Dunham valve rebuild?

Comments

-

Not sure what that is. He had to raise that ceiling as part of the boiler recertification

Look at the return angle on this rad. He says it heats up fine, how is that possible?

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

0 -

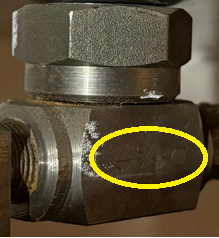

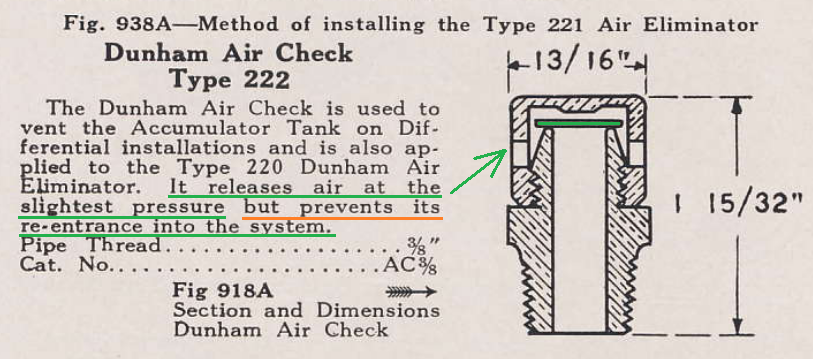

I think that is a check valve on the vent trap.

If there is enough differential between the supply and return it will push the air through the water although that won't happen until the boiler heats enough to build pressure so this radiator likely won't start heating until late in the cycle and if the system is building that much pressure the orifices might not limit the steam to what the radiator can condense(although that is only an inch or 2 wc.). I am pretty sure the controls on the boiler are pressuretrols that are not precise enough to limit the pressure to vapor levels.

All that being said, you can probably tweak that pipe to get it all heading down hill.

0 -

Thank you. Would you put a vaportrol on the boiler?

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

0 -

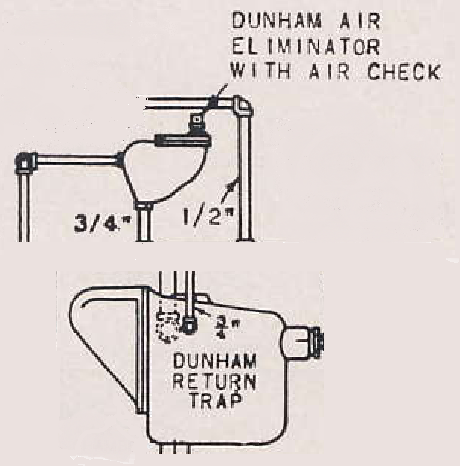

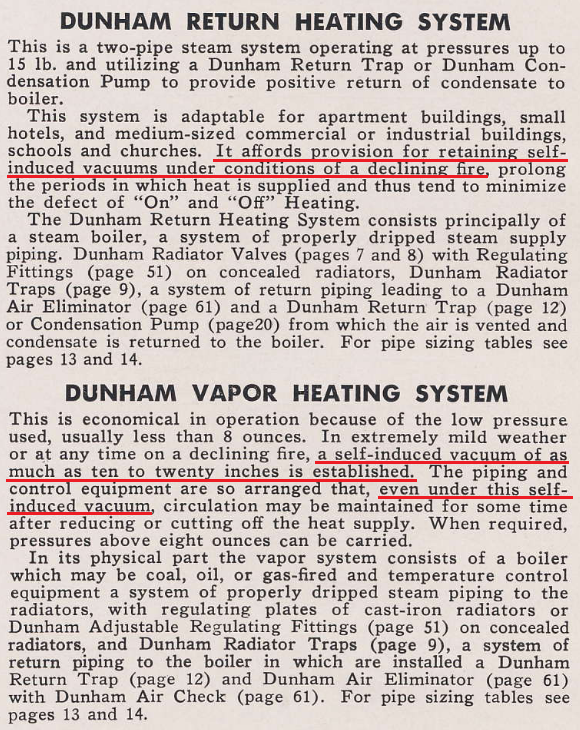

I believe your friend's system is a blend of the equipment found on page 12 of the document (page 14 of the PDF) and page 61 of the document (page 62 of the PDF) mentioned above and here.

https://heatinghelp.com/assets/documents/dunham.pdf

Yes traps should be checked for proper functionality an incorrect pipe pitch should be corrected.

Upon inspection you may find this is the only vent or vent pipe in the system.

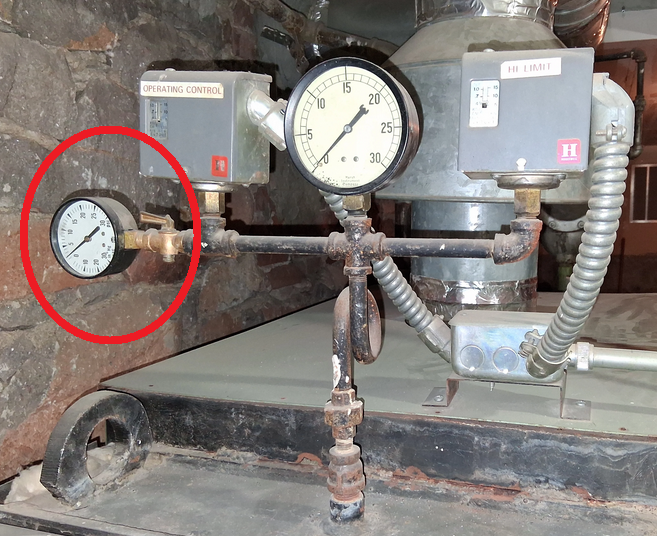

Does this gauge work ? Notice the vacuum part of the gauge.

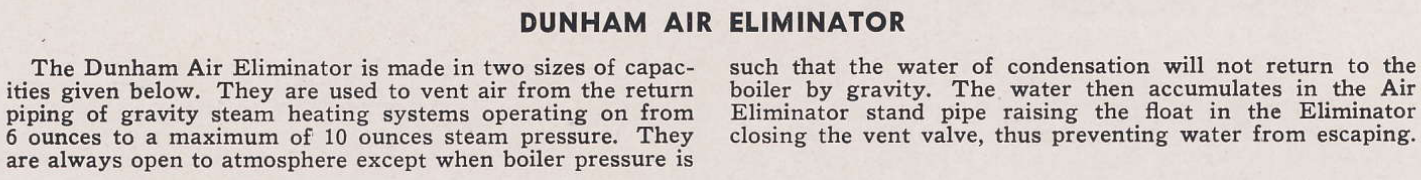

I bet when this system was working correctly (and was air tight) it would fall into a vacuum between heating cycles so the need for significant venting to get the air out with every cycle was not needed. Since between heating cycles the majority of the air is not let back into the system, hence the vacuum generated.

Does your system still have the Dunham Air Eliminator with Air Check and the Dunham Return Trap ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

"Does your system still have the Dunham Air Eliminator with Air Check and the Dunham Return Trap ?"

Pretty sure they're still there and connected. Don't know if they work though. That is not a vent you pointed out with arrow, just a check valve. Regarding that gauge you circled, i will be replacing that with a 0-3 psi unit... that gauge has to be broken. The system has not been on yet this season and all the trap lids have been removed when this was taken.

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

0 -

Looks like a check valve to me, see the arrow. Hopefully the crack pressure is less than 1 inch of Water column. To purge the air, if fuel is burned to build pressure to overcome too high a crack pressure of an inappropriately high crack pressure check valve, that is a waste.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Mepco still makes regulating steam radiator valves in several models. See the attached along with traps and everything else.

I think it went from CA Dunham to Dunham Busch-mepco as @EdTheHeaterMan said

1 -

The Dunham Air Eliminator with Air Check is the functional equivalent of a Vacuum Vent, which lets air out but not back in with a very low vent crack pressure. The air check is on top, however that does not look original. Your Gorton vents (on your system) let the air back in, only to be pushed back out with the next heating cycle, burning fuel to do it.

I'd replace the gauge with the same type to see if there is any vacuum, if you want to add a low pressure gauge in addition that is OK.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Yes. That's was Mattmia2 guessed. I'll ask my friend to check that crack pressure rating

How do we check if the Dunham Air Eliminator with Air Check and the Dunham Return Trap are working?

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

0 -

Without, disassembly cleaning / rebuilding, etc. system performance and system pressure / vacuum. I would expect to see a vacuum, but if you don't have a working vacuum gauge or a Manometer you can't monitor that characteristic.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Was just going to add: i didnt realize, until i zoomed in, that the indicator was pointing to zero on the vacuum dial so it may work. Won't know until we fire it up this season.

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

0 -

I'll have to look through that document (I'm the curious type) to see if there is any typical pressures stated. Back in the day a gasoline engine has about 18-20 inches manifold vacuum at idle, probably still close to that.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

This help? Otherwise need to take it down to look for other markings

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

0 -

This type of valve takes very little pressure to vent. No spring just gravity pulling down on the weigh of that little disk. I'll see if I can find any info on that check valve in the system.

Looks like the system may be designed to run at 10 Oz. or less.

With the design of these systems steam probably never gets to the Air eliminator.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

That's great. So all i need to do now is to fix the traps and pipe pitch and see how she runs i guess.

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

0 -

If that vacuum vent on the air eliminator assembly is working — or can be made to work — you don't need and don't want any other vents anywhere else on the system. The system will work just as well — if not better — without them.

With one caution: the crossover traps must be working. Easy enough to check: when the system fires up, the steam main and inlet to the crossover trap should get nice and steam hot, but the outlet should be cooler (it won't be cold — could be as much as 200 to 205 — but distinctly cooler).

If it isn't working, there's no real harm to putting a Gorton #2 on there instead. Unless your system is truly very large, that will be quite adequate. The only downside to that is that the system won't hold a vacuum — which is really no big deal anyway.

The desired maximum pressure for that system is 8 OUNCES per square inch, gauge. You will need to have a 0 to 16 ounce vapourstat to manage that. And no, a greater pressure is not useful. In fact, it will slow or stop the system from running! Not that it will break anything, at least within reason, but you won't get much heat, either, from the fuel you burn…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

Thanks. I'm changing out all the traps (new innards and caps) including those on the crossovers, they are all dunhams from the 1930 and can't imagine any of them still functional.

HIs boiler is slightly larger than mine at around 450k btu but with only around 10-15 rads so I'd consider his system smaller.

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

0 -

I found two names associated with a very similar check valve Swagelok and Nupro and the one spec page does mention gravity, but sadly they don't mention the crack pressure, just what I believe is maximum working pressure. I'd see what the system does, pressure / vacuum and heating performance in general.

Personally I like vacuum, (wish I had a 2-pipe system or all vacuum vents) but it can have issues like hard to find leaks. I think the benefits are less air in the system, minimizing corrosion, less air to push out each cycle, so faster heating, slightly lower boiling point.

Are the benefits worth the maintenance expense ? I have no data on that.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

if it spent most of its life operating at low pressure, i'm not sure how that equalizer works being between 2 check valves, it may not equalize the supply and return, but if it is at low differential pressure and has the orifices in place, the traps in the radiators may never operate and may still be good. there really is no way around the crossover traps needing to operate.

0 -

As @mattmia2 stated many of the traps may be good, if never actually used no cyclic expansion stress. If they did not corrode and leak out they may work. If it were me I'd test them, but that takes time, and 'New' does make some folks happy.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Thanks again. A couple of the rads have no traps, others had the internal trap element missing while 2 rads don't heat up at all. Putting in all new traps won't hurt it and is a pretty simple and quick task.

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

0 -

No heat could be trapped condensate or trapped air. New traps won't hurt other than the cost. Testing the old ones may provide spares.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I like that. Will keep them on hand.

If that were true then how did this rad heat up? Wouldn't you need substantial pressure to push through the condensate?

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

0 -

Maybe 1 inch, 2 at the most. 2 inches of water column is not much pressure (1.16 Oz, 0.072 PSIG). The air would push through if the differential pressure was there. Really the air just needs to push through at the arrow

Still should be corrected.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

feel the returns, if they are steam hot anywhere steam is getting in somewhere it shouldn't. that will keep radiators from heating if it gets in the return for that radiator. it can get to the main vent and close it before all the air is out, once that happens there is no more venting.

0 -

In this system (the friend's system) I don't think there is any thermal venting closure.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

All very interesting thanks. This system seems to be very forgiving .

Our heating season won't start for another month at least. Will keep you all posted on how it does after the maintenance we're doing now.

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

0 -

Is there a union between the trap and the radiator ?

If not, I'm having second thoughts. I know I said " Still should be corrected. " and it should…..

However, if you put the big wrench on it to turn it 15 degrees and something breaks you are probably in for a lot more work. Work that may require some serious finesse.

Maybe when originally assembled it got to a point where it got real tight so they stopped, and since it worked they left well enough alone. You may already realize that.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Correct on the Dunham Air Eliminator. It — and a number of other gadgets patented by ingenious folk (like the Hoffman Differential Loop!) did exactly as you say — they worked by ensuring, in one way or another, that the pressure differential between the steam mains and the returns never got over a particular value (usually around 12 to 18 inches of water — half a pound pressure). This ensured that the boiler water never backed into the dry returns, which would have possibly dry fired the boiler. You have to remember that coal fired boilers were susceptible to being over-fired by the enthusiastic, and there was no vapourstat to calm them down!

But — this is why the only vent on the system had to be at the gadget, because part of the game was allowing some steam into the dry returns if the pressure differential got too high. That vent had to close in that situation (normally it would never close) so that the steam could pressurize the dry returns.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Not sure, although i noticed many did have unions. Either way, good tip and will be careful.

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

0 -

-

YES! I came back just to say that.

It's early here and haven't had my coffee yet.

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

0 -

-

that valve looks pretty new as does the sheet metal. What’s the purpose of the sheet metal; part of a plenum?

0 -

-

-

Or it may be this . . . Even though it only needs to be a check valve and this may not have any check valve functionality.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Today we fired up the boiler for the first time after fixing all of the radiator pitches and replacing all of the rad and crossover traps.

Pressure stayed steady at about 0.5psi until the thermostat reached temperature. All the rads heated up nicely, no strange noises or leaks. I think we're all good. Thanks

Alex

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

3

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements