original circulator sized too small?

Comments

-

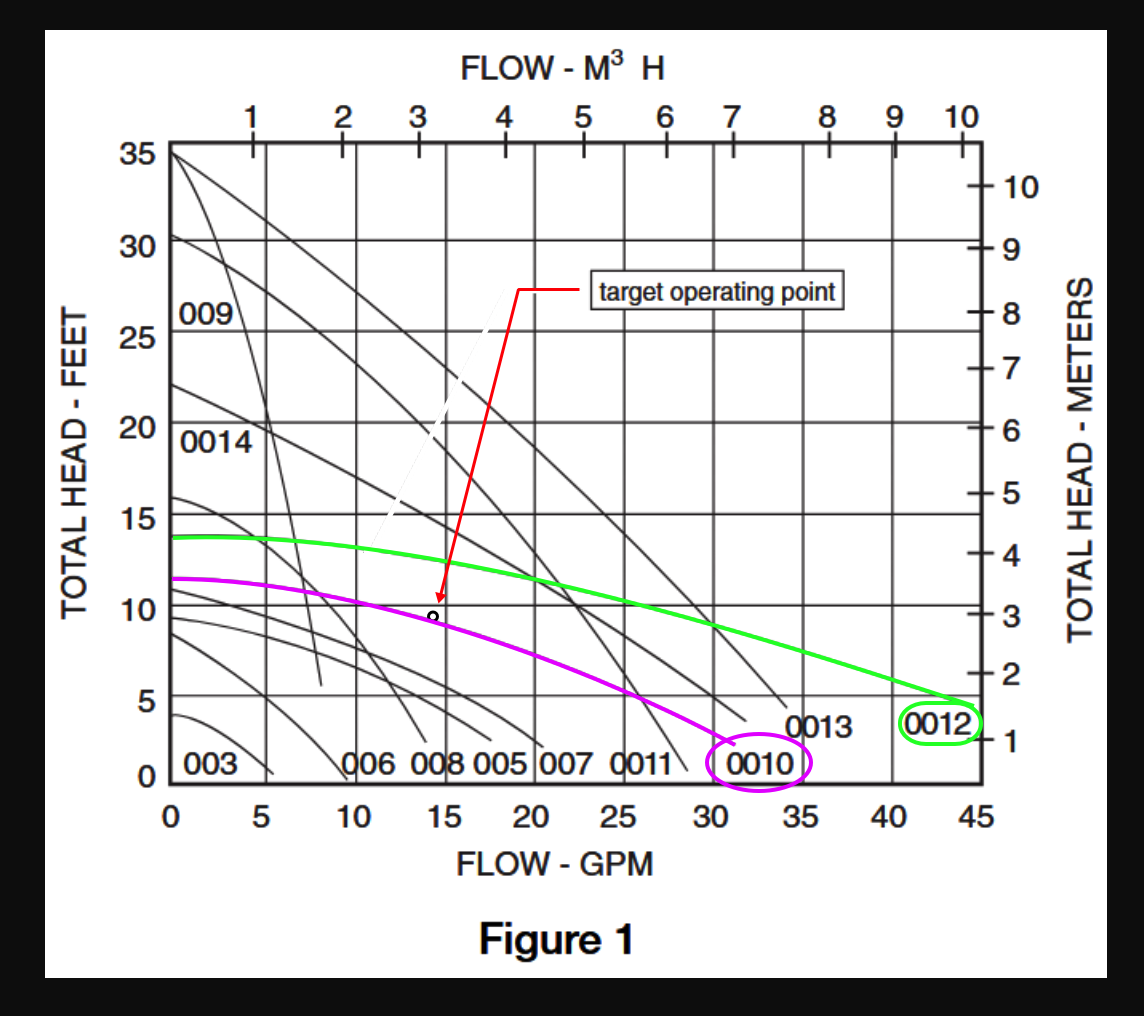

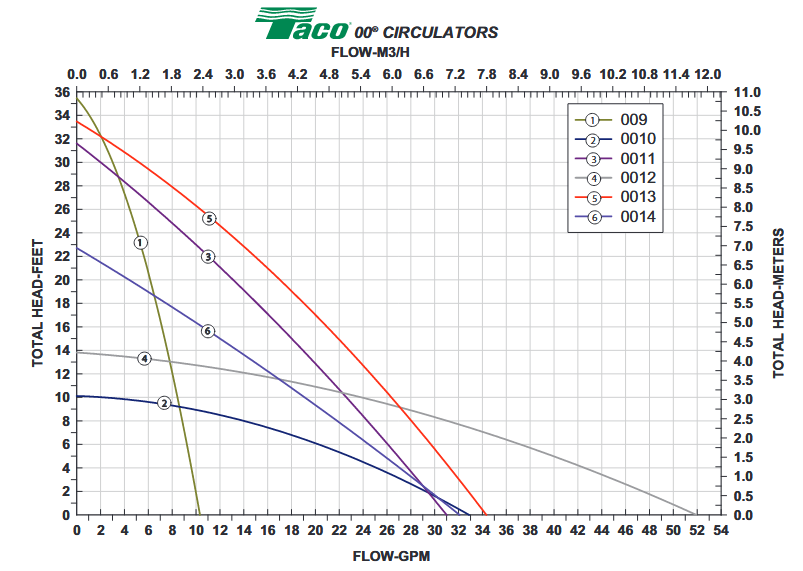

That point on the curve. 9.3 Ft head at 14 GPM (based on the max flow thru 1-1/4" pipe copper) still falls just above the 0010 pump curve and below the 0012 pump curve, so I would still use the 0012 pump. If you happen to already own a 0010 then that is a better choice than a 007.

You already have an oversized boiler for the piping that it is connected to. And you have indicated that you have about 121 Feet of baseboard for the one floor, and perhaps about the same for the second floor. That would indicate you need about 13 GPM for about 133,000 BTUh. That would actually fall directly on the 0010 performance curve. You might be good with that pump and it is less expensive than the 0012 if you need to purchase the correct pump.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

the 0010 would do it(just a little under but close enough). the 007 should give you 5 gpm which isn't enough to adequately heat the house but should be making part way in to some of the loops pretty quickly.

0 -

that sounds about right. taco 0010 it is. i was also wondering about the expansion tank, if it was undersized. ill have to check the pressure when it gets up to temp. it only has a amtrol model 30 on it. if it was undersized you would think something might of broke at this point possibly

0 -

you could also put two 007 on each zone possibly correct? instead of zone valves

0 -

no, the 007 doesn't have enough head for either zone.

i would get an ecm pump that covers that point on the curve. they can be set to multiple curves and use less power.

0 -

is there a ecm taco 010?

0 -

@mattmia2 is correct, If you have a loop that requires 9.3 ft of head and needs less than 5 GPM then a taco 007 would work. I don't believe your longest zone is that small (only 5000 BTUs of baseboard). You need at least one of the pumps to be a 0010. If the other zone is shorter, it will have less resistance to flow, so perhaps a 007 might work on that zone. But you don't need to redesign the system just to save $$ on a circulator pump. Get the 0010 and see how that works. I believe you will be pleased.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

The .04 only works if the pipe size is reasonable for the flow. 17 gpm with 1 1/4 is a little undersized.

17 gpm on 1 1/4" is 6.29 feet of head/100feet of pipe

at 154 feet (1.54 x 6.29)=9.435' x 1.5 for fittings=13.6 feet total

Looks like the 0012 that @EdTheHeaterMan picked is right.

0 -

dont need 17 gpm though for 168k boiler do you?

0 -

yeah i have two 007s so i was just wondering. would be pretty quick to sweat em in

0 -

Every 10,000 btu needs 1 gpm of flow. 168,000/10,000-16.8gpm

0 -

what do you think about the Spiro vents. I was wondering about installing one. i should probably just replace all the corroded old style air vents around the house though

0 -

automatic vents will eventually leak, if you can purge to get that part flowing i'd replace them with manual vents. i like the caleffi discal better than the spirovent but both will work if you put them where the temp is the highest and pressure lowest.

the auto vents are fine by the boiler where you will notice them leaking, out in the system I would try to avoid as much as possible.

0 -

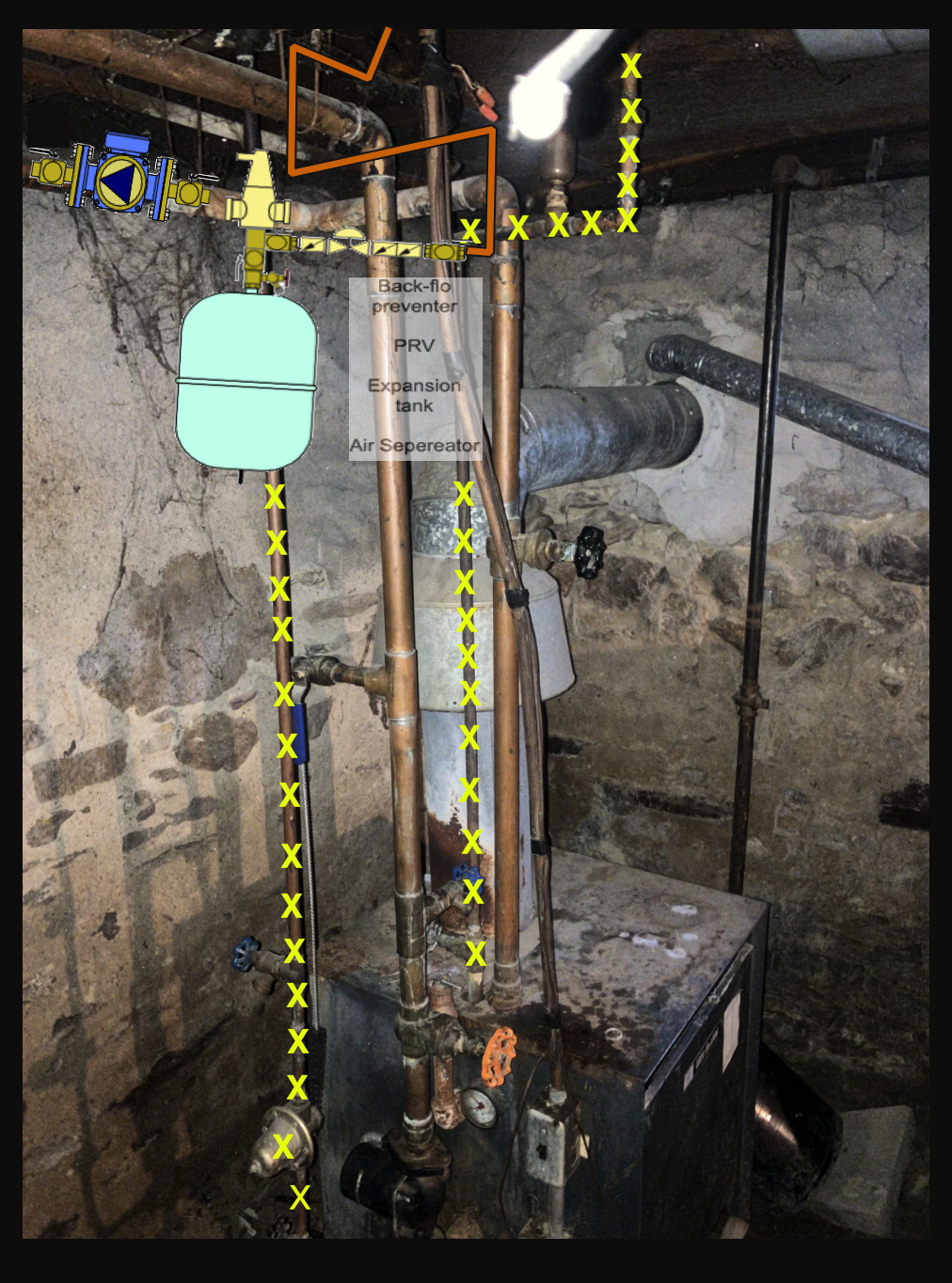

im not sure how i would pipe one in since my circulator is on the return so if you put one on the supply it is hot and it is highest pressure. and my expansion tank isnt under a air scoop. it has its on leg off top of boiler.

0 -

If you are at 5000' elevation or higher you derate boiler output also.

So in Denver that boiler output is more like 157,000 so 15 gpm would be adequate.

Yes, and air purger, the microbubble type is what you should have for an air, and noise free efficient hydronic system

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I'd go with the 0012, unless the cost is a show stopper. Why deal with maybe marginal ? So far not seeing a 0012 type with ECM features, just 3 speeds.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

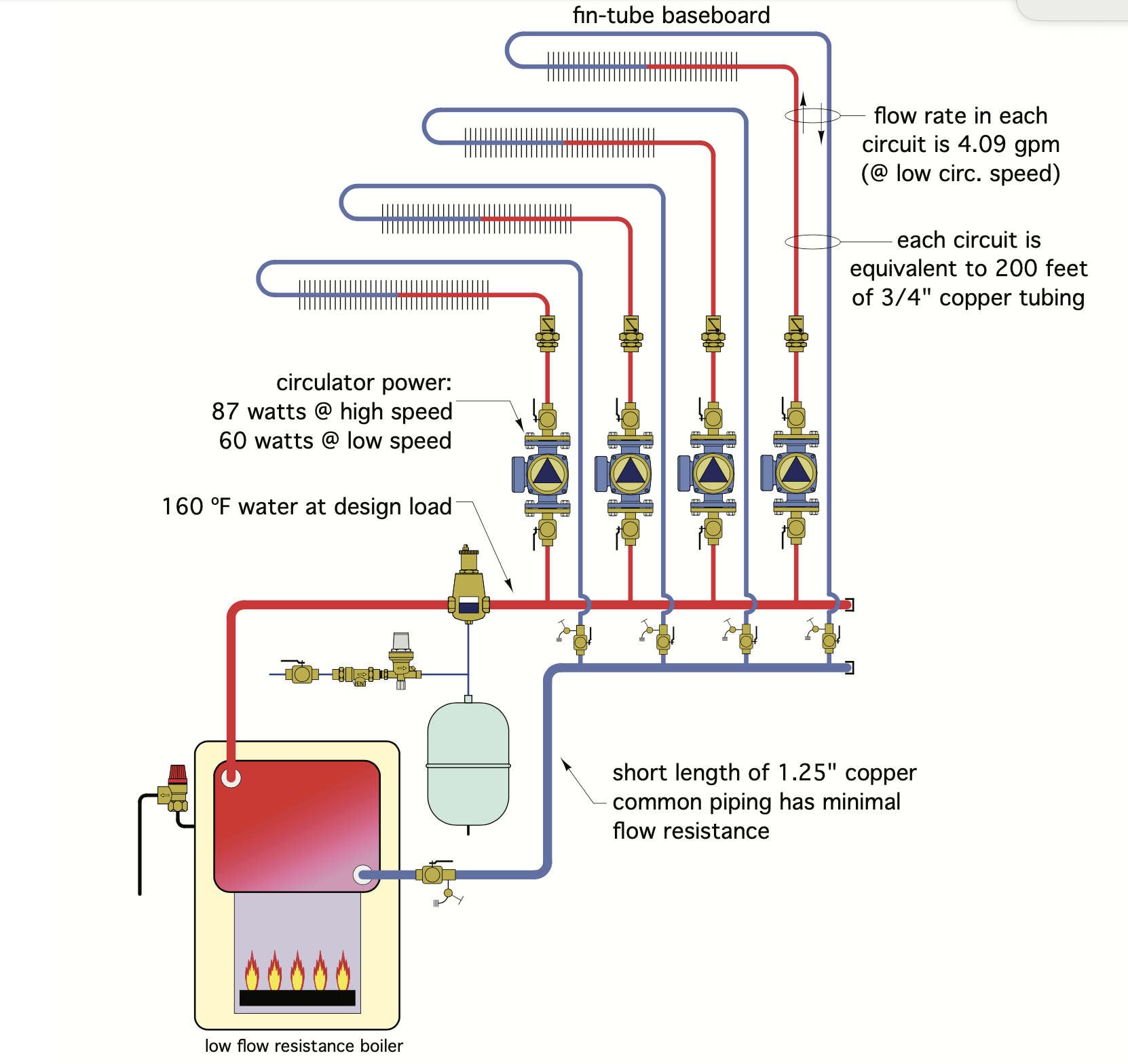

I would surely go with the Caleffi Discal or SpiroVent to make all those micro bubbles crash into the element inside the vent that causes them to make larger (more buoyant) so the can easily float to the top of the air vent chamber. Then the vent will open to let out that air. Noe your current boiler feed and expansion tank piping needs to be redesigned, you may as well just get new Extrol 60 for your system and make it look like this.

The new feed line will enter at the same location as the expansion tank so not to have the pressure of the tank and the auto feed working against each other. (see new copper feed). You can just place a set of circulator flanges connected to a 5-1/2" long x 1-1/4" pipe nipple to replace the existing circulator. No repiping needed. Just a set of flanges and a a couple of full face flange gaskets.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

where is the expansion tank and zone valves now? might want to keep the isolation valve for purging and to disconnect things at the boiler without draining the system

0 -

This is a very helpful thread!! Thanks everyone! Curious about the head and flow calculations may differ, or not, with a 2-pipe system.

Would I measure from the boiler to the furthest heat emitters the 2nd floor and then measure the return path?

Thanks!

0 -

With all thermostats calling for full heat what is the temperature of the water going out of the boiler compared to the temperature coming back.

0 -

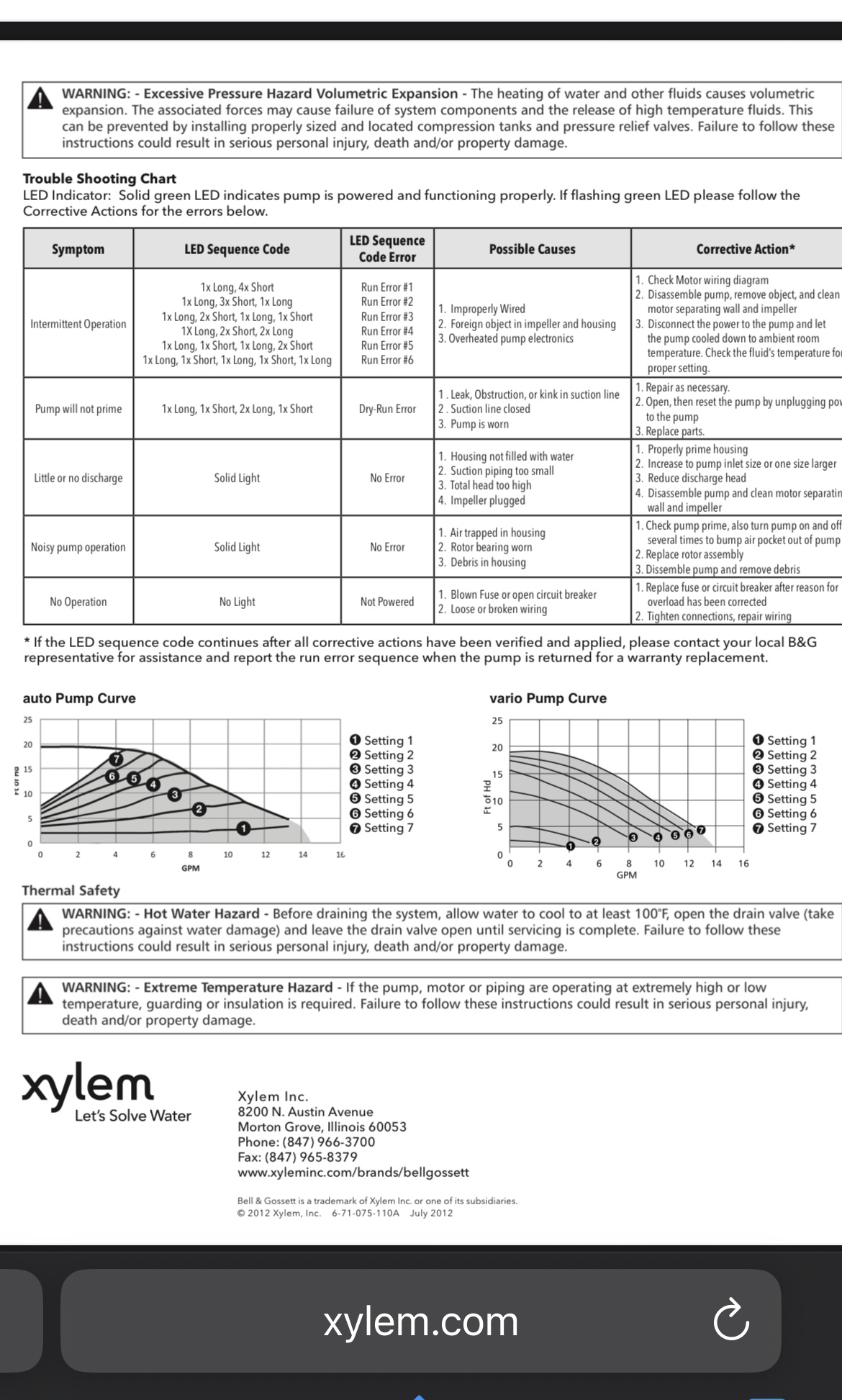

a multi speed circ is good option for unknown piping circuits

Most of the new style ECMs have a wide adjustability range

Some of the B&G Varios have a seven speed switch!

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

if I understood correctly, the approx. 120 lineal ft is two zones or 60 lineal ft each zone. At approx. 600 btu per ft for fin tube times 60 ft is 36,000 btu or 3.6gpm for 20 degree delta. You can calculate head for 3.6 gpm through 3/4” pipe. My hydraulic handbook has it at 3..4 ft/hd per 100 lineal ft.

Taco 007e will do a nice job if the two zones are in parallel

Joe Mattiello

N. E. Regional Manger, Commercial Products

Taco Comfort Solutions0 -

I enjoy just reading the Heating Help posts when I go to lunch by my self. I almost never post on anything, just read Heating Help for my enjoyment. Being retired after 50 years in the business, an old dog can sometimes learn new tricks. There was a wealth of knowledge shared by very reputable people and then there were some comments that showed some need a little more experience. I guess it does not matter who has the correct answers and who does not. What matters is that we are supposed to help an individual with no knowledge in boiler systems. His question was 'how to size a correct pump'. Did we just answer the question? In one case we did. Then we got a whole bunch of what ifs. All this did was to confuse the person looking for help. This person needs to go back, measure and provide accurate information, and then follow best design practices tought by schools, manufactures and experienced people. In addition, from the information provided he will need to repipe the system before pump sizing can be done. I would like to say that my intention here was not to belittle anyone but provide constructive criticism.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements