Combustion air for cast iron boiler

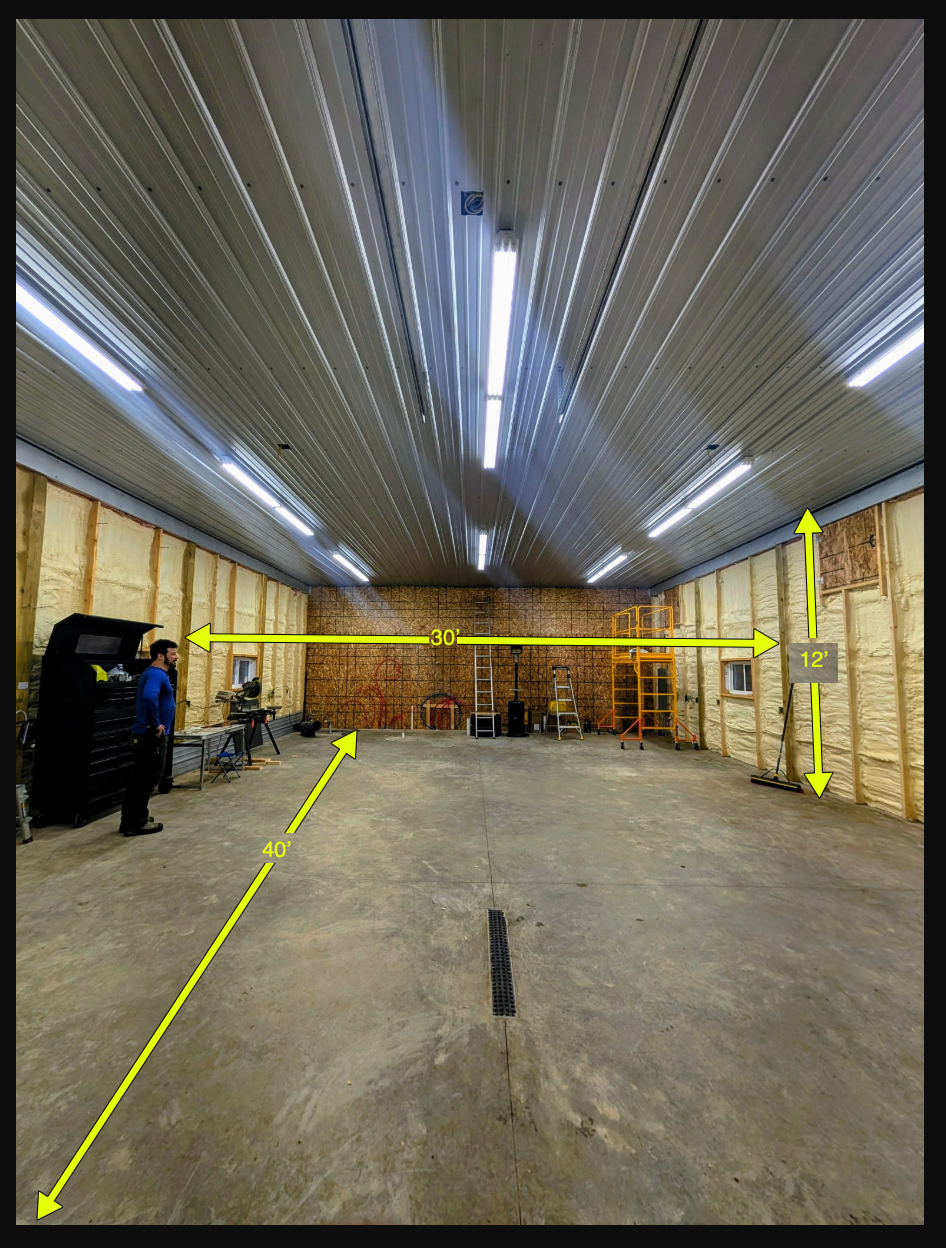

I have just finished a completely DIY (amateur) installed boiler system in our new build and am looking at options for combustion air. The boiler is located in the 30x40 shop that is very well sealed and insulated. I will be building a boiler room/closet around the boiler that will be about 6x15 with 8ft ceiling, the finished shop ceiling is 12ft high with R40 blown in. The boiler is natural gas 100k BTU in 85k out and has a draft inducer. The outside wall is to the left where the flue exits, the OSB wall has a living space on the other side.

I was thinking of putting a vent directly in the outside wall for the boiler to pull fresh air from, or possibly running a duct into the attic that would pull air in through the soffit vents.

What is the best route and how do I size and determine placement?

Western NY climate.

Comments

-

Outside air. But you need to wire automatic dampers into the combustion air ducts. They have to be wired to open on a call for heat and not allow the boiler to fire until they are open.

most locations call for two ducts one near the ceiling and one near the floor. They must be sized according to your local code.

The danger is if the boiler fails to start and the ducts are open you could freeze up. You may wan't a control to close the dampers if the boiler room nears freezing.

0 -

Was doing research on automatic dampers and saw this air pressure activated damper that opens when there is a pressure drop. Could something like this be a viable/simple solution?

0 -

-

The damper you show is a barometric damper. That will not work.

0 -

Why not?

When the boiler kicks on, the draft inducer also kicks on which is pulling more ambient air than just the burner would be alone, would that not be enough of a pressure drop to open the gate? It appears to be adjustable also. Not trying to be argumentative, just trying to learn. This is the first time I've ever put together a boiler system, or any heating system for that matter.

0 -

Where are you getting those numbers from?

Maybe I'm getting it wrong but I thought I read the national code said 1sq/in per 4k btu vertical or 2k horizontal. The vent would be horizontal so 100k would be 50 sq/in. They make all sizes, an 8" round duct is 50 and change so I figured that's all I'd need?

0 -

-

-

check with the local AHJ, in the extreme mountain climate around here the AHJ allows 1/4” per 1000, high and low.

A fan in a can is a good option. I believe it is a listed device that the inspectors would accept.Not all home brewed methods are going to pass inspection .

Ive seen the high vent into a 5 gallon bucket to help eliminate drafts. Another Mark Eatherton device😏

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

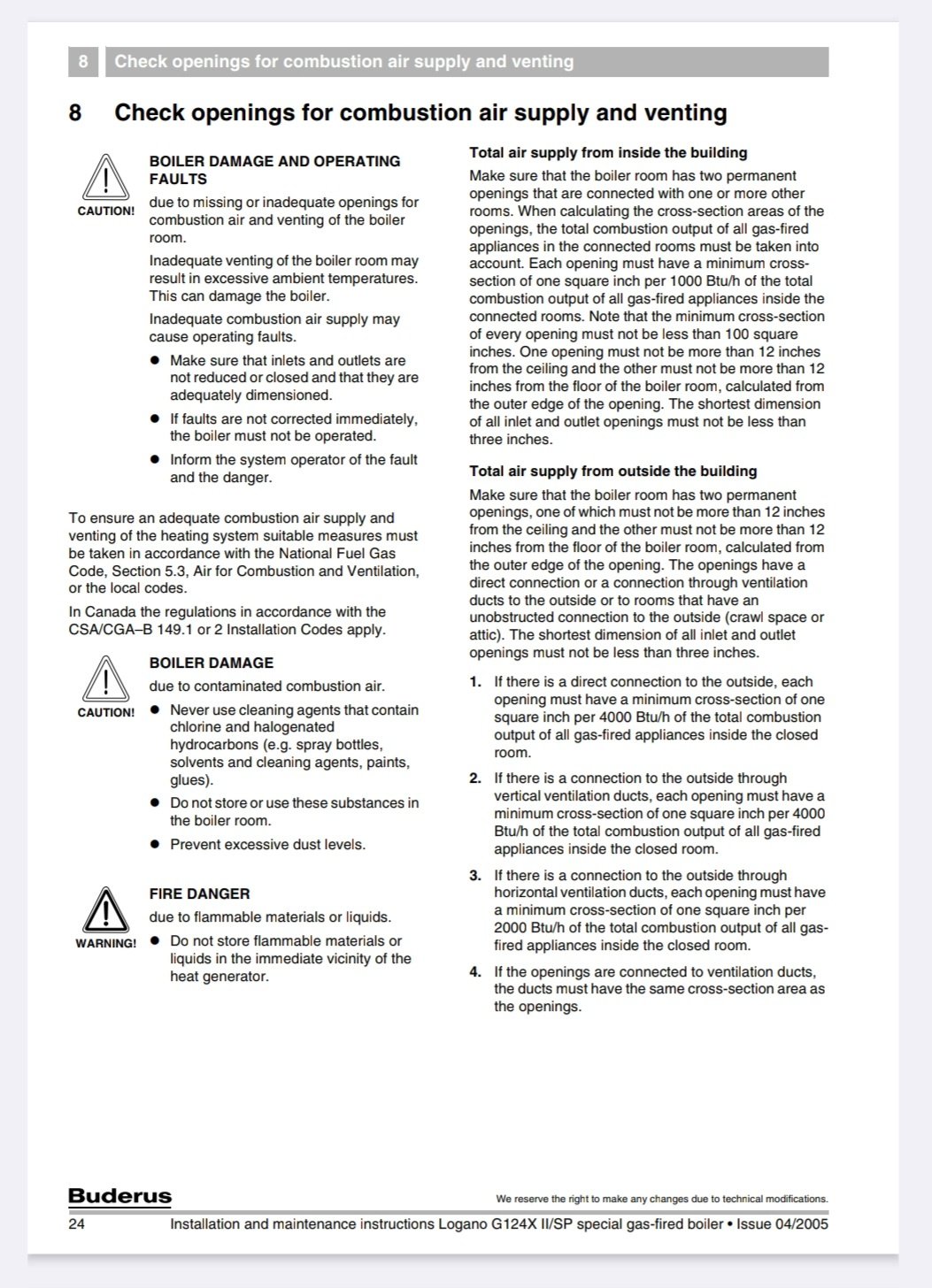

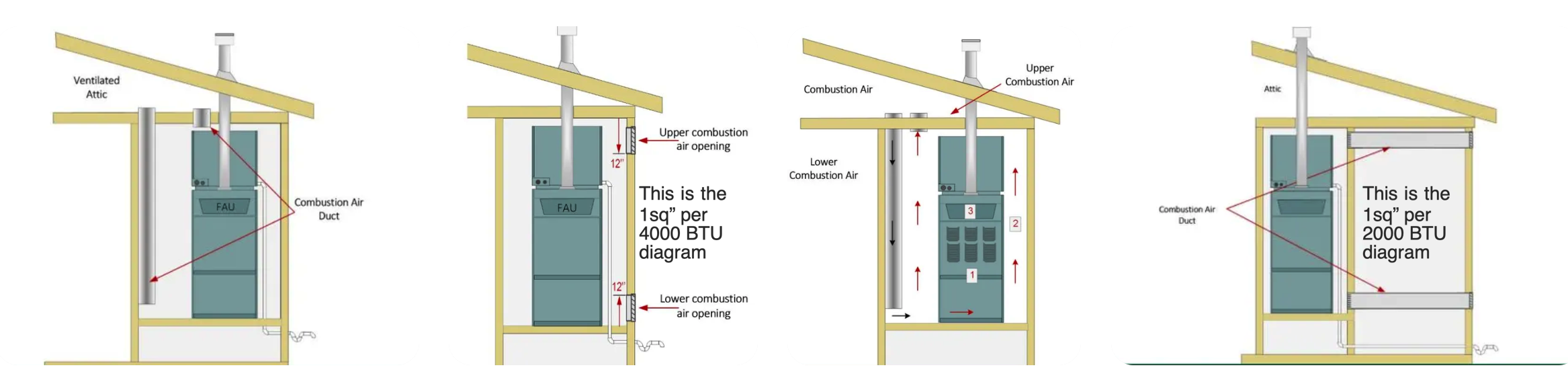

The openings to the outside for combustion air do not need to have dampers. The openings can be permanent fixed openings with the minimum free area of 1 Sq" per 4000 BTU of input. so a grill that is 4x10 with 80% free area (not blocked by the louvers) will be more than enough. you need to put one at the top of the room and one at the bottom of the room that connect directly to the outside as illustrated in the diagram.

Here are 4 different diagrams that show different sources of combustion air. two are from outside and two are from the attic. the Attic method requires that you drop one of the openings with a duct to within 12" from the floor. since that is a ducted combustion air inlet from the attic, the 1sq" per 2000 BTU number is recommended. The attic must also have sufficient ventilation to provide the combustion air. Some attics have exhaust fans that control the attic temperature in the summer. Since that burner will be making DHW in the summer, you can not use the attic if you have an exhaust fan moving air thru the attic.

If you are afraid of that cold air causing the pipes in the boiler room to freeze, and you want to put motorized dampers on the openings to reduce the probability of freeze-up, then those dampers need to have a switch that will prevent the burners from operating if the campers fail to open. If you choose not to use dampers, that is ok too.

One other observation…

It appears that you are using well water with some of the well water equipment tucked in behind the boiler and the DHW tank. After you build the boiler room wall around that area, will you be able to access the well water apparatus when it requires service? If you are going to use the two 4x10 openings directly to the outdoors, perhaps moving far enough away from the water & heat piping so freezing is not a problem would be a good idea, even if that means that your boiler room needs to be 10' x 15' with 8' ceilings.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

One more observation: That looks like a Buderus G124X boiler. That is not designed to be a fan assisted exhaust system according the the manufacturer's instructions. I was wondering where you got that combustion assist fan? I don't believe that is a manufacturer approved venting option.

And this is not the first time I have seen this setup. Is this something that is approved in Canada?

At least this contraption is using a metal housing fan…. The last one I saw on this site the DIY individual used a plastic fan that is used for lower temperature condensing furnaces on a non condensing G124 Cast Iron boiler with a open draft hood below the fan assembly.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I would check the volume of the building first, it probably won't qualify as confined space. Most cases, these don't need outside vents.

0 -

You should see the photos from the other discussion, that room is sealed with Spray foam insulation and might be on the cusp of a confined space based on how tight the building is. Also the boiler will be enclosed in a 15 x 6 ft room with an 8 ft ceiling. When all the construction is finished, that WILL be a confined space. That means that the 30 x 40 shop that is 12 feet tall will have enough combustion air for a 250,000 BTU appliance, the 15 x 6 x 8 boiler room will need the have some openings cut into the walls somewhere. To the outside will need two 4 x 10 ft openings to the outdoors or you can connect two 12 x 12 louver openings into the conditioned space to use the combustion air from the entire shop area. If however the shop is later divided into more separate rooms, there is no guarantee that the remaining adjoining shop spaces will continue to be adequate.

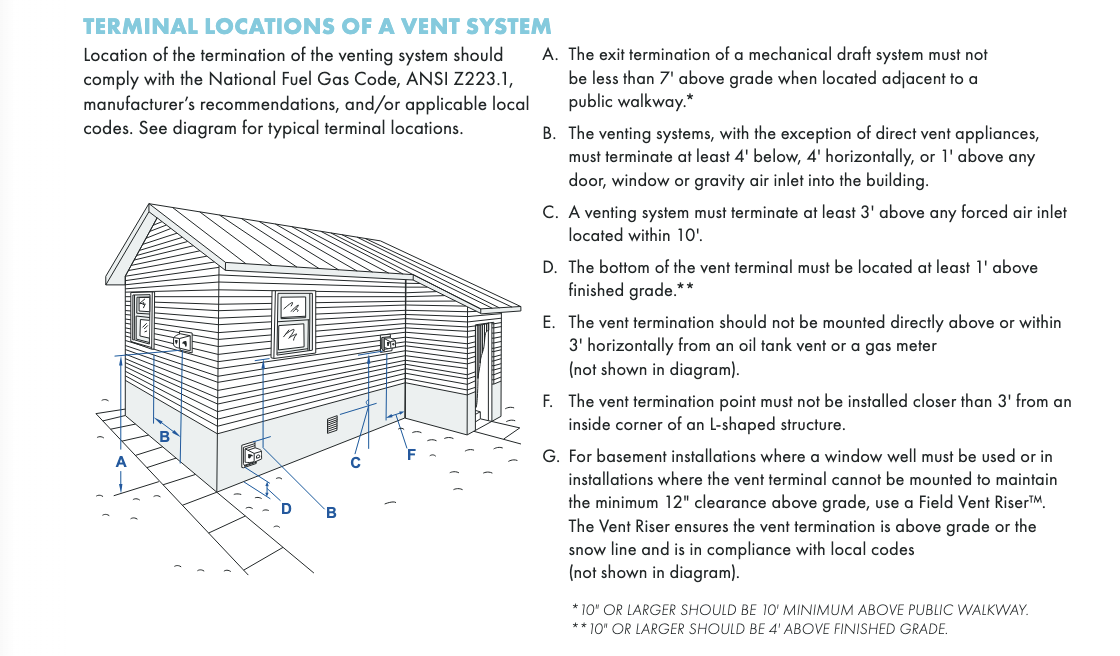

And if @ajping3830 is going to use combustion air from outside the building, then the fresh air openings must conform to certain clearances form the exhaust vent so exhaust gasses are not easily sucked into the boiler room. That boiler room might need to be enlarged to allow for a 4 ft or longer distance from the exhaust to the fresh air inlet. Item B below calls for 4 feet from the vent to the gravity air inlet to the building. Item C calls for 10 ft (for a fan in a can) forced air inlet or be 3 ft above it.

Designing a system as you go can sometimes make you cut new holes for the vent and air inlets.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

People tend to overestimate how tight a spray foam building is. Usually is better than regular construction but can still leak a fair bit if a couple of details are not handled well. Even if super tight, a power vent unit doesn't exhaust all that many CFM of air and it will take a heck of a tight building to get it any measurable depressurization in a large workshop. Power vent units are also much less sensitive to building pressure.

If the boiler does end up enclosed in a small room, than it needs a high / low vent to the open workshop space provided that workshop space is big enough.

2 -

Unless they've done a blower door test I never believe it when people say a building is "super tight." Unless I've had a chance to measure the insulation myself I don't believe it when people say "well-insulated" either.

0 -

My brother gave me the Buderus when he replaced the system in his house, yes it is a G124x. The system was installed by the previous owner so we don't know where the draft inducer setup came from or if it was factory, but it's been running that way since installed in 2004. He had a whole extra inducer fan and diverter box that he gave me with it as a spare. I saw another forum post of a guy looking for a new inducer for the same boiler, he had pictures and his setup was identical to mine right down to the sheet metal box that connected the inducer to the draft hood. I also saw another similar Buderus for sale on FB marketplace that had the same draft inducer setup.

0 -

Lots of good info here, much appreciated.

Since it was mentioned, now I'm contemplating just utilizing the shop combustion air with openings in the walls of the utility room. I think it would be ideal to keep any extra heat from the boiler room inside the building instead of dumping it outside in the winter months. The living space is just a guest house so there isn't going to be a ton of DHW demand to worry about excess heat in the summer months. There could also be issues with the exhaust being to close to the intake if using outside air.

I was already thinking about adding a heat recovery ventilator, just for the sake of having fresh air as I'll be doing some welding/cutting/grinding ect fab work here and there. But it seems like an HRV would also aid the boiler if using inside air correct?

How can I figure if there is enough combustion air in the shop space? There will not be any additional rooms, just wide open.

0 -

@ajping3830 asked: "How can I figure if there is enough combustion air in the shop space? There will not be any additional rooms, just wide open."

A confined space is considered any space that does not have at least 50 cubic feed for every 1000 BTU of burner input. The Shop is much larger than that, so you have sufficient amount of combustion air if you use two 12 x 12 louver openings from the boiler room to the shop.

The total shop + boiler room will have a total of 14,400 cubic feet volume to draw combustion air from. that means that you can have up to 288,000 BTU input and still not have a confined space. but as tight as you are making that space, I would not go much over 220,000 BTU. Since you boiler has a 100,000 input and it doesn't look like you will be adding a separate water heater any time soon, I think you will be fine.

Now you don't need to worry about cold air from the outside louvers freezing any pipes. Some welding shops do however add exhaust fans to clear fumes from the work space. especially if you have the ability to bring automobiles or other combustion engine equipment inside to work on them. That can be a real problem. I was working on a problem boiler that was connected to a shop that was 5 times larger than your shop. The exhaust fan would wreak havoc on the flame and the venting system whenever they operated the exhaust fan with all the garage and shop doors closed. The exhaust fan would suck air the wrong direction from the boiler's exhaust vent pipe. That would blow out the electronic ignition pilot and cause a flame failure signal to stop the burners from operating.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

I never seen a G124 with a draft inducer , but that doesn't mean anything .. It's a nice option.

Draft inducer , rarer then hens teeth ?

There was an error rendering this rich post.

0 -

Does the boiler need to be elevated 18” if it pull air from a garage or shop?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

What type of usage is the shop? If it’s wood working, then that’s a whole nother can of worms. If it’s automotive, that’s another.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Just a man cave/hobby shop really. Will be doing a little bit of everything but nothing full time. Will be putting in a car lift just to service our own vehicles and ATV's and whatnot, I've got some welding equipment, I do some wood working projects here and there.

0 -

so there will be flammable liquids.

I would seal the boiler room from the work area just out of caution.0 -

my understanding was that if it had overhead door that a vehicle could be stored inside, a flame needed to be elevated 18”

We did this with water heaters in garages or with attached rooms until the flame protected style water heaters became available

No harm in checking with the current codes in that area. Stay safe.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements