Trying To Estimate Heat Pump kWh Usage

Considering installing some heat pumps for my mom's ~50 yr old house in Massachusetts and so I am trying to get an idea of how much her electric bill might increase.

Looked at her oil deliveries for the past year and it looks like they add up to around 900 gallons. She tells me that she has a 65% efficient boiler that was installed in early 90s and delivers heat via aluminum fin baseboard.

As I see it, that means that she only gets ~91K BTU per gallon of oil, right? How much more should I take off for any distribution losses? Any other losses?

For quick and dirty, I had used 100K BTU net per gallon ⇒ 90M BTU from the 900 gallons. By my calculations, 90M BTU converts to 26370 kWh (90M BTU / 3413 BTU/kWh). Considering a heat pump with a HSPF2 of 8.3 (COP = 2.43), it seems that the heat pump would use 10547 kWh to produce that heat, right?

That seems like a crazy amount of kWh to me?

Am I getting confused somehow?

Comments

-

Your math looks right.

This post explains how to do a more detailed modeling:

1 -

-

This is a helpful site.

https://coalpail.com/fuel-comparison-calculator-home-heating

An intro to A2whps here

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Nothing wrong with your math that I can see. Her oil bill would decrease — but the electric bill will increase by almost the same amount. In most of New England switching to a heat pump won't save any money — it just depends on whether you want to pay the oil company or the electric company.

Then there's the capital cost of the heat pump; they don't come free. If saving money is the objective here, the first step is to make sure the house is at least reasonably insulated. Then the least expensive next step would be to swap the existing boiler out for a modern one, which will be able to hit 80 to 85 percent efficiency. The most expensive option will be the heat pump…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

-

Well then… other than the capital cost of the heat pump, it will be close to a wash on heating and probably not much different on the AC

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Good to know that my math looks right but it's still confusing. I also have heat pumps in my house (installed late 2023) and they configured with a balance low limit of 30F and high limit of 33F. They have an HSPF of 10 and I've only seen my electric usage go up by about 1200-1500 kWh a year since then. Maybe I shouldn't be looking at her total annual heat load but rather just a range similar to mine?

0 -

Not much different on AC? Different from what? Shouldn't it be more efficient than the window units that she has now?

0 -

Maybe. Depends on how good the window units are now, and what the relative spaces being conditioned are.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I’m at 1.2 kWh per heating degree day for a heat loss of about 20kbtu at 15F. So very reasonable that a higher heat loss home in a cold climate would tack on 10,000+ additional kWh. Which is good actually - the northeast has high delivery rates because people don’t use much up there. As usage increases, those costs will come down.

0 -

Always the optimist, @Hot_water_fan ! While it may be true that usage of the grid assets — mains, substations, distribution — may be less in some ways in the northeast, maintenance of those assets, particularly the secondary (typically 23 KV) distribution, never mind drops, is an ongoing nightmare for the utilities. That doesn't come cheap, and the cost isn't going down as people and PUCs become more demanding and less patient with outages.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

@Jamie Hall I’m watching the new electric heating rates in MA. Could be what the future looks like! More kWh moved across the same assets seems like a win win.

0 -

Curious how I can know what the outside design temperature should be that I use? I tried looking for what it might have been in 1977 but no luck, I think.

0 -

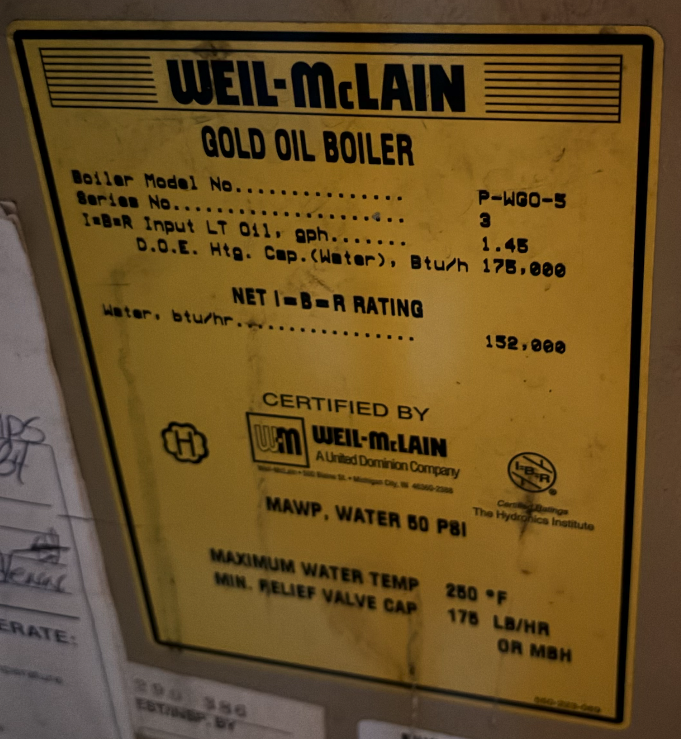

Here's sticker that's on her boiler - seems to me that it's saying that burns 1.45 gph of oil… not sure what the 175k and the 152k BTU ratings are. 152k is 86% of 175% so I thought maybe that this yields the efficiency but 1.45 gallons of oil isn't only 175k BTU. Can someone clarify? thanks!

0 -

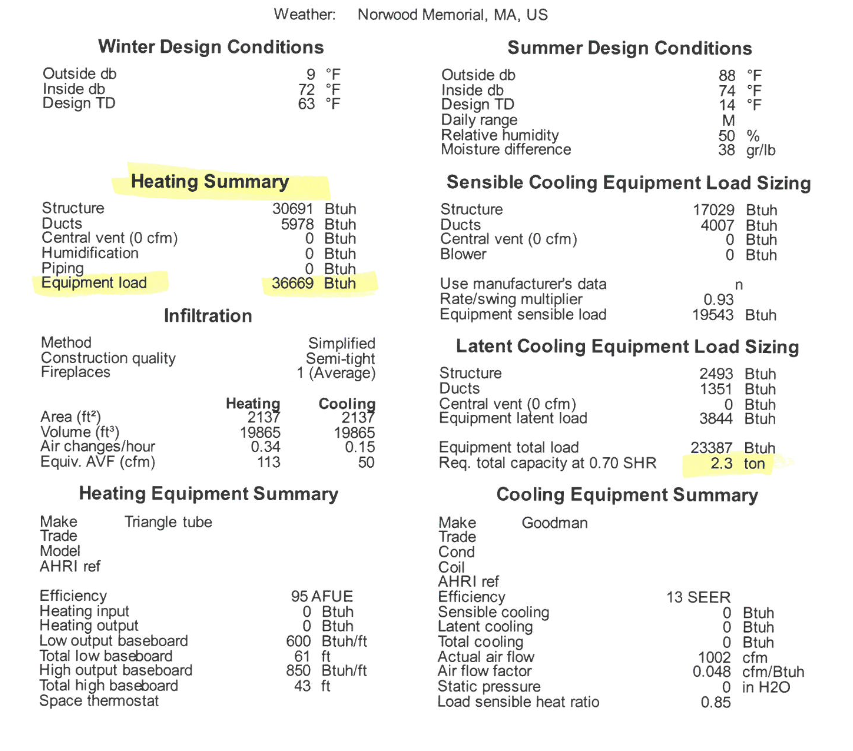

The challange with your energy costs is to get the system to hit nameplate efficiency in heating. This means getting right sized heat pumps, each on its own outdoor unit (no multi splits). Based on the oil use, the heat load is about 40000BTU (run the link from DcContrarian for more accurate result) which is well within the range of a heat pumps.

The challenge with older houses is you have a lot of rooms. The best way to get heat to all of them is with a ducted unit, which is doable if the basement ceiling is open.

The next best things is a two larger wallmounts. One on the main floor in the most open area for the bulk of the heat and 2nd one on the upper floor hallway for the rest of the heat and cooling. Again, these should be on their own outdoor units. With point heat source and older structure you'll still have the run the oil to even out the heat near the perimeter but the bulk of the heat will come from the heat pumps.

0 -

Could you elaborate on how you're getting the heat load of 400K BTU?

As his link suggested, I went and got one of her oil deliveries (12/26/24 - 1/29/25) which was 195.9 gallons.

I had used an efficiency of 65% (that's what she told me but the nameplate earlier seems to indicate higher) yielding 17.8269M (195.9 gallons x 65% x 140000 BTU/gal) BTUs supplied. I got 1129.7 HDD from a local station at 65F for that period yielding 15780.2 BTUs/DD or 657.5 BTUs / DegreeHour.

I'm not sure what outside design temp to use (the directions use 20F). Using his same 45 delta T, I get just under 30K BTU/hr.

0 -

-

-

This is near my calculation too. Energy cost wise at my 31c/Kwh rate oil has to be more than $4/gal for heat pumps to be cheaper

0 -

So how do I interpret that nameplate that I posted earlier? Does she really have an 86% efficient boiler?

And if we're thinking that her heating load is ~40K - what do you all think of the 1st proposal we received. It's for a 4-ton ducted system downstairs (Bosch) and a ductless 4-ton (Fujitsu) upstairs with (4) handlers, basically one in each bedroom (7k, 12k, 15k and 24k for the loft area above the garage).

Kinda seems like a lot to me, especially the loft area.

0 -

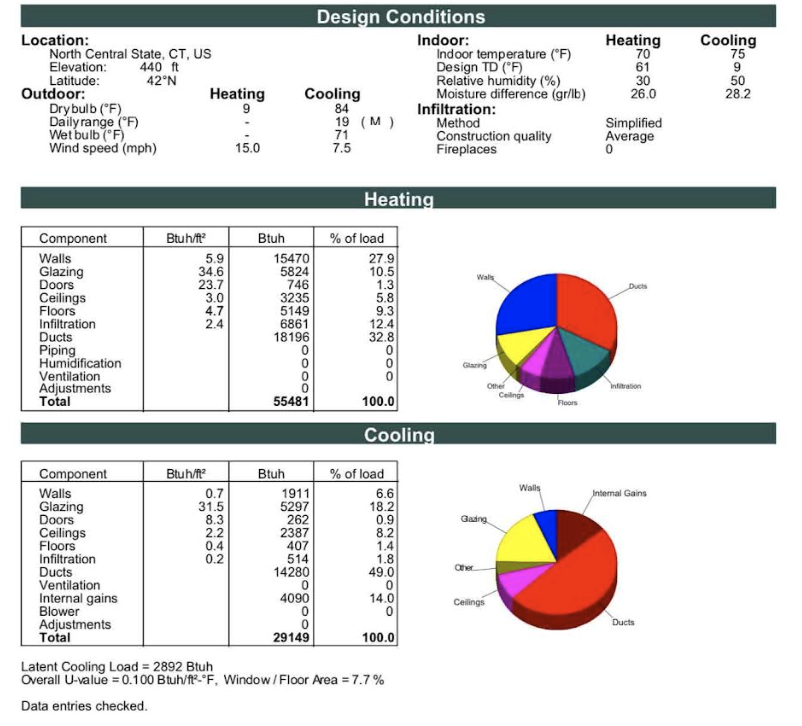

I did the detailed analysis for Boston using the process outlined in the post I linked to above — use NEEP to get hours for every temperature — and for an annual heating load of 90 million BTU's I get a design load of 38,100 BTU/hr at 13F.*

So now I'm shaking my head and wondering what kind of sorcery @Kaos is capable of.

*(I didn't do it for this question, I had the spreadsheet done for Boston for a different project and just had to plug in the BTU's.)

0 -

For heat pumps, nameplate capacity is meaningless. What matters is capacity at your design temperature or even your average annual minimum temperature.

But eight tons does sound like a lot. The four head unit in particular can be problematic. Most variable speed compressors have a minimum modulation of about 25% of output, which would be 12,000 BTU/hr. So when it's running that's the least it can produce. If the load is small and the heads are calling for less they will be forced to take more than their calling for, sometimes even if they're off. This can lead to swings in temperature which affect comfort.

0 -

Understand, just trying to make sure that I have correct heat load from her existing system per your directions. Using 65% right now, not sure if that's accurate.

0 -

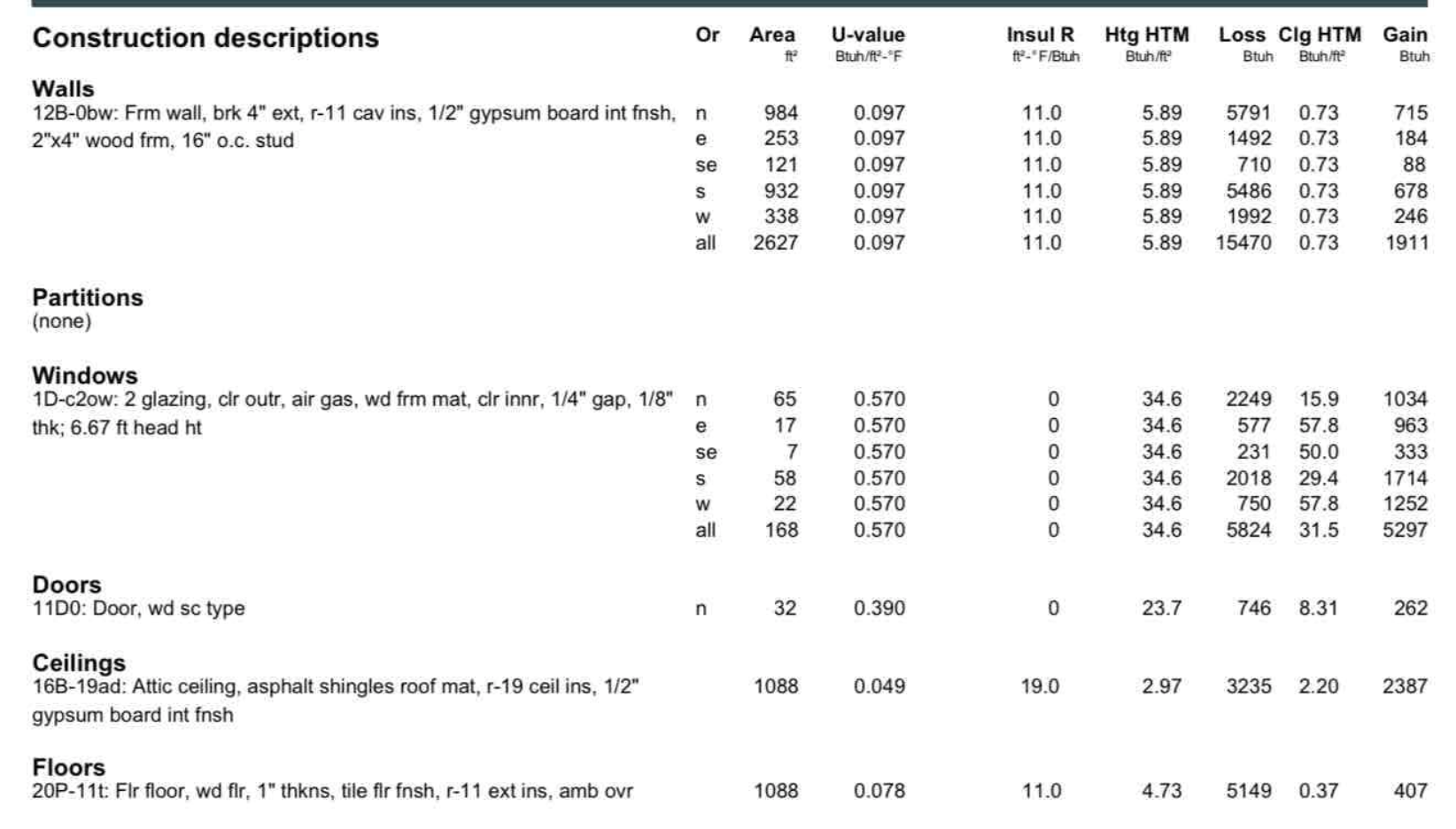

So now I'm looking into my own home (built 2013 Norfolk County MA). Here's part of the Manual J done by my heat pump installers

I'm looking at this again so I can do up the spreadsheet provided by @DCContrarian. One thing that I noticed back when I first received it was that it states 2x4 construction which is in error (house has 2x6 construction which I believe was code in 2013 MA ⇒ R-19 vs R-11 insulation) and that the ceiling insulation is R-19 while I believe it's R-30 per code at the time.

I raised these points to my installer and was told that the R-value "being slightly off" wouldn't matter with the modulating units I have. This seems inaccurate to me since, as I understand it, the ratio of the R values indicate the relative insulating performance of the two materials - is that correct?

Assuming that's correct - I believe that R-19 is 72% more effective than R-11 and R-30 is 58% more effective than R-19. All and all, heat load of 55K BTU/hr seems high for a 2013 home that's about 2200 sq ft?

Thoughts?

0 -

It's epidemic in the industry that installers don't trust the Manual J process and put their thumb on the scale to drive the result they want. With combustion appliances it wasn't a big deal, oversizing doesn't really impact efficiency and undersizing is a big problem. With a heat pump you want to size accurately.

Are your ceilings really only R19?

1 -

18K for the ducts really jumps out at me too.

0 -

Any 90s oil boiler in decent shape should get in the low 80s% combustion efficiency. The net output of that boiler available to heat radiation is 152K

You could look at the installed baseboard fin tube length and figure it at 550btu/foot. The boiler is probably oversized, and the radiation could be oversized.

1.45gph will heat a large house and what is on the boiler nameplate may not be what she is actually burning.

0 -

Just checked, they're R38 in the attic vs R30 that I thought.

Here's another heat loss that was done just after we moved in - ducts are much lower @ 6K

BTW, can you take a look at my copy of your analysis spreadsheet? I have 2x Lennox EL18XPV and went with 20K heat loss by floor so this spreadsheet is just for one floor which, for simplicity, I assumed 50% each floor.

If I did it right, what I'm seeing is that it's never more cost effective for me to use my HPs vs the gas boiler. Ultimately, not an issue since I have a good amount of excess solar production. Though, something that's confusing me is that my kWh usage hasn't gone up much since installation (approx 300-400 kWh in winter months which seems to be a good deal less than the 4000 kWh the analysis estimates (HPs used down to 30F)

Just to clarify, I'm looking at this now mostly to get a better understanding of how much the HPs cost to operate because while my gas bill in 2024 was ~25% less than 2023, my actual usage went up. This seems to be in part to more degree days but still, figured that I should see more of a drop, considering.

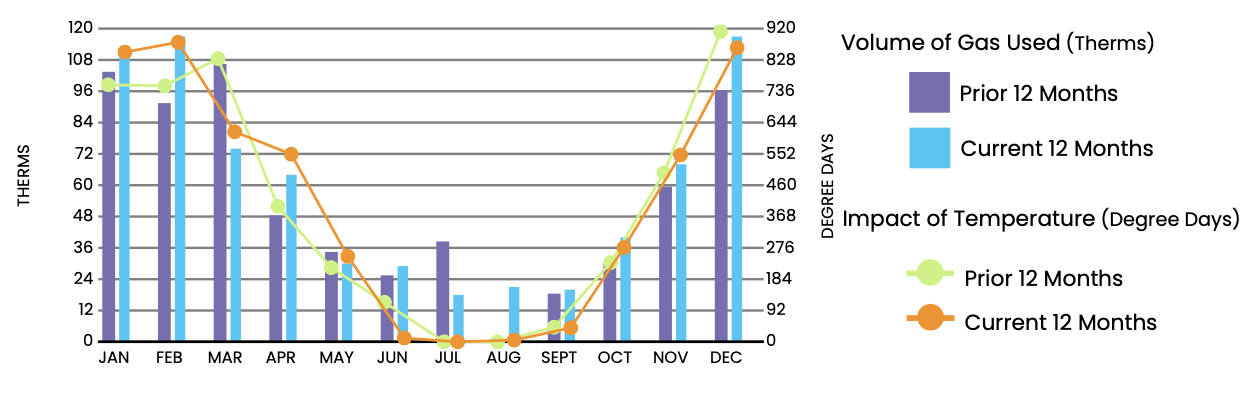

Current = 2024, Prior = 2023 with HPs installed in Nov 2023.

0 -

At some risk of being a pest, there's a major problem in trying to estimate heat pump energy consumption — kilowatt hour usage — based on Manual J or historic fossil fuel use — or even on resistance electric usage.

The COP of a heat pump varies with source air (or water) temperature. Therefore any calculation of power usage by the heat pump must take into account that variation. The relationship of COP to source temperature varies for different types of heat pump, so you need to be looking at specific makes and models for the calculations to make any sense at all.

What is worse is that in all cases the COP is less at lower source temperatures. The variation isn't trivial, either: the COP at, say 40 F source temperature may be as much as 3 or 4 times higher than that at say 0 F.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

@Jamie Hall : "The COP of a heat pump varies with source air (or water) temperature. Therefore any calculation of power usage by the heat pump must take into account that variation. The relationship of COP to source temperature varies for different types of heat pump, so you need to be looking at specific makes and models for the calculations to make any sense at all."

If you look at the spreadsheet he linked to, that's exactly what he's doing. There's a row for each degree with estimates for heating load at that temperature, annual hours at that temperature, and heat pump COP at that temperature.

The COP is going to depend upon both temperature and percent of capacity, variable speed heat pumps have higher COP at lower utilization, at least until they start short-cycling. So it also depends upon how the system is sized to the house.

1 -

@JustinS :"BTW, can you take a look at my copy of your analysis spreadsheet? I have 2x Lennox EL18XPV and went with 20K heat loss by floor so this spreadsheet is just for one floor which, for simplicity, I assumed 50% each floor. If I did it right, what I'm seeing is that it's never more cost effective for me to use my HPs vs the gas boiler."

If the prices you entered are correct, the breakeven COP is 4.94. You don't achieve that until it's 60F and there's zero heating load. So it looks like you're correct.

0 -

Do your ducts run through an unconditioned attic or crawlspace? Because if they're inside the building envelope there shouldn't be any loss at all.

0 -

The ducts are all in unconditioned space, either the attic or the basement. Isn't that pretty standard?

They are well insulated, I believe.

Glad to hear that I applied the source information correctly, I tried to follow your earlier step-by-step guide closely.

Do you think that 20K loss for each floor is a reasonable estimate?

0 -

Great job with the spreadsheet. Keep it accessible as rates change! Hoping you get the $.04/kwh shipping and handling rates we have in the mid Atlantic soon!

0 -

Just to be clear, this spreadsheet is the brain child of @DCContrarian - he deserves all of the credit :-)

1 -

I wasn't trying to down play the spreadsheet — it's excellent — but more trying to write a caution for casual readers of the thread (and there may be some!) who may not realise what all is involved.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

@JustinS : "The ducts are all in unconditioned space, either the attic or the basement. Isn't that pretty standard?"

I probably shouldn't have said "unconditioned," that's kind of an obsolete word.

For most of the 20th century there was a belief that attics and basements were kinda-sorta inside the house and kinda-sorta outside, and didn't need to be insulated, and that heat would only go where you send it.

It's only in the past 25 years or so that building codes have come to realize that insulating a house is not like putting on a sweater vest, where keeping part of your body warm keeps the rest warm, and more like waterproofing a ship, where you have to cover the whole thing. So now the codes require that all six sides of a house — four walls, floor and roof — be enclosed to control the flow of heat, air, water and moisture. Those four barriers are collectively known as the "building envelope." And every part of the house needs to be decisively either inside or outside the building envelope, and parts that are outside should be treated as outdoors and typically ventilated to the outdoors.

So conditioned vs unconditioned isn't really the way that modern buildings should be thought of, space should be thought of as inside or outside of the building envelope.

By 2013 this was well-established in the code. Massachusetts has been very active in adopting the latest codes, and while code enforcement falls to the cities and towns, I suspect in Suffolk County it's pretty rigorous. So your house was probably built this way — as evidenced by the 2x6 walls and the R38 in the attic.

With all that preamble, it's still legal to put HVAC equipment outside the building envelope. It really shouldn't be, particularly in new construction, and it's not a best practice. But it is done. In older houses it was commonplace, particularly in buildings that were originally built without central heat.

So your attic and crawlspace may or may not be within the building envelope. The quick check is, is there a layer of insulation between the space and the occupied parts of the house?

If the ducts are within the building envelope, leakage is not a concern, it all goes into warming the house. If they are outside, it is a concern, some of the heat flowing through those ducts is going straight outside. How much depends on how well they were installed, how tightly sealed and how well insulated. And it's always possible to go back and improve the installation.

0 -

The insulation is the ceiling between the 2nd floor and the attic space which has no insulation. Same goes for the 1st floor and basement. In both cases, the ducting is insulated and is located in the attic/basement along with the air handler.

How would you bring the ducts into the building envelope short of insulating the attic and/or basement?

0 -

I would insulate the basement. When you're building this house it's actually cheaper, typically there's less area to the perimeter walls than the floor of the first floor. Insulating the basement also means you don't have to worry about your pipes freezing.

In new construction, for the second floor it's easiest just to make the second floor a foot taller and put the ductwork in a dropped ceiling.

0 -

Hmmm, I've been thinking that I need to figure out a way to possibly run my HPs below the current 30F but have concerns about the HW baseboard pipes freezing.

How would you recommend insulating it? Quick google showed lining the walls with rigid foam insulation?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements