Steam Boiler Pressure & Some Of My Adventures

*Long post ahead*

Alright, long time reader, first time poster, but I'm looking for some help with my steam heating system. I've read up almost as much as I can on this, but nothing specific to my situation. Wisdom comes from a multitute of counselors, so I'd like to hear what the multitude thinks.

Unfortunately I don't have pictures right now, but can get some later tonight when I get home.

Bear with me as I fill you in on some of the context. I have a Burnham MST396, single pipe steam system. I've been trying to do some much needed maintenance on it, as it's never really had any maintenance done, and the system had several leaks in it when we purchased the home a few years ago. When I purchased the house it had 3 radiators that were leaking horribly. Here is what I have done to the system so far over the past 2 years.

- leaking radiator #1 removed and line in basement capped off

- leaking radiator #2 replaced and works great

- leaking radiator #3, I just found a replacement and will have it swapped out in the next few weeks

- replaced leaking gauge glass and valves

- leaking radiator valve replaced (I still have one that leaks out of the top and needs replacement)

- skim tappings installed and boiler skimmed. Probably needs it again. Poor thing probably has never been skimmed

- sludge drained and hercules boiler cleaner added and system run. I just finished the 2nd round of cleaner and will drain it again and refill using 8 way treatment

- basement piping partially insulated, will be finished before the heating season

- someone wired in an aquastat which kept the boiler at 180 degrees when not calling for heat. I have a separate hot water heater, so I only just disconnected this. Before this past year, I had little to no knowledge of my steam system, so this didn't seem out of place to me.

Here's a little more context. I have hard water, 14 gpg. The amount of makeup water that has been put in is excessive. Unless the auto water feeder isn't correct, close to 140 gallons over the past few years have been added. The saving grace may be that the system almost always ran right after, getting rid of any oxygen. Hopefully not a lot of damage done. And there must have been a ton of scale building, hence the cleaning. Though there is lots of water loss, I do not believe this is a cracked boiler situation. No steam coming from the chimney. With the exception of the faulty gauge glass that was replaced, the boiler holds water when not in use. I believe the water loss was simply from the excessive leaking of the radiators. (I'm talking full on sauna in my bathroom from one of them. It was about the same as a 15 minute hot shower).Now that I've cleared up most of the leaks, I've run the system a few times for cleaning and have not experienced much if any water loss. I've meticulously checked all the piping and believe that I have identified all the areas that I lose steam/water. Also to note, I have no main vents. I'm looking for a good solution to that currently. There are no plugs at all that used to be main vents, so I'd be drilling and tapping some tees, though one of my mains doesn't have any tees, only elbows. This may be related to my currently dilema, but I truthfully don't know. So let's get to that.

In the process of doing my boiler cleaning, I determined that it did a great deal for the efficiency of the boiler. The reason I determined this is because the pressure gauge on my boiler climbs much more quickly now than it did before. Now I know what you're thinking, how high is your gauge climbing? You need hardly any pressure at all to run steam. Exactly where my question lies. Until these past few weeks of diving deeply into steam, I never realized that my pressure gauge should not be climbing up to 10 psi. My pressuretrol was maxed out at 8 or 9. I've never touched it. I just set it to 1.5 with the subtractive diff at 1. That was today. I turned the system on to see how long it would take to heat up and start bringing the steam to the radiators. Only about 10 minutes in and the pressure gauge was up to about 5 psi. Near boiler piping was still stone cold except for the pipe coming directly out of the boiler. It ran for a few more minutes and got up to about 12psi. Only after this point did I start getting steam to all of the radiators. This is normally where the boiler had been operating. Again I had no knowledge that it shouldn't be this high. So, armed with this knowledge, I've come to several possibilities.

1. The pressure gauge is faulty

2. The pressuretrol pigtail is clogged

3. The pressuretrol itself is faulty (I don't think I've ever had the pressuretrol turn the boiler off, so my guess is that it's not detecting the actual pressure)

I don't know if lack of main vents contributes to this. It makes sense to me that if the air cannot get out quickly enough, that should build some pressure, but I don't know about 12psi. As a side note, all my radiator vents work. I do hear the air coming out of them, and from what I've read they should be pretty silent, but they all close properly.

So here's where I'm at. I'd like to just remove the pigtail and see if it's clogged. But I can't remove it without taking off at least the LWCO. I can do that but I'd probably rather just cut and replace the pigtail. I plan to extend it out with a brass nipple so I don't have this problem in the future. I also plan to put an additional pressure gauge on a tee with the pressuretrol so I can see if there is a discrepancy between the two gauges. My concern is that when I do that, if the pigtail is indeed clogged leading to the pressuretrol not detecting the pressure, what will happen when it actually does? It seems like my system would short cycle really early and doesn't seem like I'd actually get steam to my radiators based on my experience with it today. Additionally, I'm not sure what this should look like, but after having the boiler on the gague keeps its pressure for quite a while. I turned it off at 1pm and it probably will still be around 2 or 3psi when I get home in an hour or two. There's more I'm forgetting for sure, and I don't have pictures as of yet, but any thoughts on the situation are appreciated. And thanks for making it to the end of my sort of long post 😀

Edit: this post here seemed to be something similar, but as this is not my specific scenario, it didn't give me answers that I needed. https://forum.heatinghelp.com/discussion/201488/some-help-advice-pressure-shut-off-pigtail#latest

Comments

-

Your post is too long 😅

The saving grace may be that the system almost always ran right after, getting rid of any oxygen.

This is always the case with fresh water added to a boiler. I don't think it helps that it boils immediately after adding it. The oxygen gets released into the boiler steam chamber and attacks the metal. But that doesn't mean your boiler is in trouble. We don't know its current condition. Just fix the leaks and move forward.

Get vents on your main(s) but you already know this.

Don't worry about short cycling. The burner shuts off for a minute then starts back up, no big deal. The steam pressure won't drop below zero so it isn't going to stop steam going to the radiators. (It's the lack of main venting that is your problem here)

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

I'm going to bet that a) that pigtail is clogged and b) there is a way to get it apart without major trauma. Can you send us some pictures of the setup?

Oh and c) there's a good chance that the pressure gauge is lying, but you have to have a 0 to 30 psig gauge to keep the insurance boys happy — so keep it and, as you suggest, put a nice new low pressure gauge on the poor thing somewhere.

Do the radiator vents open properly? Do they close?!

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

As stated above verify / repair the pressuretrol functionality.

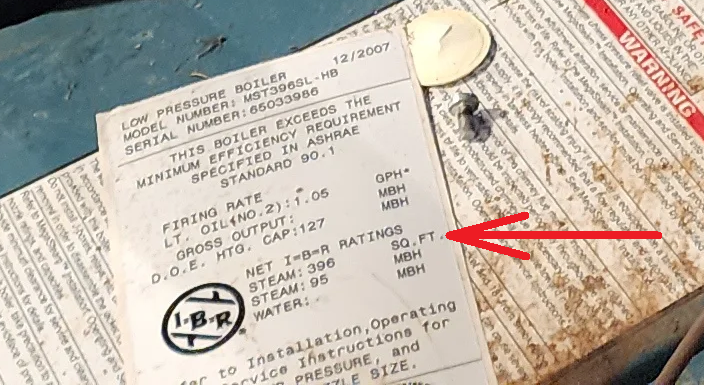

I'd do an EDR (Equivalent Direct Radiation) survey and compare that number to the Sq. Ft. on the boiler's rating plate. Your boiler may be oversized, it may be more oversized since you removed a radiator.

As an example my system (slightly undersized boiler) with the main vent in use or valved off the boiler pressure NEVER goes over 2 inches of Water Column (0.07 PSIG). With the main vent in use the main just fills much more quickly, so less fuel burned to purge the air out of the main.

As a second opinion a low pressure gauge could be added to another boiler tapping or a Tee added to the skimming port pipe. Some folks like a 3 PSI Gauge (kind of almost useless in my case). If your system truly goes over 3 PSIG a valve to protect the low pressure gauge should be added to that gauge only.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I'm assuming this is one pipe, only one pipe connects to each radiator?

It may have done ok without main vents on coal, with an automatic boiler with gas or oil it needs main vents.

you can see if the pigtail is clear by just unscrewing the pressuretrol from it.

you can probably either tighten the packing or add some string packing to stop the leaking valve stem.

0 -

Remove the pressuretrol and blow into the pigtail. If it's clear you should be able to blow right through it.If you can't, then remove it. If it's brass you can usually flush it out by just sticking it into a hose outlet and turning on the water- you might get splashed though. If it's steel, it's probably rusted, so replace it.

We like to put a 1/4" tee with a plug in the bull under the pressuretrol. This way we can check it without removing the control- just remove the plug and blow into it.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

Agree with @ethicalpaul main venting and venting in general is you issue. If you pressure gauge is reading correctly and you have pressure, and the piping is cold you are air bound.

1 -

I'll have to get a few pictures in the morning. But I believe the LWCO will prevent me from turning the pigtail fully.

Yes the radiator vents all open and close properly!

0 -

-

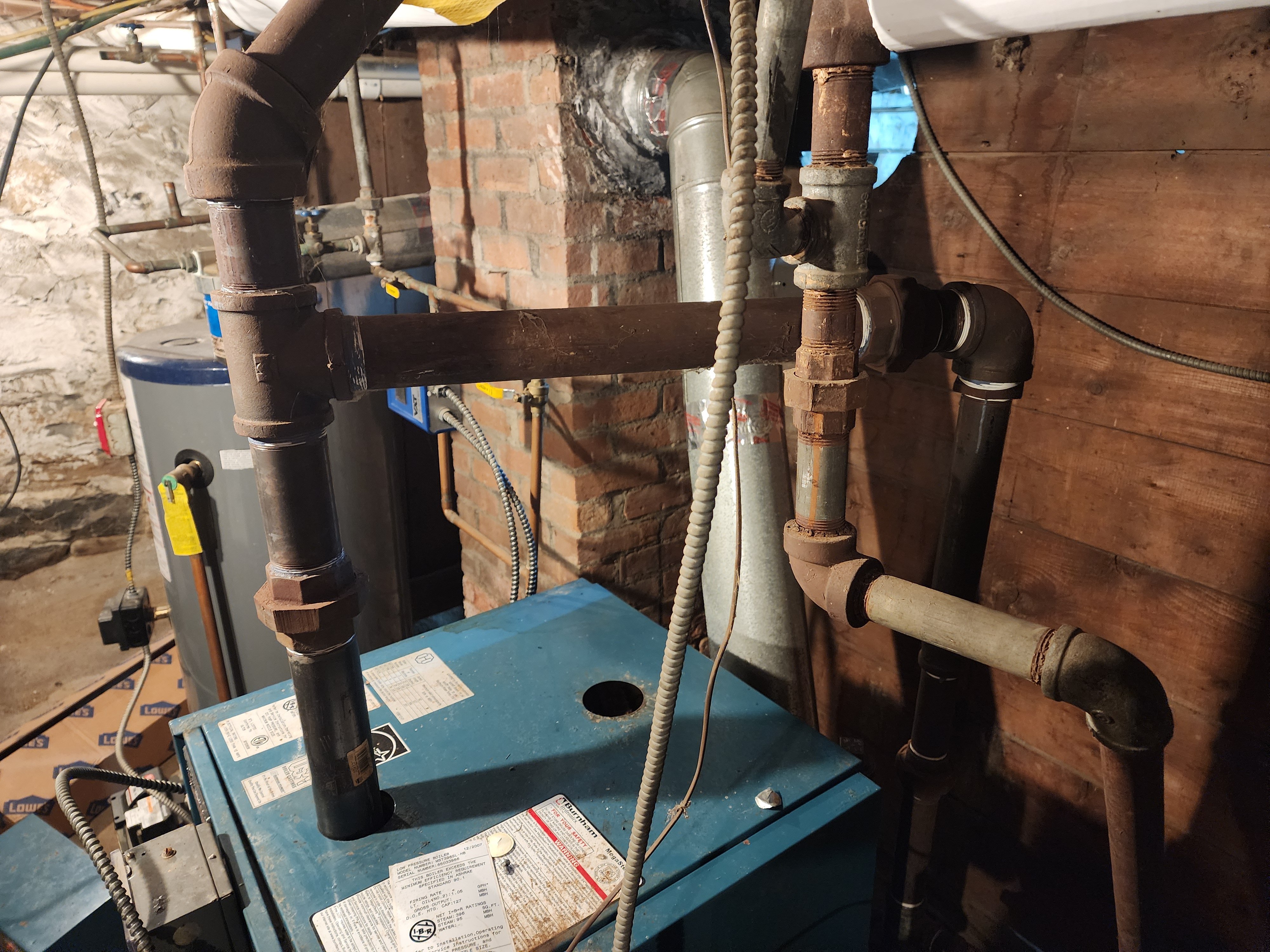

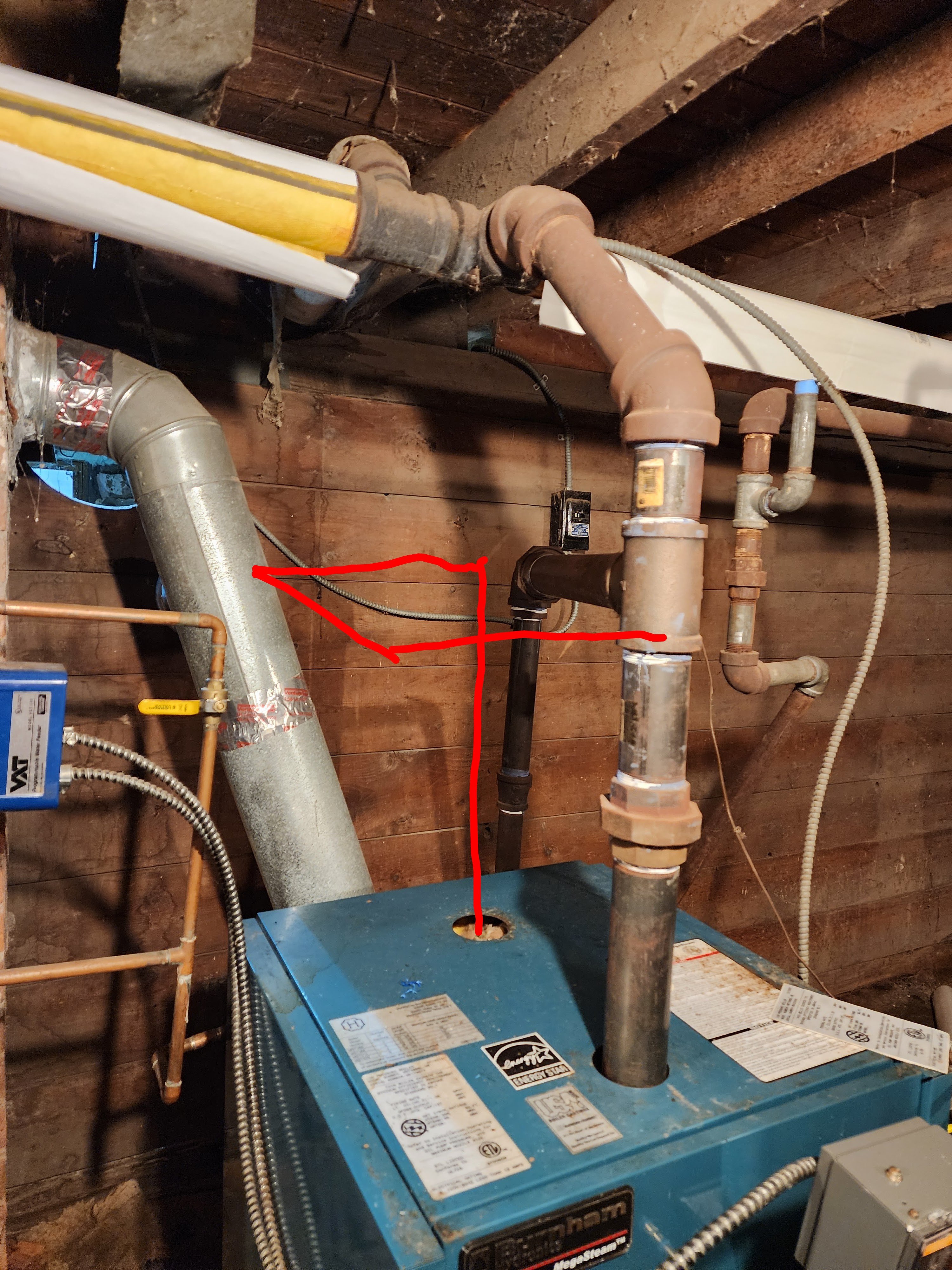

Here are some pictures, including some of the near boiler piping. I managed to get the pressuretrol off. Also I think I know why it wasn't working. When I went to turn the pigtail to remove the whole thing, the pressuretrol snapped right off. There was definitely some corrosion on it. So I'll be replacing that now 😅

0 -

Get a vaporstat and a low pressure gauge now that you have to replace it. that pigtail is brass.

0 -

Looks like it has been leaking for a while. The old version PA404A was brazed at the point it broke at.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

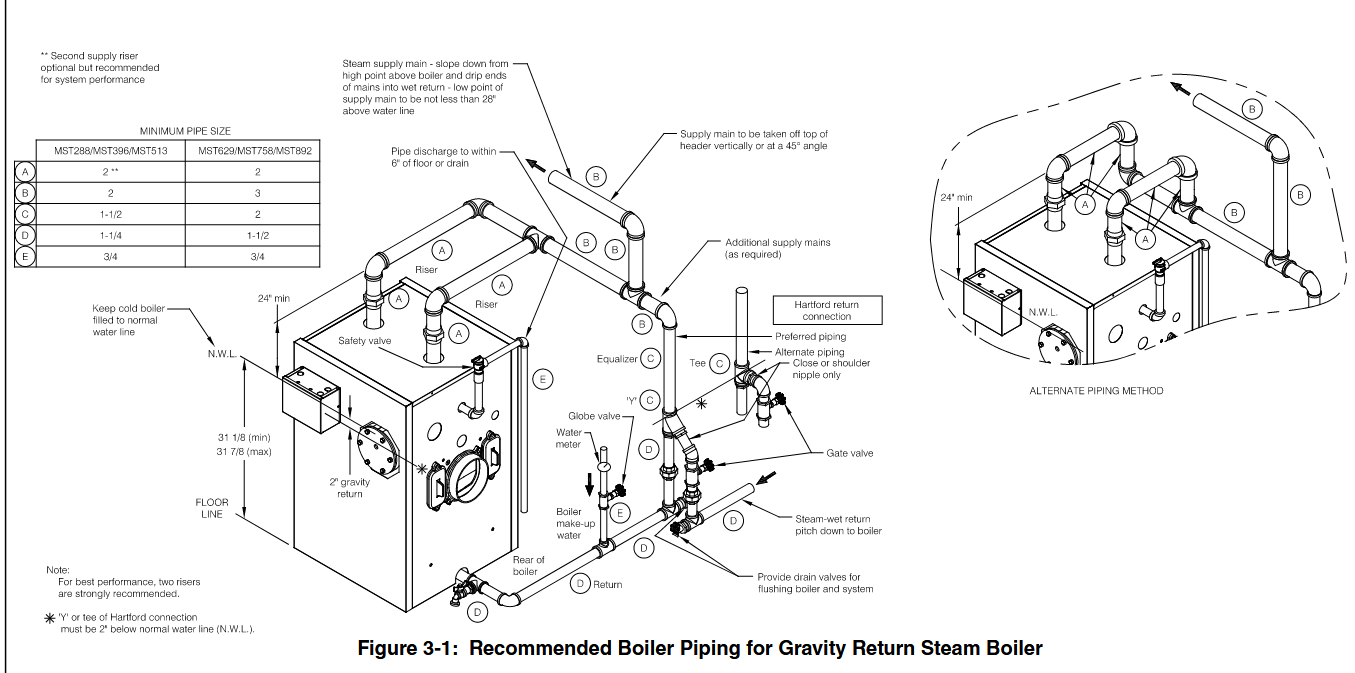

That MegaSteam is an excellent boiler, but whoever installed it completely disregarded the piping instructions. Your system will run much better when it's repiped. What model is it- should be MST-something.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

mst396

Happy to hear any repiping suggestions!

0 -

The manual shows how it should be done.

https://s3-us-west-2.amazonaws.com/catsy.782/MegaSteam+IO+Manual.pdf

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Your boiler should take in only around 5 gallons of fresh water per heating season. Your 10 year old boiler should take in just about 40-50 gallons. Since it has taken up around 150, you can be sure that the life of the boiler was cut down by around 3x times. Typical boiler lasts around 30 years, so at 10 years, you are at the end of the boiler's life. I know you don't want to hear it as boiler replacement is ridiculously expensive. (~$5k for a new boiler and ~5-10k for labor).

That said, because the steam can work on miniscule amount of pressure, even badly corroded boiler can produce heat.

In a perfect world you would replace your dying boiler and get someone knowledgeable to install it correctly BUT the world isn't perfect, thus you need to come up with temporary solutions:

- Replace the pressuretrol and set it so it cuts out power to the boiler at 2psi

- Right now your radiator vents act as "main vents". Add main vents to the ends of the pipe so the radiators heat up much quicker and your boiler doesn't have to work "overtime." And yes, without real main vents, your boiler pressure will raise quickly.

Your boiler is "dead" so further fresh water take up shouldn't be your main concern. That said, if you do the above, with everything you have done, you might get a few seasons out of this boiler.

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog0 -

I don't think there's enough information to say how long this boiler will last.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

MegaSteam boilers should last for decades.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

I would note that it is piped very wrong but it might still work ok, if it works ok I wouldn't worry about it.

I'd fix the venting and see what happens. It could just be lack of venting but it also could be water that isn't being separated because of the improper/nonexistent header keeping the steam from progressing out to the radiators where it can be consumed instead of building pressure.

If the water line is unstable or there is banging then the near boiler piping definitely needs to be fixed.

0 -

I do believe I have some surging going on, but I think that's because there's still some oil on the top of the water. I have it a good skim the other week, but I likely need to do it again. As for banging, I usually have a little bit when I first fire up the system for the year, but it generally goes away quickly. Part of it I know is from The one radiator I have that has a leak in it. They reduced the size of the pipe before going into the valve so there's always excess water in the radiator. But I'm replacing this radiator anyway and we'll bring the piping back to its original size. So I'm definitely going to fix my known issues first, but if other things like my piping need fixing, I'll get to those, too.

0 -

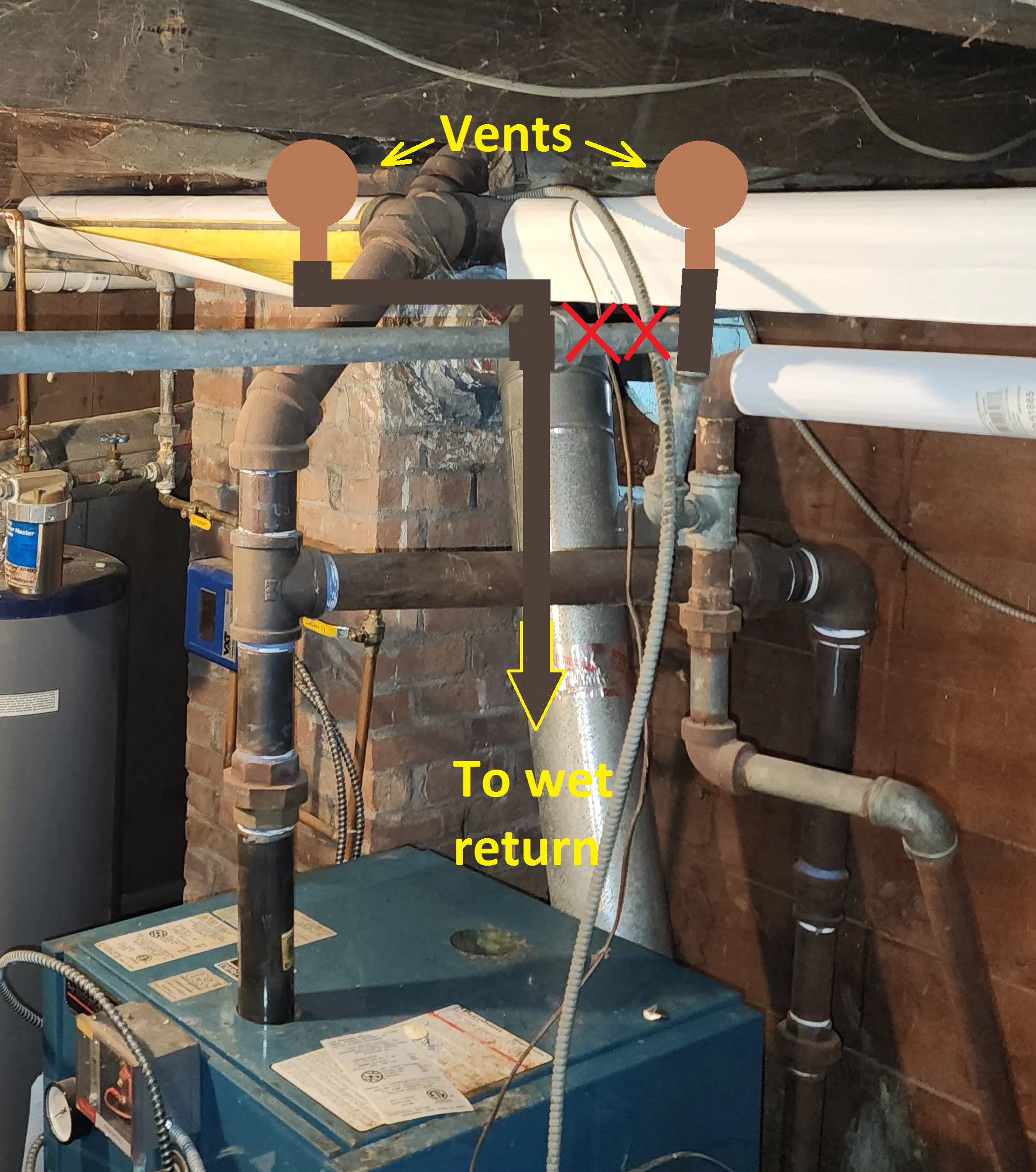

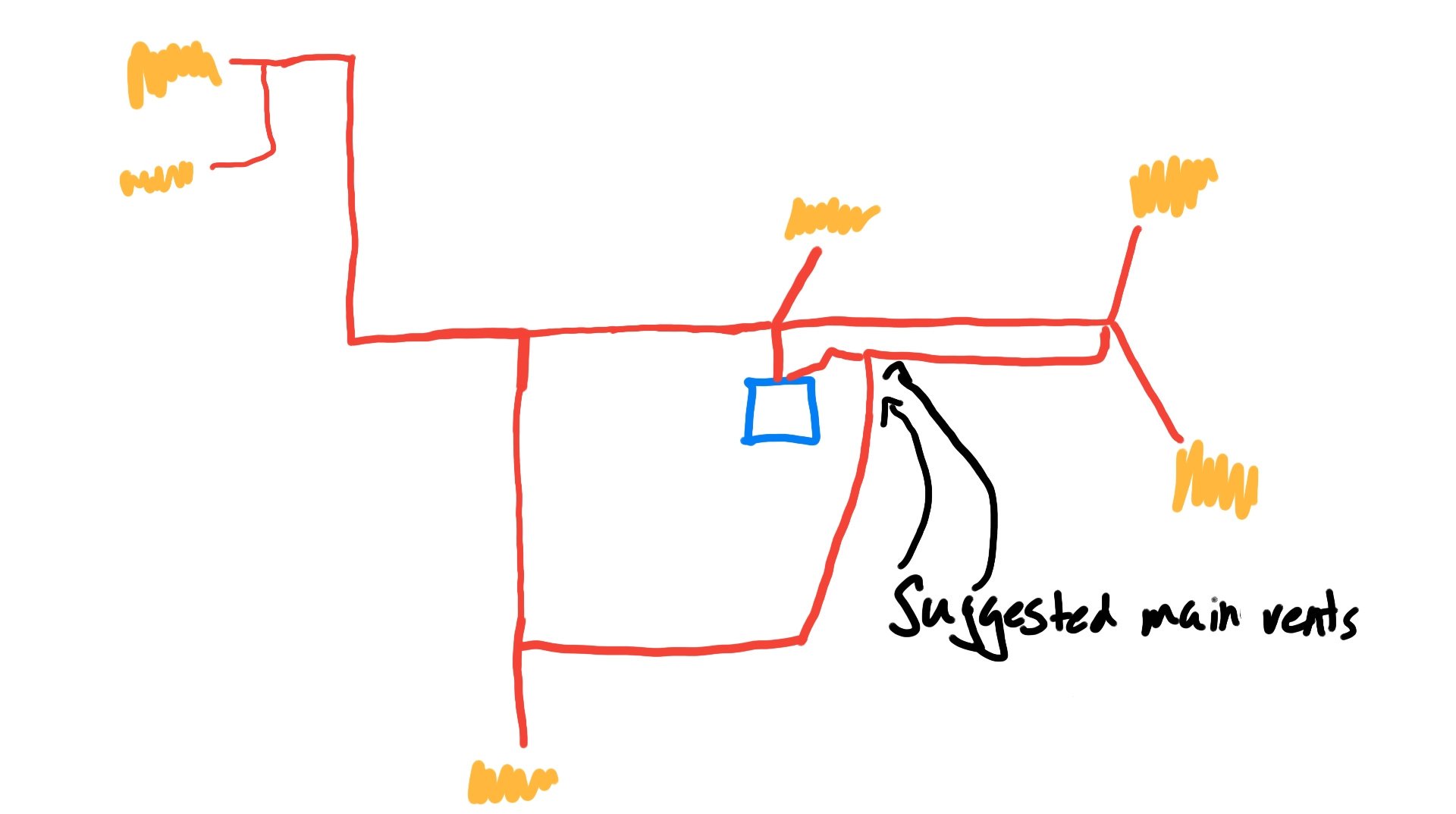

Does the riser from the boiler split into two mains at the Red box ? Is the other ends of the mains at the Red arrows ? If so, if the two mains and radiator venting are not symmetrically equal as far as air venting and steam flow, air may be trapped in the actual functional farthest part of the system until it is hopefully vented by the farthest radiator(s) venting the asymmetrical part of the system. Not an optimum configuration.

I believe to avoid this issue the 'steam main extensions' should each have its own main vent (sized to balance the mains) and each (individually) should drop down to about the level of the bottom of the boiler then combined together (as a wet return) to go to the Hartford loop. Presently it is combined way above the water line where steam can flow from one 'steam main extension' into the other.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

didn't notice that but that is probably what happened to the vents, whoever didn't know what they were doing with replacing the boiler removed the vents in the dry returns at the boiler and connected them together above the water line.

0 -

The red box actually splits into 3. One feeds the radiator that is right above the boiler, only a few feet of pipe. The pipe to the right splits at the end and feeds 1 radiator on the 1st floor and 2 on the 2nd. The pipe to the left is the longest run and feeds 3 radiators, one splitting off and going to the other side of the house. And yes the red arrows are the wet returns.

0 -

those are dry returns. wet returns are below the water line.

0 -

My mistake. Terminology confusion. I was meaning that those pipes are the primary path the condensate is taking, at least for those mains. They combine and pipe into the wet return.

0 -

Did I count right, only 7 radiators ? Unless all your radiators are HUGE, with a boiler of 396 Sq. Ft. you are going to have a pressure issue (IMO). I suspect the boiler is grossly oversized for the connected radiation.

" I turned it off at 1pm and it probably will still be around 2 or 3psi when I get home in an hour or two. "

This seems odd too so maybe the pressure gauge has issues. When the boiler is off the pressure should drop quickly (no new steam production, existing steam condenses) radiator vents cool and open. Open vents should bring the system back to atmospheric pressure.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Yes, only 7 radiators. I have not done an EDR but I suspect it's oversized, too. Unless it's causing major issues I don't plan to downsize until the boiler is truly ready to go. But, I'll cross that bridge when I come to it.

I may have been a bit off with my estimation, but the gauge generally doesn't drop that quickly. I'm putting a gauge on my pressuretrol pigtail so I hope to see if there's any discrepancy with that gauge. I'll see tomorrow when I get the new pressuretrol hooked up.

0 -

If your boiler actually does go to 10 PSIG and you install a low pressure gauge, say 3 PSI I would put a shut off valve on the low pressure gauge only to protect it when not needed. Hopefully with a working pressuretrol or vaporstat the system will never go over 3 PSIG again.

I would not replace a boiler simply because it is oversized. IMO there are other control strategies to help tame it, obviously not the same as a correctly sized boiler, but better than wasting fuel making crazy pressure and/or short cycling especially with oil.

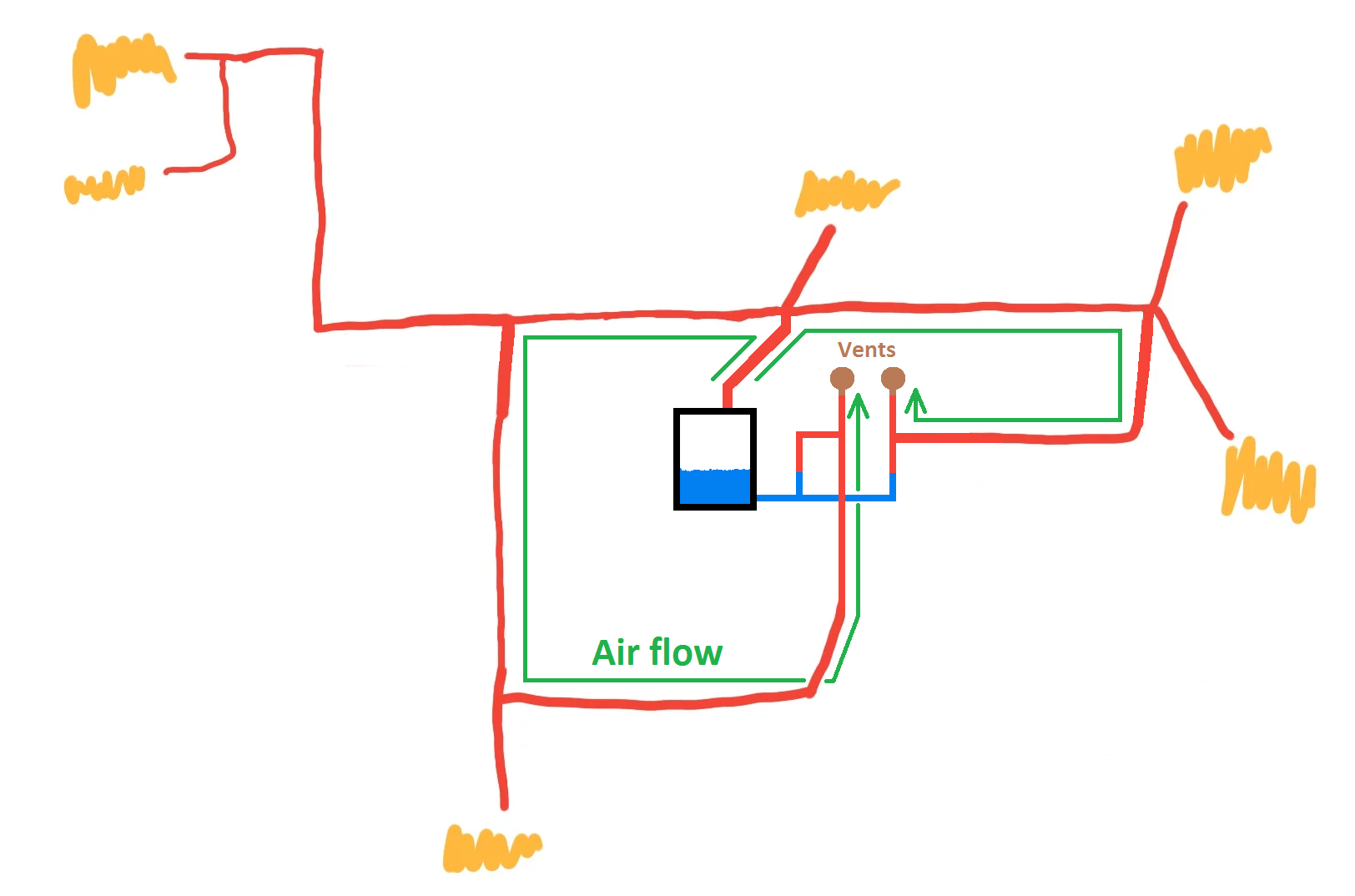

As far as the main venting and drips for the 'steam main extensions' goes I'd probably do something like this. The longer main should be vented faster.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

as noted they must drop individually down to the wet return otherwise when steam reaches the end of the main and close one vent it will continue on to the other vent and also close it, preventing the slower main from completely venting which will make heating at the end of the slower main very slow.

0 -

All right so let me make sure I've got it correct, should those be my only main vents in the system? Here's a very crude rendering of my piping in the basement. The long leg on the top/left has no accessible fittings aside from elbows. And I should take that one pipe noted there and pipe it down to the wet return? In other words, instead of combining them as they are above the water line, combine them below the water line? Thanks for the help!

0 -

The vent can be anywhere after the end of the main, they could be in multiple places at the same time but there is no benefit to that. what is critical is that the returns drop below the water line before they join together.

There is a slight advantage in having the vents at the end of the mains instead of the end of the dry returns because the dry returns won't heat and lose a bit of heat to the basement if the vents are are at the ends of the mains, but i wouldn't worry about that. If the dry returns are vented then steam can get in to them and they will also be steam hot.

On the other hand if the vents are at the boiler rather than off in some dark corner of the basement, they are less likely to get forgotten about.

0 -

The very end of the mains are steam isolated. The air is vented individually from each main. The main(s) venting (vent rate) is set up so the last radiator runout of each main gets steam at the same time or the main vents close at about the same time. Green path in the image is the air purge path of the mains. Modifying the very ends of the mains is probably the best place to get the most gain for the work.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Here is an example of @EzzyT beautiful work. Green arrows air flow, Blue condensate. The actual vents are hidden behind the main pipes, the vent pipe on the right can be seen the left vent pipe is mostly behind the conduit. Two separate drips down to the wet return.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Okay so assuming I wanted to correct the near boiler piping to be in line with what is shown in the manual, what would be the optimal way of connecting the main back in? Another crude rendering attached 🙂

0 -

Personally if it was my boiler, I'd not mess with the boiler supply piping this time of year, getting the pipe plug out of the top of the boiler and reworking the mains into a new header may open up a can of worms.

Presently I'd correct the venting and the gauge issue. Then see how it works. See how long it takes and when it builds significant pressure. If you still want to redo the supply side plan it out over the winter, then in the spring redo it when there it time to recover if something bad happens without being in a time panic with no heat.

Although not optimum your supply piping may work reasonably well, mine is similar, been that way for 50 years and seems to work just fine. If my boiler failed I would change it then.

Typically the boilers over a specific size have two or more risers that have swing joints then go into the header. A drop header is even better. Each steam main is individually connected to the header all in the correct order. This method reduces heat related expansion stress on the boiler section connections and helps dry the steam allowing gravity to separate out the water droplets. Review @EzzyT's postings (and others), many header examples.

Another great @EzzyT venting example.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

In a one pipe system such as yours, the "dry returns" (which are actually steam main extensions, not true dry returns) must NOT be connected to each other at the ends, but much be dropped separately to below the water line and vented separately as in @109A_5 's coloured sketch. The vents are best located anywhere along the piping after the last radiator on the particular line

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

So, I made the changes to the main extensions and added main vents as suggested. I've also added a new pressuretrol and 15psi gauge (lowest I could find on hand) on a tee coming off the new pigtail. I turned the boiler on. It took about 15 minutes for it to go from stone cold to feeling the main vents venting. It didn't take long for the piping to get hot, and no leaks on the new piping as I continued to check it. Shortly after this, maybe another minute or two, the 30 psi gauge on the boiler started to climb. It hit 5 psi in less than a minute and continued to rise. When I finally shut off the call for heat, as I had to leave, all of my radiators were starting to get hot (around the same time might I add), and the pressure gauge directly connected to the boiler was at about 11psi. The new gauge that I added with the pressuretrol hadn't moved at all. Everything ran for less than 30 minutes. And the whole time the boiler was firing, the pressuretrol never cycled it off. It's set to cut out at 1.5psi with a 1psi diff. So I'm not quite sure where this gets me. I guess I'm going to replace the 30psi gauge, and possibly the lower pressure one as well. As of right now, I don't know if either of them are working. The only other thing I'll add is that the boiler did cut off when the LWCO did it's intermittent test. Otherwise, it doesn't seem like the pressuretrol turned it off.

I plan to run it again tomorrow and let it run for a bit longer, so that all my radiators can fully heat.0 -

So the "30 psi gauge" is the same as "the pressure gauge directly connected to the boiler" ?

Turn the power off, disconnect a Pressuretrol wire, insulate or isolate it safely, turn the power back on and raise the thermostat, does the boiler fire ?

If the boiler fires there is a wiring error and the Pressuretrol is effectively not in the circuit.

If boiler does not fire recheck the Pressuretrol pressure path all the way back and INTO the boiler's casting to verify it is not plugged anywhere. Pressure check the new Pressuretrol.

EDIT: Another test is with the Pressuretrol (or the new gauge) removed you should be able to easily blow through the pigtail into the boiler's casting.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Yes, sorry, should have clarified. The 30psi gauge is the one that is connected directly to the boiler.

I'll check this in the morning. After posting, I also realized I may need to check where the pigtail threads into the boiler to make sure it's not plugged.

Thanks for the help!0 -

is there only one gauge that is reading like 10 psig? if so my bet is that the jacket or something is pushing on it such that it is moving the needle.

0 -

Yeah, I now have 2 gauges, but only one is reading anything. The 30 psi gauge that's original to the boiler consistently gets up to 10-12 psi during operation. The other one is a 15 psi gauge connected to the pressuretrol pigtail and currently isn't reading anything.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements