Loop PEX *under* joist instead of through? Reasons it won’t work?

Hi HH Pros,

Your thought? Why wouldn’t this unconventional approach work?….

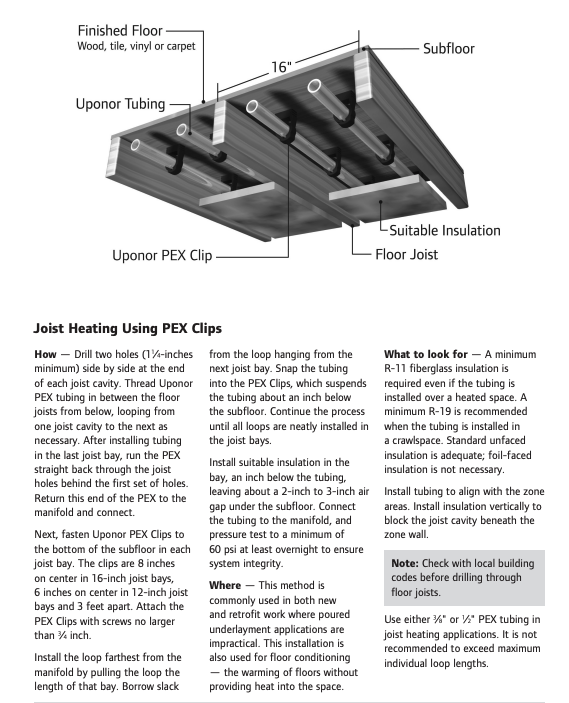

I’m about to install Uponor Joist Trak. Normally, people drill a hole through the end of joists and snake the PEX tubing through the holes to go from one joist cavity into the other cavity and so on across the heating zone. I understand that.

For many reasons, I want the PEX to loop under the joist when moving from one joist cavity to the next. The PEX goes under instead of through joists. No drilling holes through the joists.

The joist are on 29” centers (project is in Europe, atypical sizes) and 7.5” tall. So, they are wide and short joist cavities.

I can place the Joist Trak and the tubing in a way to avoid crimping tubing when going under the joist. Further, the tubing running under the joists will be covered from view and protected from potential damage

The question: Is there any technical reason I can’t loop under the joist instead of drilling through the joists?

Thank for your insight!

Brian

Comments

-

-

I did it that way for awhile until I got used to drilling joists. No problems other than it takes a few inches longer to get the pipe to the correct plane to snap into the plate.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

Thank you @hot_rod and @Alan (California Radiant) Forbes !😎👍

I completed some of project with the „under-joist“ method…

Really like it because:- Don’t need to prepare by pre-looping (?) the needed length into each joist cavity. Can simply lay the tube coming directly off the roll.

2. My joists are 5 inches wide of solid pine so a lot to drill through.

The photo shows an example.

Unfortunately the yellowish vapor barrier obscures the tubing routing. But from left to right:

Feed line comes under the left joist

Tube placed into track 2, water flow towards the viewer

Tube placed into track 4, water flow away from viewer

Tube placed into track 1, water flow towards viewer

Tube place into track 3, water flow away from viewer

And so on…

The „non sequential“ order of placing tube was to broaden the loops in the tube to make installation easier, eliminate kinking in loops, makes exit and entrance of joist cavity more gradual.

Used Rehau RauTherm Neo X5 16mm (1/2“) for tubing and Uponor Joist Trak for heat transfer.

Project is in Switzerland

1 -

-

If you want the heat to go up and not down it would be harder that way. If you drill through the joists all you need is a layer of insulation below everything.

0 -

Forgot to mention, under the Joist Trak and tubing will be ~6 inches of mineral wool (Flumrock brand) insulation and finally drywall to provide nice appearance. The subfloor is Kanuf GIFAfloor 1.1" (28mm) gypsum fiber panels. On top of the GIFAfloor subfloor will be ~3/4inch wood parquet floors in living areas and ceramin tiles in wet areas both glued directly to the GIFAfloor.

0 -

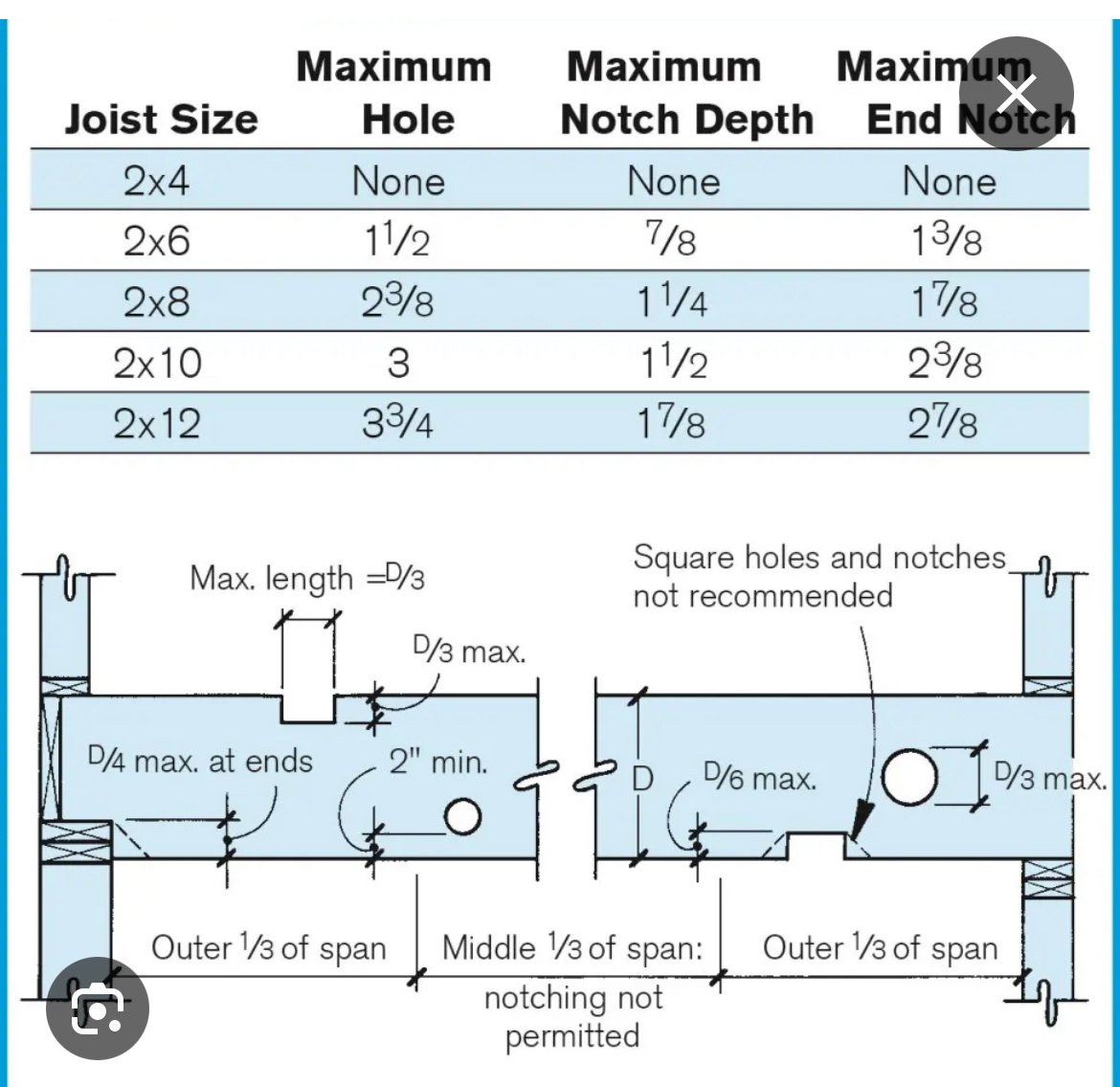

if that is a standard joist size, you could maybe find a hole drilling chart. Typically you do not want a hole near the bearing point of a joist

Code around here asks for fir or hem/fir for structural framing members.

Around here we use a 1-3/8” hole for pex, which allows room for an insulator around the tube

The install look nice, clean& straight

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

So now I'm curious what the point of 5" solid wood joists is when they are concealed?

0 -

I’m guessing the finished ceiling lands on the nailers on each joists, and the bottom inch or so exposed.

I think he should’ve drilled the joists. This way looks a little ugly. Plus the insulation detail on the ends is going to be hokey, and it looks like the tubes will run and creak.

0 -

he mentioned insulation and Sheetrock below, sounds like everything gets covered?

Constant circulation and or ODR will minimize any noise potential

This is a common UltraFin installation method when joists cannot be drilled

It looks like a 5” beam with 2x4 on either side. That would be a lot of drilling

With TJI an 1-1/2” hole can be placed anywhere and many have 1-1/2” pre punched indents every 12”

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Why would the heat go down? The vast majority of transfer is via conduction to the floor material, no?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Heat travels in all directions, wherever there is a temperature difference. A plate like that in free air will lose quite a bit of heat to convection.

0 -

Correct about Sheetrock landing on nailers on each side of joists. That leaves ~2 inches of joist exposed below Sheetrock.

Yes about insulation complications. Stuffing mineral wool insulation around tubing will be tedious and slow. I am investigating if spray foam specifically and only in the end of the joist cavity where tubes cross and loop under joist might be a better and faster option than stuffing mineral wool…

interesting with the RauTherm Neo-X5 tubing: They are almost silent when wiggled inside of Joist Trak. I started with a ‚standard‘ PEX-a tube from Uponor / Georg Fischer. Those clearly made the squeaky noise when rattled inside the Joist Trax. The different material used in RauTherm plus a constant circulation and slow temperature ramp gives me confidence the tubing wont create noise. 🤞0 -

This isn't my area of expertise but I remember reading something a year or so ago about spray foam. I may not have this exactly right but from what I recall if the spray foam is in contact with PVc or ABS (don't know about pex) while it is curing and the spray foam is in a heavy layer the heat produced during curing process has in some cases damaged the pvc/abs.

Just something to think about or check into.

0 -

They hold the floor up, silly.

0 -

Ceiling too.

That's kind of my point. If they're hidden by drywall, appearance doesn't matter. There are easier and cheaper ways to hold up a floor.

0 -

2" of the pine joist will be exposed below the sheetrock, it should look nice, based on the workmanship so far :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Right, so they could have put a 2"x5" piece of pine on the bottom of the joist and gotten the same look with conventional joists. Then every piece of plumbing or electrical wouldn't be a struggle.

0 -

How much will it lose to convection? It's not in free air, it's screwed to the floor.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

If insulation is pushed tight against the tightly attached plates, there really is no convection space.

The suspended tube, aka joist bay heating, convection system design left an air space above and below the tube to get currents moving. Same with the UltraFin system

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@ethicalpaul : "How much will it lose to convection? It's not in free air, it's screwed to the floor."

Despite their name, "radiant" systems heat mostly with convection. So they do heat more readily up than down, because air rises.

The rule of thumb is that a floor will deliver 2 BTU/hr/sf for every degree difference between the surface and the room, and a ceiling will deliver 0.7 BTU/hr/sf. So about three to one.

In this installation, though, there's nothing between the plate and the space below, and a subfloor and a floor between the plate and the space above. Let's say the room is at 72F and the heating load is 20 BTU/sf/hr. The surface of the floor would have to be 82F. Let's say the floor and subfloor together are R1.5, the plate would have to be at 97F to deliver 20 BTU/sf/hr. If the room below is also at 72F that's 25F colder than the plate, which means 17.5 BTU/hr/sf going down. So you get 47% of the heat going down and 53% going up.

If the room below is a cold basement it could be even worse.

OP has clarified that there will be insulation below the plates, and drywall, which helps limit airflow.

1 -

Thanks. That 47% going down heats the air at the top of the joist which stays up there causing less temp differential between that air and the plates, resulting in less heat loss in the down direction.

The complexity is not trivial!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

Appreciate all comments and challenges. The perspectives are very informative.

Always part of plan but not mentioned detailed: Presence of ~4in of mineral wool (brand FlumRoc) with R value ~16 with snug fit between joists (see photo). That is to help send the heat „up“ into the subfloor and not down to ceiling.

So, from top ("0" layer) to bottom ("-5" layer):

0) Floor finish: 0.6 in wood parquet, but ceramic tiles in wet areas. (est. R value of wood: ~0.6)

-1) Subfloor: 1.1 inches Gypsum fiber board (28mm Knauf GIFAfloor, R value: ~0.4)

-2) Heat transfer plates: 1/2“ Alu c-clamp plates (Uponor)

-3) Pipe: 16mm, O2-barrier (Rehau RauTherm NEO-X5, 0.63 inches OD)

-4) Insulation: 4 in Mineral wool batts (10cm FlumRoc with R value of ~16 h•ft2•F/BTU)

-5) Sheetrock: 5/8“ sheet rock for 21“ span between joists (R value: ~0.6)

(Note: You may notice I didn't use screws to fasten plates to the gypsum fiber board. The screws simply twist off when driving them in. Pre-drilling would take forever. Opted for concrete nails instead. Hilti BX-3 battery-powered nail gun with 2/3 in (17mm) nails on a magazine. Incredibly easy and fast. Incredibly strong fastening. Would recommend that system if fastening to thick gypsum fiber board. Battery-powered roofing nail gun (DeWalt) might be option if OSB subfloor?…)

2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements