Am I blind? Not seeing the gas shut-off valve.

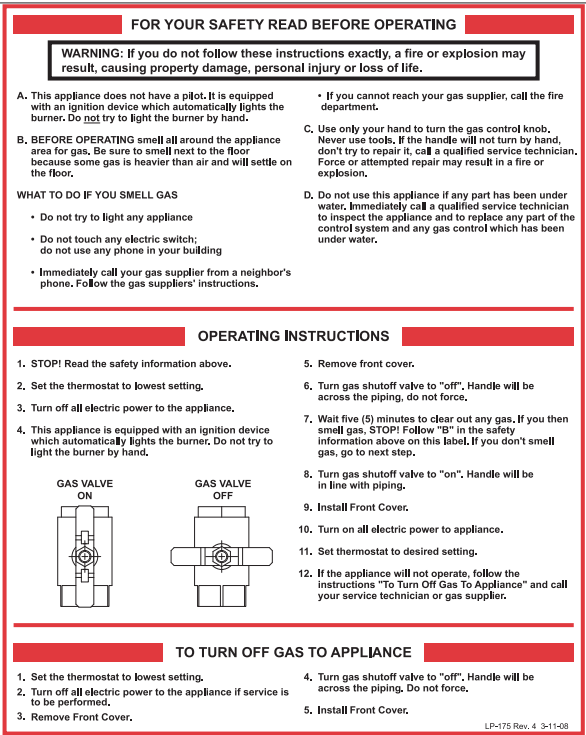

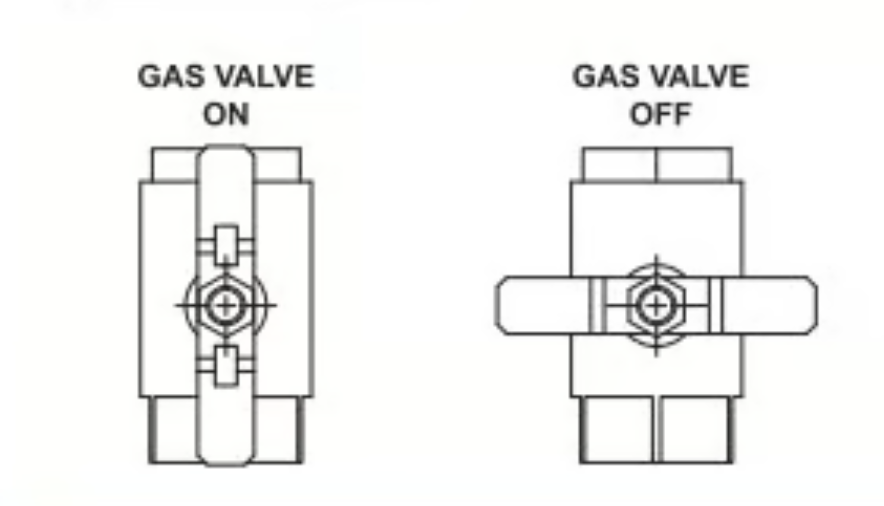

I turned off the power to my NTVN-199 gas boiler and removed the front panel according to the instructions on page 2 of the manual. But when I got to the part where you shut off the gas valve, I was unable to locate it. Here's the drawing of it from the manual:

Apparently I'm blind now. Why am I not seeing anything that looks like that in there? Does it look completely different than the drawing? Is it actually located somewhere outside the panel instead?

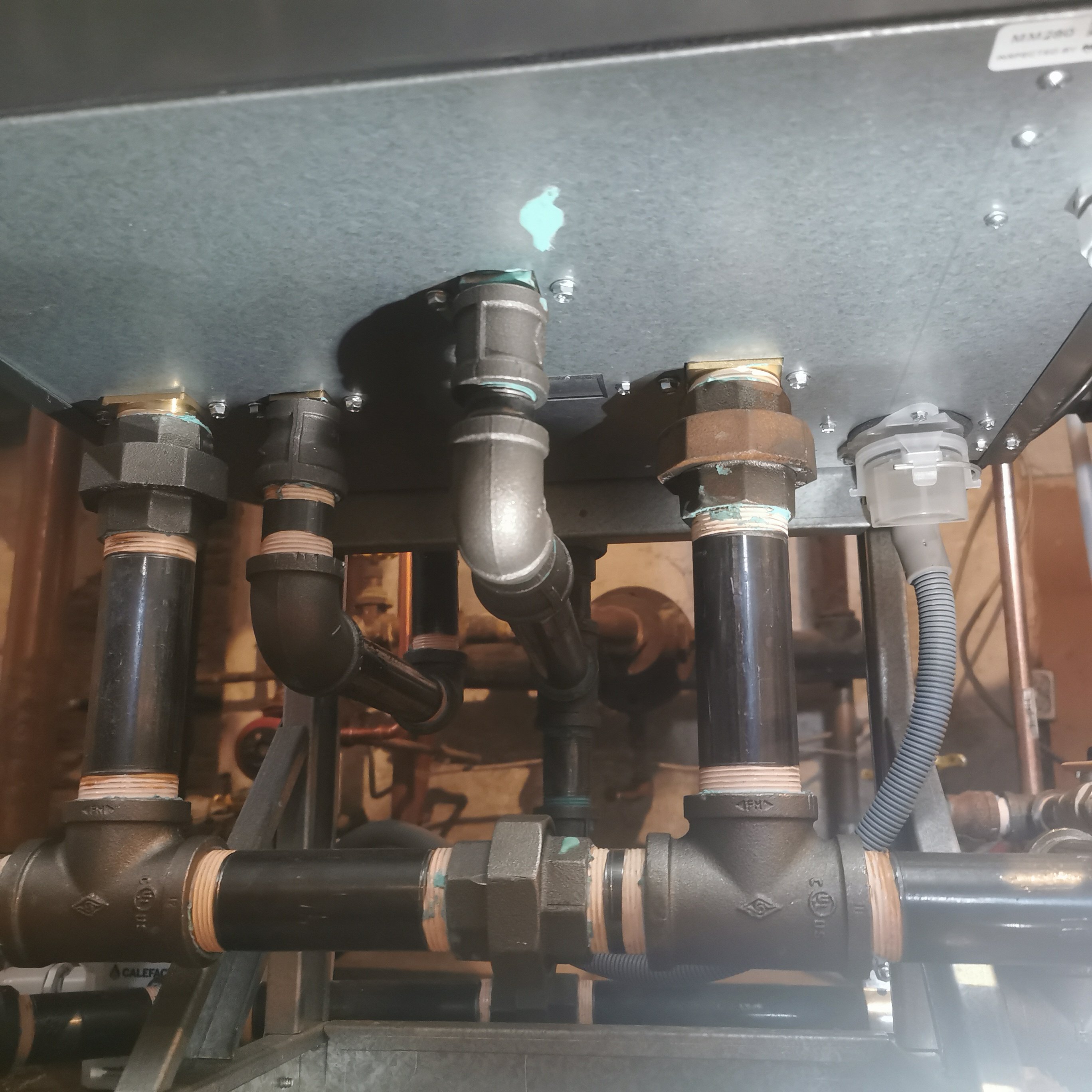

This is what I see when I open the panel:

Comments

-

-

-

-

-

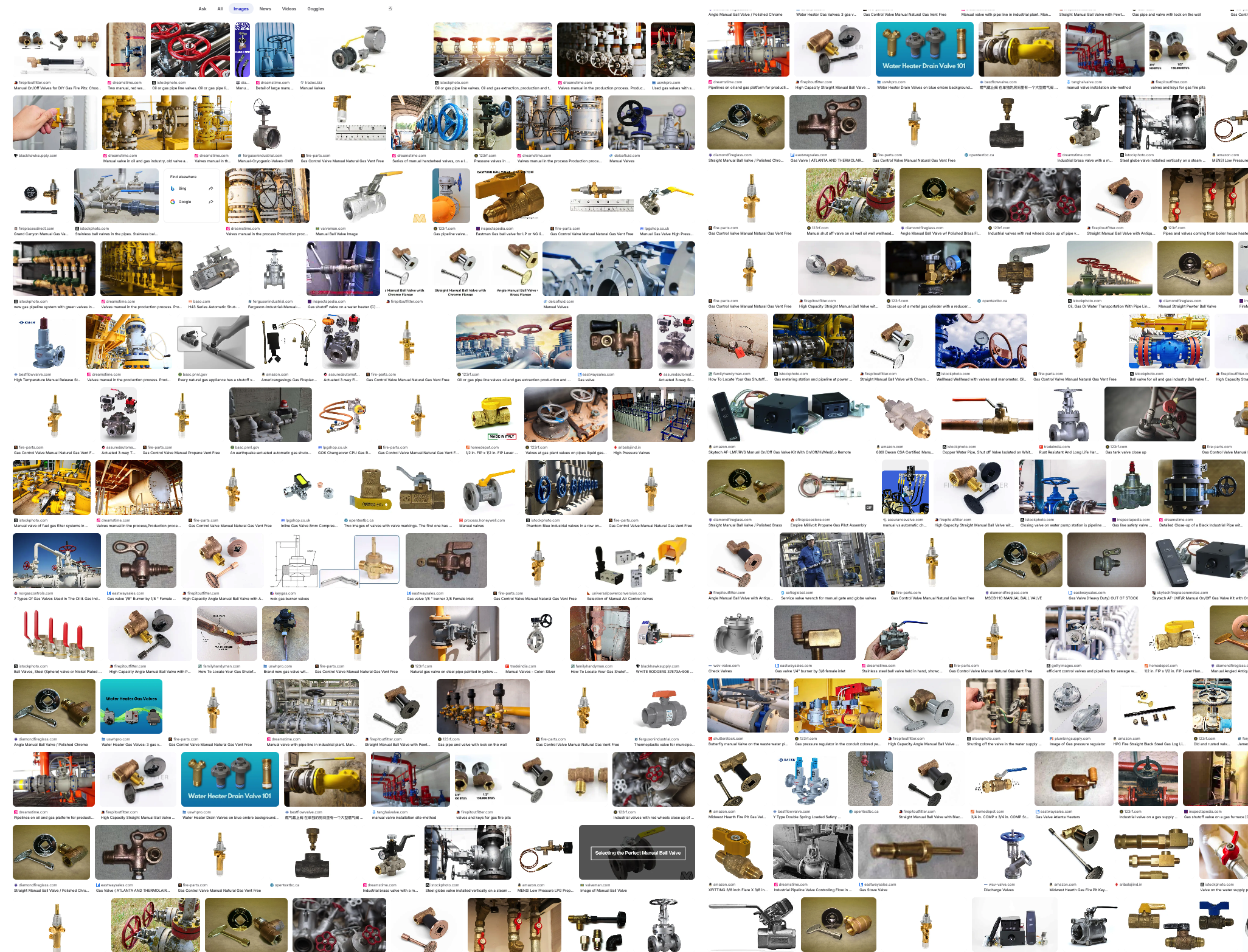

The only shut-off valve that I can find is the Master Shut-off valve. Is that what I'm looking for? Or is the manual referring to another valve? Because the Master Shut-off valve looks completely different from the one drawn in the manual, and why would NTI be telling people to open the panel first before shutting off the gas if the valve isn't inside the panel?

Master shut-off valve:0 -

as far as i can tell there is no space inside for a field installed manual valve. It looks like there is factory installed tubing from the gas inlet on the bottom to the automatic gas valve.

that is likely boilerplate they bought from someone that has been the same for 40 years and is for conventional boilers with a manual knob on the automatic gas valve.

1 -

I consider the shutoff just past the meter to be the master shutoff. Valve come in many types and can be rated for multiple purpose. Lots of gas valve have small wing type shutoff. The on you have is common across water and gas.

Do you have any other gas appliances in the house? Does that line split off or go just to boiler?0 -

There are no other gas appliances besides the indirect water heater they installed at the same time.

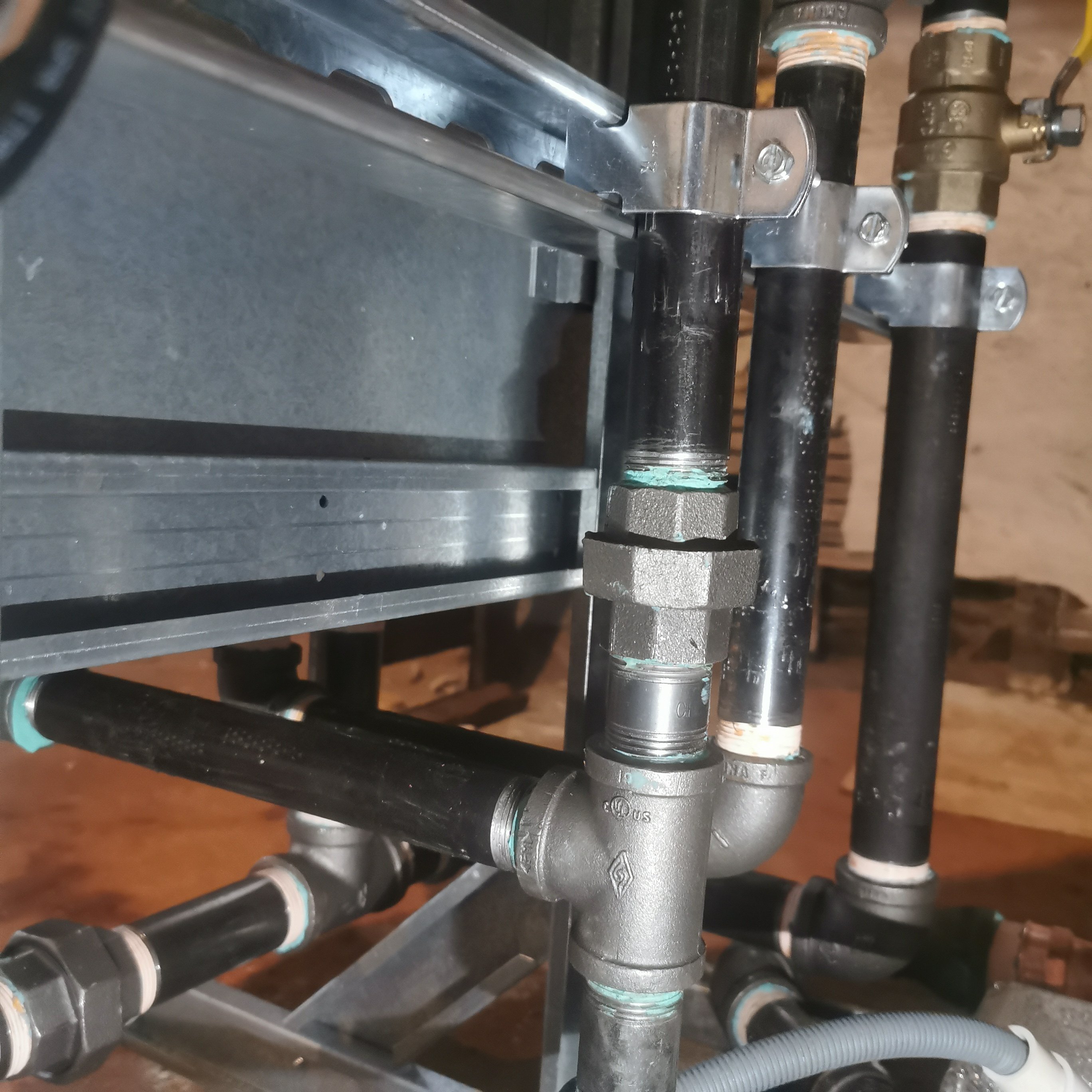

I looked again, outside and below the panel, along the gas line. Still don't see anything on the gas line resembling a valve.

Underneath:

Behind it, low down:Behind it, wider view:

0 -

-

-

-

The meter is outside though, on the sidewalk. If there's something there that anybody walking by can manipulate easily, I'm surprised.

0 -

-

-

-

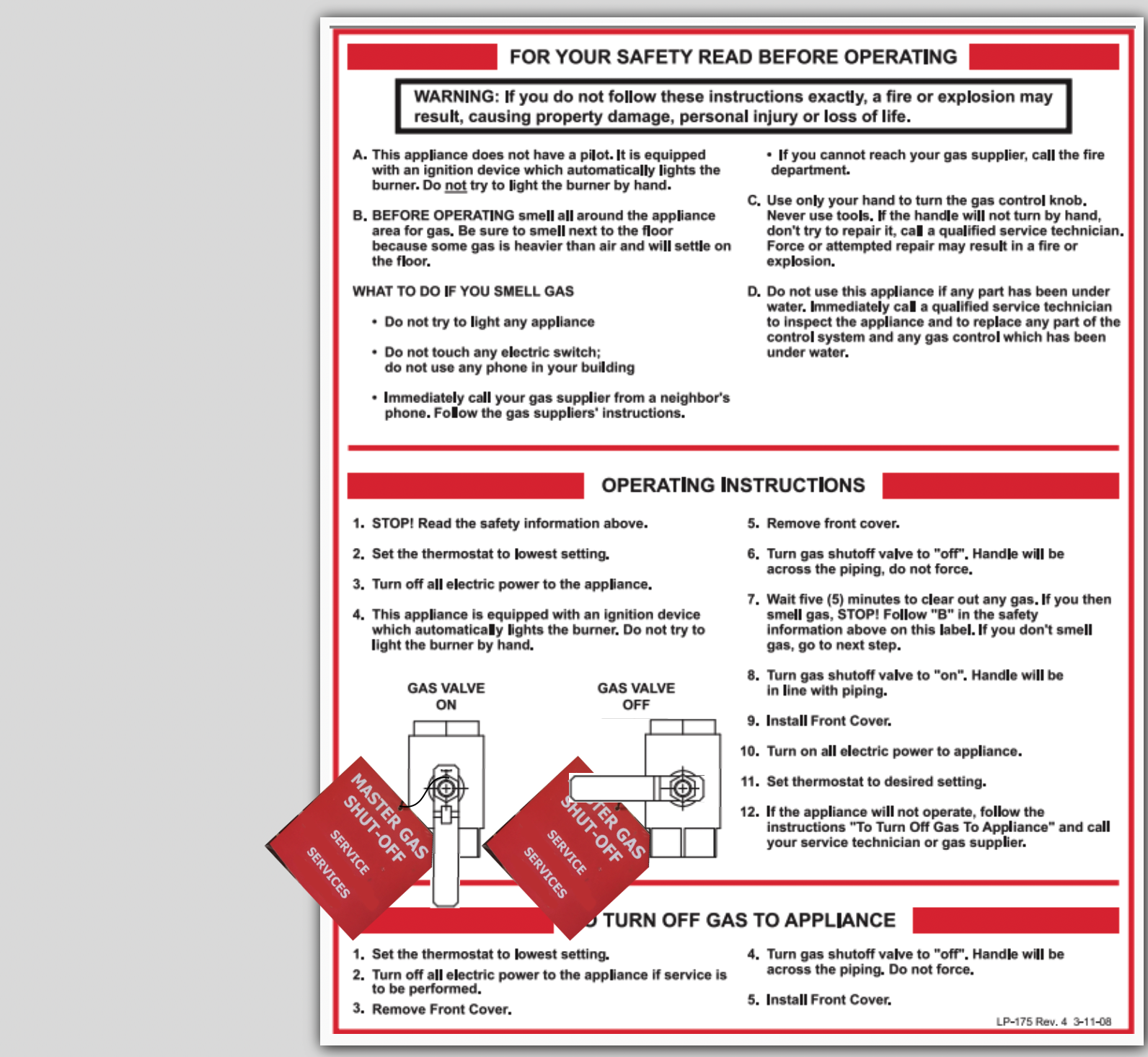

The manual can not know what your installer uses, there are actually some gas valves that look like the one in the illustration but that illustration was not to show you what valve the installer should use but to tell you that the handle that is parallel with the pipe is ON and the handle that is perpendicular to the pipe is OFF.

If they needed to show you exactly every possible gas valve they would need a 4 page book to list the 300 most common gas valves that you might have. And in your case, if it was not in the 300 plus pictures, you would be in the same place asking the same question. A little common sense is supposed to be used when reading the instructions.

Everyone of these valves are used to shut off gas. Some are bigger to shut off gas to bigger things, others are smaller to turn of gas to smaller things.

The installer chose to use this valve to shut off gas to your equipment. And I don't think that the installer could do a better job of telling you that this is your gas shut off valve… I mean it says "Master GAS SHUT-OFF" on the tag attached to the valve.

I hope this helps.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

This is something I made for you so you don't get sidetacked in the future. Print this and tape it over the incorrectly illustrated instructions neat the boiler and another for the instruction manual.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Thank you Ed. I'm just trying to do everything to the letter, according to the correct procedures, without guessing "oh, maybe it's this other thing instead", or "well I don't see this thing shown in the manual, so maybe I don't have to shut the gas off, because maybe it doesn't apply if there isn't a shut-off valve inside the unit." because guessing wrong could be fatal. They tell you to remove the panel cover and the next step is to turn off the gas - clearly implying the gas shut-off valve is inside the unit. They don't have any further instructions for doing anything inside the unit once the cover is removed, therefore, logically, they're telling people to remove the cover in order to gain access the gas shut-off valve. So I'm being as careful as possible. Since it seems there is no other gas shut-off valve installed, and you have explained why there isn't, I will use the one that is clearly marked and visible.

And thanks for the edit.0 -

-

-

A) To become familiar with the procedure and B) because I want to inspect a circulator pump whose bearing assembly is making loud noises and doesn't seem to be working and I don't want to do that while the system is powered on and gas is still being fed into the boiler. There's no separate switch for that circulator, so I would have to shut the power off to most of the circulators to work on it, and I assume that would be unsafe while the boiler is operating. Also, there are 2 other circulators that may or may not be working properly that I also want to take apart and look at.

Should I start a new post about that under one of the other forum categories, or can I ask about it here?0 -

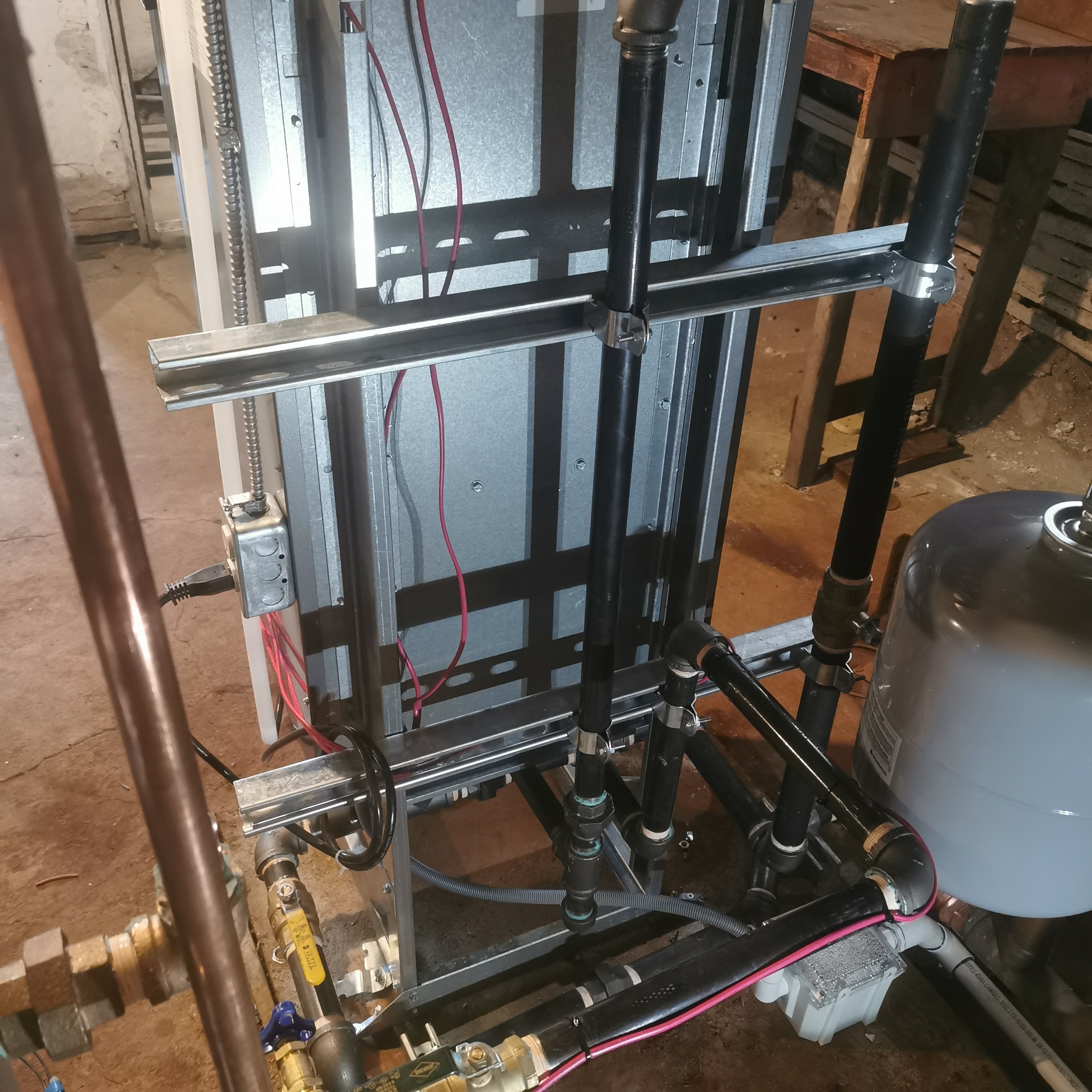

Post it here but take some pictures of the whole install first, try to show as much as possible to give everyone a bit to work from to start. frustrating as some of this may be keep in mind first that a boiler SYSTEM is not just an appliance you bought. there are things that must be installed in the field. the gas line being one of those things, must be sized and built in the field. you should have an appliance gas valve to the unit, a union and dirt leg, those components need to be accessible and outside of the cabinet. This may be required by local code (almost definitely), but more importantly its just smart. The valve so you can shut off gas to just the appliance, a union, so you can take apart the gas line to that unit (changeouts etc) and the dirt leg just in case junk is in the gas line, it should collect in the dirt leg so it doesn't end up in the gas valve. You may see on larger units a separate shutoff inside the cabinet, especially on a dual gas valve unit, but even then you still must have a valve outside the cabinet, union and dirt leg (and its smart!)

2 -

-

-

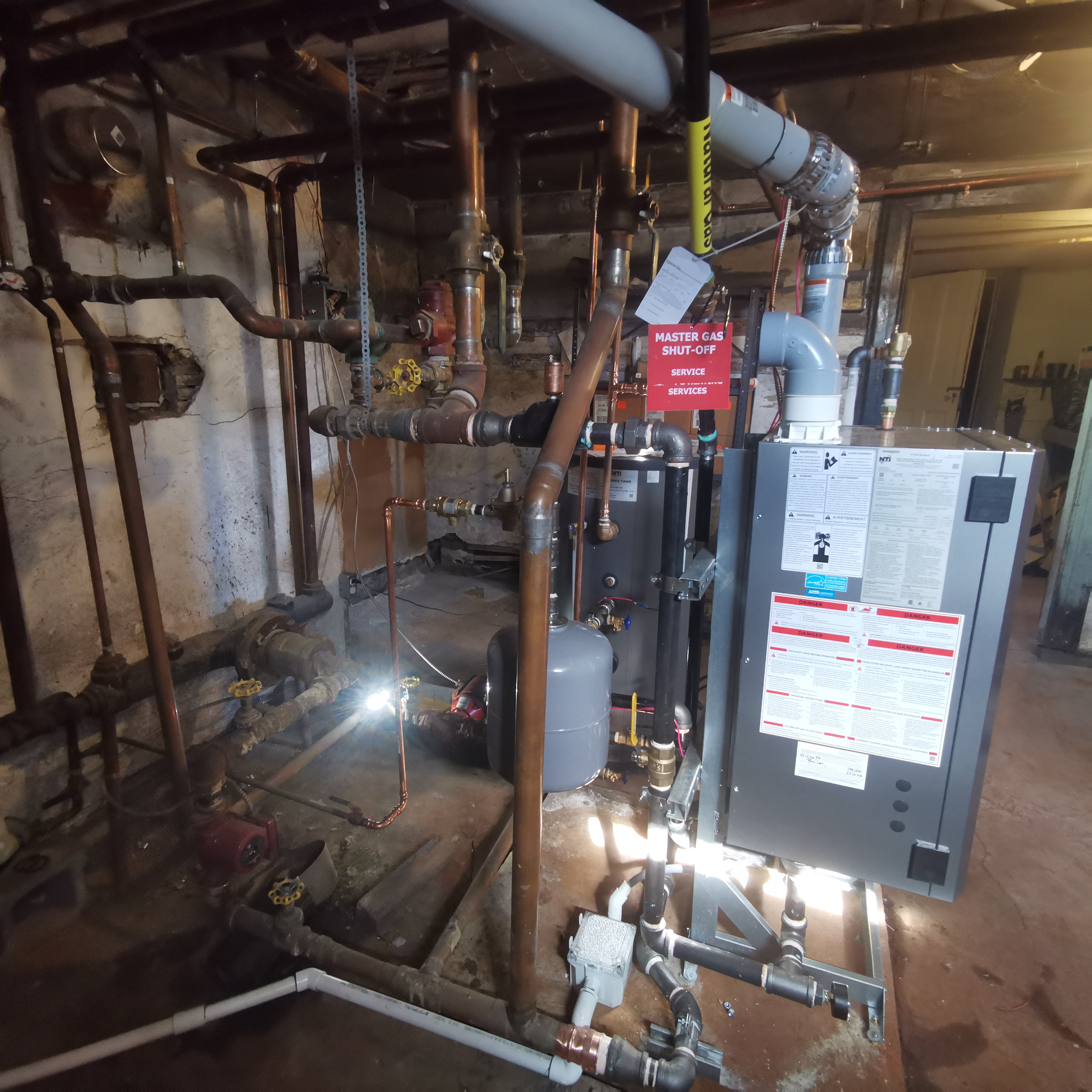

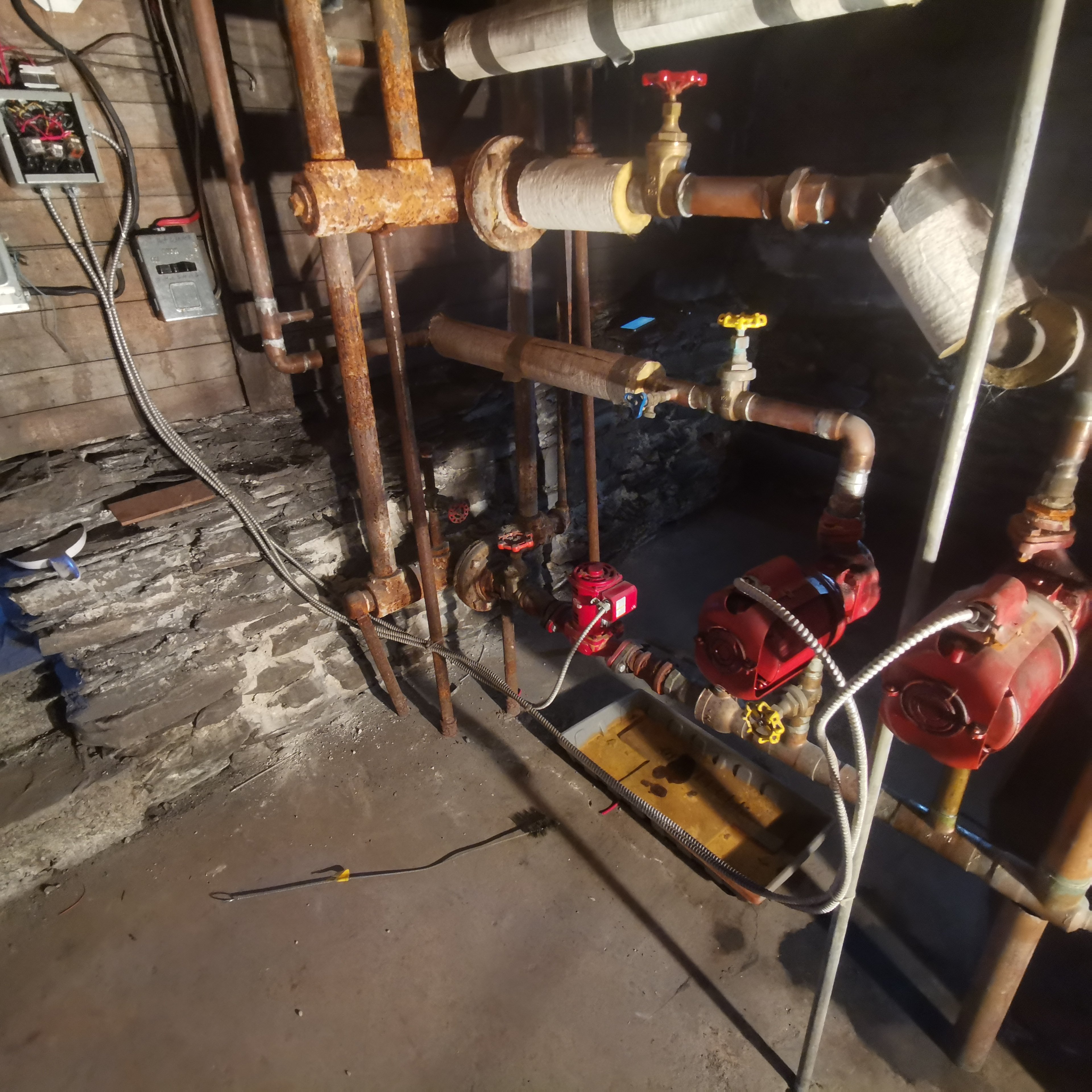

So as requested, here's some photos of the installation:

12

3

The circulator shown near the bottom of pic 3 is an Armstrong bearing assembly with a Bell and Gossett motor. It was making extremely loud shrieking noises. It's the first one I looked into after shutting the power, gas, and water off.

See here:Here's what it sounded like:

Wait, you can't post video here? In that case, the photos will have to do. But hearing the sound it's making would have been helpful.

I unscrewed the motor from the bearing assembly and looked in. The coupling appears to be seated properly and not broken, and oiled enough by the self-oiling mechanism.I twirled it around a bit, but couldn't find anything wrong with it. It remained in place when I did that.Next circulator is in a different section of the basement.

It's the short Bell and Gossett on the left. Did not open it because I couldn't find the size wrench needed to remove it from the pipes it's connected to. There are screws on the top of the unit which I removed, but the holes directly below those apparently don't contain screws. I had to clean those holes out with a q-tip to see if I could see any screw heads, and I didn't see any. That means to remove this circulator, I'd have to find the correct size wrench to take the whole thing out. I'll find a wrench for that if I have to go back and try working on it again.

Closeups:It makes a very loud constant noise.

Last one I'll show you is another Armstrong bearing mechanism but this one has a spring in the bearing assembly instead of a coil between it and the Bell and Gossett motor. I opened it up and saw nothing wrong, but there's a good chance I don't know what to look for.It's the one on the right. The one on the left is the only one that I for sure know is working and delivering heat to the rads. But the one on the right feeds the 3rd floor apartment, but that apt. is not receiving any heat whatsoever. The spring seems ok - it's attached the way it's supposed to be attached.

So IDK what I can do to show what's happening without being able to post video. There's no heat in most of the building and I think it's related to the loud noises coming off 2 of those circulators.0 -

-

I'll definitely consider doing that.

The funny thing is, they were very quiet today. Yesterday, the ones I opened up, I manipulated the coil in the first one and the spring in the other one. Also scraped off some dirt or caked dried oil or whatever it was, that was inside that one. Didn't see any dirt in the other one, but I oiled it up again, just in case that's what's wrong with it.

So they were making normal noise that they make when they're not broken, but there's still no heat in the parts of the house that they are supposed to be feeding. And most of the pipes don't feel hot.0 -

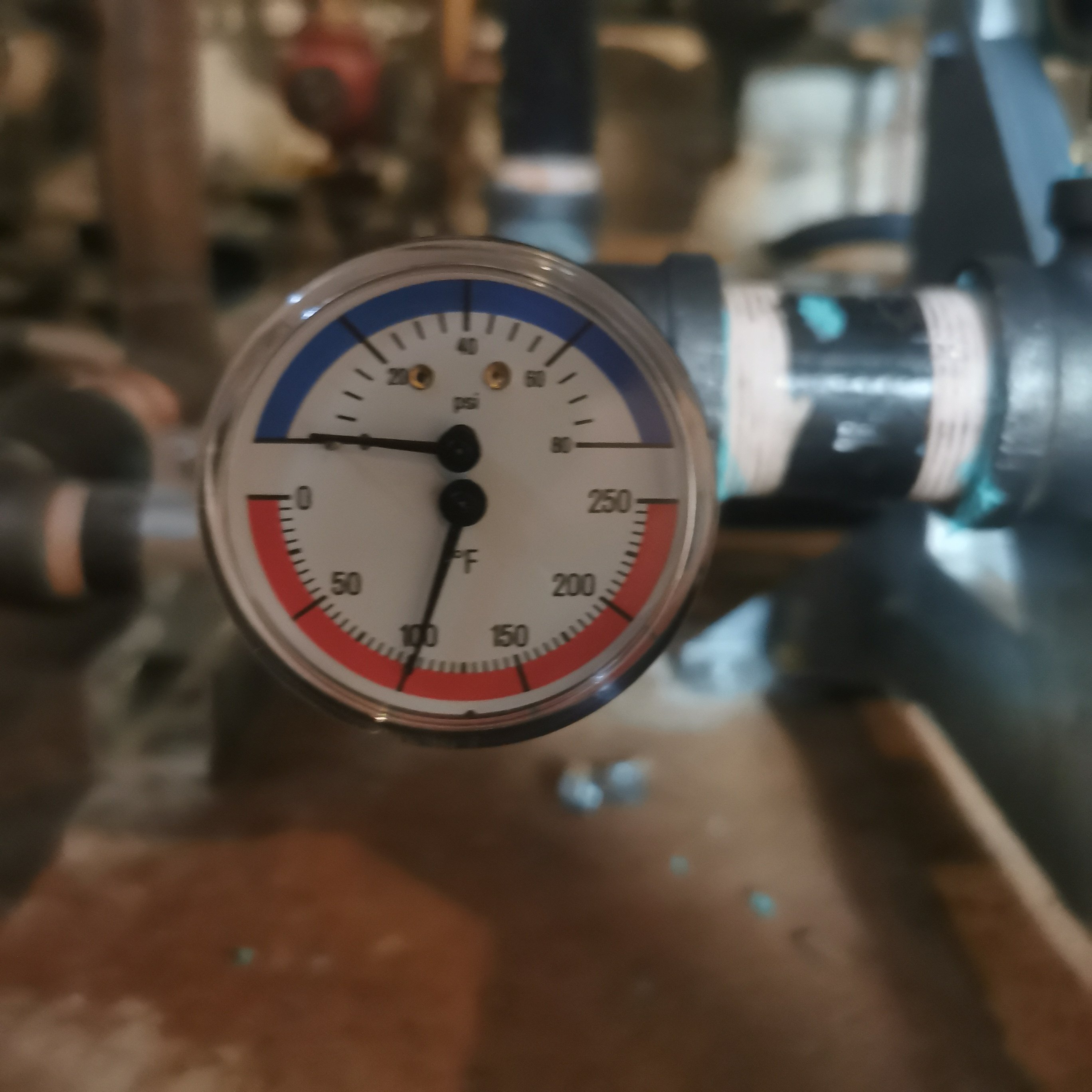

It is probably air bound. what is the pressure on the gauge on or near the boiler?

Is one or more of those circulators leaking?

It looks like that gas valve only serves the boiler in that picture. am i missing some other gas appliance?

0 -

This one leaks oil.

The pressure at the boiler is really low whenever I look at it, like I think it's at zero sometimes. That must explain some of this. I'll take some readings tomorrow.

There's just the boiler and the indirect water heater that they installed along with it. No other appliances.0 -

-

Yes it's a 3 storey building not including the basement. Currently, the 1st floor and 3rd floor are not getting heat. Only the 2nd floor is. The low pressure I've seen is very likely part of the issue but it might not be the entire issue - I think at least one circulator is bad or something else is going on. I'll see if I can increase the pressure tomorrow if it's below 15 when I go down there and check. The installers told me it should be around 15.

Another thing I've noticed is on the 3rd floor, I hear water sloshing around in the the baseboards, so they're getting water, just not heat.0 -

If the boiler is low on water pressure you should shut the pumps of before you damage them unless that has already happened.

0 -

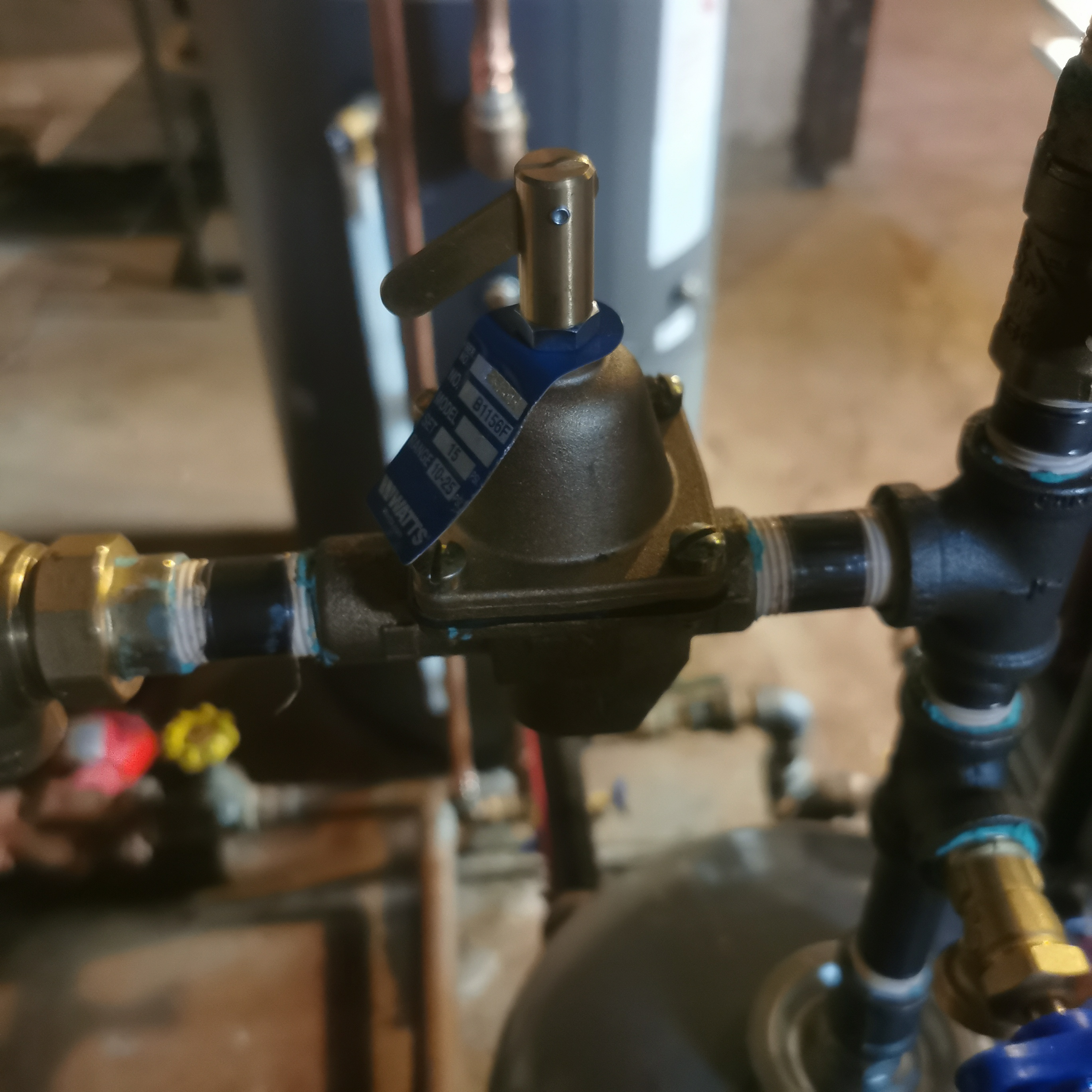

Is this what you use to increase the pressure?

Current pressure:

0 -

-

I don't believe it, but this handwheel was apparently turned off, because I just turned it counterclockwise all the way, and now I hear water moving through the pipes:

It definitely wasn't me who turned it off. I even checked the handwheels and handles yesterday to see if any of them were shut but I must have missed that one.

Wider view:edit: after half an hour, still no pressure according to pressure gauge. What do you do to add pressure? Is it that pressure valve that I posted a photo of earlier? Do you just lift the lever, or do you have to unscrew 2 areas of a pipe it's connected to like some videos are showing: https://www.youtube.com/watch?v=ReKh8NTwLQ4

0 -

I lifted the lever on the pressure release valve, thinking that would increase pressure in the system. Did it slowly and carefully, only lifting it a little at a time. Gauge showed no increase in pressure. I increased the pressure I was adding to the system at a faster pace. Still no difference. Then I added it a bit faster, still no difference in pressure showing on the gauge. Then, the release valve for the boiler started shooting water out:

So I gave up the attempt. Obviously something else is wrong besides low pressure.

0 -

-

I don't know what's going on. See my post that I posted at the exact same time as you so you might not have seen it.

0 -

-

The gauge is brand new and came with the boiler, but it doesn't look high quality and I'm open to replacing it. Could it be not seated properly? What is the correct way to replace a pressure gauge without shutting down the entire system? Can I just cut the water off to it, wait for that to drain out, and rescrew it in? Because if they screwed it in on an angle, maybe it's not reading the pressure accurately. I haven't noticed any other gauge in the room, not including the boiler's led screen.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements