My SteamPunk boiler

At the beginning of last winter i've zeroed out my automatics water feeder. At the end of the season it read 247… Not good!

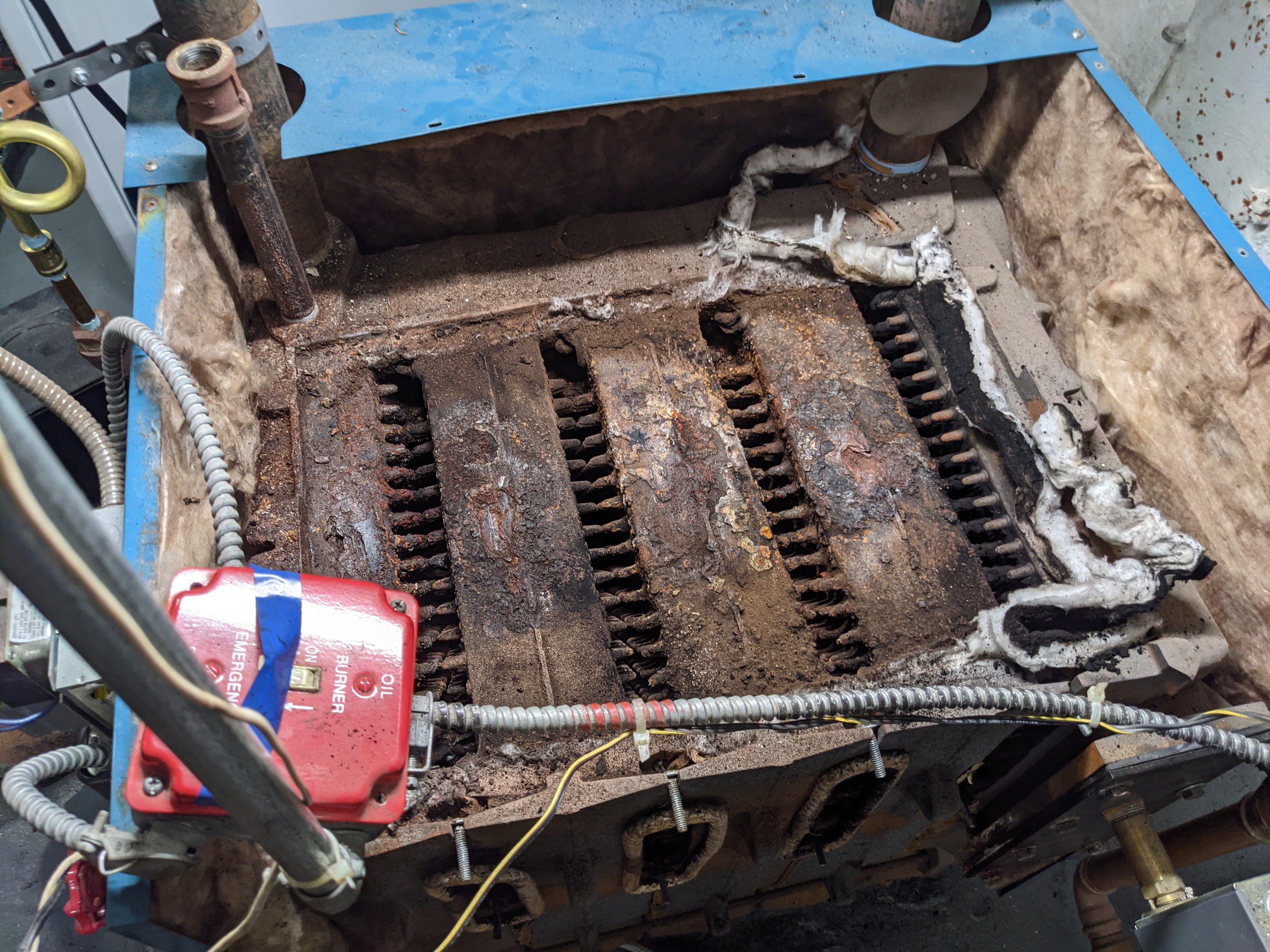

Opening the boiler covers i saw a sorry state of the boiler's top - with huge rust holes.

I though i could seal it with some kind of steam-resistant high-temp epoxy.

I've searched long and identified some pro epoxies uses used in the oil industry. Sales rep has confirmed that it could work (key word: "sales rep"...)

I cleaned up the surface prepping it for the epoxy. I filled the holes with the marine version of JB Weld (btw, very good epoxy!)

Then covered the top with the "pro" grade reinforced with some carbon mesh.

Soon i started having doubts.

In my research i didn't consider high temperature of the flue gases. Though metal jacket heats up only to around 250F, the surrounding flue gases can get to 600F (the verge of the epoxy stability).

Even before fire test, i started thinking about plan B.

Test fire has confirmed my doubts.

The surface, despite the prep, showed epoxy delamination due to rust developing between epoxy and the cast iron. Surprisingly, the water resistant JB Weld held quite well.

The boiler was "dead" again so i removed the epoxy and this time chose not to stop until i found some solid metal. The holes kept on growing...

I started to think the whole cast iron section turned into a clump of rust held only by wishful thinking. That said, i started to see some hope. Some chunks were still quite thick. If i could manufacture metal plates, drill then tap some holes to hold those plates then maybe - just maybe - i could get another heating season out of this boiler.

I drilled some holes in strategically located places. Surprisingly all had enough metal to tap those with at least a few threads.

Some extreme heat silicon (rated at 750F) was applied to create gasket between cast iron and metal plates.

The plates were bolted onto the boiler with stainless screws (ah, why not at this stage?).

After a few days of firing, so far so good.

Wish me luck this heating season!

(i'll update you as the months go on)

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog

Comments

-

Never seen that done before- it'll be interesting to see how it works out. That said, start saving for a new one. And make sure there aren't any leaks out in the system- fresh water shortens the life of a boiler.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

-

-

It's kind of ironic…the boiler will have to be replaced, there is 100% no doubt of that. The question is when. You have gained a year or maybe 3, and boilers will be more expensive then, so unless you are investing all that money in something that can beat inflation, you just cost yourself money in addition to all your effort.

When you get a new one, be sure to size it to your radiation, the existing one is almost certainly oversized.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I'm not so sure I agree. They're far from free, that's for sure.

It seems like boiler prices have gone through the roof vs when i bought mine back in 2011. I understand inflation etc, but it just seems like it's far more than that. Off the top of my head, I think my EG series costs double what I paid yet I think inflation is less than 50% since then.

Maybe I'm just remembering wrong.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

You know what else you could do? Add some sodium silicate to the boiler, flood it and bring it up to near boiling. That water glass will find any small hole and seal them.

Miss Hall's School service mechanic, greenhouse manager, teacher, dog walker and designated driver

0 -

I think my EG series costs double what I paid yet I think inflation is less than 50% since then.

Inflation of your boiler, according to what you said above is 100%. The inflation of eggs and stuff isn't relevant to this.

I should have said "…so unless you are investing all that money in something that can beat boiler price inflation…" for clarity

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

-

They're using a lot of cast iron boilers in these transitions?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

necessity is the mother of invention. That actually looks pretty good.

The temperature changes and different expansion rates of the two steels may cause looseness in the bolts, so maybe check their torques until you are comfortable they wont loosen.

0 -

At this moment, the boiler is a "science experiment".

Will it last? Yes, it will.

How long? Noone knows.

Yes, when i see a sign of leakage, i'll clog all my radiator vents with temporary plugs and add some boiler stop-leak (so the vents don't get clogged with that stuff)… after all, with 250 fresh water units in one season, this thing has drank itself to death.

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog0 -

the fresh water will corrode everything below the water line, not just the boiler.

0 -

I disagree with that, but different opinions is what makes the world interesting!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

"The speed of corrosion for a metal is highly dependent on its specific location relative to the waterline. Generally, the most aggressive corrosion occurs not when the metal is fully submerged or completely dry, but in the area that is intermittently wet, known as the splash zone or waterline region."

Which puts in question how my specific corrosion has occurred.

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog0 -

That boiler in particular (if it is, as it appears to be, a Burnham IN series), but lots of other boilers too, maybe all atmospheric boilers, rust out at the top I believe because at the top the temperatures are hottest from the lack of liquid water up there

There are a few variables that affect rusting rate and temperature is a significant one of them

There is some discussion out there that the IN boilers' castings may be thin up there as well but I have no personal knowledge of that.

Keep in mind the entire interior of that style boiler probably isn't very dry ever.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

1 month later and the boiler is going strong. just 1 gallon of fresh water intake so far (and i'm sure it's my radiator vents).

i'll take the covers at the end of the heating season so we can "learn" something from this experiment.

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog1 -

If you lost a gallon of water from vents etc during an extremely mild month, I'd start working on that as it's likely why your boiler rotted out.

Obviously weather is different all over, but I haven't added water since last March or so.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

Congrats on having tight system!

1gallon/month (around 6 per heating season) is within the specs of this boiler.

That said, due to history of extremely high fresh water intake (assuming that the water counter wasn't zeroed out at some point, around 600 gallons), this boiler will fail sooner rather than later. So whether it's 1 gallons or 2 per month isn't of consequences at this point.

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog0 -

There's certainly no need for sarcasm.

A gallon a month in a mild month is bad.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

Without a little sarcasm, life would be a bit boring.

My point is: let’s not lose sight of the forest because of the trees.The fix works and drastically reduced water intake — and therefore energy consumption as well.

Moreover, your idea of “mild” might be very different from mine. My neighbor keeps his house at 68F; I keep mine at 74F. I bet his boiler hasn’t fired even once this season, so one gallon for him means something quite different than it does for me.

When a new boiler is installed in a season or two, if I can average 6 gallons per year in fresh water intake, I’ll be ecstatic. I’ve seen what 600 gallons can do to a 10-year-old boiler — AND that it can still have just enough metal left to survive another season (or two?).

As i mentioned before, this boiler is now a working "science experiment." I'm not sure if reducing the water intake further will serve us much.»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog0 -

Understood, the boiler is an experiment.

The rest of the system isn't and it will greatly effect your next boiler. If you used a gallon in October, it's going to use a whole lot more in January-Febuary.

The point is, start fixing the rest of the system while you've got time and that way when it's new boiler time you won't even have to look at it, it'll be done.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

If you look at the indoor temps of 68 and 74 on a mild day, 45 to 68 is 23 f degrees and 45 to 74 is 29 f degrees. That is only about a 20% difference in heat load.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements