Help!! Steam expert in Allentown/Reading PA area?

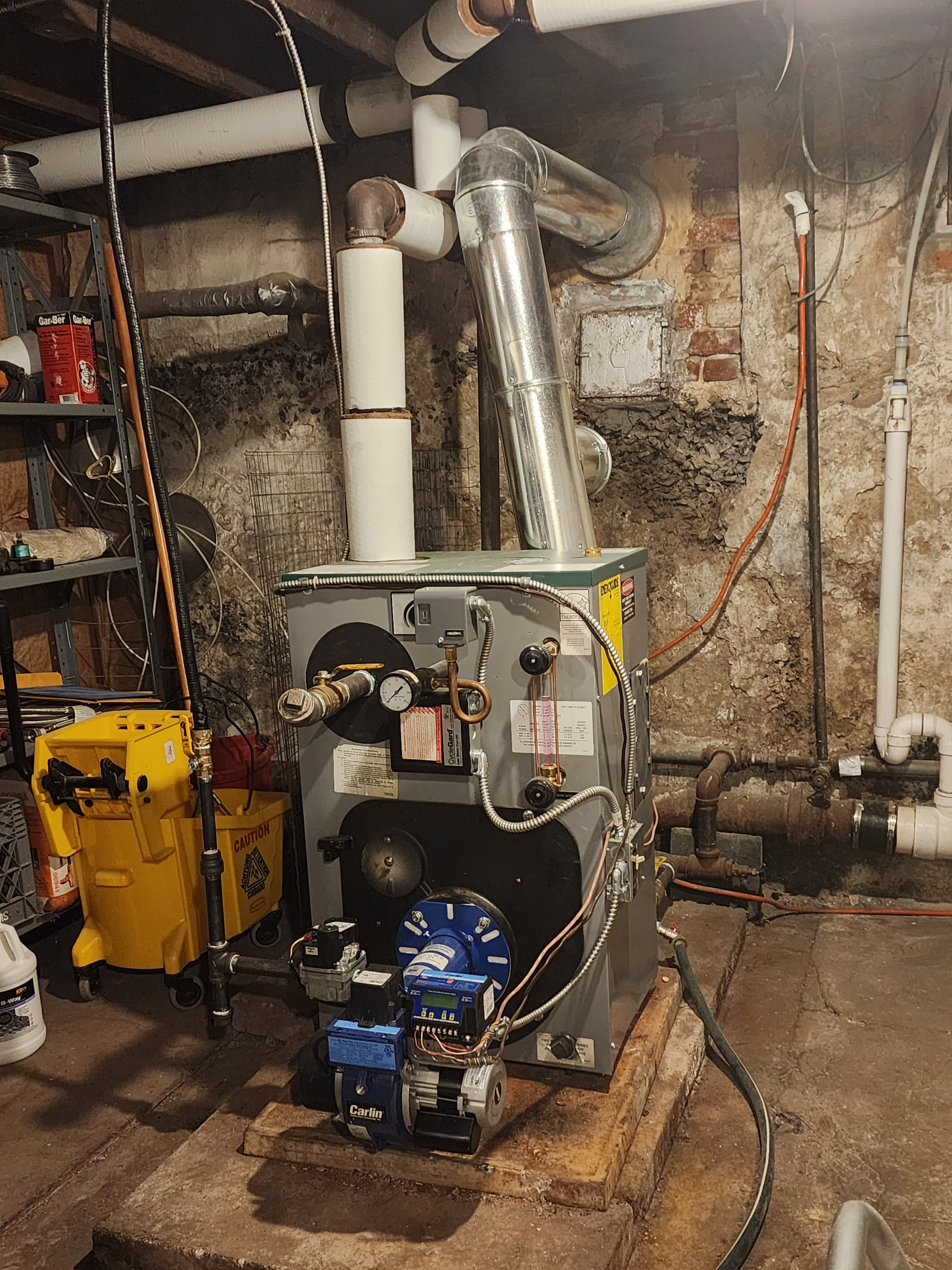

I'm so depressed. I've spent a lot of money now on a new boiler (Peerless) and switched from oil to natural gas at the same time, and my system is working worse than it ever has. My old boiler had a hole in it, was sending steam out the chimney, and I had to add water every day, but it still worked better than the new one. The installers did not change any piping. I have two mains, and it always favored one over the other and was never balanced perfectly, but now, even after nearly an hour, the "unfavored" main is only just getting steam at the end of the run. The "favored" one, meanwhile, has all three of the radiators it serves blazing hot all the way across. I tried taking the vent completely off the end of the "unfavored" main, so it should have been venting very fast, but it literally made no difference. I can hear and feel air escaping from the stem, so it's not blocked, but it makes no difference. The "unfavored" main serves five radiators. Two on the first floor and three on the second floor. One on the 1st floor does eventually get hot 1/2-way across after an hour, but it sits practically directly above the boiler in the basement. The other 1st floor radiator only has 1 to 3 hot sections after an hour. Two of the upstairs radiators have one hot section after an hour, and the fifth radiator, who's riser is at the end of the main, is still completely ice cold after an hour. Removing the vent completely at that one also makes no difference (but it is venting air from the hole, so it's not blocked). My old boiler and oil burner had it hot at least 1/4 of the way across after 50 minutes. I'm worried the new gas burner isn't powerful enough for my system, if that's a thing. The fact that I have one of those low-water cutoffs that keeps shutting the system down every 10 minutes for 60+ seconds doesn't seem to be helping matters, either. The guys that put the system in didn't seem clueless, but also didn't seem like steam experts either. I'm sure I'll get some diagnostics on warranty, but I'm not confident the issues will be completely resolved. Do any of the experts on here cover the Allentown/Reading PA area?

Comments

-

pic of boiler piping, did they flush the boiler? can you loosen the union at the rad, do the pie bow at all? Can you feel how far the piping goes? Let’s start with a pic, also what pressure are you at.

0 -

@JudyW I’ve done some work out in your from time to time.

You can reach me at (201) 887-8856

3 -

-

-

Sounds like your system is rather small, 50 minutes seems like a long time even from a cold start. Did the boiler installers measure the radiators to determine the size of what the new boiler should be or did they just match the old one ?

Did they skim the boiler to remove the manufacturing oil ? Venting and maybe piping issues too. A new boiler is an opportunity to improve system deficiencies, sounds like they just installed a boiler.

@EzzyT does some beautiful work, here are some examples;

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

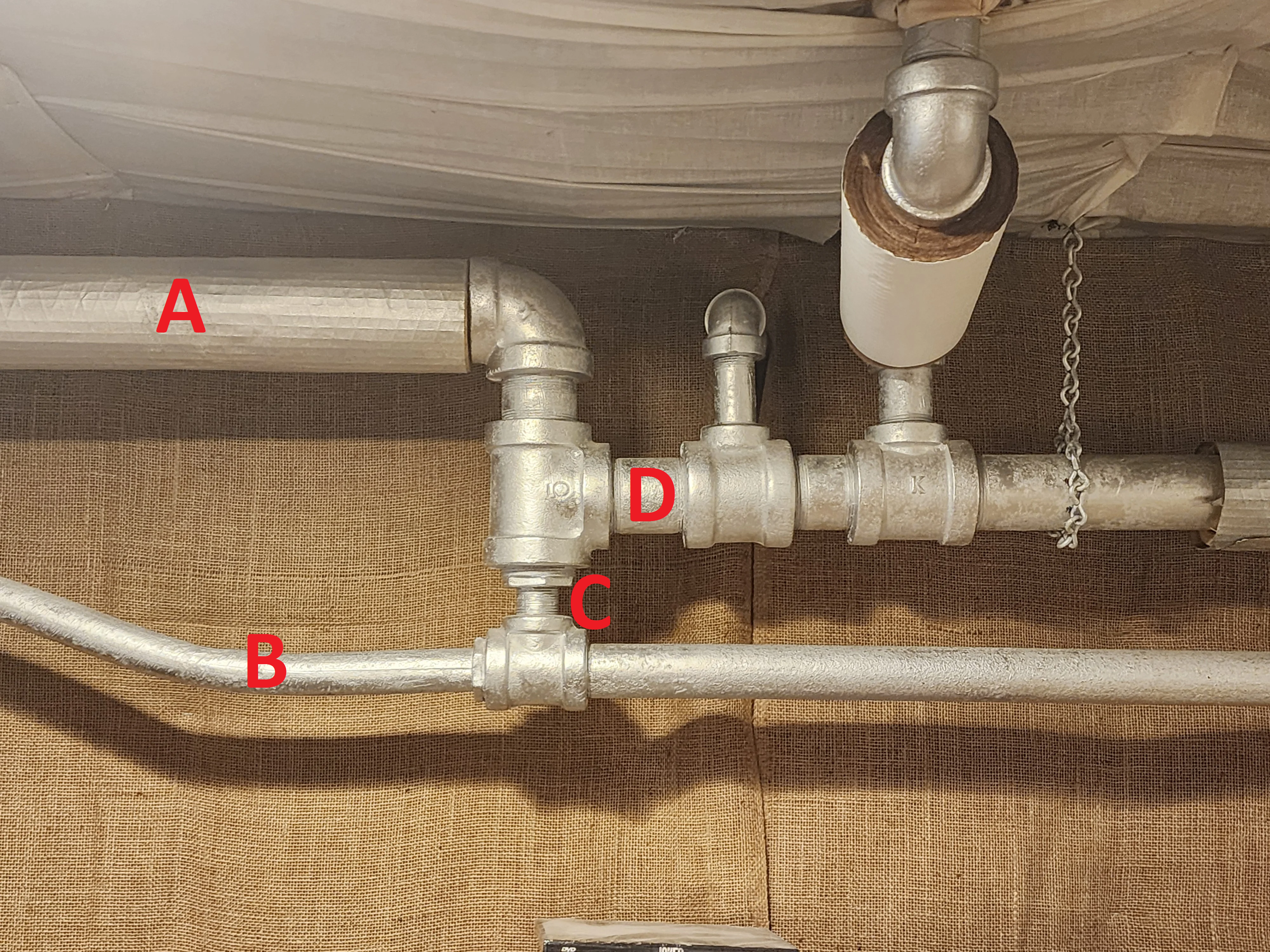

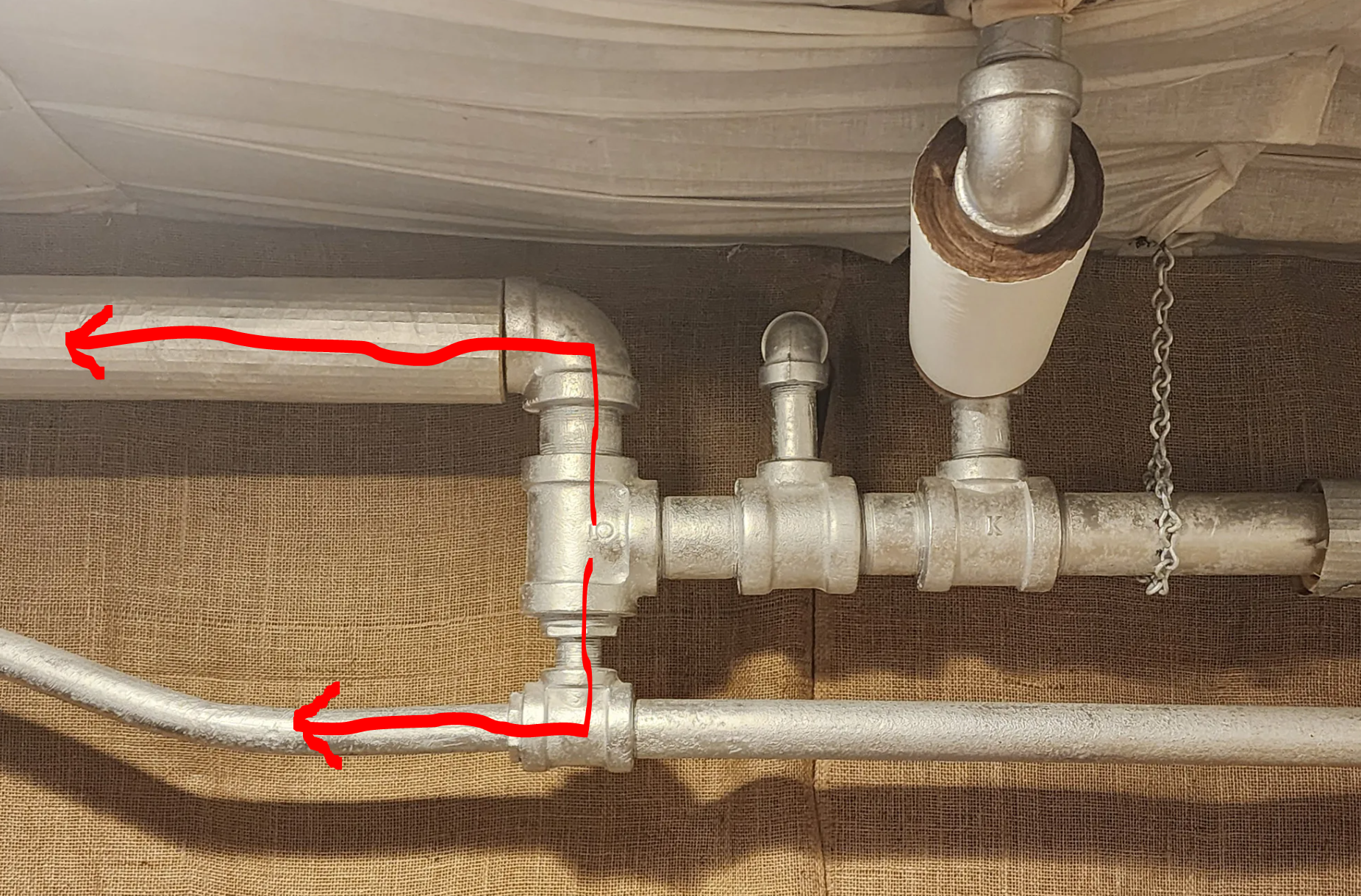

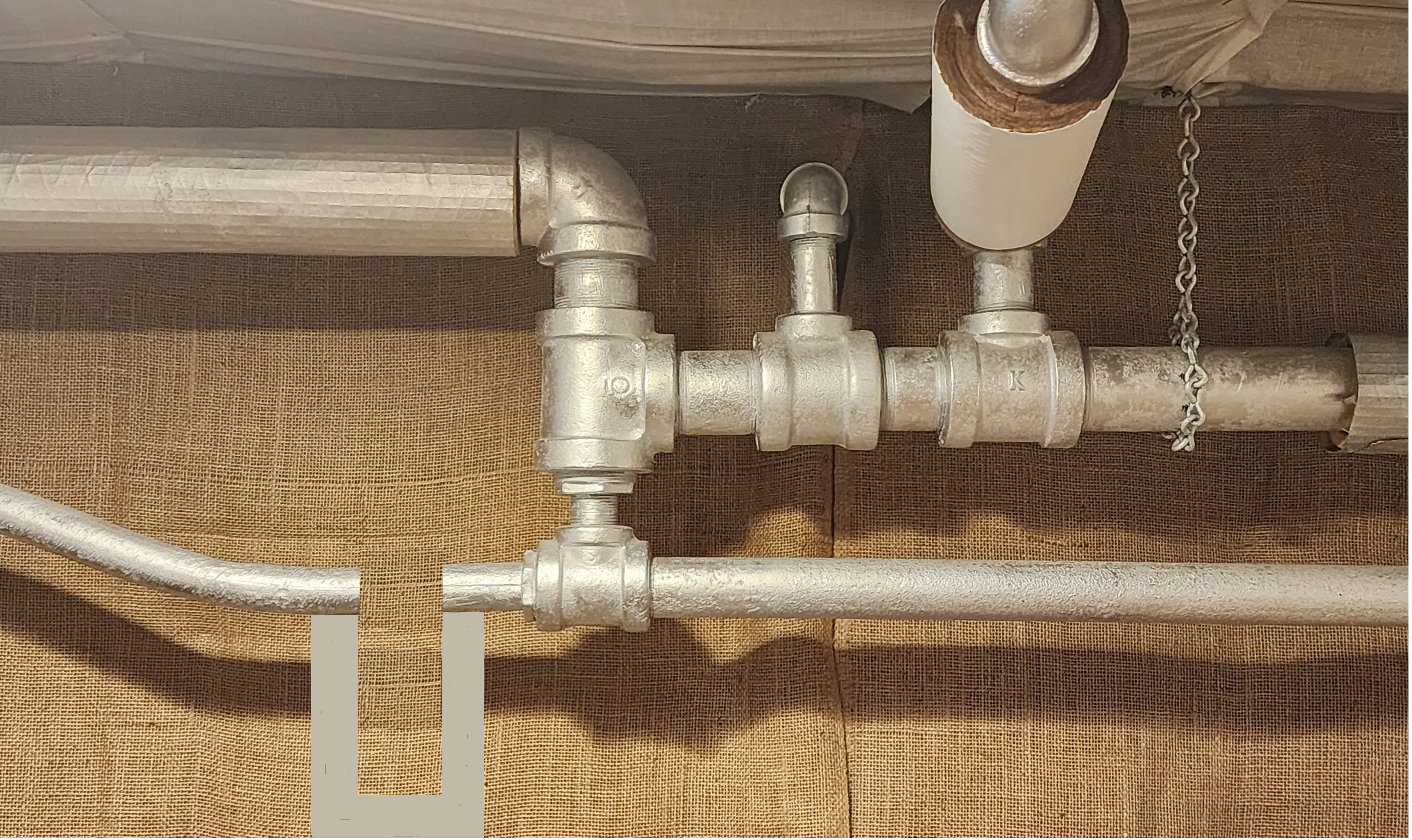

Thank you! I will give you a call this coming week sometime! Attached are some pics. I've always thought the strangest part is that there are two pipes, one much larger than the other, that are connected at the end of the "unfavored" main (as if it's one long pipe folded in half). My guess is that the lower pipe is a dry return (???) The main itself has this odd section where it comes to a tee and takes a 90 degree turn upwards, then another 90 degree turn to continue out. The tee also connects into the dry return (???), so steam gets up into that pipe too. The two radiators whose risers branch up right before this odd configuration are two of the ones that have serious trouble getting steam. (one is on the 1st floor, the other on the 2nd). I know those main vents are undersized, but like I mentioned, I completely removed the one at the end of the longer "unfavored" main and air vented out of the stem, but it made no difference whatsoever. Still took an hour for true steam to get down there.

0 -

Barometric damper on the flue pipe is very wrong.Edit: Baro is correct

0 -

Does 'A' and 'B' service more than one radiator, I suspect two ?

I think the whole A, B, C, D pipe configuration thing was to either raise the height of the parallel flow main or provide more headroom to where pipe 'A' and 'B' are going or both. Since 'A' is higher than 'D' you don't want to trap condensate in 'D' so you need 'C' as a drip so condensate in 'D' can drain away. The problem is Steam can take both paths 'A' and 'C' to get to the Left main vent pushing out more air than is necessary to get steam to the radiators to the left slowing things down. Pipe 'C' should go from 'D' down significantly (maybe to the floor, pressure issue) and back up to 'B' to trap condensate to block the steam path but let condensate return to the boiler. Improving the venting a lot may be easy and all that is needed for that issue, changing 'C' is more work.

The flexible gas line wrapped with black tape may be too restrictive. The burner may not be able to output its full BTU/Hr rating (as you suspect).

Why did they install an oil boiler then modify for gas ? Was the gas conversion a later decision ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

It looks like someone in the distant past replaced a wet return with a dry return and connected a drip that had to go to a wet return to the dry return.

or a loop of pipe that made it a wet return was removed somewhere.

0 -

All of the A, B, C, D stuff goes way over my head. Lol. To clarify, though, the boiler is to the right, abut 15' or so, of this weird configuration. I didn't post the photos in order following the pipes. The system is designed for two radiators off the end of the main, but I have one of them removed and capped off atm. It's been like that for over a year and the one removed is only a 3-section radiator.

There was no natural gas line to my house yet when I had the boiler replaced. UGI came out and put the line from the street over the summer. Boiler was shot and needed to be replaced before they could get the gas line in. It was cracked, sending steam up the chimney, and I was constantly adding water. I used the new boiler with my old oil burner for the last month of the heating season. It worked better than the new gas burner.

ETA: That lower pipe does drop way down once it's closer to the boiler.

0 -

What's wrong with the barometric?

I don't care for the CSST gas line but I hate csst anyhow. It could be undersized. piping around the boiler I have seen worse. If its sized right it may be ok. Wondering if the Hartford is the right height? Looks high but may be the camera angle

Probably needs more venting.

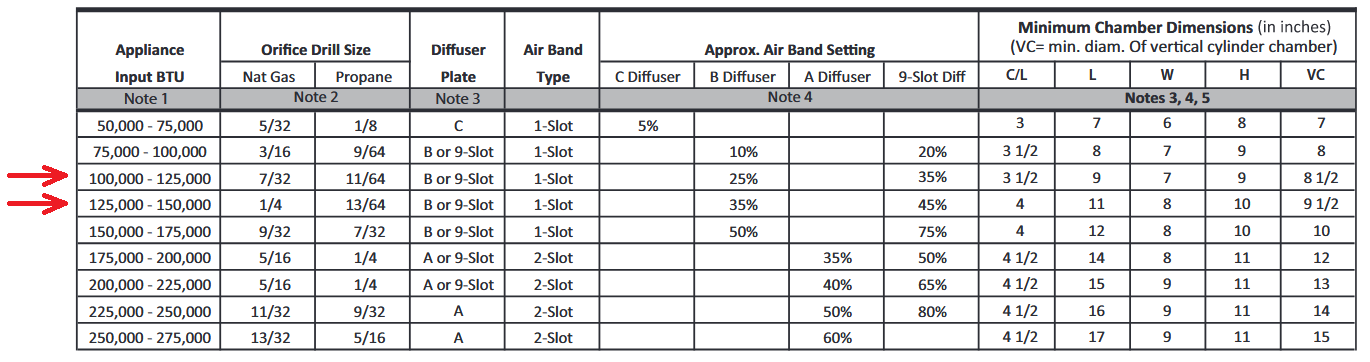

If I had to take a wild guess, I would guess a gas pressure/ orifice size/ combustion issue.

At least they put in a skim tapping.

The reason I suspect a gas issue is the OP said it worked better with the oil burner installed. Plus, the burner may not have been bought with the boiler as the gas line was not installed. If that was the case that increases the possibility of the wrong orifice.

If Carlin does not know what boiler its going in they usually ship with a small orifice nipple which can be drilled out.

2 -

-

Would the fact that steam ends up traveling down both pipe "A" and pipe "B" once it hits this configuration, and needs to push out a larger volume of air in order to make it to its "radiator destinations" have anything to do with how slow that leg is? Like I mentioned too, the steam seems to almost just bypass the two radiators in line there, even if I completely remove the vents off of them. Eventually a couple of sections get hot, but only after an hour.

0 -

Is it dangerous? The barometric damper thing?

0 -

the steam will follow both of these paths toward the vent. if the one without the radiators on it wins, the vent will close and keep those radiators from heating

that may be part of something leftover from the original coal boiler.

0 -

This. @JudyW , did the installer do a combustion test?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Yes, I remember him saying something about a test.

0 -

Did he give you a copy of the results? If not, I'd have my doubts. Digital analyzers come with printers for this purpose.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

The two pipes (A & B) are connected at the end of the main on a single vent. So they can be added together volume-wise as if they were one big pipe. That's the way I think of it anyway. I'm not sure how it affects the physics of it all. How would increasing the diameter of a main towards the end of it's horizontal run affect the system, if at all? This is the end where they're connected:

0 -

I don't have a copy of the results, but my invoice states it was adjusted and tested. I know he mentioned a BTU number to me as well, but I can't remember what he said. I'm sure they'll retest when they come back out. I'm sure they have the records too. These guys aren't at all unprofessional. I just know they don't do steam systems all day long. Lol

0 -

If steam travels through the lower smaller pipe and closes the Left hand main vent the only venting remaining to purge the Left main (larger pipe) is the one on the remaining radiator (the other is capped off), so everything on the Left side of the boiler is slow. Once the radiators on the faster side of the system start to condense steam causing a lower pressure inside the radiators on the Right hand side of the system, the steam movement favors the Right hand side which slows down the Left side more. If the burner is set up undersized for the boiler / system that just makes things worse.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

Ugh. Sounds like a vicious cycle. Would keeping a smaller vent on the right side main and radiators help? Does pipe "B" even really need to be there at all if the main were angled back towards the boiler? It does get hot before pipe "A"!

I know the btu number he mentioned from the test was not in the 100's.

0 -

This is great to know. They were, indeed, NOT bought at the same time!

0 -

Since it is a parallel flow system (the mains slope away from the boiler and a return at the end of the main brings condensate back to the boiler), if the main is raised as it moves away from the boiler, the lower section needs a drip to allow condensate to return. That drip should drop to the floor so the drip connects below the water line. There are also arrangements with u bends in the piping that could keep that elevated section full of water and stop steam from passing through it.

I think that section may exist because the original coal boiler may have had 2 steam outlets, one of which was connected to the tee.

0 -

It is a vicious cycle, every cycle of the boiler. It is all about balance. The mains want to be vented as fast as possible, but equally so the steam is available at the radiator runouts at about the same time. Then when the main vents close the steam can propagate evenly to the radiators at the rate the radiators are vented at.

If you remove the 'B' pipe and raise the 'A' pipe the radiator and radiator runouts would have to be raised also so the condensate can drain.

" It does get hot before pipe "A"! "

The 'B' pipe has less air in it and less metal to warm up as the steam propagates.

Not sure how your boiler was originally set up with the oil burner but both ways are in the 100's

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

So, could it help if pipe "B" had some kind of P trap or a dip in it right after the tee to prevent steam from traveling up there?

This house definitely had a coal boiler when it was built. The hole in the wall for the chute is there, but it's boarded up.

0 -

-

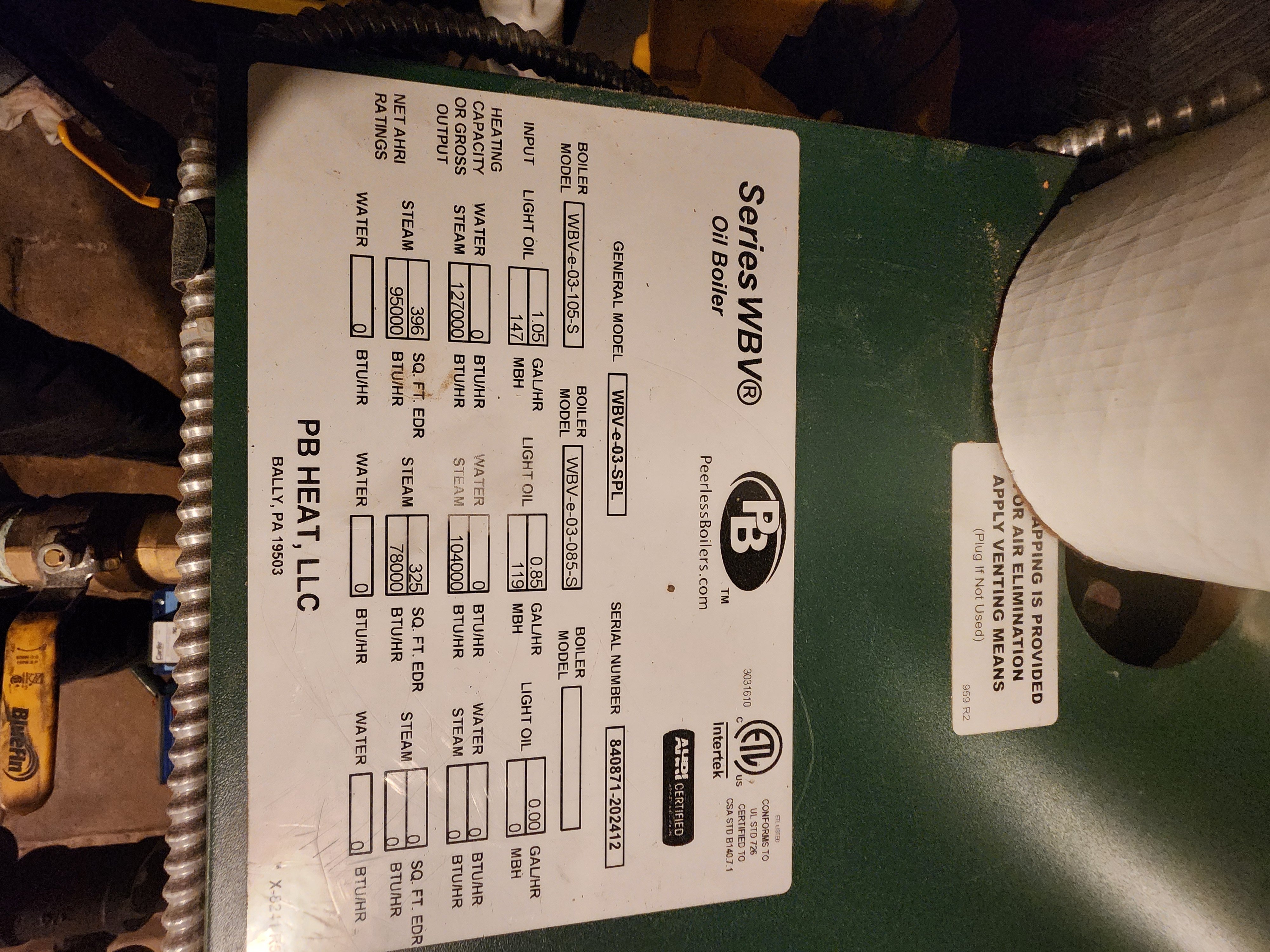

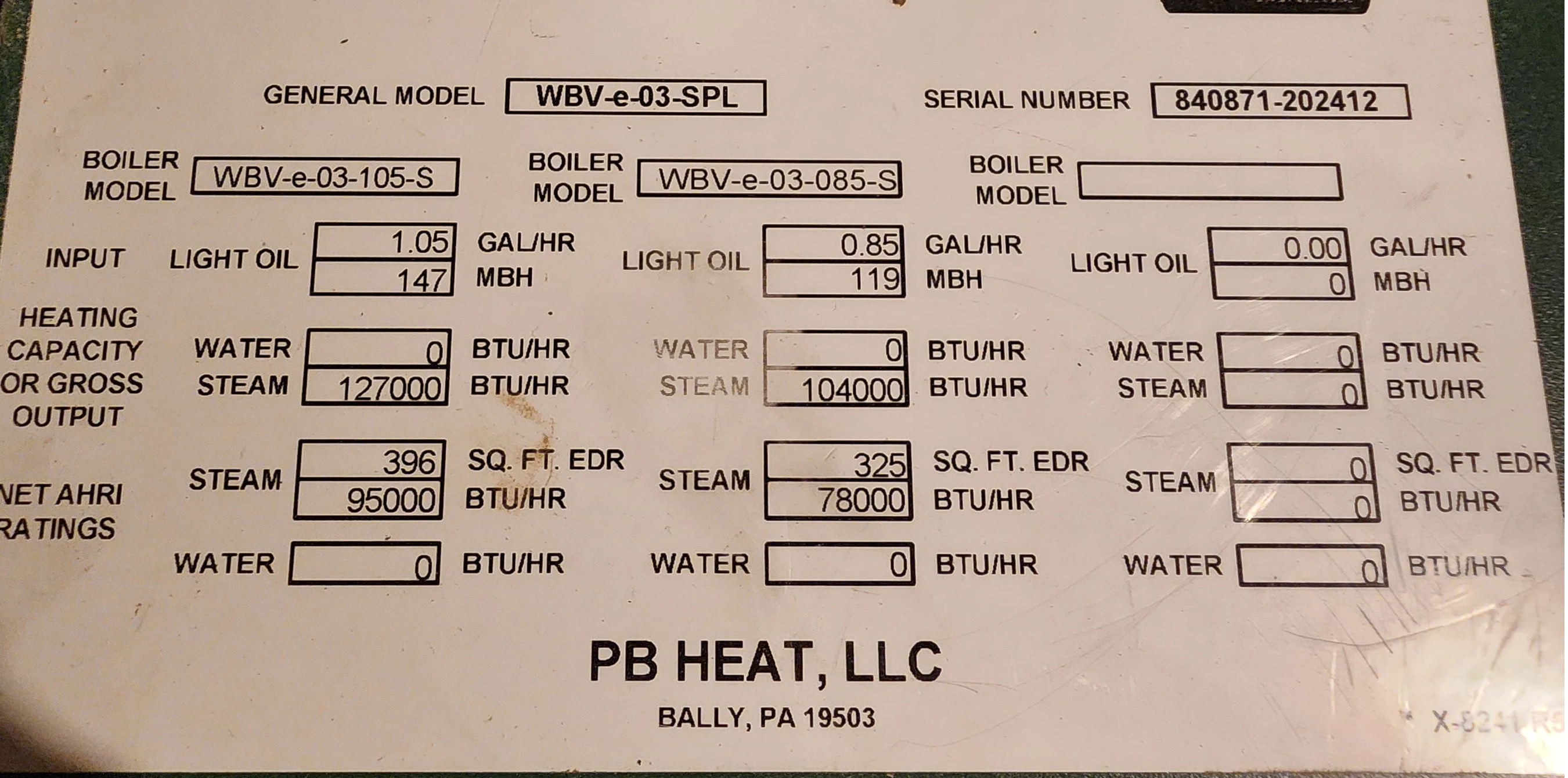

I don't know if I have the first one or the second one. Or are they the same thing, just set up differently? What's what with the BTU numbers? Am I looking at the capacity/gross output or the Net Ratings, which are both below 100,000?

I'm pretty sure my EDR is right around 310. It would be 322 if I include the 2-column, 3-section radiator I currently have offline and capped atm. (edited to fix)

0 -

Is this accurate or am I missing something ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

The Gross output, since you need the fuel input to achieve that output. The difference between the Gross and the Net is what is radiates through the boiler jacket etc. and also what goes up the chimney.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I suspect it is the same boiler just factory set up with a different capacity nozzle for the oil burner. It would be interesting to know, since you are comparing that performance to the present performance.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

An example; my old gas boiler is in the same size ballpark as yours. There is a pilot light keeping the boiler mildly warm. From a cold start (has not been run in days), in about 10 minutes it is steaming and in another 8 minutes the supply ends of the radiators at the far end of a 36 foot long 2" main are getting too hot to touch. After 30 minutes all radiators are significantly hot. No LWCO interruptions.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Yes, that's accurate. There's about 10' of pipe between the two photos, though.

0 -

What IS the deal with the LWCO shutting the system down constantly (like every 10 minutes)? I know I don't actually have low water. Is it some kind of over-the-top safety feature? Seems like it's slowing everything down and using more fuel than necessary.

0 -

Your boiler is capable of 396 square feet of steam so if you rads total 322 you fine.

Call @EzzyT he will find the issues. It's probably a combination of 2-3 minor things.

Everything is just a guess at this point.

Things need to be gone over and checked and possible issues eliminated

0 -

You guys are a godsend! I agree it's probably a combo of 2 or 3 minor things and I have nothing to be fretting about. 😊 If having the installer tweaking those things doesn't work, I'll definitely be on the phone to @EzzyT Either way, I'll give a near future update!

0 -

Needs to be double acting for gas

From the manual…

"…Install a double-acting barometric draft regulator in the vent piping. (The damper must be located in the same space as the appliance.) Install a manual reset spill switch (blocked vent switch) per spill switch manufacturer’s instructions. Wire the switch into the 60200FR control’s “BV” (Block Vent) terminals or into the appliance limit circuit to shut off the appliance/burner if sustained downdraft or flue blockage should occur…"1 -

" What IS the deal with the LWCO shutting the system down constantly (like every 10 minutes)? I know I don't actually have low water. "

If you look up the on-line manual (I assume they did not leave you the paper copy) of that make and model LWCO it explains that Test feature (safety feture). With oversized boilers it can actually help, otherwise it is annoying IMO.

There are other LWCO units that behave differently.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements