Now ya see why PVC on mod con flue is not a good idea

Installed approximately 17 years ago...glue joint pulled apart easily. Mad Dog

Comments

-

In my opinion that PVC was not properly solvent welded, that isn't the materials fault it's the installers fault.

I don't think that even get hot warm, look at the barcode label on the coupler.

B vents can pull apart easily if they're not twisted and locked together correctly.

Single wall galvanized pipe can pull apart easy if there isn't the proper 3 screws per joint.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

10 -

Obviously from what we have learned PVC for flues is not a good idea unless approved and the only one I know that is is Ipex,

It looks like the glue and primer is good but who knows.

Dis they sand the fittings and pipe?

was the glue old?

did they let the primer dry tooo long b4 gluing?

It doesn't look like the PVC was overheated, it usually turns brownish.

3 -

yeah, that looks like the glue was allowed to dry too long before assembling or they went over it a couple times because it dried

0 -

I just want to mention that when PVC is solvent welded, you're using a solvent like acetone or MEK to literally melt the plastic. Once the solvent evaporates it leaves the PVC solid again and in literally one piece rather than two.

I'm not sure that even counts as glue, technically.

If memory serves PVC cement is solvent with some pvc mixed into it to act as filler material.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

2 -

I installed dozens of GB- 142s with PVC exhaust before they banned it in NY. Never seen it be an issue, but apparently "they" decided it was. Mad Dog

1 -

-

MA has basically banned it I think.

If the existing PVC flue is in a wall (difficult to replace) you can reattach a new boiler to it if the new boiler is listed for a PVC flue and the pVC shows no damage or overheating but then they want you to go to the new boiler with "approved pvc" like the Ipex so now you have a mix of PVC so its an issue.

0 -

This Installer, whomever it was, was neat, conscientious and thorough...using plenty of primer and glue. I'm not supporting installer error. Mad Dog

0 -

-

-

That PVC pipe and coupling was not pushed in all the way. There is no way that pipe bottomed out in the coupling. My guess is the installer didn't notice it was pushing apart before it dried. The PVC is still white like its relatively brand new.

0 -

-

-

That looks like 2" PVC. 2" couplings are a poor excuse of connection IMO.

I Have always used pressure couplings for 1 1/2 and 2" venting and DWV…..over twice the bury and better stability.

The ratio of bury to circumference gets better at 3", 2" is the worst.

0 -

I have used PVC venting on scorched air systems for over forty years. That is clearly a poor installation job. A proper connection is actually a solvent WELD, impossible to disassemble after curing.

0 -

The listed IPex system 1738 includes primer and adhesive with additives to allow for inspection via UV light.

the primer and adhesive solvents seem to be more aggressive than standard PVC products with much stronger odor.0 -

You can armchair quarterback your opinions and guesses as to the failure but without lab analysis you are still just grasping at straws. Was it installed per the mfrs. listed instructions as well as those of the PVC pipe mfr, the primer and the solvent cement? Was the pipe used within the approved applications by the pipe mfr? Was the pipe properly supported? Was it leak tested prior to use? Was the appliance inspected and tested including gas pressures, orifices, firing rate, MUA, intake air obstructions/ sizing/ pressures? Flue gas outlet temperatures? Any signs of overfiring in the unit or historical evidence such as tripped safeties? Was the heat exchanger ever replaced? Lot's of questions in a forensic investigation.

I don't like PVC for a number of reasons: The pipes out there were never listed for this use but specifically forbidden per most pipe mfrs. While the pipe itself might withstand short term temps upwards 170F, the solvent cement routinely fails at 140F or lower. I've never seen an HVAC tech properly cut, chamfer, deburr or join PVC for venting. Never. I see pipe cut with a Sawzall held with one hand and the pipe with the other. The end of the pipe resembles a hole saw with all its jagged edges. The end is never chamfered nor deburred and there is no way to tell externally once the joint is made. Meanwhile, inside, the rough joint plows the cement pushing a dam of it ahead while scraping cement from the outer walls. The result is a very weak, often leaky joint.

The pipe mfrs. expressly FORBID pressure testing with gas, such as done with gas piping. You can do a low pressure water test but how are you going to test the seal on a flush wall termination like a Bayvent? You would have to test with the pipe extended, tested, cut to length and attach AFTER the test. You might be able to rig a test ball in some cases. Also, on long runs through crawlspaces, you may get a few drips that harbinger a future failure yet not manifest during the test duration. You have to rely on one end of the pipe or another just as with gas pipe testing. That brings in the gauge resolution, test duration and allowable leakage. It has to be reasonable yet reflective of the conditions.The UL 1738 test seems fairly reasonable and reliable. It is also repeatable.

Everything made by man can and will eventually fail. It's just a matter of when and at what cost.

2 -

when glue gets old and starts to gel it doesn’t work so well

PVC that turns beige is an indication of over heating. If the boiler runs 140f continuously it is exceeding the temperature rating of pvc.

boilers running 180 tend to stress the pvc quickly, color turns darkBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

We have removed and replaced at least forty condensing boilers (mostly light commercial) that used PVC for venting and fresh air. All of these jobs used solid core PVC as opposed to hollow core.

On most of these jobs, the condensing boilers replaced cast iron boilers on high temperature systems. When we removed the boilers we almost always had to replace the PVC vent piping for at least the first ten feet. In many cases, we switched the venting over to Fas-N-Seal stainless or Centrotherm polypropylene vent material.

In all of these systems, I cannot remember one job that the glued joints came apart easily. As you would expect, the PVC vent piping was tan in color instead of the original bright white. As mentioned above, the heating systems with the highest average boiler water temperature had the most discolored venting. On many of these tear outs, we noticed the PVC pipe was very brittle. The fittings were also brittle, but not as much as the pipe. In the worst cases, the pipe would break if you lightly tapped it with a hammer. If you dropped a section of the pipe more than one foot off the ground it would break into pieces.

5 -

when I got rid of the old combi unit in my PA property I installed the polypro pipe for the intake and exhaust. The old unit had PVC which seemed to be holding up well since the installers installed it back in the day but man when I was comparing the weight of the newer material and the gasket instead of glues sealing methods I was really debating using the pvc in my install but the polypro was on the approved list so I bit the bullet and went with it. I just hope the polypro thinner walled pipe and the gasket seals hold up as long as the pvc did. Time will tell.

0 -

high temperature systems with PP and long horizontal run can be a problem if not supported properly.

I have seen the piping sag and leak condensate at the joints.

HTTP failed , standard PVC and CPVC isn’t the best solution, some stainless suffered gaskets or silicone adhesive failures,

Hopefully PP holds up better. It is a harsh environment for the tube and seals

Dirty or plugged HXers can run the flue temperatures up pretty hot. Hot enough to trip temperature safeties.

Mod cons in DHW mode are generally exceeding the PVC, maybe even CPVC temperature limitsNot to mention the lack of listing for flue gas conveyance on typical PVC pipe

Yet manufactures are still sending equipment out with PVC or CPVC “starter pieces” PVC fittings and rubber sewer pipe connectors😲 Some brands sent ABS start pieces, which would often get connected to PVC. Crazy!

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

I can remember installing a boiler back in the 80s. MOD CON where they required ABS vents. Can't remember the boiler.

0 -

Some of the early HTP products included a short piece of ABS, the Voyager maybe?

What I find is

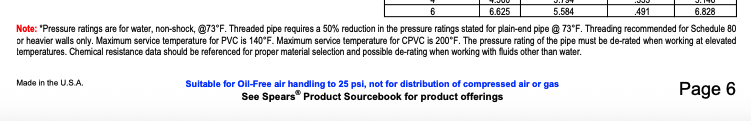

PVC 140°F max

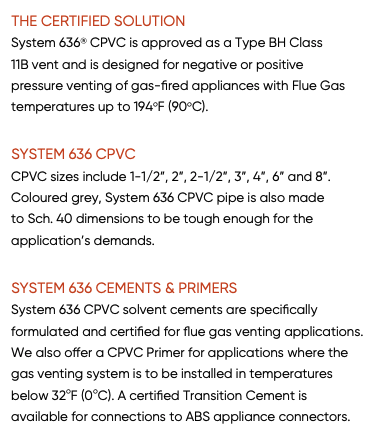

IPEX 636 CPVC (flue gas certified) 194°F, with their solvent and glue

CPVC 200°F max

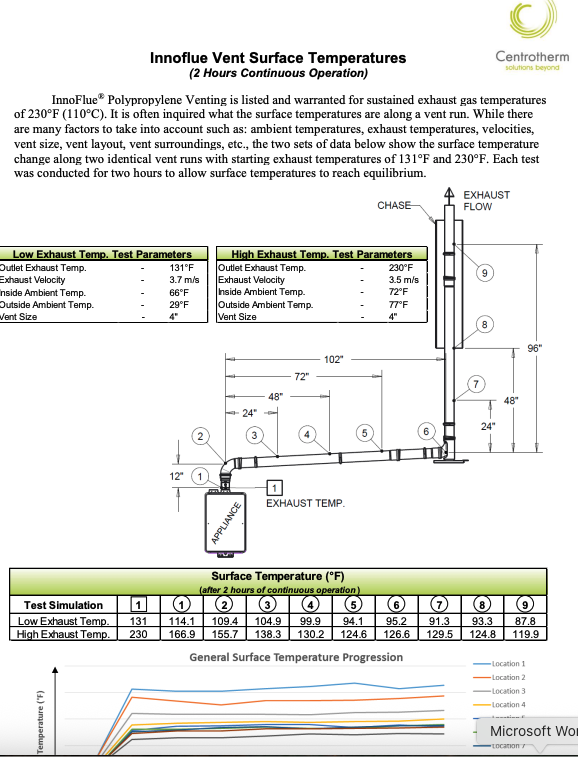

Centrotherm PP 230°F continuous

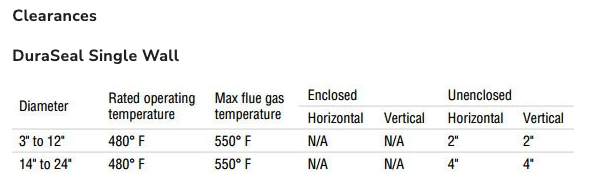

DuraSeal single wall stainless 480° operating, 550°F max

Flue gas sensor on my Lochinvar Knight is 225°F to shut down burner. So essentially only the Centrotherm and SS vent pass the potential flue gas temperature question

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

This was 3"pvc... .I agree with Bob Harper...we're all just taking a stab at why...only a lab analysis can possibly determine why it pulled apart. Let's just keep an open mind....could the manufacturers have very sound reasons for disallowing pvc in flue exhausts?

Could acidic flue gases cause this is as well? Mad Dog

1 -

-

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements