Mixing valves in oil fired radiant floor heating system

I have an 1100 sqft house that I am moving onto a new ICF basement and will be installing radiant floor heat in the basement. The main floor will be heated with forced air. I will also be adding an 800-1000 sqft garage in the future which will be radiant floor heat. The boiler will also provide DHW with an indirect tank.

I have been looking at an NTI Caprice oil boiler or a Viessmann Vitorond oil boiler. I've been told by the plumbers that due to the higher temp of oil boiler vs propane, I will need to have mixing valves installed in the loop to reduce the temperature enough for the floor heat.

However, the marketing materials for both boilers talk about using a hydrostat and outdoor ambient temp sensor to lower the boiler water temp and account for varying heating loads. I'm having trouble understanding how this would be any different than a propane boiler. I understand that oil has more heat per volume than propane, but shouldn't this just cause the oil boiler to come up to temp quicker and run less than a propane boiler?

I would imagine the system would have 3 zones - basement, garage, DHW. I'm not quite clear on how the mixing valves would be integrated into the system and if they are even necessary.

If anyone could clear this up for me and explain if I am misunderstanding something, I would appreciate it.

Comments

-

Let's get one thing out of the way first: the temperature of an oil fired boiler will be no different from that of a propane fired boiler under the same load and BTUh input conditions.

Where a propane boiler may run at a lower temperature is with lower load conditions and modulating the burner flame to match — what is called a mod/con boiler.

Now your sales people do have a point: residential oil boiler power output can only be modulated by turning them on and off, not by lowering the flame.

Both oil and propane systems will only work well for radiant if they use a mixing valve and outdoor control of that valve. They both will also need a control to modulate the boiler to match the load — which may take the form of a modulating control for a propane mod/con, or a simple aquastat for the oil boiler or a conventional propane fired boiler.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Your first 3 paragraphs all make sense to me and pretty much align with what I had in my mind. I suppose the on/off control of an oil boiler could become an issue if it there is a minimal heating load causing short cycling? Or is this not usually an issue? If it is, how is this usually overcome?

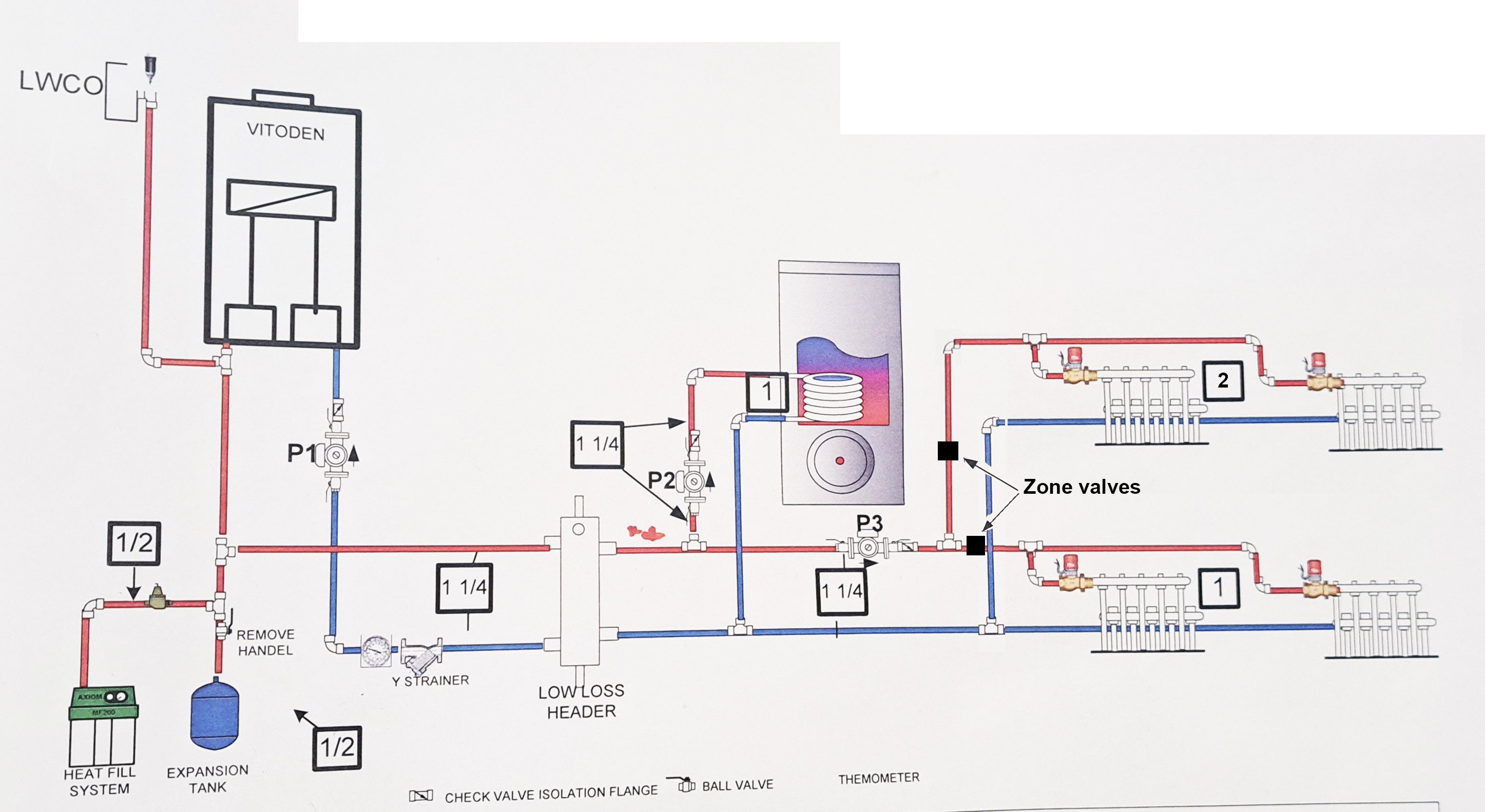

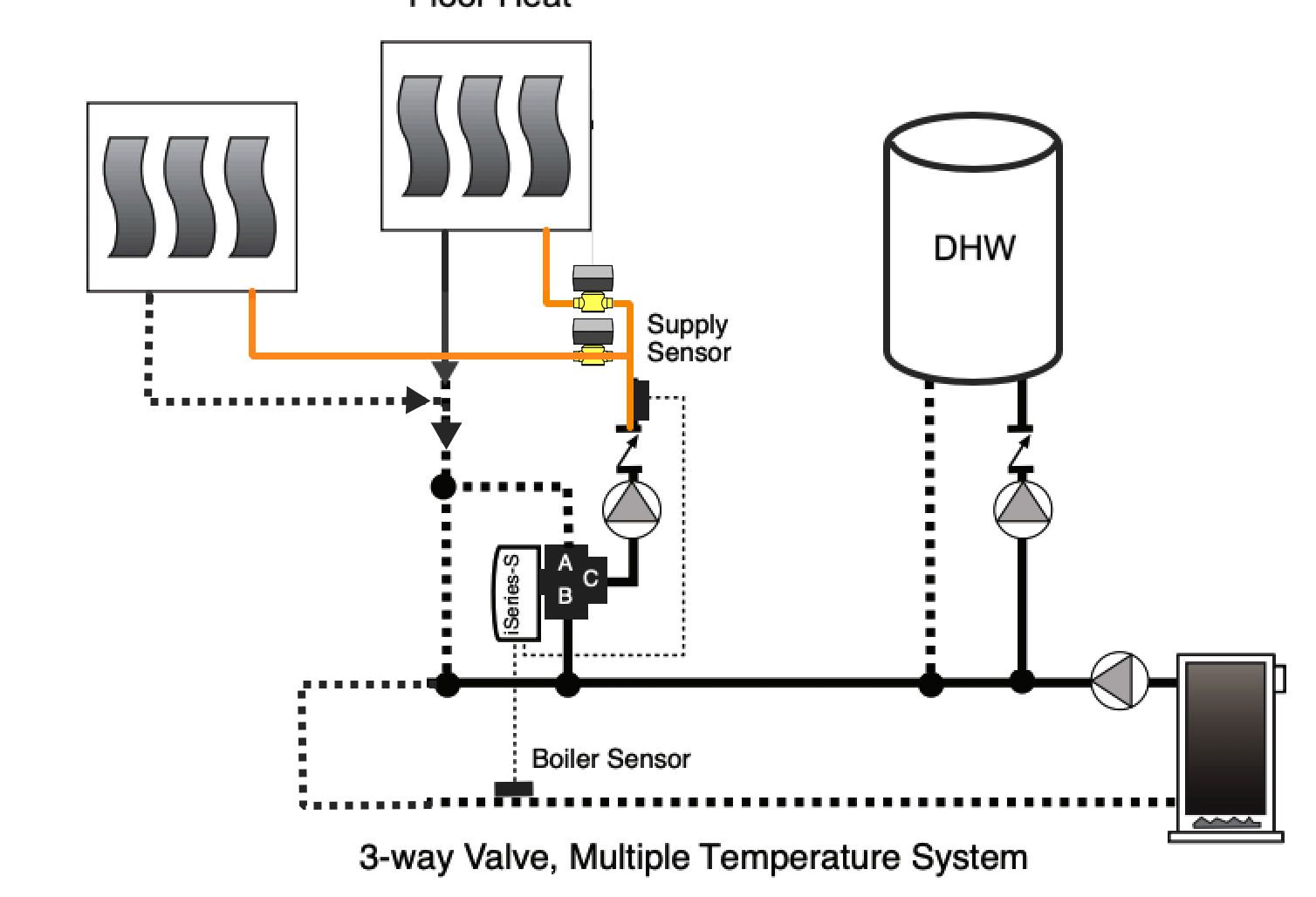

Your last paragraph is likely where my confusion comes from. I have attached below a diagram of the propane boiler system in my parents house. One zone for basement, one for garage, and one for DHW tank. There is no mixing valve that I can see. It does have outdoor control, which I assume is just varying the temp of the boiler water. Is there an implicit mixing valve or something I am missing here?

0 -

A propane or natural gas condensing boiler can output low enough temp water to feed radiant directly. a cast iron boiler(weather it is gas or oil) can not. It would condense at low supply water temps which will destroy the cast iron. Condensing boilers have special heat exchanges that can handle the condensation. I thought Viessman used to have a condensing oil boiler but i'm not sure. Energy Kinetics also makes some higher efficiency conventional boilers for gas or oil.

1 -

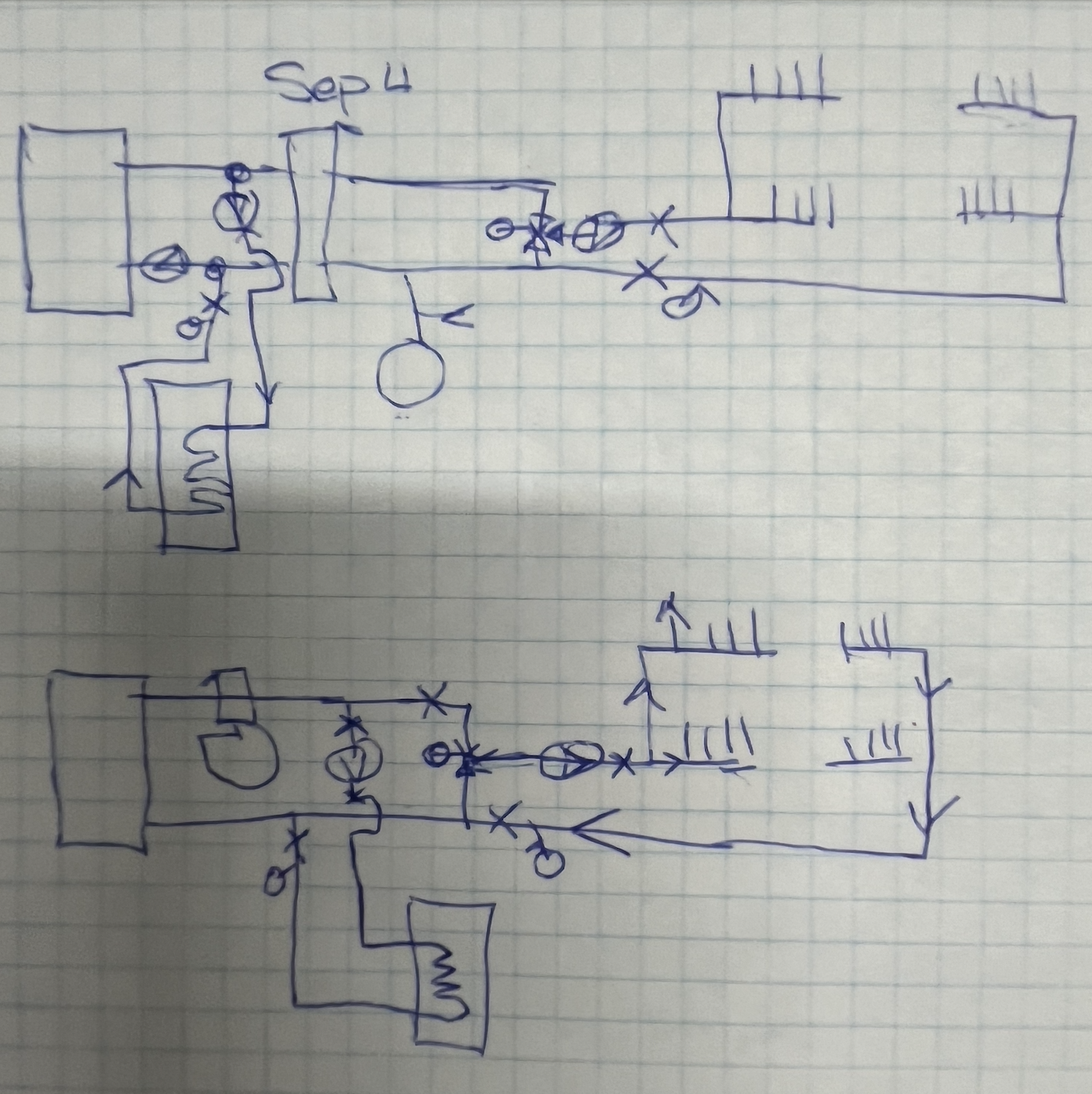

Use a 4-1 type hydrosep for air, dirt, magnetic and hydraulic separation. Eliminates the y strainer

P 1 is the boiler pump, it runs on any heat call. Needs a check valve

P2 is the indirect circ, it runs for DHW, P1 is off. Needs a check valve

P3 is the low temperature, always pump away from the 3 way mix valve.

The boiler runs on outdoor reset, 135 minimum for boiler protection.

The lower drawing is without a separator, if the manufacturer allows direct piping.

P1 indirect

P2 radiant mixed down via 3 way

Expansion and fill connect at the separator into either of the bottom ports.

Depending on the pressure drop through the boilers, you may not need a hydraulic sep. Unless the manufacturer requests it? The smallest zone needs to assure enough gpm through the boiler.

Bottom drawing is a two temperature system with indirect

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@skippy_ said: Your last paragraph is likely where my confusion comes from. I have attached below a diagram of the propane boiler system in my parents house.

I don't see in that diagram how the radiant floor water temperature can be different from the DHW tank high temperature without a mixing valve of some type. The only way this might work is if the DHW has priority and can send the boiler to 160° or above to make DHW. When there is a call from the lower temperature radiant zones during the DHW high temperature, the higher temperature boiler water must drop quickly so the floor does not get the 160° (or higher) water so not to overheat the floor. That can end up working with the proper control system. There may be some short bursts of higher temperature water to the radiant loop(s) but that will dissipate in the radiant floor concrete quickly and the lower temperature water from the boiler will take over heating. There can never be a simultaneous call for radiant and DHW.

I don't see that same design working on an oil fired boiler system, as of this date there are no ModCon oil fired boilers on the market. Oil boilers are either on or off. There are 2 stage flame burners for oil, but those burners are only offered in commercial sizes. Also, the nature of Cast Iron boilers indicates the minimum return water temperature of 135° to prevent flue gas condensation and ultimately premature boiler failure, means that the supply temperature must operate above the maximum water temperature of the radiant zones. A mixing valve is a must for the oil fired systems.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Viessmann does make an oil-fired condensing boiler, unfortunately it has never been imported here

Vitorondens 200-T Cast Iron Oil Condensing Boiler | Viessmann UK

0 -

It is not modulating though… so not a ModCon

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I appreciate the responses, there is a lot of good info here

@mattmia2 said: A propane or natural gas condensing boiler can output low enough temp water to feed radiant directly. a cast iron boiler(weather it is gas or oil) can not.

This is the piece of info I was missing. It is not an oil vs propane issue, it is a condensing vs non-condensing boiler issue. That clears up a lot of confusion.

@hot_rod said:

P1 is the boiler pump, it runs on any heat call. Needs a check valve

P2 is the indirect circ, it runs for DHW, P1 is off. Needs a check valve

P3 is the low temperature, always pump away from the 3 way mix valve.

I do not see how P1 can be off if P2 is on. I assume this is a typo unless I am missing something.

For 2 low temp zones, would I tee in before the mixing valve and add a second mixing valve for the other zone, or would one mixing valve serve two zones each with their own pump?@EdTheHeaterMan said: I don't see in that diagram how the radiant floor water temperature can be different from the DHW tank high temperature without a mixing valve of some type. The only way this might work is if the DHW has priority and can send the boiler to 160° or above to make DHW.

This must be what it is doing. I double checked the boiler piping and the diagram is correct - there are no mixing valves. This is what was confusing me as I never realized it must be doing some kind of control scheme in the background to allow different temp water to the floor and DHW tank.

So as I understand it, for 2 floor zones (basement, garage), and DHW, I'll need:

- 2 (?) mixing valves

- 4 pumps (boiler, basement, garage, DHW)

- hydraulic separator

- oil boiler with hydrostat

- Tekmar or equivalent controller

I assume manual mixing valve(s) would be used since the floors are large thermal masses. They would be set such that the max boiler temp would result in the max acceptable floor temp and then as the ODR adjusts the boiler temp, the floor temp would track as well.

Essentially I am looking for the simplest, most reliable system that still gives good performance. I don't want to spend $$$ and add extra complexity just to get a marginal performance/efficiency bump, but I also don't want to cheap out and have a system that does not operate properly.

Let me know what you think. Thanks

0 -

-

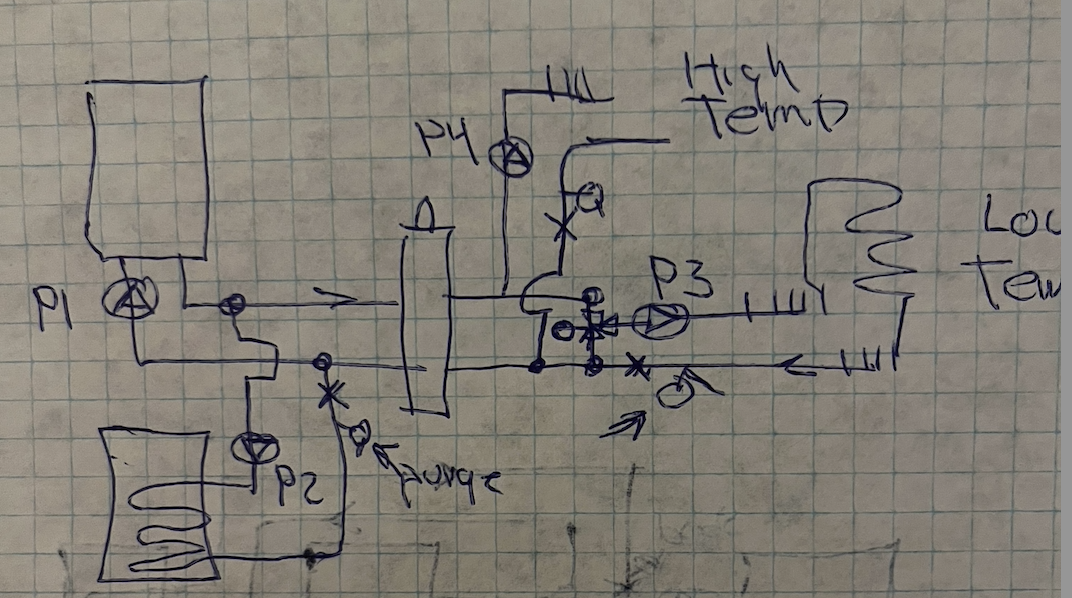

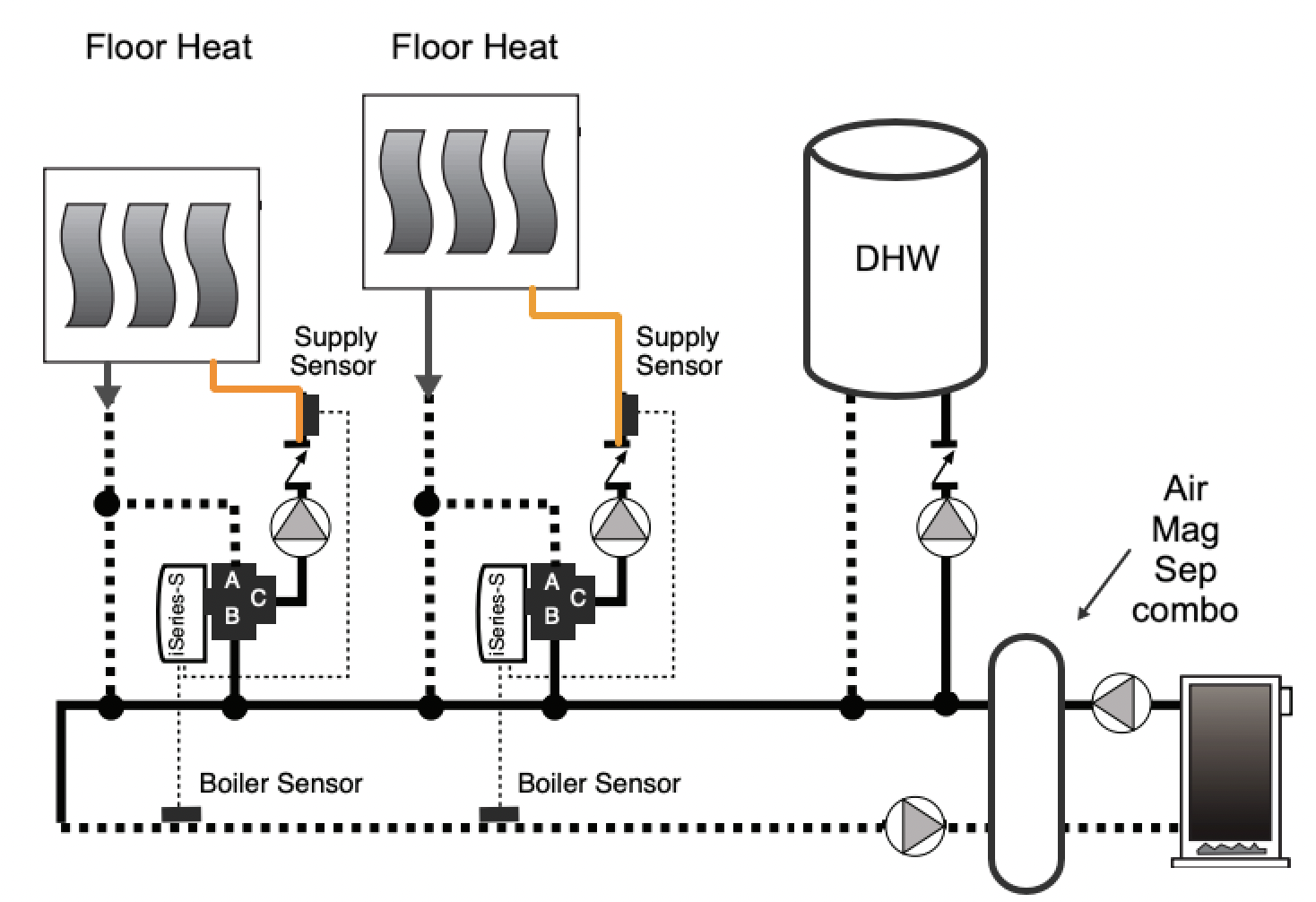

A fixed temperature mixing valve will not track with the boiler's ODR. A fixed temp mixing valve will take the changing boiler temperature and add more or less return (cold in) temperature water to create the set temperature of that mix valve. In order to get true ODR for the floor heating slabs you might consider using something like this: Taco I-Series ODR valve This will do the mixing from the higher temperature Boiler/Buffer Tank/Separator water. I don't know if @hot_rod's company has a similar product but if they do, then He would know the best Hydraulic separation/air elimination/pumping away/mixing valve design for your situation. I might start here:

- 2 Taco iSeries mixing valves

- 5 pumps (boiler, system, basement, garage, DHW)

- hydraulic separator if needed to maintain boiler temperature and/or reduce short cycling

- oil boiler with hydrostat

- Taco iSeries valve motors or equivalent controller

You can place the mixing valves near each floor system.

EDIT: To save on pumps and on iSeries valve you could eliminate the Separator and use one mix valve for both floors. The mixed water can be made in the boiler room and lower temperature water piped from the boiler room to the two different floor locations.

- 1 Taco iSeries mixing valve

- 3 pumps (boiler, low temp, DHW)

- 2 Zone Valves

- oil boiler with hydrostat

- Taco iSeries valve motors or equivalent controller

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

If you use a hydraulic separator you could pipe the indirect on the primary side of the sep and you only need to run 1 circulator when the tank calls as a priority zone. Also you get full boiler output to the tank. The indirect on the secondary side requires you run the boiler pump and the indirect. You get some temperature blending in the separator, so the indirect may not get the full boiler temperature.

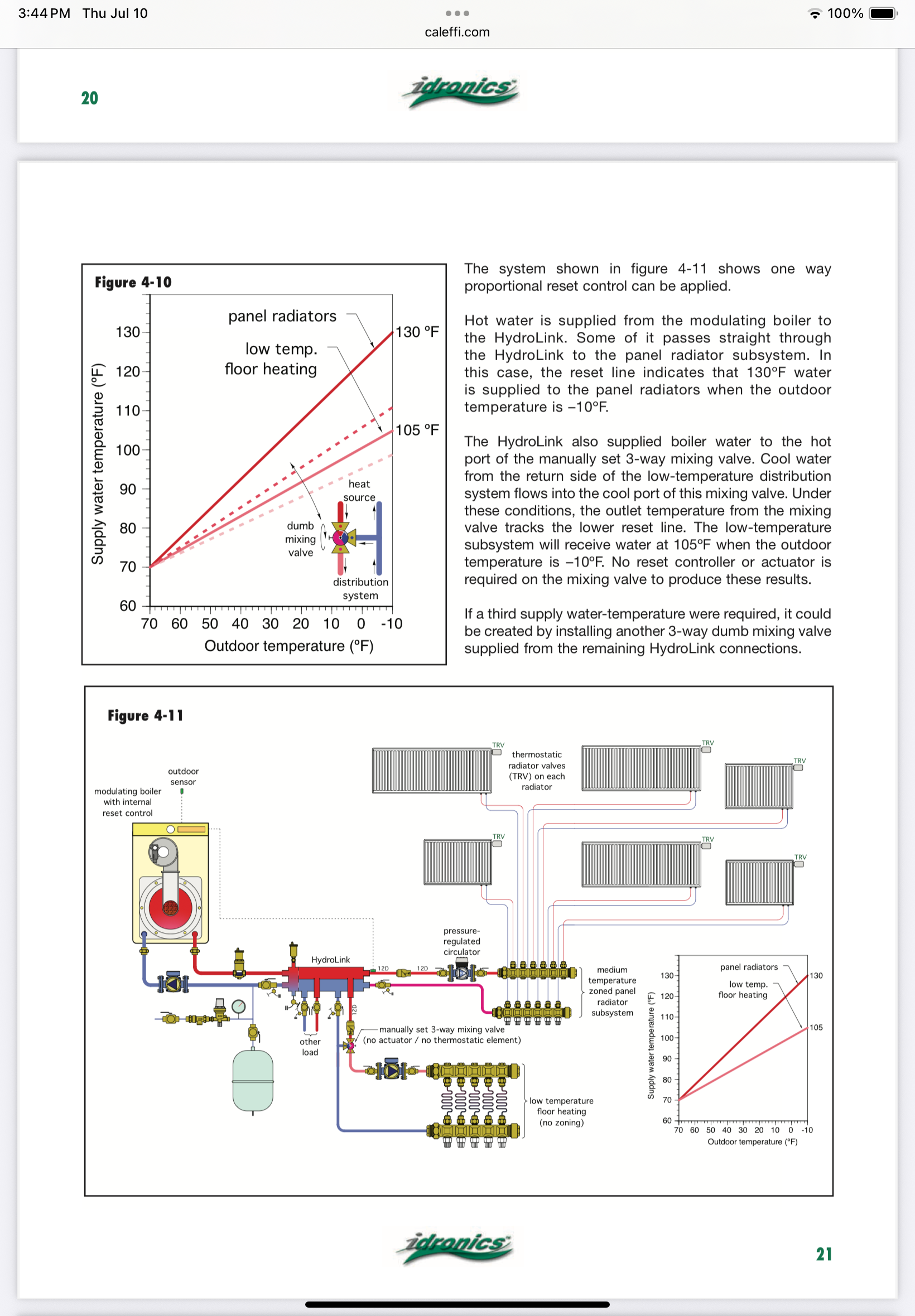

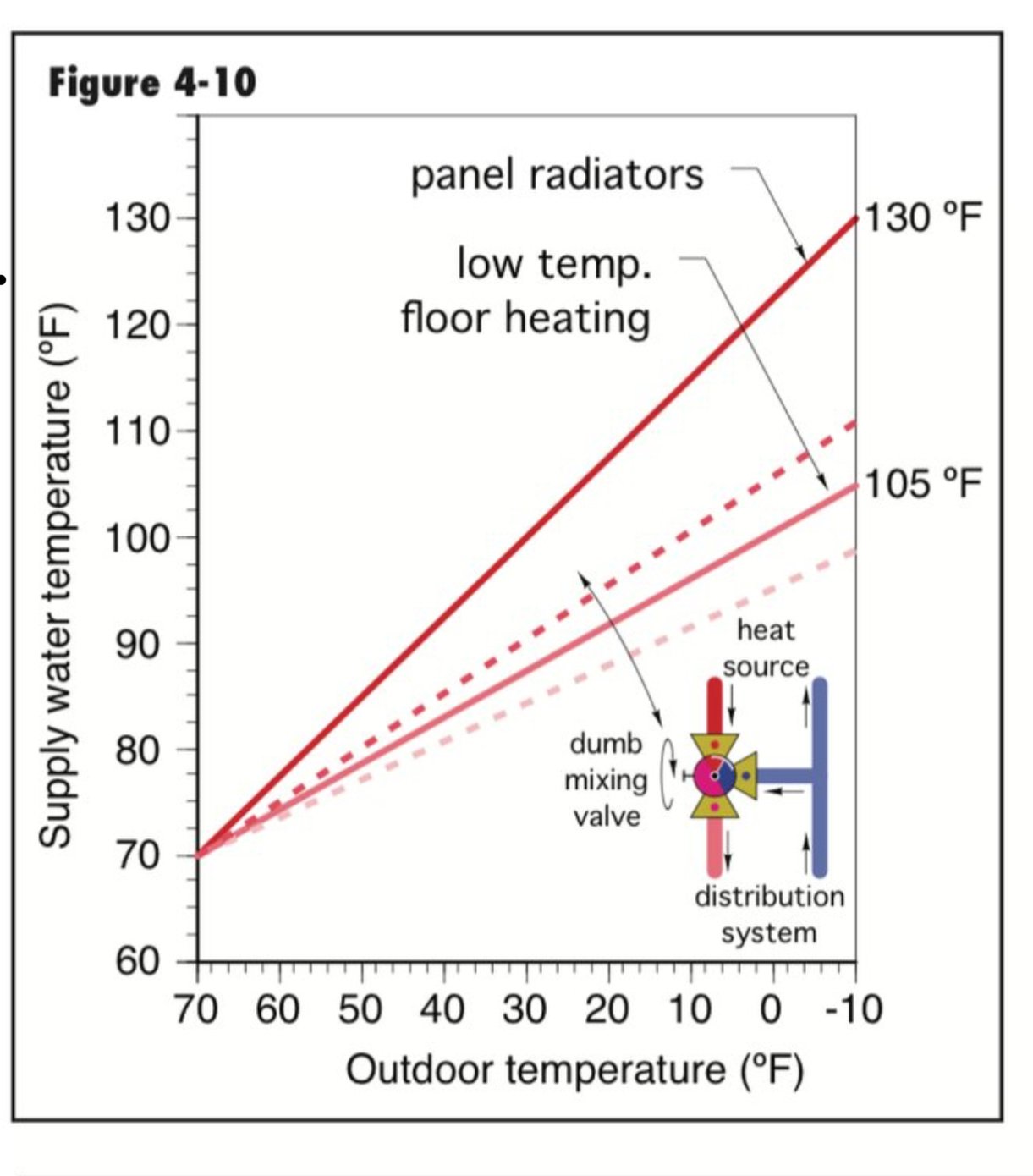

Proportional reset uses a boiler with ODR, then a manual “dumb” mix valve supplies low temperature zones. So that manual mix valve tracks along with the ODR reset. I had this mixing option my last home.

Here is a better explanation from Idronics #7

This example has a mod con modulating on ODR feeding a panel radiator system, the radiant is via a manual valve.

Thr HydroLink is not required to make it work. A hydro sep or close tees works IF the boiler needs a dedicated circ

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I made an edit to the Taco Mix I-series Mix valve. I did not select the outdoor reset offering. this is it:Taco I-Series ODR valve here and it is corrected above. I also agree with @hot_rod Bob on piping the indirect before the separator. Good call on that one.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

The supply water temperature to the floor will not change with the weather for the most part.

Lets say the fixed temperature mix for the floor needs to be 125° for the design days. (the coldest days) and the boiler will create 160° for that using the ODR when there is no call for DHW and the minimum temperature for the boiler return of 135°. The fixed temp mixing valve will take 160° supply water and add the proper amount of return water from the radiant in order to make 125° to the floor

When the boiler temperature drops lower temperatures based on the boiler or Tekmar ODR control sensing a warmer outside temperature (say 145°), the fixed temp mix valve will take the 145° reset temperature and mix less return water from the radiant return to make the supply 125° to the floor. So when the floor needs the lower temp on the warmer day, it will still be getting 125 °. That will over heat the room enough to satisfy (turn off) the thermostat until the room temperature drops below the thermostat set point and it calls for heat again. Room temperature thermostats and radiant floor heat are not the best combination to avoid large temperature swings in the rooms because of the slower reaction time of radiant floor systems.

Eventually the Tekmer or boiler ODR control will drop the supply temperature to 120° when the outside temperature is above 50°. That is when the 125 mix valve will not allow any return water from the radiant loop to mix with the 120° supply water. the 120° supply water will go straight through the mix valve. You will then get the lower floor temperature. Now this 120° boiler supply temperature will only happen when the boiler's burner is off. If the boiler's burner is firing then the minimum return temperature of 135° will need to happen by some function of the control system to protect the boiler from flue gas condensation.

I'm not saying that it won't work, I'm just pointing out the reason you might want to consider the Taco iSeries ODR valve. They were not available when I installed my radiant floor system so I installed fixed temp mix valves and used room thermostats. It worked fine for me. I just wanted you to know that without the ODR valve, you may be wasting your $$$ on using a Tekmer or other boiler ODR system.

What you think you are achieving with a Tekmar or other boiler temperature ODR may not happen after you spend all that $$$ on the control system. Save on the system ODR and use the ODR mix valve where it will do the most good. Or forget about ODR completely and save $$$ in installation costs.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

The forced air runs off the boiler as a high temperature loop? Or is all the hydronics low temperature. If so a mod con lp boiler would be my choice, running ODR.

the manual mix valve will in fact track with the boilers changing temperature. As the boiler drops so will the mix from the manual valve. The manual valve does not have a sensor, it is a fixed blend.On the mix down manual valve you can also adjust the offset, dotted red lines, how it tracks with the higher temperature.

This shows the relationship with a 130 panel rad system, but it could be a 160, 180 or higher zone also.

There is no reason to have ODR on the boiler and also on the low temperature zone.

Of course with a cast boiler you will have a minimum return to be aware of.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I agree @hot_rod. There is one DHW high temperature loop. I like the mod-con for the ODR idea, because the mod-con will do the low temp and DHW temp on priority. The ideal situation with the logic already built into the boiler controls. But the original post indicated that they were using oil fired boilers. Probably cast iron. So the non condensing Cat I venting system would require boiler return protection. That is where I am looking at the Taco iSeries ODR valve for floor temperature control as a better choice for ODR. Spending $$$ on a Tekmar or other ODR to control the boiler temperature will be wasted for over 50% of the heating season, if at all.

Ideas Bob?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

it would probably cost less to size the indirect to work on the lowest non-condensing boiler temp than to try to control a ci boiler at 2 setpoints.

0 -

I guess the first decision is which fuel is going to be used?

If it is LP a mod con is my suggestion, I believe they all have ODR

If it is oil, the Viessmann oil also includes ODR. Some. Viessmanns have a basic return protection function, a simple aquastat that holds the pump off if return drops too low. although the ODR control may include return protection also.

Download the manual, Viessmann usually has top notch control logic onboard

What is the heat load for the completed project? The smallest Vittorond may be too large? Another reason to consider a mod con on LP. The modulation alone is worth the consideration

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I have a lot of info to provide here and I will try to do it as concisely as possible.

Fuel Type:

I live in the country in Canada 2hrs from the nearest major city. There is no gas so my options are LP and oil. I purchase oil in bulk (1000s of gallons at once), so accounting for efficiency differences, my cost per BTU for LP vs oil is very similar.

I've decided on oil as I have massive amounts of fuel on hand, where as for LP I am at the mercy of delivery trucks to keep me topped up during winter. I also have a 500gal oil tank on hand to use for the house, whereas I would have to buy an LP tank. Another reason is simplicity. The parts for an oil burner are much cheaper and there are also fewer of them. I am able to have every common part for a Beckett oil burner on hand for a similar price to a control board for an LP boiler. This is valuable to me when the boiler or furnace decides to fail on a -45° night during a long weekend. I can easily get it back up and running myself with parts I have on hand.

Heat Load:

This is a tough one. The house is an 1100sqft house that was originally on a concrete basement and heated entirely with forced air. The furnace that was in that house originally was a gas furnace with 76000BTU output. I have now built a new ICF basement and moved the house onto it. My plan is to have the boiler providing DHW and hydro floor heat for the basement, with a separate forced air oil furnace heating the main floor.

However, in the near future, I will be adding an 800-1000sqft garage that will be heated exclusively with hydro floor heat. Another future addition will be a ~400sqft solarium. I do not know whether I will put hydro floor heat in the slab under the solarium to supplement the forced air heat, or heat it solely with forced air.

Calculating the actual heat load is difficult as I have an old construction house on a new construction basement, neither of which I have historical fuel usage to go off. There is also the future additions which I have to consider.

System Design:

As I understand it, I am able to swap out the nozzle/blast tube to downfire an oil burner or furnace, so long as adequate stack temp and water temp are maintained. I would like to oversize the boiler enough that in the future, if the furnace heat exchange ever fails, I could get an air to water HX and run all the heat from the boiler. However, I am not sure whether it is possible to downfire a large enough boiler to have this option.

I am not afraid to work on my heating equipment or tinker around to get it set up. However, I don't have experience with mixing valves on a dual temp hydronics system, and trial and error is probably not the best option.

I appreciate all the replies and info.

0 -

@hot_rod said: "What is the heat load for the completed project? The smallest Vittorond may be too large? "

I found this to be true about oil heat on many jobs. So there will be short cycling unless there is some type of additional load added like a buffer tank that can be charged with 40 (or more) gallons of 150° water (or higher) that the low temperature zones can draw from, for up to 30 minutes until the buffer tank temperature drops to say 125°, before the burner operates again. This will offer longer on cycle when there is a call for heat. The high temp DHW can also be purged from the boiler to reduce off cycle loss during summer, to reduce fuel usage.

I believe the goal is to increase the burner run cycle to at least 10 minutes on a normal (not design load) winter season day, and extend the off cycle when the net output exceeds the project's load by 2, 3, or 4 times the smallest boiler offering a manufacturer has.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

A WAG of 25 btu/ sq ft for the house and solarium = 37,500 btu/ hr

A well insulated 1,000 shop maybe 20,000

So a 50- 60,000 boiler would probably cover it. You could let the garage drop if you come up short on below design days

Im not sure what the smallest oil boiler you can buy is?

That Viessmann may be twice what you need 95K

Since the oil will not modulate, on mild days it may cycle a lot. So the efficiency number takes a hit. So for comparison oil at 80%, lp 87+

Some fuel numbers here

https://coalpail.com/fuel-comparison-calculator-home-heating

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

You're on the right track! Even with outdoor reset controls, oil boilers often run hotter than needed for radiant floors. That’s why mixing valves are used, to lower the water temp going into the floor loops. It helps protect the floor and keeps things more efficient.

0 -

Mine is circa 2000 2 story (reno'd upper floor was lifted up and its 70's), 1000sqft each, attached 600sqft garage. Conventional oil boiler feeds main and shop at about 100f (IIRC) thru a mixer. Forced air upstairs at boiler temp . No DHW connection. Design temp is -21f

Main is 6 zones, plus the shop. Single loop in shop was a mistake (diy). We keep it at 60f and it holds even in the bitter cold. Until you open the door and bring a frozen vehicle in. Electric heaters for now, but Im planning on bringing a loop thru the drop ceiling into shop to feed a hydro unit heater. So.. consider 2 or 3 zones for garage, especially if you're going to be parking in there during winter.

I had to tie some of my short loop house zones to stop the short heat calls, but it sure is nice to have the bathroom toasty warm while the bedrooms are cooler for sleeping.

Your forced air is going to want 150f or such but I run mine down to 135 and thats fine as long as it's not blowing right at you (use lower fan speed even).

Good luck on the adventure. Read lots.

30+ yrs in telecom outside plant.

Currently in building maintenance.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements