Viessmann Vitocal AWHP for hydronic baseboards or retrofit floor heating?

Hello,

I hope I am in the right subcategory.

We are currently on hydronic baseboards with oil furnace. We will definitely be moving away from oil.

However, we do want to keep heating with a hydronic system for the various advantages it has compared to forced air heating. My wife has also made clear that for her forced air is not an option.

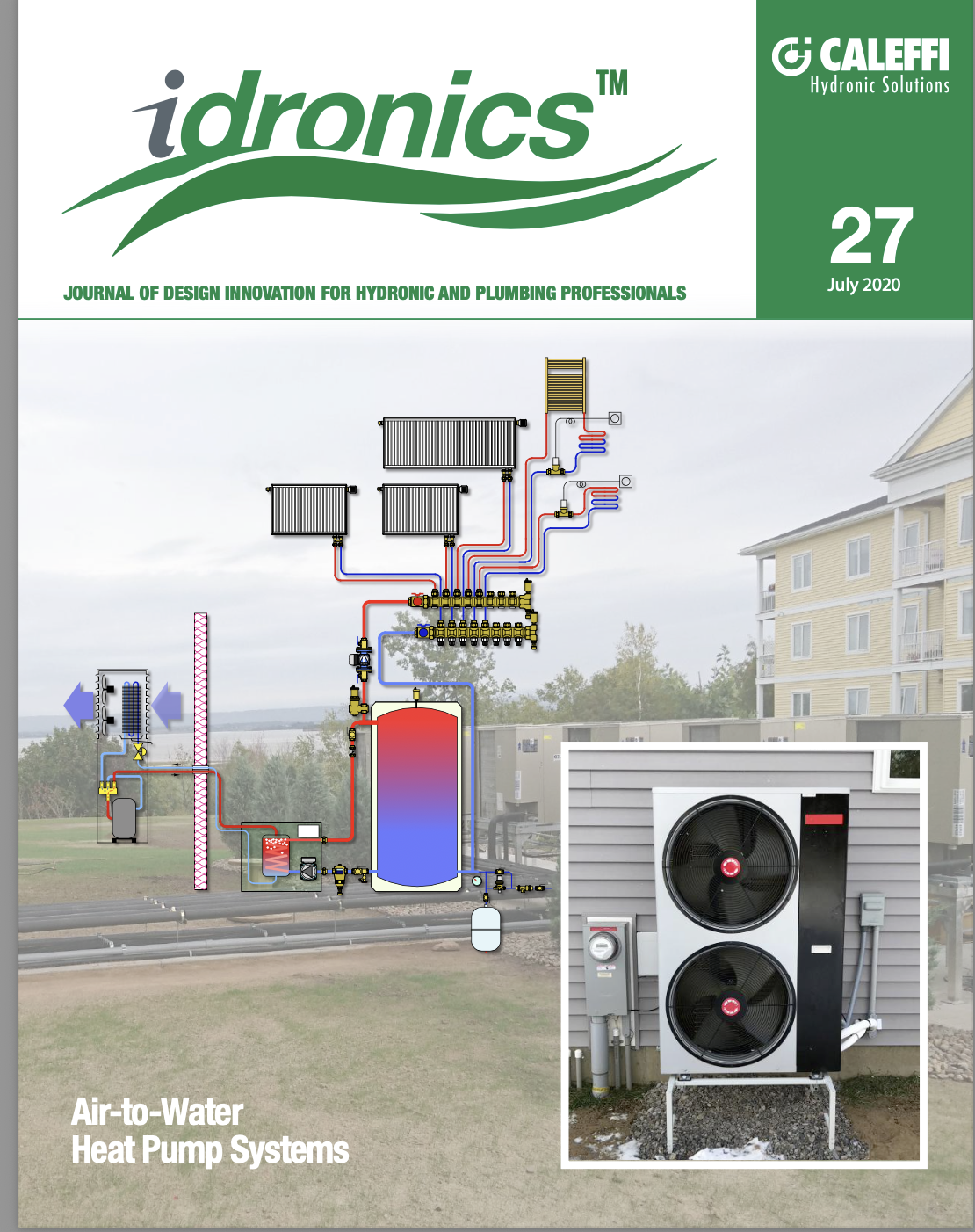

This brings me to the point where an air to water heat pump comes into play.

I have tried to read a lot about capabilities of that heat pump with baseboards, the efficiency in heating with a legacy hydronic system, but information is limited.

Do people have experience with running an AWHP with baseboards?

Is a floor or wall heating retrofit feasible and which system system would be advisable?

Regards

M

Comments

-

I would first do a heat-load for the home

Make any energy upgrades, you can. The lower the heat load the better tir the hp and energy cost going forward Then determine how much fin tube you have. The actual fin, not just the enclosure

Then use an output chart to see how the fin tube matches the heat load

Dual fuel is a good option if the HP cannot make the load in the coldest periods

I have that exact HP in my shop. With radiant slabs I can run the system 115f or lower

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I will get on it.

We were wondering if retrofitting actual radiant heating in the walls or floors from underneath makes sense? Ideally we would have the main and first floor with radiant heating and leave the basement on baseboards, maybe a fan coil.

It would obviously involve quite a bit of drywall work.

0 -

The advantage of retrofitting a lot of radiant heat into the floors or walls is that you can get away with running lower temperatures in the circulation. This is a definite factor when considering air to water heat pumps, as their maximum output temperature is much lower than the maximum temperature achievable with a boiler — at least with the present state of the art.

The downside is obvious: you'd be gutting most of the house. This would be inconvenient (at best) and expensive.

As @hot_rod said, the first three steps are improving the envelope as much as possible. Keep in mind while doing this, however, the minimum recommended air changes in a house to maintain indoor air quality.. Anyway, having done that, then determine the actual heat loss of the house. Then looking at the existing baseboard radiation and determine at what temperature it needs to run to satisfy that heat loss.

Then you can start looking at what heat sources — including the air to water heat pump and mod/con boilers or a combination — will satisfy the requirements.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

As Jamie mentioned, necessarily tightening up the house resulting in reduction of air change requires that you pay close attention to indoor air quality. This requires yet another expense for a mechanical system—an HRV or an ERV—that changes the air and recovers much of the heat in that process.

0 -

First step is to figure out your starting point. How many liner feet of baseboard you have and how much oil did you burn through last winter. Winter energy used in Therms*42 is about your heat loss. For more accurate number run the math here:

https://www.greenbuildingadvisor.com/article/replacing-a-furnace-or-boiler

AWHP likes to run at around 115F max, you can then see how much of the house heat your existing baseboards can supply at lower temp.

From there, you need to add extra emitters to make up for the shortfall. The easiest is oversized low temperature panel rads to replace sections of baseboard and a bit of floor heat where easier to get to without major demo.

2 -

Thank you for the input. I will get into finding out what our heat loss is soon and then work from there.

I would be very much open to expanding the current system a little bit with a few rads or replacing some baseboards if thats enough.

For the under floor heating…we would have to install a PEX system with aluminium heat plates on the subfloor from below. A very good friend is a carpenter and has offered to do/help with this, mostly taking care of the drywall demo and reinstall part.

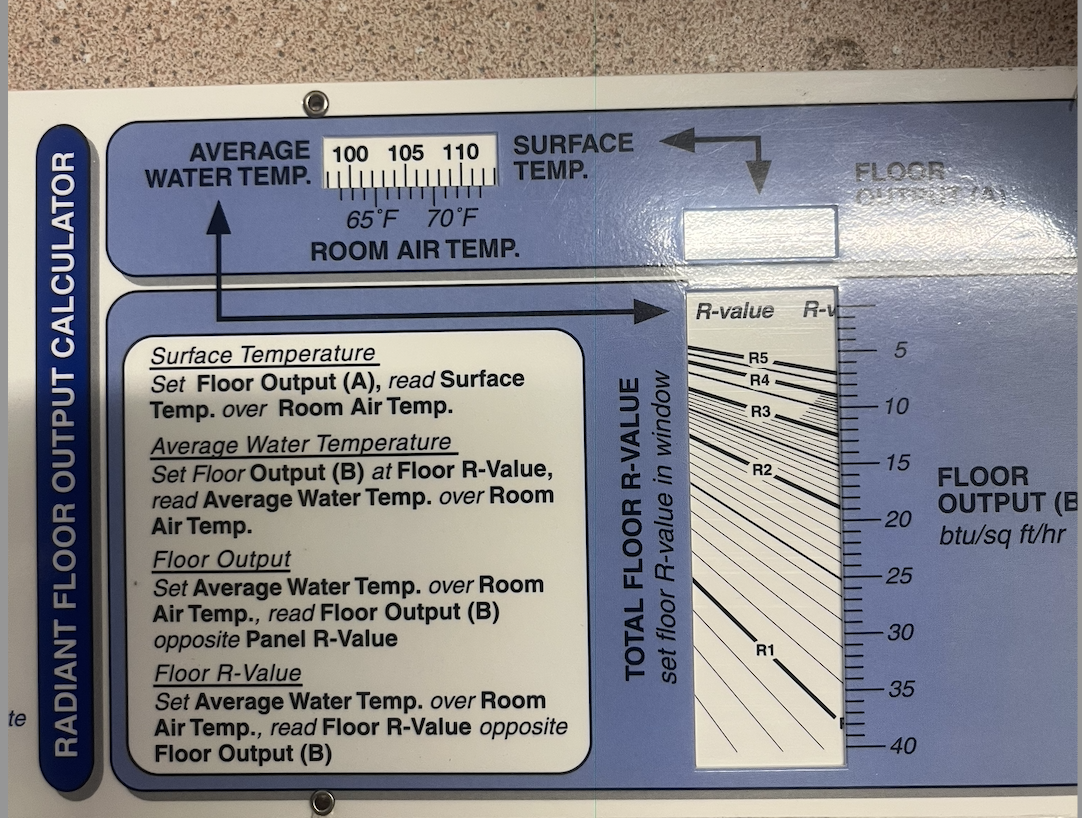

Our floor is solid wood throughout the house though. Is there a calculator or a way to find out if in floor heating in the main and upstairs floor would be enough to heat?

0 -

How much heat you can push up through the floor can be determined pretty easily. Floors have a max floor temp as well. But you need the heat loss first before working on that.

0 -

So we had an energy assessment done and the heating load of our house is 38000 BTU. The auditor said that insulation is up to date and there is nothing we can do that would not be invasive and economic.

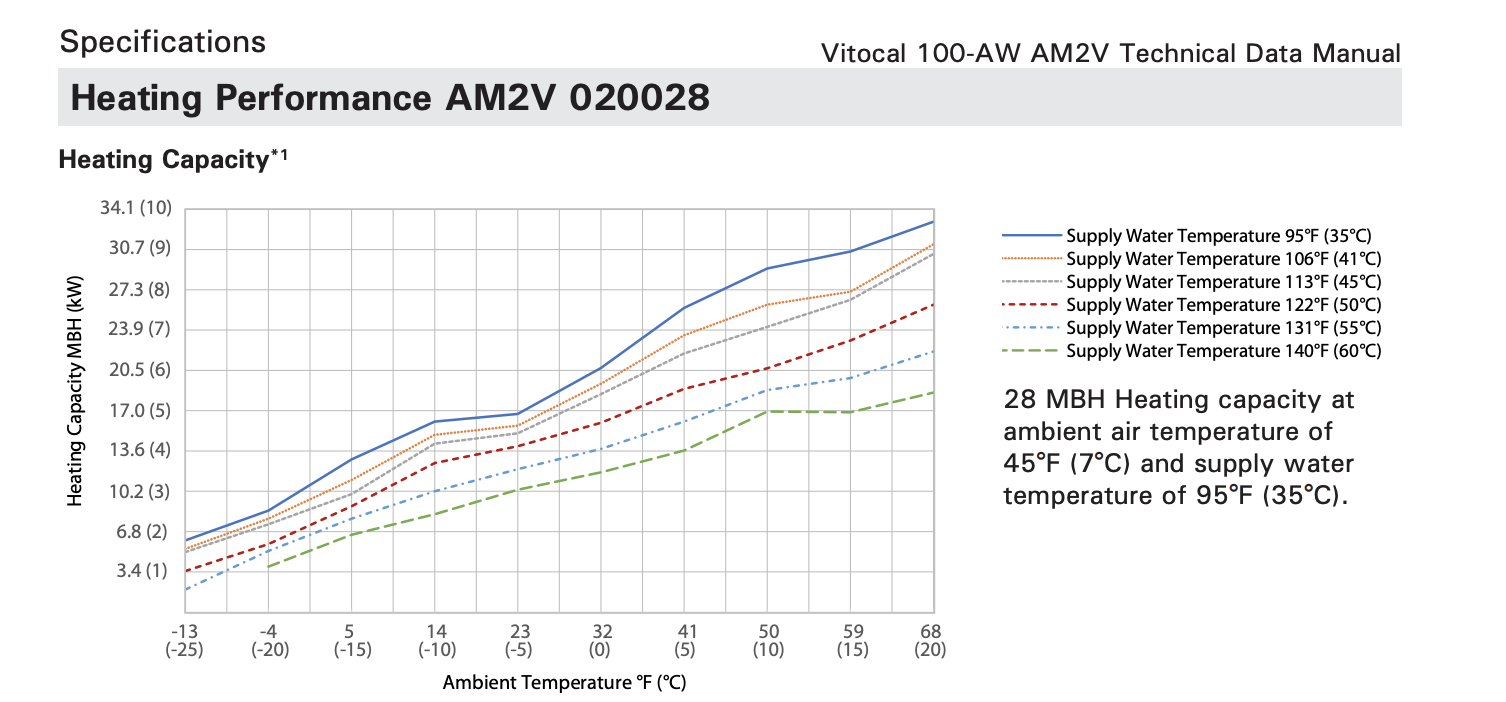

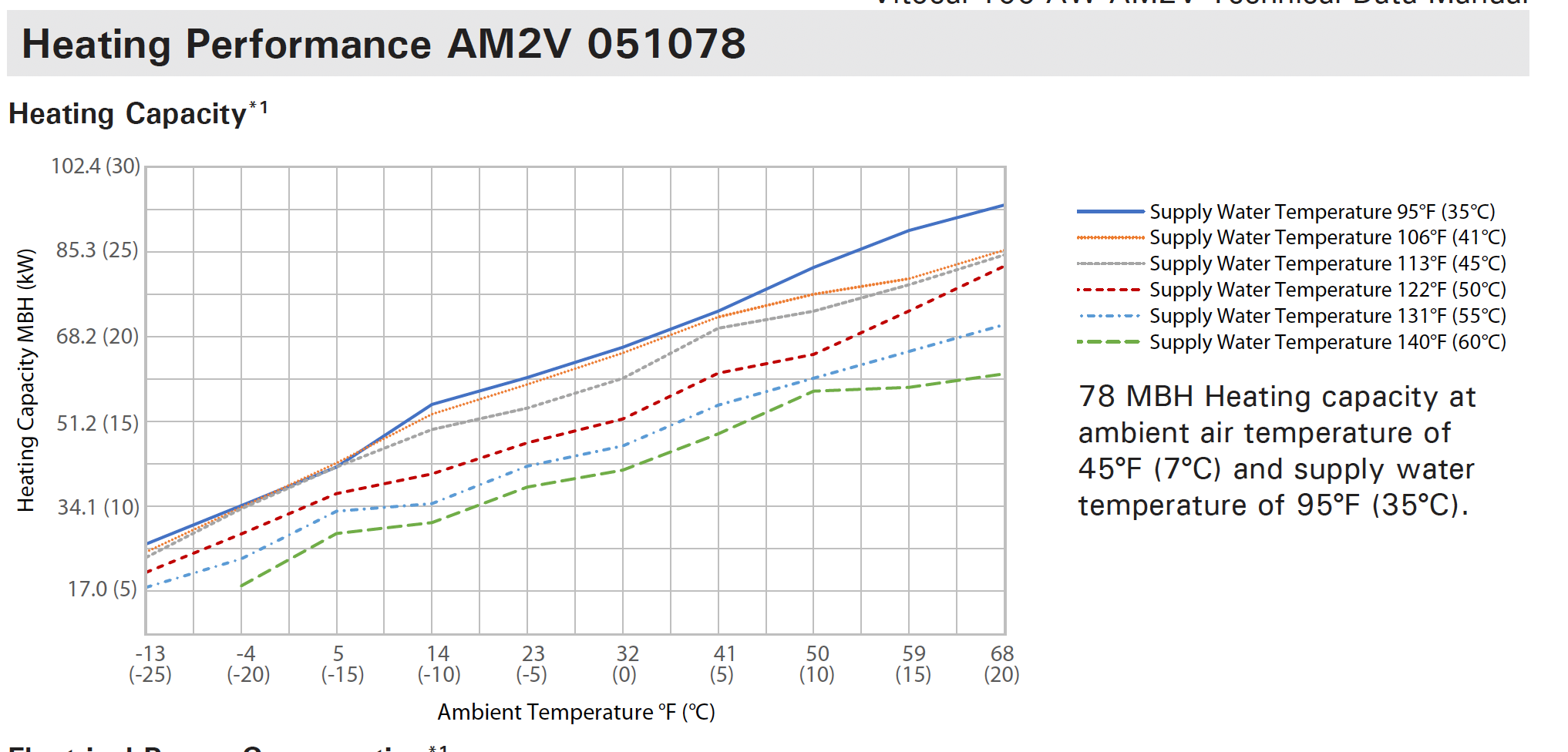

With that in mind I was looking at the sizing of the Viessmann Vitocal 100 AW which comes in a 34000 BTU or 58000 BTU size.

What would be the way to go?

0 -

How does the fuel use calc compare to the assement? How many BTUs is your existing radiant capable of using 115F water?

Generally with AWHP oversizing buys you a bit of extra efficiency as long as you are not short cycling it. Check the min output of the unit and make sure your smallest zone is above it or add a buffer tank.

Since the install cost is so far removed from BOM cost, there is very little drawback in this case for the larger unit.

0 -

what temperature water do you require?

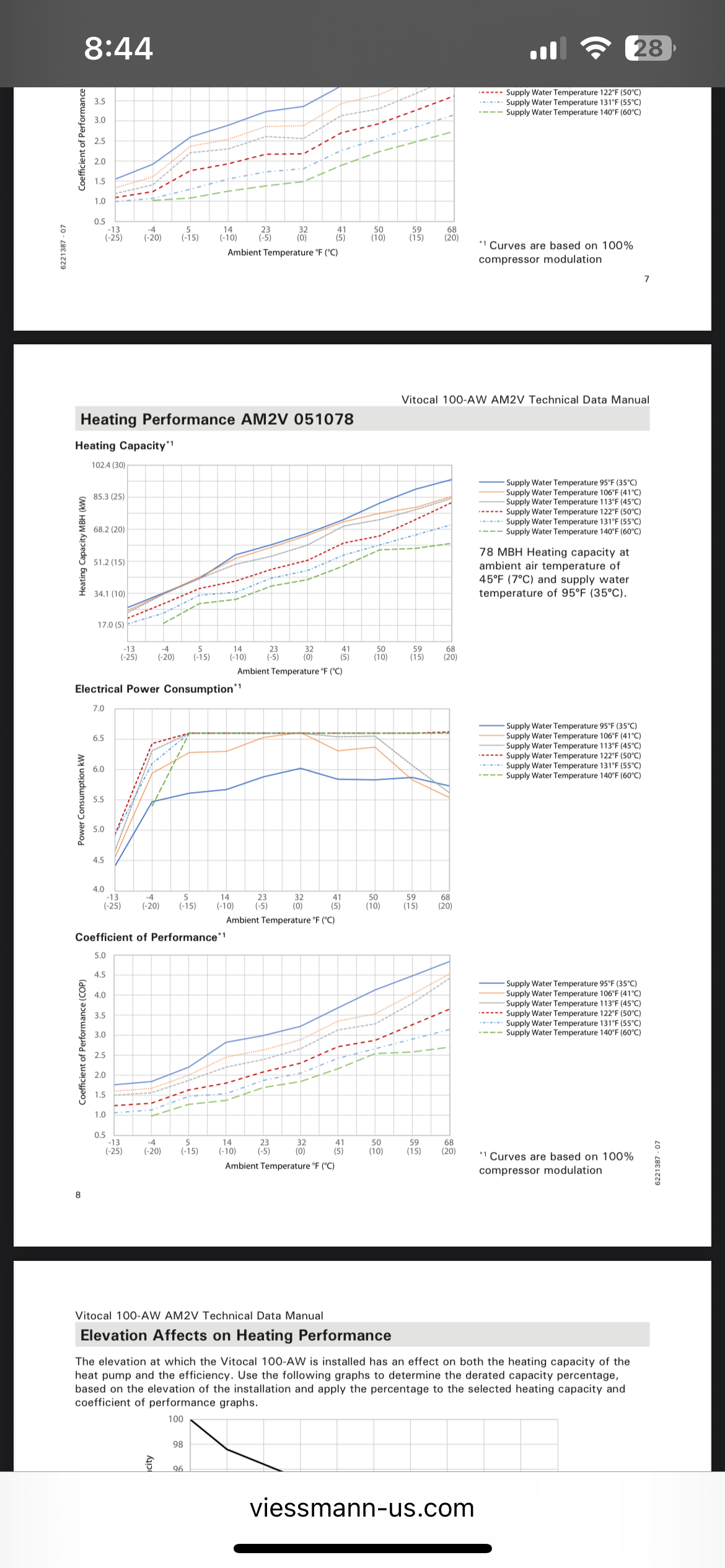

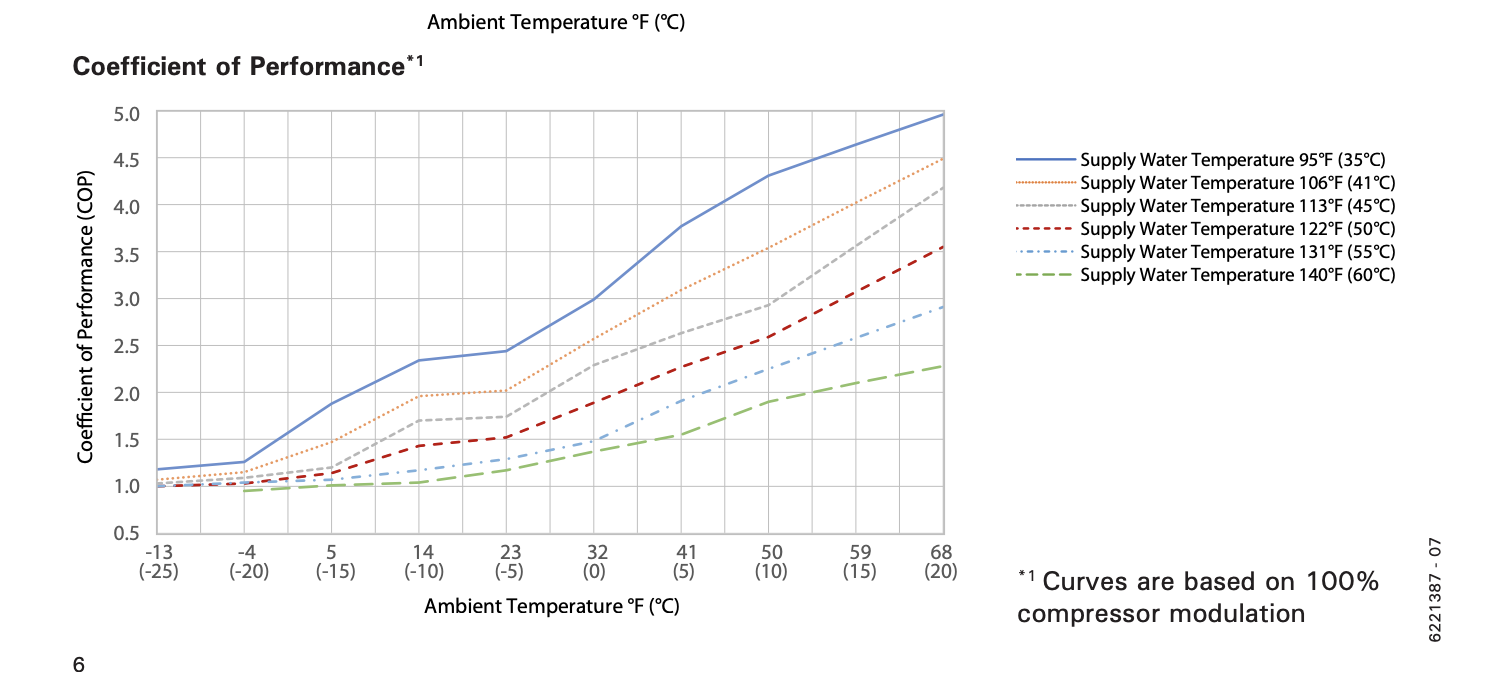

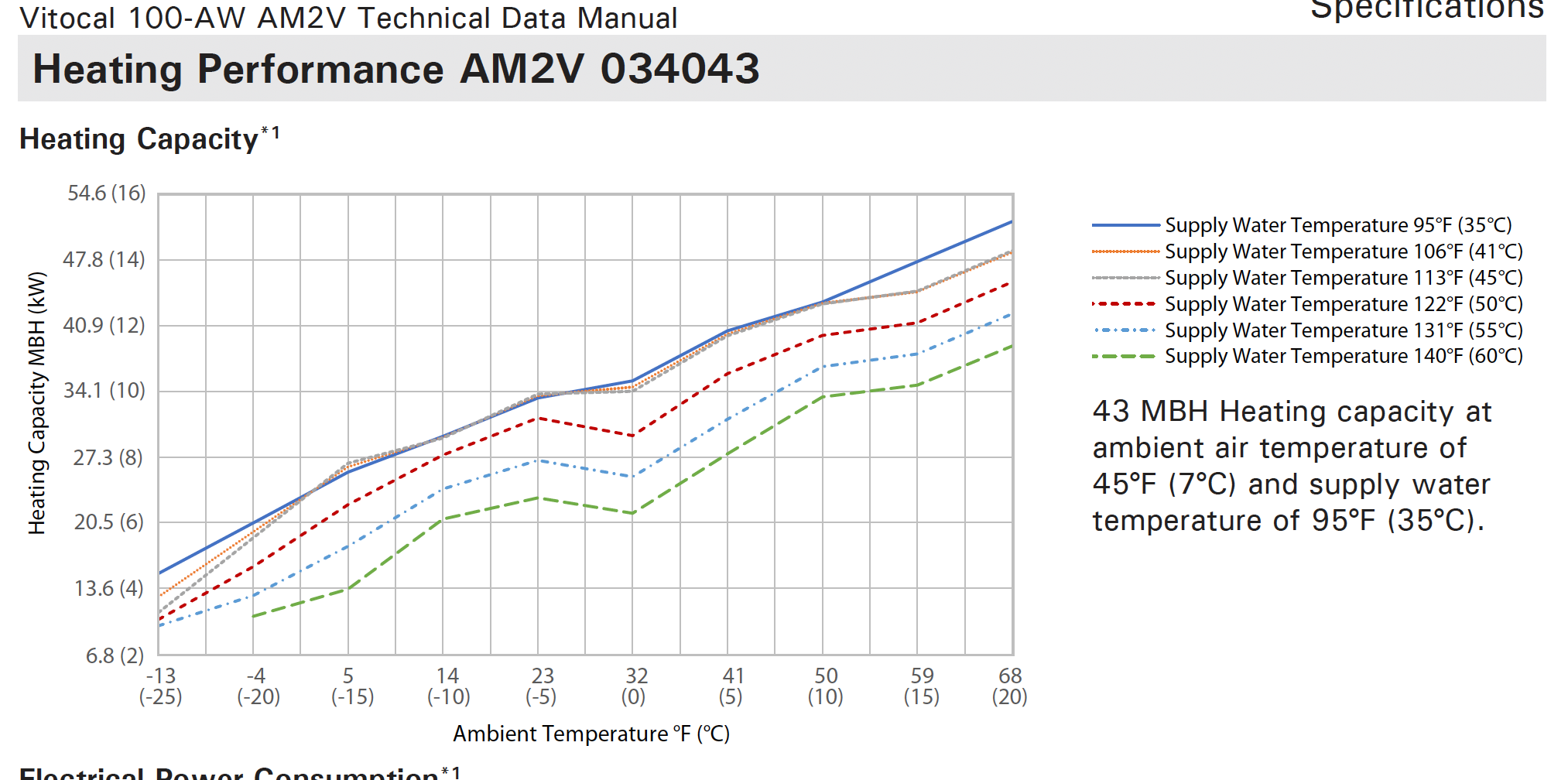

The tech manual has good graphs for performance and efficiency at difference conditions

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

When I use an average of 30 BTU/sqft for the radiant heating system I would be able to output 60k BTU/hr. at around 100°F. But that is only for the main and first floor.

0 -

Hi, we had our manual J calculation and it came back with a 34000 BTU/h load at design temperature.

I keep thinking about the output of the system though. Our hardwood and subfloor will have a combined R value of about 1.6-1.7. How do we fare with that? The contractor seemed very optimistic.

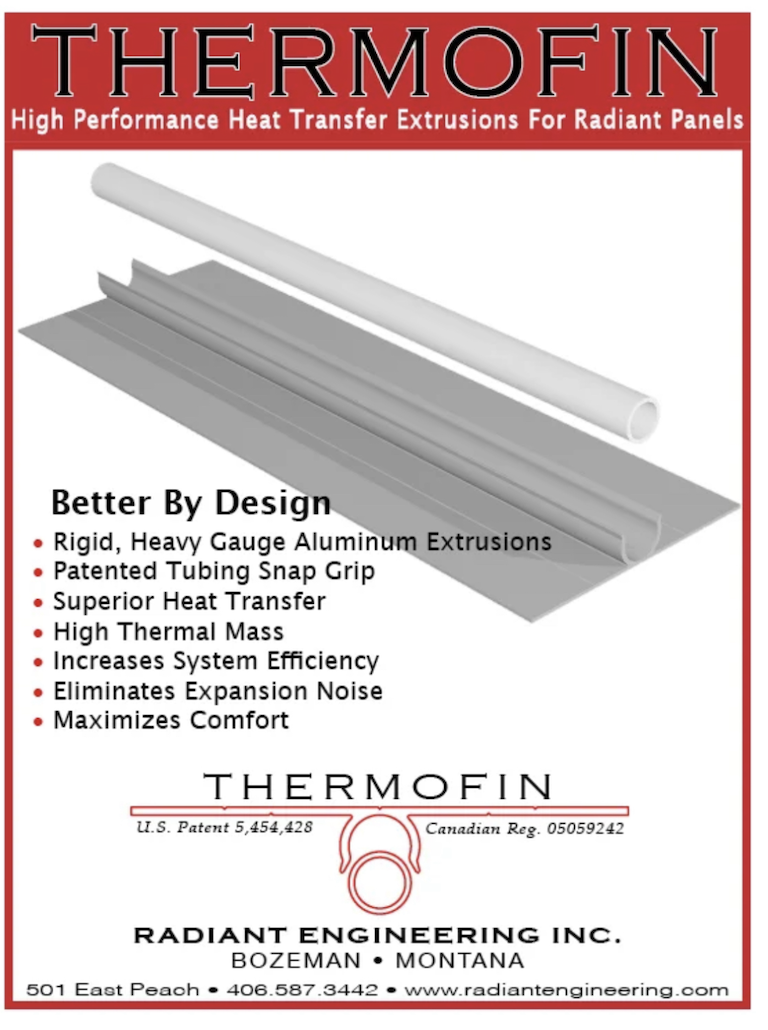

We definitely need heat transfer plates for the 1/2 inch PEX. Which ones? Are the expensive Uponor better than the flat aluminium plates? The Uponor seem rather narrow and do not cover much width?

Does somebody have experience, data or an opinion on the two different products? We would need 20 BTU/sqft output.

0 -

R-1.7 floor, 20 btu/hr design, shows 108 AWT, so around 112-115° supply should do the job. That is comfortable for an A2WHP. 80% of the heating season you will be below that 115° requirement, better COP still.

Some key components with transfer plates, the thicker plates will not expand/ contract and make the crinkle/ oil-can noise. The tightness of the tube in the groove prevents the tube from moving, that is where the ticking noise comes from.

Radiant Design used to have ThermoFin and ThermoFin lite. The lite was narrower, a bit thinner gauge too I believe. I've found the lite versions work fine.

It's possible the extruded plates from various tube manufacturers are Radiant Design products re-labeled.

The key to RD fins are the amount of aluminum around the tube channel. The knock off missed that crucial part of the design. This is what gives the channel the holding strength.

It's good to check the output and COP at your expected outdoor temperatures. Down around 14°F COP drops.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thank you. Does the width of the transfer plates play a big role. The thicker, extruded ones tend to be only 3 1/2 inch wide while there are thinner ones that can be 4 or 5 inch wide or even double groove. They can cover the entire width in between two joists while covering two PEX tubes.

0 -

With the loads you have, 20 btu/ sq ft or less, I don't think you would see much change with the wider version. Maybe if you had high load areas they would be worth the extra cost.

There are some FEA and infrared models out there that show performance difference. I did some for the RPA years ago. But before all the various versions were available.

No doubt a product like Warmboard with a solid aluminum sheet spreads heat evenly.

From left is copper tube in ThermoFin, 2 plates per 16" oc joist bay

Suspended pex

Rubber tube staples to subfloor

Pex in ThermoFin

Warmboard, note where I routered through the Warmboard aluminum!

The cost difference is all about the amount of aluminum in the plate.

I have not used the double groove version. I think @Ironman or @Bob Bona_4 have used the Rehau version.

A lot comes down to installation and workmaship. Install and fasten them as the manufacturer requests and all the brand name plates will get the job done, quietly and efficiently.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Does anybody know how to get Rehau or Thermofin products in Canada?

0 -

-

contact Radiant Design for ThermoFin availability

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Wolseley carries Upanor Joist track. Not cheap though.

0 -

Unfortunately, the Thermofins dont ship to Canada. I cannot get prices at Wolseley.

0 -

Phone them:

Uponor A5080500 Joist Trak, 1/2 in. Heat Transfer PanelBrand: UponorSKU: WIRA508050

Price is about what you would find on the internet.

0 -

Below is a link to a post I did a while back with some FLIR camera shots I took of a test to compare effectiveness of a couple of thicknesses and widths of heat transfer plates. The wider, thicker plates show a notable difference. Take it for what it's worth.

I have the handicap of being in Alaska and many vendors either won't ship here or shipping isn't cost effective (they love to send things UPS second day). That affected my choices.

The thicker, wider plates came from pexhouse.com in Canada. They were the only supplier I found who could provide a plate that was wider and thicker than the common .016" X 4" plates but less expensive than extruded plates. I am using them in a part of the house that will be challenging to heat using underfloor plates and I'm using the thinner plates in the rest of the house. With today's tariffs on Canadian goods and aluminum to the U.S. they would probably no longer be cost effective.

My system is still a work in progress. I had initially looked at routing grooves in the top of the subfloor, but decided to put plates under the floor.

0 -

Thanks for the link.

We are talking to several contractors now and the quotes have been very heterogeneous.

We are talking about 1300 sqft of heated floor area divided in 3 zones and the quotes have ranged from 15,000 CAD to 44,000CAD. I am not quite sure what to look for in these quotes and how to decide other than what kind of panels they use and making sure there are two runs in each joist bay.

0 -

Price is what the installer will charge. Hydronic heat is already considered specialty, add heated floors and AWHP and you'll pay a premium. About the only way to do this on the cheap is to DIY.

0 -

You are right. Contractors selling and installing these are scarce. We found one, who quoted us a reasonable estimate and we accepted it.

Now for the design part, there are lots of open questions.

It was my understanding that the Viessmann Vitocal 100 AW has outside temp control and uses room sensors as well. I never set one up. So I am by far not an expert as you can see.

From what I read, the AWHP should handle 3 zones of radiant in floor most efficiently without a buffer tank.

Other say, the buffer tank is needed and the AWHP will just keep the water temp of the tank steady according to the heating curve.

And others say the buffer tank needs to be in line with the return to add volume to the cold return/system.

In Europe I almost never see a buffer tank with these. They say it runs up to 20% more efficient without, the contractor says I need it.

Then I do not understand how to wire and setup the circulator pumps and zone thermostats. I thought the entire heating system will be run by the indoor unit.

I appreciate it, if someone can help.

0 -

It depends on whether you use zone valves.

With a heat pump, you need to keep it from short-cycling. Which means that it always has to have enough water circulating so that the compressor has a decent run time before hitting the high limit and shutting off. If you have zone valves, it's possible for all the valves to close at once, which means no water circulating, which means short cycling, so you need a buffer tank to provide volume when all the zones are closed.

If you don't have zone valves you have the full volume of the system available whenever the heat pump is running so you don't need a buffer tank. This is simple and at a certain level more efficient.

The reason I say "at a certain level" is that the purpose of a heating system is to deliver comfort. If you are unable to deliver comfort without zone valves then it's failing at its primary purpose, that isn't efficient.

0 -

Well, the buffer tank will likely go in and then we take it from there.

As to the components between the buffer tank and the manifolds. What do I need there?

So the wiring diagram of the heat pump says that it can have two heating circuit pumps wired to it and two temperature room sensors.

We will have two manifolds, one for the main floor and another for the top floor. The more I think about it the less likely i find it to make set the floors to different temperatures.

That means I would want the same temperature everywhere and would only need one zone, meanung only one circulator pump for both manifolds? And since there is no high temp emitter on the system, no mixing valve. The individual loops would be balanced on the manifold.

Should the loops be limited to a room each for better balancing or can they just cross room borders etc.?

So, only a circulator pump in between the buffer tank and the manifolds and the supply sensor?

Or would would install a circulator pump for each manifold with sensor and wire them as HC1 and HC2?

0 -

A guiding principle when working with heat pumps is that if you're mixing, you're doing it wrong.

I'm not familiar with the data sheet for your heat pump, so I pulled up one for one I am familiar with:

Scroll down to where it says "Heating Data." Note that when it's 17F outside, if your water temperature is 95F the capacity is 20,575 BTU/hr, and if you're water temperature is 122F it's 15,494 BTU/hr — 75% as much. So if you're heating water up to 122F and then mixing it down to 95F you're losing a quarter of the heat pump's capacity for no gain. Note also that the COP is 2.66 at 95F and 2.03 at 122F — so you're using 33% more energy for no gain.

One of the issues with buffer tanks is they introduce mixing. That's why a system without them is more efficient.

A second guiding principle is ignore the nameplate capacity. This unit has a nameplate capacity of 2.8 tons of heating, it says so right at the top of the page. That's 33,600 BTU/hr, and if you look at the chart, it does in fact have that capacity at 47F with 95F water. But what you should care about is the capacity at your design temperature, which is probably going to be closer to 17F where the capacity is 20K BTU/hr.

So before designing anything I would ask how the capacity of your heat pump compares to your heating load at your design temperature. Specifically, are you going to be able to heat the whole house with one heat pump? Because if you're going to need more than one, it's easiest to design each as a separate system.

0 -

At -25°C it has 25k BTU at 41°C water temperature. So almost exactly our design load.

0 -

If you go with a lot of zoning you want a buffer tank, the 3 pipe method is the way to go.

Lots of good piping info here. A single delta P circulator with zone valves or a manifold home run shown here. A home run system takes more tube but gives you the ability to infinitely zone, or combine zones at any time by wiring actuators together or separate.

I run a single low temperature to a slab, the heat pump is controlled by a sensor in the tank. I keep the tank at 115.

Zoning is up to you. I would not micro zone every room in the home. Main living, dining kitchen can usually be combined. Maybe a master bath as a separate zone. It really depends on your floor plan.

Run the loops so you have the ability to separate room if you want, but it will take more loops and manifold ports.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Eventually we will only have two manifolds and probably just one circulator pump. The infloor will be designed with that in mind.

However, I wanted to circle back to the sizing question. The manual J calculation said the house has a 36000 BTU/hr load at -19°C design temperature. The heatpumps will supply 2 of 3 floors, the basement doesn't have in floor and has mini splits.

That means the heatpumps will have to supply a heat load of roughly 22000 BTU/hr.

Looking at the output curves, the 051078 our contractor wants to put in can exceed that even at -13F and 113F water temperature. It seems way oversized for most of the year and shoulder season.

The one size smaller, 034043, is undersized for design temperature, but can meet demand for most of the year.

See graphs.

The will supply DHW as well. I dont know hoe that affects capacity.

Is the big one really way oversized and should we go with the smaller one and take the slightly undersized capacity at design temperature?

I can not find and data how far the big one can modulate down.

0 -

@Voodoo90 : "They will supply DHW as well. I don't know how that affects capacity."

DHW is a poor fit for air to water heat pumps.

Compared to a heat pump water heater, it saves you nothing on operating costs, saves no space in the mechanical room. It has a negative impact on comfort in cold weather — the system can't provide heat when the hot water tank is recharging. With a 34K BTU/hr capacity, it will take about an hour to recharge a 65 gallon tank, that's long enough that you'll notice that the heat is off when it's cold out. And the kicker is that the DHW setup is going to be really expensive.

0 -

That does make sense and in that case using our electric water tank, which is still relatively young probably is way more economical.

0 -

I agree that 3-pipe is the way to go if you have to have a buffer tank.

I have to take issue with that picture that shows a nicely stratified buffer tank though. That's not going to be realistic in a heat pump setup.

There are going to be two circulators — one on the heat pump itself, one to serve the zones. Between them is the tee that goes into the buffer tank. The flow through both of those circulators will be variable. The one on the heat pump will vary to meet the output of the heat pump, which will be trying to match its output to the load. The one on the zones will vary depending on how many zones are calling for heat, and which ones.

The difference between those two flows will go through the bottom leg of the tee on the buffer tank. If the heat pump flow is the greater one, water will be flowing down into the buffer tank. The buffer tank should be small — Chiltrix recommends a 17-gallon tank for their 5 ton heat pump — so the entire tank will quickly reach the temperature of the water flowing into it, which will be coming straight off the heat pump.

If the flow to the zones is the greater one, the flow will be upward out of the tank. The tank temperature will quickly reach the temperature of the water being returned from the zones. If the load is low and the heat pump turns off altogether, all of the flow to the zones comes out of the tank.

Neither flow is constant, so the flow to the buffer tank can reverse directions as conditions change.

From an efficiency standpoint, things work best when the flow out of the heat pump is the greater flow, the emitters get water at the temperature being produced by the heat pump. When the zones are greater than the heat pump the water supplied to the zones is being mixed with cool water coming out of buffer tank. And when you're mixing, you're doing it wrong.

Fortunately that usually happens when the load is low so you're not asking much of the system anyway.

0 -

Thank you.

In terms of sizing, the smaller unit would probably suffice?

0 -

Before I answer, can you tell me your zip code or even your county so I can look up some weather stats? I want to verify the design temperature you're using.

I'm a little dubious of your heating load — 22K for the above ground and 14K for the basement seems unusual. 22K is low, indicative of a well-built modern house. In such a house the basement is typically insulated, which would mean 14K is kind of high.

0 -

Halifax, NS Canada

House is from 2009. So the basement would account for only a third of the total load or even less usually?

0 -

Ah, I don't know how to look up Canadian weather stats. Sorry.

I would sanity check the whole house load against the process in this article:

https://www.greenbuildingadvisor.com/article/replacing-a-furnace-or-boiler

An insulated basement usually has lower loads than the above-ground part of the house, but you don't want to be guessing. You want to be doing room-by-room load calculations.

1 -

This the link to the design temps. I was actually wrong. I was looking at 2008, not 2025. The design temperature is actually just -15°C.

0 -

The pump in those Viessmann runs constantly. The small buffer that Viessmann provide is a stubby, so not much stratification even if the pump would stop. When all the loads satisfy, the HP continues to tun until the buffer is heated to the setpoint temperature. Next call for heat comes just from the tank until it drops the differential.

I believe all the VitoCals have a backup electric element built into the indoor unit, that can be enabled if they fall short.

If @DCContrarian has a better piping diagram, go for it. Confirm with Viessmann that is piped to their requirement so you do not void warranty.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements