Dream of skimming leads to rabbit hole

We converted to gas from oil, and got a new boiler installed about 4 years ago, along with an indirect water heater. Still using the same ancient steam piping though. No maintenance has been done on the system since.

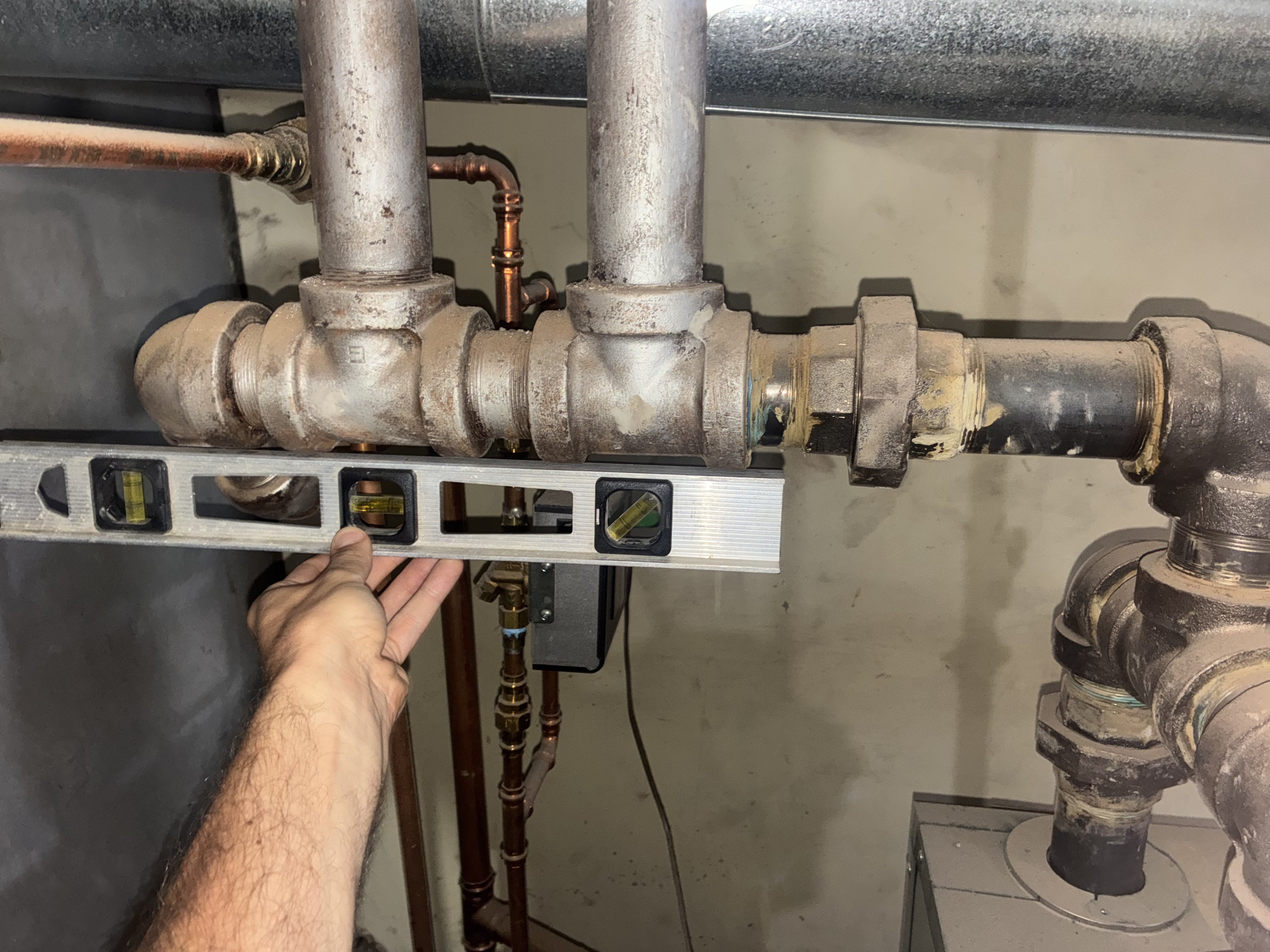

I was thinking it was overdue for skimming and maybe I could do it myself. But looking into this install, it looks nothing like what the manual calls for, and nothing makes sense to me.

It was installed by that classic plumber who's been doing these forever and isn't exactly spending time with his nose in a damn book. As you can see.

My untrained eye caught the following:

- Seems like the skim valve(s) are used by the pressuretrol(s) and other… stuff.

- The hot water tank has its inlet & outlet from the boiler reversed. Hot is coming in from the bottom…?

- There are valves before the circulator - the manual says " Do not install valves, or other devices having a significant pressure drop, between the boiler and the circulator inlet"

- There is no Y strainer after the circulator, also contrary to the manual.

- The header is tilted towards the boiler, not the return. Is that a big problem?

- The way the steam returns run is just confusing the hell out of me, but that might be me.

Let me say that this thing has worked flawlessly. We have plenty of heat, and have literally never run out of hot water (6 people/2 full baths) and our bills are … well, they're lower than they were with the old setup, anyway.

So, 2 questions:

- Any tips on cleaning this thing out? I mean skimming and maybe other cleanouts that are needed.

- Is there anything that really should be fixed/changed on this system, even though it seems to be working pretty well so far?

Thanks in advance…

Comments

-

Well… there are a number of things which aren't really right, but —

You mentioned the bottom line. It's working, giving you good heat and apparently not bugging you with noises or other nuisances.

So, in my view, if it ain't broke, don't fix it.

I would look at the pressuretrol; it may be set higher than it needs to be (ideally it would cutout at about 2 psig or a bit less). That's easy.

On the indirect piping: you need as much head on the inlet side of the pump as possible, so having that come from the bottom of the boiler, though it seems odd, is probably not a problem at all (the boiler water will be pretty well mixed to the same temperature throughout when the boiler is running).

On skimming. There may be a helpful fitting somewhere — but see my first comment. If it's working… leave it alone.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

The only way to escape the rabbit hole is to not start down it in the first place. (Or maybe kill the red queen, I forget. It's been a while.)

Like Br. @Jamie Hall said, if it ain't broke there's no need to start fixing it.

2 -

As much as I agree with " So, in my view, if it ain't broke, don't fix it. ". . .

And as much as you have the itch to get it set up as close to what the manual states as possible and the boiler is not too old. I would wait to Spring to do the work. For two reasons, time to plan over the winter, planning on what needs to go where AND if something unexpected happens you have all summer to get it straightened out. I don't like messing with stuff that is not urgent prior to or during the heating season.

If the water line is fairly stable when steaming and the system runs quiet it may not need skimming.

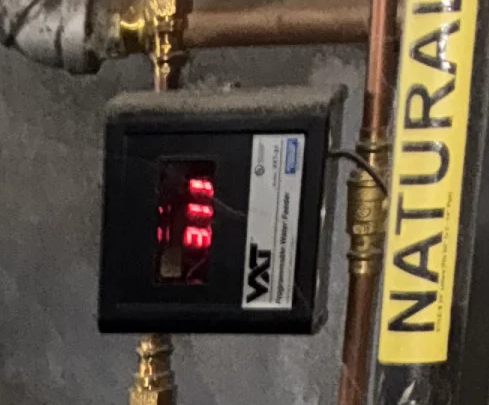

How many gallons of water is this ???!!! 311 ? Is there a leak ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

1.The header has no swing joints which could possibly damage the boiler. However the length of the header is so short the amount of expansion may not be enough to cause an issue.

2.The header is pitched wrong (as you mentioned) but the amount of condensate in the header is not much so if the boiler is quiet skip that

3.Same with the indirect. If you are getting enough hot water leave it. but the indirect

4.The horizontal run on the Hartford loop is too long. Again, no noise leave it

5.I do not like the safety relief valve on the long horizontal tapping. The relief valve must be mounted upright and should be directly on the boiler

6. I have no Idea what the xtra low water cutoff are for.

The guy that installed this never reads an install manual "I have been doing this for 40 years" Yeah, 40 years of doing it wrong.

If it seems to work ok, I would leave it alone except for the two things I am most concerned about.

The location of the safety valve (which may be the skim tapping)

and the header with no swing joints.

If you read the manual, it mentions the safety valve being vertical

it shows swing joints and a 3" header (depending on the boiler size)

It shows not to do a "BULL HEAD TEE" with the steam outlet between the boiler tapping's.

I think your skim tapping is below the black switching relay on the left side of the boiler. It's an 1 1/4" tapping according to the manual

2 -

Thanks everyone! Consensus seems to be don't mess with it too much if it's working well. Good advice I'm sure.

@Jamie Hall thanks for the info. I could try turning down the pressuretrol - but which one? There are two, one on the right and one on the left. Attaching photos. The one on the right side has Main set just above 4 PSI and the Diff at around 1.2 PSI. (You can also see from this photo the color of the water in the sightglass, with a layer of oil on top). The one on the left, on the safety release valve tapping, is set at 12.5 PSI. It doesn't have a Diff control.

@ratio I probably shouldn't have eaten that mushroom before starting this 🤣

@109A_5 Yes the water feeder does indeed say 311… is that an issue? I have no idea how this works!

@EBEBRATT-Ed Thanks for this info. Changing the header would be a big job but fixing that safety valve situation seems like a no-brainer for next Spring.

Really appreciate you all!

0 -

Sound like it may need skimming.

From

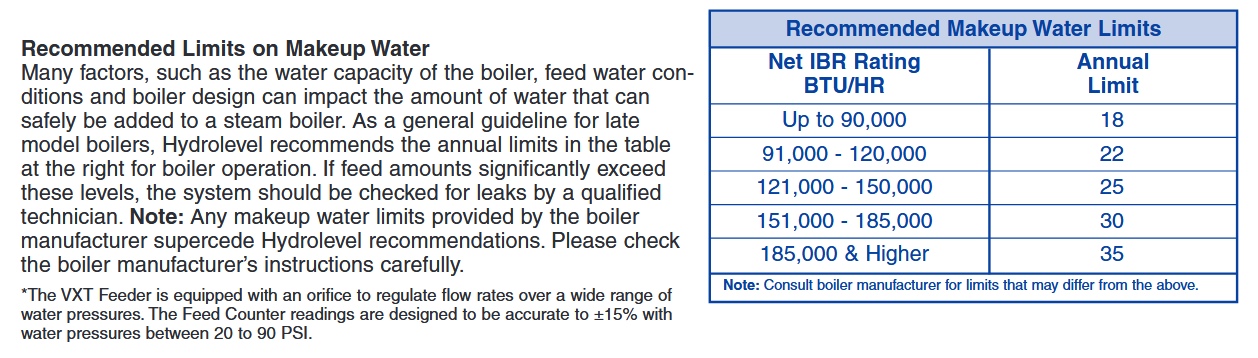

4 years times the biggest boiler in the chart is 140, you are more than double that. Kind of makes me wonder where the water went.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

The pressuretrol on the right (set at 4.5 psig) is the control pressuretrol. Try setting itthe main down to about 2 psig cutout. Differential is finel. That won't hurt anything — and might save some fuel.

The other pressuretrol is a safety cutout — it's fine as it is.

And yes, the bit of oil in the sight glass does suggest skimming might be something to do… but no rush on that.

The 311 on the feed counter is rather high — and could mean that you have a small leak somewhere. Try keeping an eye on it, and seeing how often it changes. How often or how much is variable — some systems go months without needing any water at all, and some may need a gallon or so a week.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

With everything that's going on the water usage is what I see as the worst problem. That is several lifetimes worth of usage. Mine is coming into it's 12 season and sits at 70. 311 is crazy usage. There is a leak, or leaks somewhere. Could be steam could be actual water, but somewhere there is a leak that needs addressed.

0 -

When chasing a presumed excess water usage issue.

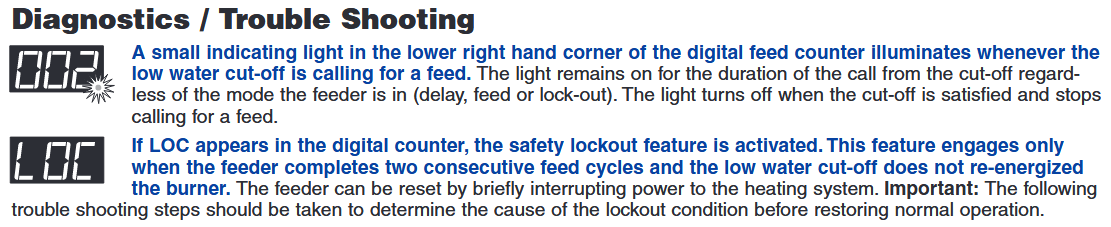

The VXT does not measure water volume like a utility water meter does. It measures the time (displayed in minutes) the the water feed valve is commanded to be open. The water flows through a calibrated orifice that at an average water pressure passes a gallon of water per minute. So the VXT display, displays how many minutes the feeder has the valve commanded open.

If your water pressure is abnormally low or the orifice is restricted or the screen is restricted the displayed value may be erroneous, there could be other reasons too. I would drain at least 2 gallons from the boiler and use the feed switch to refill it, see if your 311 goes to 313.

If the VXT seems to work correctly;

It appears you could close this valve and see how fast the boiler water drops during the heating season. At some point the LWCO (Low Water Cut Off) should eventually trigger the VXT. The VXT should trigger and start counting since no water is flowing with the water shut off valve closed and it may go into LOC mode.

If excess water usage does seem to be an issue, inspect for water and/or steam leaks, wet returns buried in concrete floors, vent valve(s) that don't close with the presence of steam.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements