original circulator sized too small?

i have baseboard heat in my house. and a weil McLain 210k btu boiler from like 1980. it has a taco 007 on it. i feel like this is undersized since you would want 16 gpm through the boiler. i have two zones one for upstairs and one for downstairs. the downstairs zone has around 121 ft of just baseboard i haven't measure upstairs. i was wondering what's the best way to measure and calculate head to size a circulator pump.

Comments

-

Maybe this document will help.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

either a heat load calculation. Or a total of all the heat emitters connected would determine required flow. Possibly the boiler is oversized ?

121 feet of fin tube would be around 66,500 btu/ hr, figure 550 btu/ ft as an estimate for residential fin tube

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@wyatts If you are experiencing some cold spots in your house, it may be due to that there is 121' of baseboard in one continuous loop, typical max length is around 70'.

When you exceed that 70', the last pieces of baseboard start to see lower temperatures and therefore don't put out enough heat (unless the lower temp was compensated for and more element was added) and then calculations were done based to fine the flow rate and head loss and then choose the proper circ.

Don't assume the boiler is closely matched to the heatloss of the house. 10 times out of 10, it is oversized.

What problems are you experiencing to say that the circ is undersized?

Dave Holdorf

Technical Training Manager - East

Taco, Inc

2 -

What problem are you trying to fix?

0 -

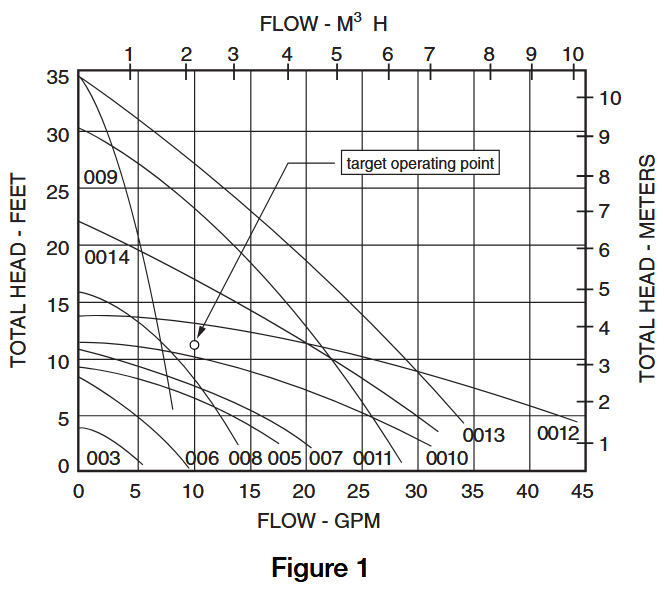

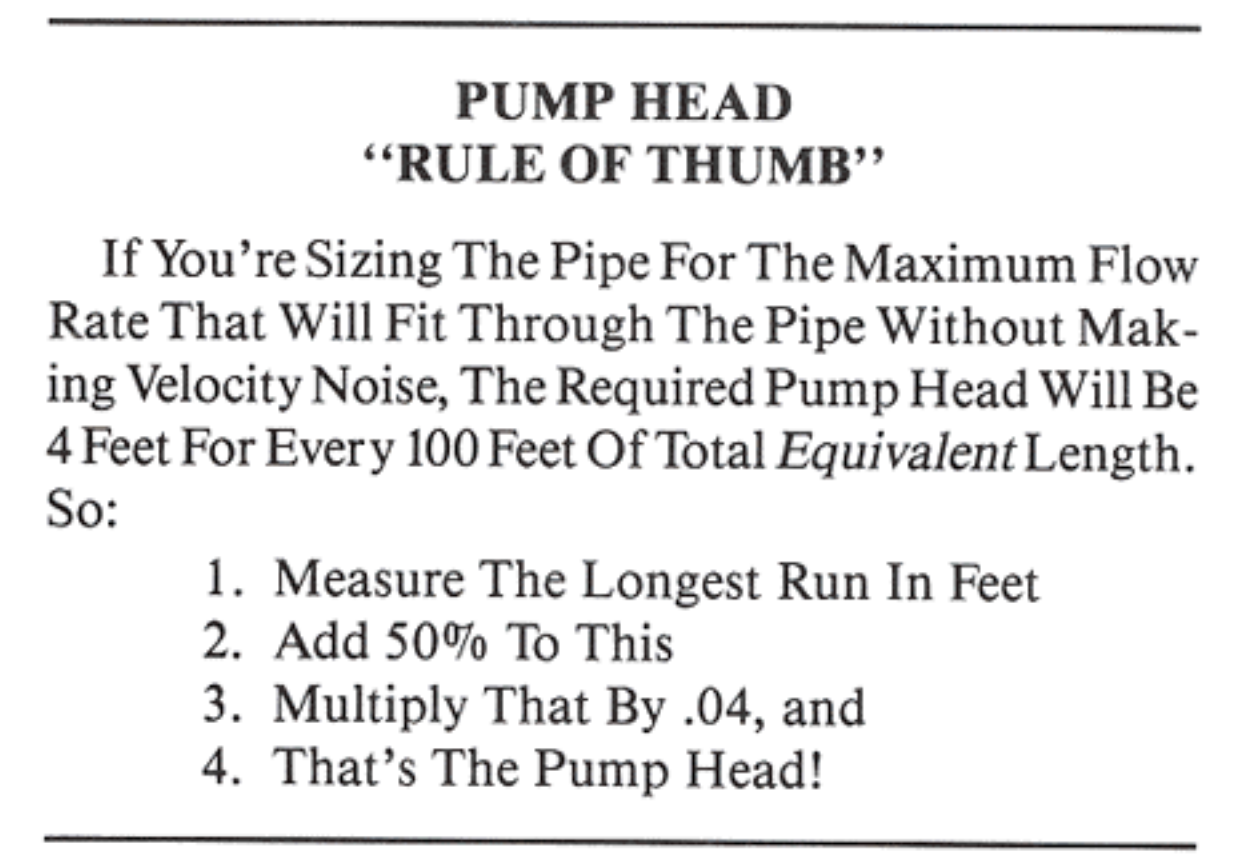

To answer your query about selecting the proper pump head you can find a simple explanation starting on page 7 of Zoning Made Easy and it continues on page 8 where there is this rule of thumb for small residential systems.

Of course there are some other insights about your system that were brought up. You indicated that there is 121 feet of baseboard radiation on one zone. If that 121 is one continuous loop of 3/4" with 121 feet of aluminum fin behind all those covers, then you will have a problem getting heat past the first 70 feet of aluminum fin. if you reas the first couple of pages on Zoning Made Easy, then you will see that you cant fit enough heat for that much baseboard in one 3/4" pipe. As @hot_rod stated, that pupe can only handle about 60 to 70 feet of baseboard. That zone will need to be split into two sections that are fed by a 1" shared pipe from the boiler to each individual section as it tees off the shared pipe.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Are you sure the 120' section isn't fed from a tee in the middle with a return at both ends or fed from both ends with a return in the middle?

0 -

ir is it possible the 121’ is already multiple zones?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

its not a 121 foot loop. off the boiler is a 1 1/4 supply that feeds into two zone valves. off each zone valve is a 1 inch supply these feed the upstairs and downstairs. off each 1 inch supply it splits off into 3 3/4 loops series loops i assume. i would assume the upstairs has the same or more baseboard then downstairs. my house is 2200 sqft and uninsulated. so in the dead of winter my house will never ever reach set point of t stat. if its 0f outside it will probably be 55 in my house. im not really expecting stellar performance i was just wondering if i could get it to run a bit better

0 -

im not sure how the head calc works. it seems it depends on how its piped in, because ive seen you just need the head of the longest circuit and I've seen you need to get the length of all the piping for the head calc

0 -

Does the boiler cycle on and off on high limit while the thermostat is still calling for heat?

If you have twice that length of baseboard that is abut 130,000 btu/hr which sounds adequate to oversized for anything but the most extreme climates for 2000 ft^2 unless you have something unusual like a couple walls made entirely of glass or something.

You may not have enough circulator although my bet would be on something else like trapped air or some sort of boiler or piping issue.

0 -

the boiler does say 168k btu output so that sounds about right. but my house is like 100 percent uninsulated balloon construction. my horsehair plaster is the most insulation i got. and it does seem like it short cycles. the supply will get super hot right off the boiler along with the expansion tank piping off the top but 6 inches further up its cold still, like the circulator is not doing much

0 -

That sounds more like either the circulator isn't working at all, there is a bypass that is stuck open or open too far, it is air bound, or some valve is closed somewhere.

Is this all one zone or are there zone valves?

You should do a heat loss calculation to confirm but I would expect the heat loss of a 2,000 ft^2 house in a northern continental US climate to be under 100,000 btu/hr even if it is uninsulated. If it is 2 stories it only loses heat on the outside walls and roof so the first floor has relatively little heat loss per square foot.

0 -

my reply farther up explains so more about the system. but only two zone valves. my house is more like 3 stories since the attic is a full floor and then above the 3rd floor attic is a crawlspace. my house is very tall. the zone valves are working but i did replaced them somewhat recently. im not sure there are any bypasses of any type on this system. i know there are some bronze little flow regulating valves id assume in some places

0 -

and with the taco 007 it doesn't really supply much more then 16 gem at best case scenario head. and i was assuming with a 1 1/4 supply flowing at most 16 gpm that it would have to be undersized

0 -

-

What happens if you manually open the zone valves, does more of the piping get hot?

Can you show some pictures of the boiler and piping? In this type of system the circulator is usually run off the end switches on the zone valves.

0 -

it gets hot eventually but it moves at a snails pace even with only one zone valve open

0 -

it is only circulating by gravity if that is happening. figure it out and your gas bill will go way down.

0 -

if the circulator is getting power and it isn't air bound or there isn't a valve closed somewhere or something like that, use an ecm circulator, you can adjust the flow and it will use less power.

0 -

The oo7 is undersized.

1 Give us an idea of the total feet of Fintube with actual fins

2 give us the length of run of the longest circuit

0 -

it may be undersized but it still should be heating more than a couple feet from the boiler.

0 -

@wyatts Said: "its not a 121 foot loop. off the boiler is a 1 1/4 supply that feeds into two zone valves. off each zone valve is a 1 inch supply these feed the upstairs and downstairs. off each 1 inch supply it splits off into 3 3/4 loops series loops i assume."

This sounds like a proper piping design for the amount of BTU the boiler has to give you, almost. If you look at the first few pages of the Zoning Made Easy booklet, you will see a pipe size to BTU capacity chart. The 1-1/4" pipe can move up to 140,000 BTUh when there is a 20° temperature drop (∆T). Since your boiler can deliver 168,000 BTUh, there are 28,000 BTUh that can't fit in the 1-1/4" pipe unless you do some changes like move the water faster, which may be noisy, or a higher ∆T.

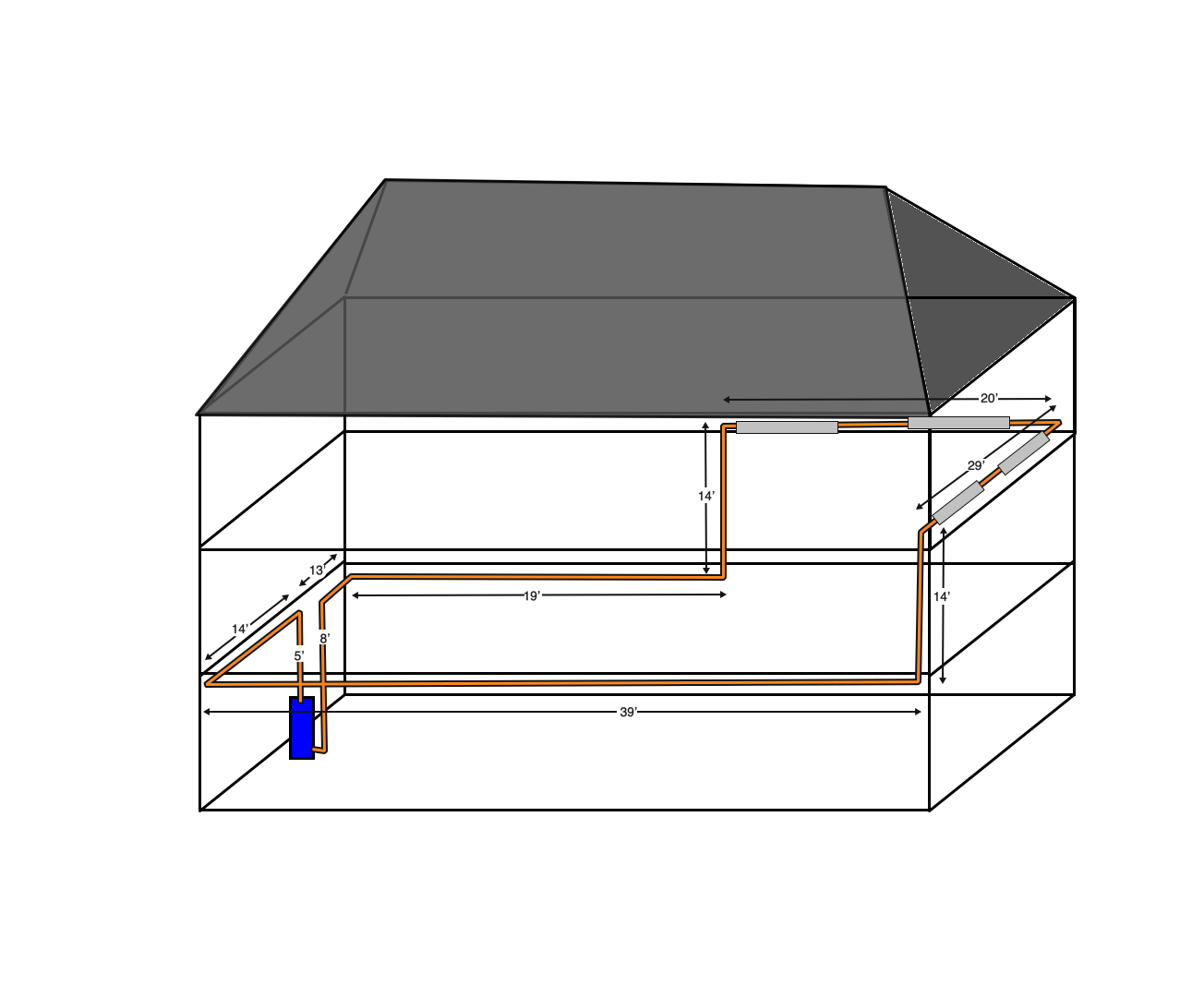

So to determine the needed pump head, you take the loop with longest run of pipe. Now if you have a 2200 sq ft. home. Lets say that there is 1100 SqFt on each floor and each floor's dimension is about 30' x 40'. the boiler is at one end of the basement. The longest run of baseboard goes from the boiler. The riser is about 5 feet to the basement ceiling. Then it goes to the front of the basement about 14 feet, then 39 feet to the other end of the basement where it turns to go up to the second floor. That takes about 14 feet to get there. Then that zone wraps the baseboard with ¾” tubing around the far side of the house for 29 feet and turns across the back of the house another 20 feet. Then it drops down to the basement for another 14 feet. Once in the basement it will return to the boiler room across the back of the basement about 19 feet. At the back of the basement it turns to the boiler for about 13’ the turns down to the boiler return about 8 feet. That is a total of 180 feet if you count all the 8” drops and risers from each baseboard as it jumps from room to room.

Here is an illustration of that loop:

Now here is an easier way to do that calculation. House dimension is 30 x 40. The total perimeter is 140 feet That's the round trip around the house. There are 2 risers from the basement to the second floor at 14 feet each 140 + 14 +14 = 168 feet. Now add the near boiler piping at about 12 feet and you get a total of about 180 feet of total piping round trip. There is the first number you need for the rule of thumb calculation 180 feet.

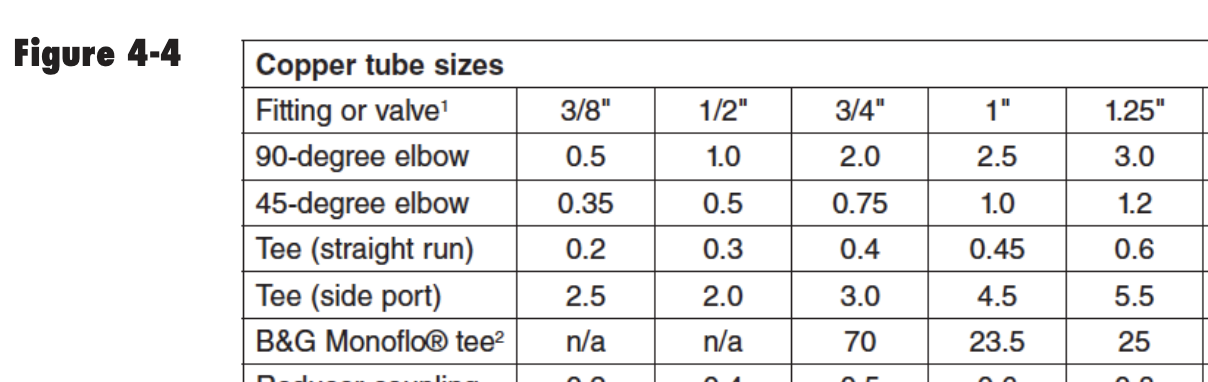

180 x 1.5 for additional fittings = 270 total equivalent length of pipe.

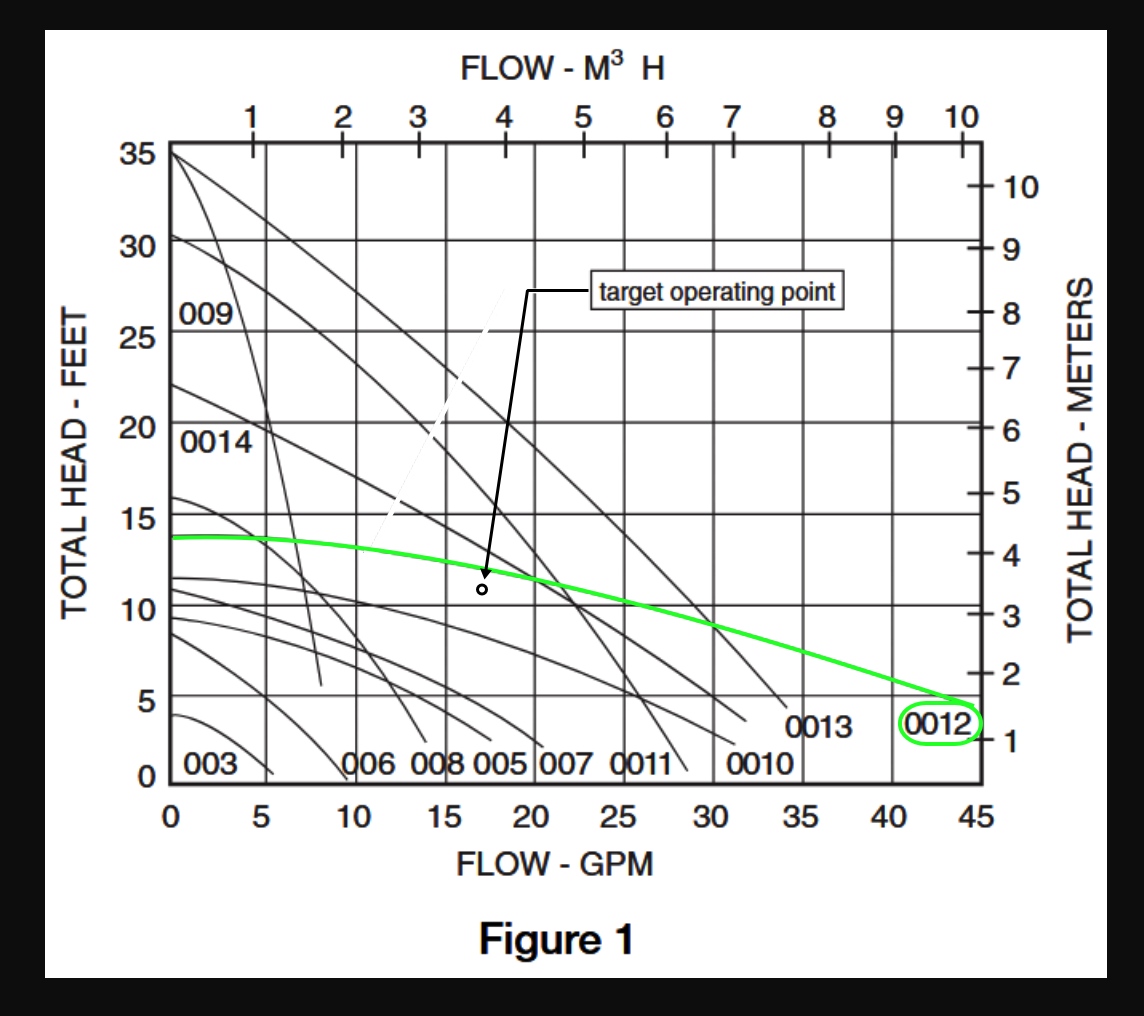

Multiply that by 0.04 for noise free operation, and your pump head is 10.8 or just about 11 feet of pump head. So look for a pump that can deliver 17 GPM for 168,000 BTUh at 11 feet of head.

The Taco 0012 looks like the pump I need for my hypothetical 2200 sq ft house. The Taco 007 falls short by a lot.

You need to measure your longest run to see what you require.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Any way to insulate or tighten up the structure? Then you wouldn’t need 16 gpm, perhaps

Fuel bill goes down also.

A blower door test could help show where infiltration could be dealt with

A 75 btu/ sq ft heat load!!

2200 x 75=165,675btu/hr

That is more like a small snowmelt btu number😲

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Another reason to select the 0012 pump over a 0011, 0013 or 0014 is because the pump performance curve ofthe 0012 is so flat. Think about it this way. When you have a zoned system and one of the zone valves is closed then you only need to move enough GPM for the smaller load of one zone. That might be about 8 gallons per minute when only one zone valve is open. Look at the head of the 0012 when it is only pumping 8 GPM. Compare that to the pump head of the taco 0011. That pump will move 8 GPM with a pump head of more than 20 ft. That much extra power may actually move the water thru that single zone too fast and you will have noisy operation and poor performance. The amount of pump head increase from 8 GPM to 17 GPM is very little on the 0012. This is a great pump for zoning. .

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

If you look at @EdTheHeaterMan pump selection at 11' of head the 007 is out of gas.

Service technician:

"An 007 will work because that's all I have in my truck. Besides the last 10 houses I was at all had 007s"

My BIL father had a really old gas boiler installed in the 20s back when gas boilers had tankless heaters. The tankless had been disconnected and replaced with a gas fired water heater.

So they used the tankless to heat a small addition with hot water…..never worked. The pipe was oversized 1" supply going out and split loop with only 1 medium size rad on each loop and 2 3/4" returns real overkill.

Pump was a Taco 110

Think about the 1/2" connections on the tankless and the feet of 1/2" tubing in the tankless.

He lived in a small town and had every plumber in town look at it and no one could fix it.

It had me stumped too but the water on the supply would only get hot the first 10-12' and it wasn't air bound. I put in a Taco 112 and it fixed it

1 -

we still haven't seen the boiler. in 1980 it probably came with an 007 installed on the return.

0 -

Actually the 210,000 BTU boiler may not have been shipped as a package boiler. The boiler needs a pump (or group of zone pumps) that can move 17 GPM and the boiler manufacturer can't tell if it needs High Head or not. The boiler may be installed on a multi zones system with 7 or more individual taco 007 pumps. So they left it up to the installing contractor to select the proper circulator(s). They would certainly know that one Taco 007 was not enough. I think @EBEBRATT-Ed is probably closer to the right history. but we will never know…

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

if you follow that over to the 007 curve that is like 3 gpm although since the building is short and tall the head for the first floor is probably a lot less than the estimate. i would think the shortest zone would heat, it just wouldn't have enough flow for all of the zones but we'd need more information. an ecm pump that fits the head and flow is still the way to go because you can set it to multiple curves and it uses less power.

0 -

Is this a new problem?

0 -

The OP stated that the boiler is 168K btu/ hour output

You need 17 gpm and an 007 will not even be close to moving enough water.

The 007 runs out of gas at 4' of head which is 1.73 psi differential across the pump.

Not going To work

0 -

I’m not sure he needs 17 gpm. We need to know what heat emitter capacity he has

He mentioned 121’ of fin tube, thats 6 gpm, on one floor what about the rest of the house? If he has the same amount on the other floor, that’s 12 gpm needed. A 007 might cover 10-12 gpm

Also, the boiler is piped 1-1/4, a bit small to move 16 gpm

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream3 -

My point is that you are sizing for a guess at the worst case loop, if there are closer loops with several parallel branches the head on those will be much less and those should heat quickly.(I suppose the longest loop method oversizes the circulator in the same way the simplest gas piping calculation method oversizes. you need to cover the head of that longest loop, but you don't need to cover it at 16 gpm, you probably only need to cover it at 4 gpm or less but then you need to figure out how much of that curve the other loops need.)

We need the OP to roughly sketch out the system with rough measurements and pipe sizes to figure out if the only heating by the boiler makes sense with the 007 or if there is something else wrong.

0 -

Thats because you have to satisfy the worst-case loop.

Look at the facts. You can't back your way into saying the 007 is the right circ for that job.

If you worked at a supply house and were selling a 170K output boiler to a contractor that said that was the size he needed and he asked you to supply the circulator you would use a circ that would do 17 gpm with enough head.

No one in their right mind would put an 007 on that size boiler. Now if you say the boiler is oversized, he doesn't have that much radiation etc etc the fact is the water is not moving.

I had this happen in my own house a 50K load with a 5 room ranch and an 1 1/4 monoflow system and the 007 would not move enough water. I had to take out the Honeywell zone valve 1" with a 4 Cv and put in a Taco with an 8Cv to get it to work.

The 007 is not as strong as people think

0 -

i'm not arguing at all that it is the right circulator, i'm just saying that unless all of the loops are that long and small pipe, some of them should be heating.

monoflo is a different beast. it is one loop with a lot of splits and recombinations in it, if you don't have enough circulator to overcome the resistance of the whole loop nothing will heat. here, from the limited description we have, the water has a lot of paths with a lot of different resistances

0 -

If you are sizing a pump for the maximum flow thru a pipe, then you use the method I offered. If you have oversized pipes and you have oversized boilers and you have oversized radiators, then of course you can use a smaller pump. I was just saying that the 007 pump is probably too small based on the limited information offered. And My 2200 fictional house was used to illustrate how to use that formula because @wyatts said: "i'm not sure how the head calc works." There is an easy way (perimeter plus the number of risers) and the actual measurements of all the strait pipes. Now @wyatts just needs to do the math for his actual home.

@wyatts also said "I've seen you need to get the length of all the piping for the head calc" and that is not true. You need the total GPM for selecting the pump. Not the total of all the pipes. If the pump has enough head to move water thru the longest loop, then the pump will have no problem moving water thru the loops with less resistance (smaller loops) To select a pump you need to know how much water you are going to move, and how much force you need to move it.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

A B&G 1-1/4 Monoflo tee has an EL of 25' of straight pipe. So that adds up quickly for calculating pressure drop.

Also heat emitters are in series in a Monoflo tee system, so the end radiators see much lower SWT. Two reasons that they may need more pump power.

Not enough data to calculate what circ will get the job done. But that is a common thread around here :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I agree we don't have enough data to size the pump.

My point is with that size boiler it was probably the wrong pump from the beginning and whomever installed it originally didn't do the right thing

When you buy larger boilers, they don't always come with a circ for that reason

0 -

So, since 1980 it has never heated adequately?

It would be interesting to check the date code on the 007 maybe it was installed as an incorrect replacement along the way

Or it has worked fine and the system is air locked or the circ is not functioning ?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

if by heating adequately means the pipes aren't freezing then yes

0 -

i measured around 154.5 foot * 1.5 = 231 * .04 9.27ft of head so maybe smaller then taco 0012

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements