Mitsubishi Minisplit Inverter Board

I had an issue with my garage minisplit last fall and did very poor troubleshooting resulting in a new inverter board popping upon installation. Shame on me for sure.

The outside unit is a MUZ-GE15NA2 and the inside unit is a MSZ-GE15NA-[9]. The unit was installed in 2018 and generally ran fine. Every now and then it would be barely cooling, but if I shut it off and turned it back on a half hour later it would cool again for days/weeks. I assumed dirty coils, but hadn't gotten around to cleaning it. Then, one day, it wouldn't blow any air and had a flashing code (I believe 7 flashes, but don't recall). I went to check the outdoor led and it was not flashing and there was a burnt electronics smell.

The original board had 2 burnt spots on it, I checked the compressor and fan motor phase resistances and they were within spec, so I just put in a new inverter board (i.e. terrible troubleshooting on my part). As soon as I turned on the breaker, I heard a little pop and saw a small trace of smoke from the unit. As winter was approaching, I just figured I would deal with it later.

The new board has a blown chip near the LEV connector as shown in the picture. I measured all of the components this time instead of just the compressor and fan motor and the LEV measured open (440MOhm on 2 legs and 24MOhm on the other two). I used a magnet tool to make sure the LEV was not frozen up and it can bottom out and back out fine. I set it to one turn open, which I think is around 40 pulses based on the coil configuration.

I reinstalled the board with the burnt chip to see if it would at least try to start the compressor or show any life otherwise. Nothing else popped, but the indoor unit is flashing 7 times and the outdoor unit is flashing one time. The manual says this means bad nvram on the board, which I guess is no surprise as boards don't usually just fry one thing with no other repercussions. I removed the S3 wire and bridged S2-S3 to see if the LED pattern changed on the outdoor board, but it did not. With S3 connected, I got variable DC voltages from S2 to S3 ranging from 10-29-ish, but it was changing fast/seemingly randomly. I noted that S2 to ground is 124VAC and S3 to ground is 123.6-7VAC - not sure if that is normal or not.

While I am sure at this stage I need a new LEV coil and a new inverter board, I wanted to know if a shorted/open circuit LEV coil was a likely cause for the initial board failure or if there is something else I can check prior to attempting a repair again. We had not had any bad weather near the time of failure and I do have a surge suppressor installed as well.

Thanks for any suggestions as to things to check prior to attempting repair again. I'd prefer to not waste another $500 in parts if at all possible. . .

Best Regards,

Sandy.

Comments

-

-

How good are your soldering skills? do you still have the old board? is the same component damaged on it? What plugs into cn72? If you put back the old board does it give the same error codes?

Sometimes when coils burn they short through to the chassis which pops other parts. Make sure to measure resistance also to ground on all the bits. Anything with resistance to ground is generally dead even though terminal to terminal is fine.

0 -

The old board has similar damage to the chip, but my soldering skills and equipment aren't up for SMD components for sure.

CN724 is the LEV coil connector. Per your recommendation, I checked the 6 wires to ground and 3 measured 30, 55 and 59 ohm, while the other 3 were 1.5k, open and 50+MOhm. I assume they should all be in the open/many MOhm range.

I will put the original board back in tomorrow and see if there is any difference in the error code. All I remember is that the on-board LED was not flashing at all, but it will only take a few minutes to re-verify my memory and see if the code is the same.

Thanks for the suggestion on measuring the coil to ground. That makes me understand a little better how it might have caused a board to fry, as I was having trouble wrapping my mind around a board failing due to the coils being open, but if they failed to ground instead of pin to pin, that would make more sense to me.

Sandy.

0 -

Looks like the LEV uses a stepper motor. If a winding is compromised to an adjacent winding, to ground or also what is called a one turn short it could damage the Stepper Motor's Driver I.C. One turn shorts are hard to detect with an Ohmmeter since it may not change the winding's overall resistance much. The power supply voltage to the Driver I.C. may have been too high due to another defect.

The result of the damaged Driver I.C. may be causing the single flash at the outdoor unit.

Check that the wires to the LEV are not chafed or crushed and/or otherwise compromised to ground or to each other.

Seems the 7 flashes is due to the inside unit can't detect the presence of the outdoor unit.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

If you knew the Chip number and someone that can do surface mount rework, the chip is probably inexpensive and about a 10 minute or less job to change.

An example I.C. that is under $5 in single quantities.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I put the old board back in and there was no LED activity at all on the outdoor board. The inside unit displayed 2 solid green lights and the fan ran on full. This is the same thing it does if S3 is completely disconnected.

I checked S2 to S3 and it was a constant 1.4 DCV, whereas the 2nd board was varying the DC voltage and giving the 7 flashes on the indoor unit and 1 second flash on the outdoor unit.

I pulled that board again and replaced the one other blown component (1000uf capacitor C884) and retested with the exact same results - no outdoor LED, both lights on and fan on with indoor unit.

So, the 2 boards appear to be broken in different ways, at least. . .

I was unable to read the chip data on either board for IC854.

Looking closer at the traces, about half of the traces do go to CN724, so that chip is part of the LEV control for sure.

The wiring for the LEV itself look fine, but the open circuit measurements between phases of the coil, plus the lower resistance values to ground on a few mean that component is definitely defective.

I appreciate any other thoughts on what/how to troubleshoot the remainder of the system.

Sandy.

0 -

The stepper driver looks to be connected directo to the main processor. There is a good chance when it blew, it took the uP with it. Unfortunately, you'll need another board.

Since it looks like the LEV coil was the culprit, there is a good chance that it will work with a new board.

0 -

I'm no expert with the mini splits but i know that with some of the Mitsubishi's the condenser motor causes the damage to the main board. The last unit i worked on i replaced the control board and it fried again. i only changed it without consulting Mitsubishi due to the 4 hour wait time for tech support (it was like 95 degrees out and a heat wave around the country). Bad idea. when I did finally get tech support they said that you need to change both the condenser motor and control board together or else they won't guarantee the new board. needless to say that I was pissed because that's a terrible design. how would one really put that together without some serious time spent on the unit control strategy. I can't say this is the problem but i had this more than once.

1 -

Well with the limited data available, one possible chain of events is C884 failed on the original board, this made the voltage unstable with the low voltage power supply (DC-DC converter T801 / IC802 etc.). This then caused damage to the LEV stepper motor, which then took out the Stepper Motor driver I.C. Since the LEV stepper motor defect was not discovered that took out the Stepper Motor driver I.C. on the replacement board.

It could have just as easily been one minor defect with the LEV stepper motor caused excessive current draw through the DC-DC converter T801 / IC802 etc. but not enough to blow F801, C884 overheated and failed, ultimately leading to more damage to the stepper motor and the stepper motor driver I.C. failure.

Since I am curious, I would check all the fuses on both boards. The board that does not flash any error codes probably has a blown fuse or the DC-DC converter is overloaded due to the condition of the Stepper Motor driver I.C. An overloaded switching converter often won't fully start, it just sits there and hiccups, never achieving a normal start up.

I would expect replacing the board and the LEV would restore normal operation, but something else may be unknown.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Thanks for the continued comments and suggestions. If nothing else, I am learning which will take a little sting off the parts bill.

Part of me was wondering if the LEV coil was having an intermittent issue due to corrosion etc. Not really sure what would cause the coils to fail, but maybe the symptoms I saw before failure (indoor unit not blowing very cold, but after turning the unit off a while it worked fine) is a clue. Possibly turning the unit off and letting it sit then restarting reset the LEV and it was semi-functional for a while, even though it was in the process of failing. Just guessing for sure.

Since there's not much else to lose at this point, if it sounds interesting, I can try to desolder the defective stepper driver chip after verifying all fuses are still good again. Not sure if that would remove some short or something and if that would make the two boards be in a similar failed state or not. At this stage, I'm game for learning anything I can.

I'll go ahead and try to find a good source for a new LEV coil and board. The place i got the last board from last time does not carry the LEV coil.

Thanks again for the continued help!

Sandy.

0 -

You mentioned " I can try to desolder the defective stepper driver chip " just so you know some of those chips are soldered to the board on the underside too, for heatsinking. Hard to remove with conventional soldering equipment without causing damage.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

I was able to get the new LEV coil and board installed and after double checking everything, it fired right up.

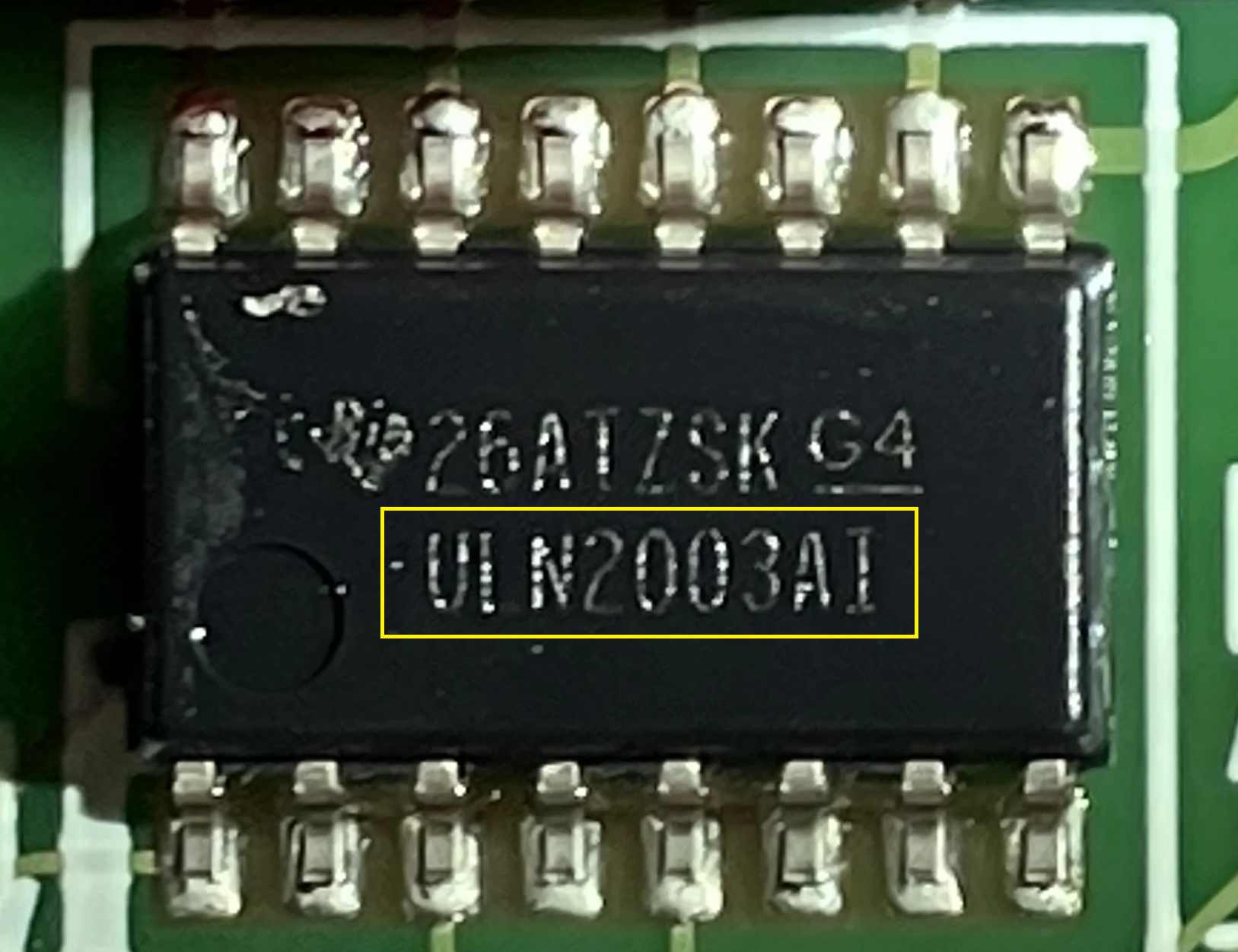

Thank you all for your help. I went ahead and took pictures of the chips in that area of the board in case it is helpful for anyone's future reference. Also, if anybody in the thread wants the old boards to work with for some reason (I assume the inverter section parts are still good), I'd be glad to ship them to you for the cost of postage.

Thanks again for the help!

Sandy.

0 -

Looks like this chip is a ULN2003, a 50V 7-ch darlington transistor array, nothing very special there.

An Op-Amp

Not sure about the 100 legged Chip. If it is bad and it has embedded code, probably not worth the effort.

Glad to hear you are up and running !!!

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements