Steam Boiler sizing?

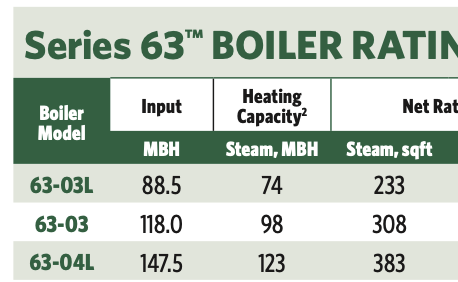

So a friend of mine had a someone start a job take their money and run. So I went did a load calculation on house measured all the radiators and used dan holohans load calculation formula. I did the numbers twice to double check and came up with 92,160btus and total sq ft of steam of 256sq ft. But the boiler says 147,000 but max input gross output of 123,000btus. And rating plate says boiler makes 383sq ft of steam.

My question is do you think this boiler will shoot water out the air vents if I hook it up for him? The guy that took those money and ran bought the boiler by just matching rating plates never measured anything. I have picture of the rating plate.

Comments

-

Well, it won't shoot water out of the vents if you set it up properly including the near boiler piping and setting the pressure correctly. That won't be your problem.

What will be is that the poor thing will short cycle, and there's nothing to be done about that.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

What is that x1.5 in your numbers for?

Are you increasing the radiator size by 50%? Is there actually 62,000 btu/h worth of radiation installed?

You do not want to add 50% to your radiation, it's a huge mistake. I'd recommend 15-25% and try to find a boiler that's somewhere in that range, 33% being the absolute most.

What boiler did they buy?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Make your life simple and completely ignore BTUs in steam capacity calculations. They aren't necessary or helpful in a residential installation.

Just compare the sq ft of steam from the rating plate directly against the total EDR of the radiators. And round down to the next smaller boiler if you are between two models.

Your friend needs the very smallest boiler that Peerless makes, the 63-03L, see this chart:

But I guess it seems like your friend already has the oversized boiler in their basement? You can hook it up and then you can plug a burner orifice if you want, that will reduce the short cycling.You can also turn the gas valve pressure down to about 3 inches of WC (nominal from factory is 3.5), that will make less heat which will also reduce short cycling.

Run a combustion gas test if you want to make sure things are OK but frankly, this atmospheric burner design just works even with these changes, it's not rocket science, it's basically a gas stove. Those things run in people's homes without any venting at all. Can you believe that?

But like Jamie said, the boiler will perform fine, it will just shut off every couple minutes during a long call for heat once the system is hot. Make sure your main venting is good.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

The problem with downfiring an atmospheric gas burner is that it is designed with the spaces around the burners and hx and vents in the covers and opening in the jacket as admitting a certain amount of secondary air. if you downfire it you change the amount of gas but don't change the amount of secondary air, with an oil burner or power burner you control the secondary air with a shutter on the burner so you can downfire it significantly and still have it burn correctly.

0 -

if you downfire it you change the amount of gas but don't change the amount of secondary air

I haven't seen anyone post any combustion analyzer results from down firing an atmospheric boiler, I would love to see what actually happens. With less fire, there may be less "drawing in" of secondary air, but this is just my speculation.

I will also speculate that any reasonable down firing of an atmospheric boiler does not result in any meaningful change in combustion. I would try it myself but I only have 3 burners so it's hard for me to reasonably downfire it. I guess I could bring down the valve pressure.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

If the new boiler size is basically the same as the old one, I would expect the overall system performance to be about the same as it was.

If I was in this situation, stuck with an oversized boiler that cycles on pressure, I'd add a delay timer to the control circuit. So once the boiler trips off on pressure it can't restart until a delay (in minutes) has expired. Skipping most of the useless cycling.

The way I see it, if you are cycling on pressure the radiators are pretty much full and not getting much hotter. And for comforts sake you may not need them to be hotter longer per thermostat cycle. I do not see a point in cycling the boiler on and off rapidly to maintain the steam pressure roller coaster of a pressuretrol or vaporstat hysteresis (pressure differential).

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

I agree with Paul on just using units of square feet. Assuming the 256 sq ft EDR is just the radiators, that boiler is oversized by fifty percent. Not great but should be workable.

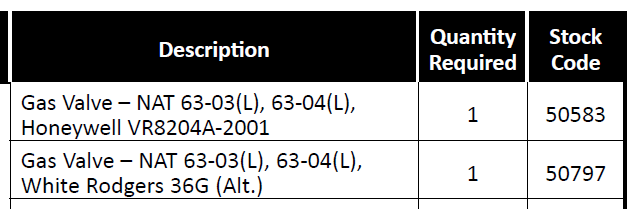

Peerless boilers have two burner configurations for each boiler size. Unfortunately, the 63-04 is already downfired. From the parts list, it looks like the gas valve is the same for the smallest four boilers — 3 to 6 burner tubes — so I doubt it's a big deal to go from 5 burners to four:

FWIW, I worked out my system by pipe length x outer diameter for the main and the risers, and the standard 1.33 factor is accurate for me. I'm running 320 square feet with a 63-03, rated for 308 net, so sized just right.

As a test, I turned the thermostat way up, started the system and ran it until the main vents closed. At that point, I plugged all the radiator vents to see if the system would cycle on pressure. The answer was no. It took an hour for the low-pressure gauge to peg at the maximum reading of 40" water column = 1.44 PSI. With the vents open, my large radiators take a long time to heat all the way across, and there's never even half a PSI of pressure.

If the radiators are OK for the OPs heat load, I don't know that the system will cycle on pressure… I'd make sure there is enough venting for the radiators to accept all that steam, but if the system is balanced right, it should heat up quickly and satisfy the call of heat before the pressure rises.

0 -

When the boiler's capacity is well matched to the dissipation (the radiators and piping) the pressure should not rise significantly, since the the radiators and piping are dissipating 100% of everything the boiler can output. And it does not take much pressure differential for steam to move. Once the radiator vents close the steam condensing inside the radiators makes a vacuum (or less pressure). So unless you overwhelm the radiator with steam the pressure should not rise significantly. The vents are only there to provide a means to expel the air from the system so the steam can get to the radiators.

In the case of an oversized boiler. The radiators can't keep up with (dissipate) the boiler's output so the result is the pressure rises. IMO running the boiler to maintain higher pressure than needed to fill the radiators is wasteful (other than maybe the coldest day of the year if the system as a whole is undersized for the heat-loss of the structure).

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements