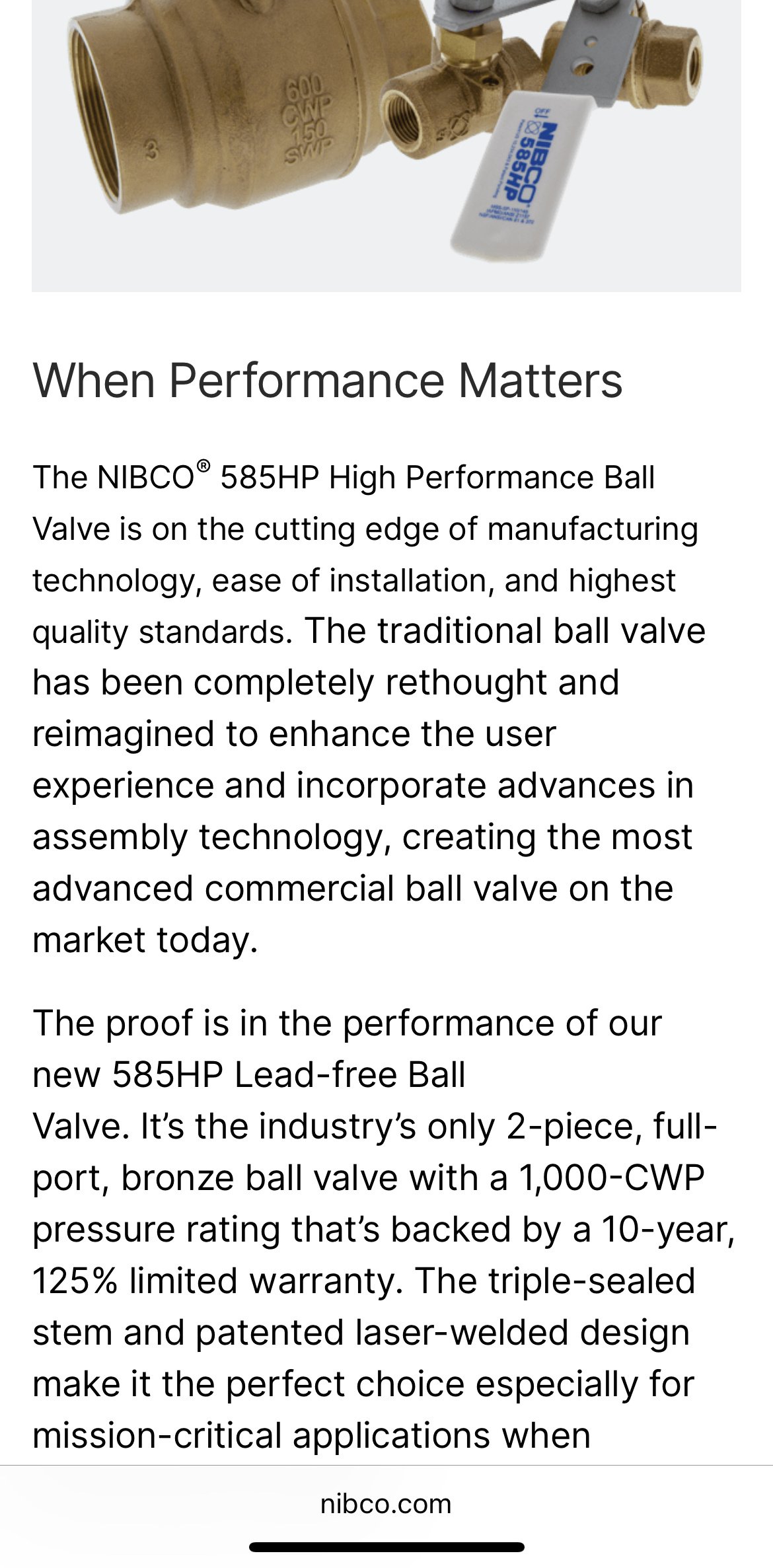

Anyone know about disassembly of these full-port Webstone (Nibco) ball valves?

I'm repairing a leaking press fitting that was introducing air into the hydronic system.

I cut it out using a Milwaukee close quarters cutter, and want to ream the pipe without fear of a copper shaving falling down into the vertical section and damaging the pump.

I was thinking to disassemble the top and bottom half of the ball, but wasn't sure if that's asking for trouble long-term. Alternatively, I can stuff some blue paper towel down there.

Anyone taken apart the two halves of the valve like the one shown on the left and is it a no-brainer to re-assemble or will I be more at risk for leaks (or be in for some other surprise)?

Tried to reach out to Nibco without any response for 2 days.

Comments

-

-

-

-

@EdTheHeaterMan - in my case, just curious if it's a safer approach to keep out reamer shavings… sometimes I get a single curly-q, but not always, esp. when it's up near that gas pipe and more difficult to do so (vertically). Once one end is cut out, it's only press fixed on one end.

@Jamie Hall - that's what my gut was saying, but if easy to disassemble/reassemble, didn't want to feel silly doing it a different way. Suffing will be the way I go. I figure someone probably makes some silicone insert that looks like an inverted plunger. If not, there's a new tool. But blue paper towel is readily available :)

@hot_rod - read you loud and clear… not the way to go. Thanks for sharing that context.

Saw the wrench flats, and had to ask. Thanks everyone!

0 -

-

i think the ball is the laser welded part

0 -

-

delta stainless balls are 2 hemispheres welded together. probably because it is easier to make stainless sheet than to cast it so they stamp 2 hemispheres from a sheet and weld them together and machine and polish it in to a ball.

0 -

much different than a basic plumbing heating ball valve

The delta ball opens and modulates two flows h&c to the outlet port

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Ok, so since we started talking about these ball valves, I had an unfriendly discovery. This is on the potable cold water supply - the valve shuts off half of the house.

What do you all make of this? Maybe 4 years old.

0 -

-

What I make if this is that the valve is not a Nibco 585HP valve.

I agree with @Intplm. low on the 2 DO list. maybe a little wire brushing every year or so is all I might do in your case. If it gets worse, then replace it at that time.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

This is why i like to use NPT valves and adapters. Less stuff that is difficult or impossible to disassemble that goes in to a box somewhere in the corner of my basement.

0 -

-

Yeah, agreed it is possible to just clog up. It is a good point.

That said, the joist space behind the mechanical room will be finished, and cutting/patching/painting the drywall will be much more expensive than the repair. The downside to repairing is that I was sure to leave enough space for one replacement with press fittings, but after that it becomes much more difficult. I went press because I didn't have the skill to sweat most of my home with the confidence I wouldn't end up with any bad joints behind drywall. It's pretty sad that a $50 valve only a few years old is having problems.

0 -

-

Alright, everyone can poke fun at the press fitting cost, but really… plumbers run about $175/hr here. So, I can spend $90 in parts and an hour of time to replace it, or I can call a plumber for $250-400 + parts. To me, the fitting + valve costs seem relatively light :)

The valve is fully accessible in the mechanical space, just up in joist space, backing up 1/4" from plywood and over a top plate of the wall - so it's very difficult to do any work without cutting the tubing from the adjacent room.

0 -

if you used an npt valve with press adapters, you could cut the part of the pipe you can get to and unscrew the valve from the press fitting on the pipe you can't get to.

propex is great for making up hard to reach connections, you can expand the tube out in the open and shove it on a fitting back in some dark corner to shrink back down.

1 -

Matt, that sounds like a great call on this one, should there be a future issue. I do have propex/hepex as well. great for quick hot water delivery to the tap. But more and more over time, I do wish I ran copper with all the propex failures being reported.

0 -

you had a valve with a bad assembly seam, it happens, maybe more-so with some imports.

Not many plumbers put valves in with a piping plan to remove and replace them😗

The more threaded connections, the more potential for leaks. Especially with todays thread quality .

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

-

Is there a more reliable brand of valves than nibco/webstone that I should look to in the future?

That's a great tip. Thanks for sharing.

0 -

-

Most ball valves are assembled with Loctite or a similar aerobic product. I have seen green and blue colored product used. At Caleffi we assemble brass components with red Loctite 545 or 272.

There is not much of a thread to seal and hold a ball valve together, very little on the "value engineered" valve products.

To disassemble a Loctite joint heat with a torch to soften and it will come apart easily

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

unfortunately so will the teflon seat.

0 -

Thanks, I will definitely give that a shot! I spent enough money on their products between all the plumbing zone and hose bib shutoff valves, the well, drains, and the hydronics, there are probably 15 of them in the place. I'm hopeful they will warranty it and will let you know how it goes. I'm even more hopeful these aren't junk valves.

0 -

Just had a job where I used use of Locktite to seal slow drip on nibco ball valve. Steps are:

Drain system enough to remove pressure from valve

Clean all corrosions off valve body

Heat valve body with torch for short period to drive off water

Apply locktite 290 sealant; I find a couple drips on top will flow around entire joint on horizontally mounted valve

Wait 5 minutes and reheat for short period for to cure Loctite

Apply pressure.

2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements