Steam sight glass

Looking for help.I just installed a new crown boiler with a beckett propane gun. When there is a call for heat and it starts making steam the sight glass goes empty and the low water cut off trips. What can cause this?

Thanks

Comments

-

-

-

When not steaming, how does the water in the sight glass look ? Any oil film at water line. Pictures may help.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

As other have mentioned the boiler and the water were probably not skimmed and cleaned. Or it isn't piped properly

0 -

0

-

The water in the sight glass should be clear.

Boiler model ?

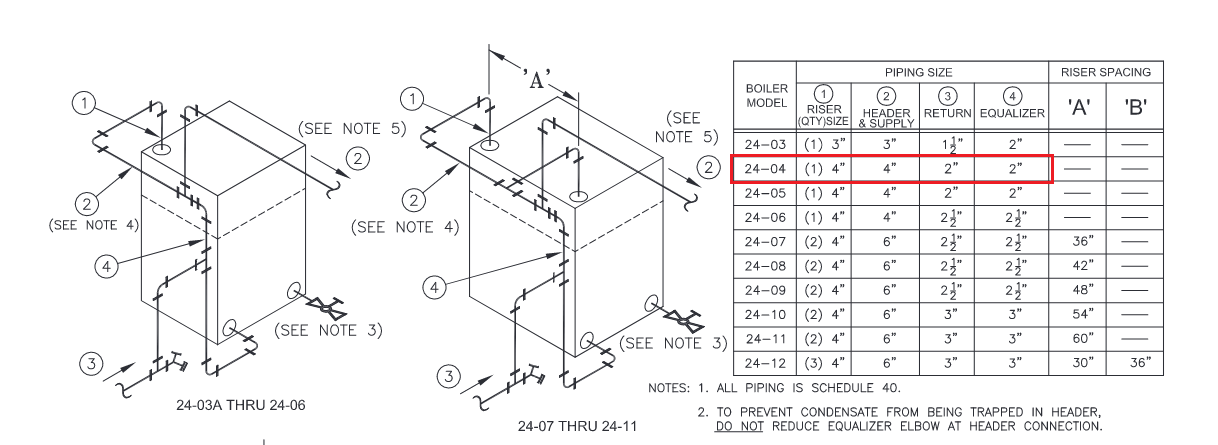

That appears to be a drop header. With that size boiler it would not surprise me if there should be two risers coming out of the boiler.

How much of this stuff is in the boiler ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

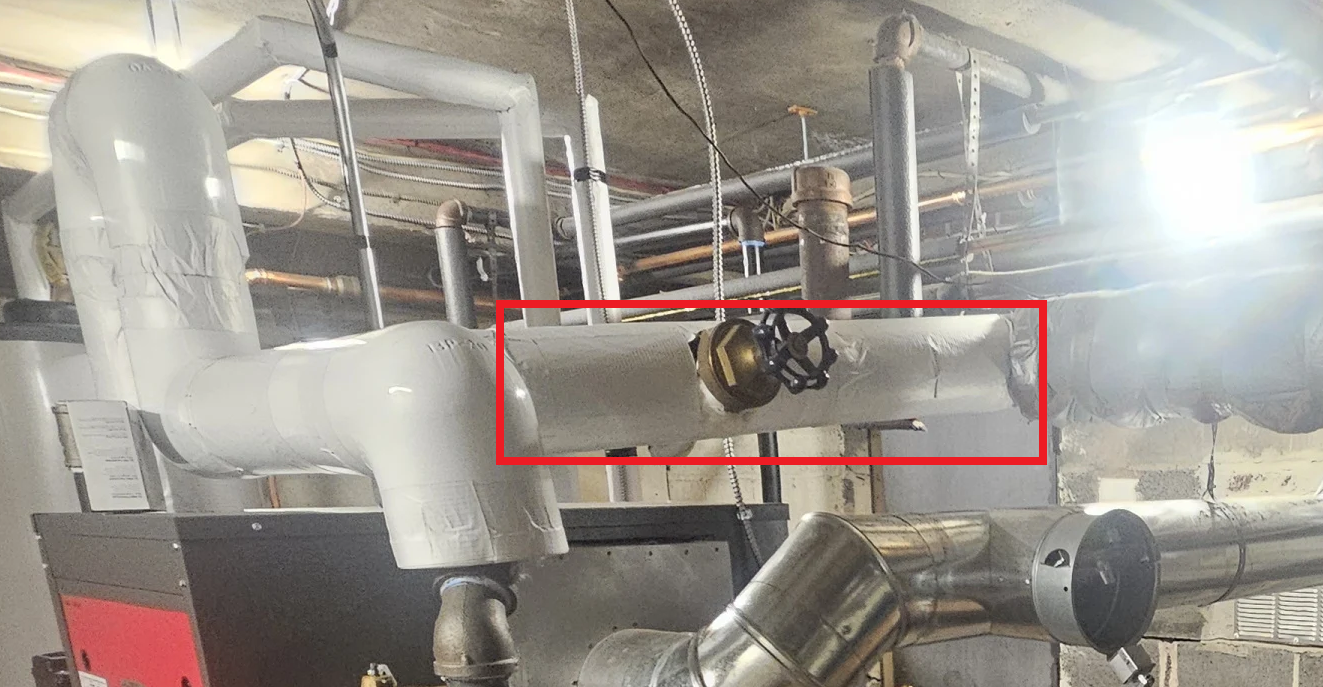

I'm assuming the safety relief valve path is the Red arrow and the Blue arrow is the Skim port, why does the valve handle (Blue circle) look like the valve is open ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Crown 24-04

Only one bottle

0 -

That is correct with the path of the pipes

0 -

only….

0 -

also, it isn't really a drop header, the riser to the main has to be up, not horizontal. It is about equally likely that water that gets in the header will go in to the mains vs back in to the boiler through the equalizer.

0 -

Is the riser and header both 4 inch pipe ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

This does look counter-flow ish, could be better.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Would have been a cinch to make it right. Should have dropped the heater below the steam supply. If they had to swing it to miss the boiler jacket so be it. Then the steam could have come off the top of the header.

Then drip the counterflow if it is really counterflow,

0 -

Not sure if the mains are counter-flow, I just meant the part in the Red box is.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

True but the supply should not be coming off the side of the header, it needs to come out the top

1 -

or at least at a 45. the steam should have to go up so the water can't follow it.

what is happening one way or another is liquid water is being thrown out of the boiler and in to your mains.

if the boiler is surging (producing steam in violent bursts instead of an even steam because there is oil on the surface of the water) or priming (foaming because of too much additive in the water or other water chemistry problems) or just normal carryover of water droplets entrained in the steam, that header with the riser to the steam main horizontal isn't going to separate the steam and water very well. that water takes some time to work its way back to the boiler and that is why your water level is falling. over time that liquid water will rot out your steam mains in addition to the other operational problems.

0 -

-

condensate is a very small amount and it is distilled. the water from the boiler makes much more of the pipe wet for much longer. when people have rotted out mains they almost always have issues with keeping the water in the boiler.

0 -

Not true. Or at least it shouldn't be. When the system is heating up at first, there will be a fair amount of condensate flowing in the steam mains. If the mains are insulated, once they are heated there is very little condensation. In a one pipe steam system, again there is condensate flowing in the mains — but it is a remarkably small amount of water and it is distilled water.

Once the burner shuts off, the condensate flow reduces very quickly to zero, and assuming everything is pitched properly nothing will have liquid water left in it (though it will be very damp!).

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

the distilled water is probably more corrosive than what is in the boiler (especially if there is any water treatment in the boiler).

I'm not sure what you mean about "much more of the pipe wet for much longer", the pipe is constantly condensing steam into water, the entire interior is wet the whole time it is steaming.

I think when you are thinking about people with rotted out mains, you are thinking of people who have sags in mains when the water sits there 24/7 even when not steaming.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

"In a one pipe steam system, again there is condensate flowing in the mains — but it is a remarkably small amount of water and it is distilled water."

I'm not sure why you think that condensate (distilled) water is less corrosive than what is in the boiler. And I'm not sure why you think that the amount of water flowing in a pipe causes noticeably more corrosion. Maybe there's something I'm not thinking of.NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

The nature of corrosion gets rather complex, and I'm not about to run a course on it. However, pure distilled water — while corrosive — has a limitation as a corrosive agent: the only available anion is the hydroxyl ion. The only cation is hydronium. in the context of a more or less sealed pipe, there is very little oxygen. Iron, under those conditions, tends to form a nearly insoluble layer (very thin) of Iron (II) hydroxide, which actually protects the underlying metal up to a point. Similar reactions occur with other metals. Now in a boiler the water — almost inevitably — contains other anions, in particular chloride and the carbonates. Unfortunately, the iron compounds formed in the presence of these anions are soluble, and thus the underlying metal is not protected There is also usually some dissolved oxygen present, which will accelerate the conversion of iron metal to the iron II ion.

But there's no need to go into the details. The bottom line is this: the interior of a steam main will indeed corrode, but very very slowly — unless there are areas of standing water such as sags and incorrectly pitched pipes. The interior of true dry returns also will corrode, but again very very slowly. The interior of wet returns, however, can and does corrode rather quickly.

There is a slight tendency for there to be additional corrosion in both steam mains and dry returns at threaded fittings. This is not due to dissimilar metals, but simply because the fitting may have made up in such a way as to leave a small pocket for standing water. This is not usually a problem — at least over reasonable time spans (say a century or two) but is why if one is looking for leaks in steam lines and dry returns fittings are one place to go looking.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

the pipe is also thinner where it is threaded.

0 -

Thanks Jamie. if a bottle of 8-way (shown in a picture and briefly mentioned) was put into a non-skimmed boiler it will surge.

only put in maybe a quarter or less and only after the water is cleanNJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements