’s a lot cheaper!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

That's the weird little secret of true two pipe steam systems! Putting a vent on what might just as well be an open pipe started when people figured out clever patented widgets to occasionally pressurise the dry return to keep the pressure differential between the returns and the mains to some reasonable value — to keep the water in the boiler where it belongs. (The Hoffman Differential Loop, for instance, was advertised as "The Watchman of the Waterline").

Then people realised that if you put a vent there and steam got into the return from, say, a bad trap then it would close and you didn't get steam in the boiler room and the building super didn't get complaints about steam in the basement. Great! Doesn't help the heating much, but… who cares?

Funny world.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Yes, on a dry return, however, the old vent was spitting *a lot*, so either steam or water was getting to it somehow. Various problems in my system that might be causing that. I believe my radiators are letting steam into the returns because they have missing or faulty steam traps / orifices. Pressure may be getting too high also.

@mattmia2 @109A_5 @ethicalpaul @Jamie Hall Thanks.

@EBEBRATT-Ed edited to add picture in original post. Thanks.

0 -

the trap is also a vacuum breaker. be better if the trap were turned 180 degrees so the outlet was facing up so that any condensate in it would run back to the return.

0 -

Right, thanks. But would it be even better for the T to be reconfigured so that the vent is oriented vertically and the outlet is pointing out horizontally? That’s how it’s shown in the spec sheet.

0 -

-

One thing at a time… you'll get there!

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

For best performance regardless of the defects present in the system it should be installed as the spec sheet shows, that is 'Best Practice' in this case. Is there a clearance issue ? Why the plumber install it the wrong way ? Having the vent port pointed up invites debris contamination and I would not suggest that.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Well just saw the picture. You should not need the PVC pipe leading to a bucket.

I'd figure out why you are experiencing

" the old vent was spitting *a lot*, so either steam or water was getting to it somehow. "

You want to minimize system water consumption, if it is loosing water with every cycle, that is not good. Once that is corrected then correct the Big Mouth vent orientation.

" But would it be even better for the T to be reconfigured "

I would leave the T as is.

I would do this; Disconnect the PVC pipe. Then unscrew the union to disconnect the Big Mouth, unscrew the Big Mouth's spud (requires a Hex tool 5/8" (I think) if it is a 3/4 pipe thread) add a threaded nipple and a 90 degree elbow (preferably brass) pointing up, reinstall the spud and reattach the Big Mouth.

Personally I think the vacuum breaker is kind of useless.

Actually I'd probably just remove the vacuum breaker and put the Big Mouth there if it will fit, then plug the other pipe where the Big Mouth is now.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements