Fixing the gurgling at the end of my Steam Mains

I've made a lot of improvements to my steam heating since moving into this house 8 years ago. Couldn't have done any of it without this wall….so THANKS!!!! Hopefully this is the last thing that needs to be looked at…for a while anyways.

It's two pipe steam. Vapor type system. I had a new boiler (SteamMax) put in two years ago as the old one was leaking. The system doesn't build pressure since the new boiler went in. I've had it go for long runs (45+ min) without the pressure going over a few ounces. All the radiators get heat. I have a vaporstat set to 10 oz cutout but I don't think it ever trips with the exception of when I've needed to skim it after the install.

The only problem is that I get a lot of gurgling, bubbling sounds at the far end of the house from the boiler. It happens on a cold start and goes away within a few minutes of the radiators getting hot. I hear it in both the basement as well as from the radiators on first and second floors. It's something I can live with but if I can fix it I will. Other radiators in the house are pretty quiet. Not totally silent, but quiet.

Two section of mains come from the boiler. These each run one side of the perimeter of the basement and meet up again at the other end of the house. The picture below shows where they meet up, transition to copper and drop to the ground (it's hard to see the copper line drop in the picture. It goes straight down after the 45). The two lines drop independently, join well below the water line and the wet return runs back to the boiler. The mains are long (one goes 60 feet. The other 90 feet) and run flat along with basement ceiling without any pitch.

I had someone from the company which put in the boiler come look at the situation. He ID'd the reduction circled in red as trapping water. The noises are coming from radiators which are fed just prior to this spot so it makes perfect sense (and it's something you guys already helped me learn about on previous posts). He did not think that the other main had the same 'trapping water' issue, though there are similar reductions in the piping (circled green). There is an additional reducing bushing on this line a bit further back outside of the picture. This area of piping leading to the green circle has some pitch to it and radiators on this line do not seem to be making noise, so maybe it should be left alone.

The pro who was here today recommended something in addition to correcting the reducing bushing. This is really where I need your help. He wants to put 'bucket traps' on both drops to the wet returns - around the positions I put the blue squares. I am guessing a bit as to where exactly he wants to put them but definitely on the vertical drop above the waterline. He thinks the steam is 'getting down into the return' and 'messing with the waterline' if I understood him correctly. Bucket traps are new to me….so help me out. Thoughts?

Comments

-

Hello trivetman,

This makes no sense " I have a vaporstat set to 10 oz cutout but I don't think it ever trips with the exception of when I've needed to skim it after the install. " why are you building any pressure when skimming ?

I'd get the mains to drain correctly first and correct any other pitch issues as best as possible.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

@109A_5 - thanks for the feedback. After the boiler was first installed and skimmed, the vaporstat started cutting out after only a few minutes of steaming. After skimming again, the pressure buildup stopped happening. I went through a number cycles of this happening over the first few months of operation. After 4 or 5 skims the system was cleaned up and I don’t think the vstat has cut out since.

I won’t say I fully understand why the pressure built so quickly early on but it did.

Anyways, what I am really after is info on these bucket traps my guy wants to put on. Sounds like you don’t think its the right move, at least not now.

The arrow you put asking about a size change…..There is not a size change there. However, there is a size change on that main 6 to 8 feet prior to your arrow (outside of the picture). But the noises I am hearing are not coming from that main. The noise is definitely from the main with the ‘red circle’0 -

OK so the pressure build up was not during actual skimming event. During steaming there was probably some surging going on due to the manufacturing oils.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

yes exactly

0 -

What does the Pro think the bucket traps are going to fix ? Presently I don't see any benefit.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

That’s kinda why I am on the wall asking. He thought the steam was going down ‘towards the waterline’ and stirring things up. He wanted to prevent the steam from going down towards the wet return.

Im having a hard time seeing what the traps would do as well.

0 -

@trivetman , if those drips go to a wet return, the traps are not needed. The standing water in the wet return will keep steam from entering the drips. Traps there might cause banging, because they change the "A" dimension to a "B" dimension which will cause water to back up.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

" The only problem is that I get a lot of gurgling, bubbling sounds at the far end of the house from the boiler. It happens on a cold start and goes away within a few minutes of the radiators getting hot. "

From a cold start, if there is some trapped water in various parts of the system the moving air trying to get out of the system through the vents may bubble through and/or push the puddled water around and along. Once the main vents close that flow is dramatically diminished and is mostly just condensate flow (not much sound).

The majority of the steam then goes to the radiators and condenses, the condensate then fills up the low points again and waits for the next cycle. Correct the poor piping techniques (lack of an Eccentric Reducer or other appropriate technique) and add pitch if possible.

You said it is a two pipe system, the condensate end of each radiators drops down to the wet return ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

@109A_5 - yes it is two pipe. The returns from radiators feeds into dry returns which ties back to the boiler at the hartford loop. They do not meet with the wet returns at the far end of the basement in the picture.

@Steamhead - thanks. I am trying to sort out if putting these traps on is a ‘might help and won’t hurt’ move, or if its a ‘might cause more problems’ move. Your comments make me think its the latter, which I had been afraid of.

I might have to do this myself next spring after the cold. Trying to convince a pro to fix it ‘my way’ often doesn’t go well…..

1 -

I like a little hisssing and gurgling. It lets me know the house is alive.

0 -

Always looking on the bright side….

0 -

If those drips go below the water line, traps on those lines are a "won't help and WILL hurt: item. Don't do it. Don't let anyone else do it.

The gurgling you hear is, as has been said, almost certainly condensate trapped in low areas on the piping. The guys have pointed out some locations which are suspect.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

If I do this myself, I think it seems easier to do using eccentric couplings rather than run 2" iron the whole way until turning vertical.

Is there an online retail place which is good to get the eccentric couplings? They don't seem to be at supplyhouse which is my usual go-to.

0 -

-

I would just cut the copper remove the present iron reducing bushings put in a 2" nipple and a reducing ell pointing down then rework the copper a few inches lower so it drains correctly. You may want to extend the 2" a bit so the vents are not so close to the end. I would replace the horizontal copper in the picture with a 2" nipple.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System3 -

@109A_5

Ive been thinking about this project and definitely plan to dig into it over the summer. Extended the 2” pipe out from the red circle and then turning down and transitioning to copper makes perfect sense.

a couple questions.

1. Can the transition be directly from iron to copper with a threaded fitting? Do I need to use a brass fitting for the transition?2. The vents above the red circle don’t have a lot of height from the main. Is there a better placement for them? There is no place nearby where I have more height to extend them. I could run them out further horizontally. Would that be helpful or not worth the trouble. There is some evidence they spit a small amount of dirty water but they have been venting no problem for 7 years since I put the current arrangement up there. Also, redoing the turndown should give them less of a water supply to spit in the current arrangement.

ill be extending the other set of vents (green circle) up as well but that main has downward pitch at the end giving me room to extend them up a few inches.

0 -

Sound like you have a plan.

Having a male copper into a female black pipe seems to hold up well, like your is, I'm not actually sure what code is in this situation.

Once you get the main extended and draining properly that should further reduce any spitting from the vents, I would just see how it goes. The 4 vents have a lot of 90 degree bends to get to them, so it may be fine.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Reviving this old thread as the repjping is under way!!

i got the fittings off where the piping reductions were this morning with the help of my musclebound nephew and his big blowtorch.heres what the inside of one of the pipes looked like opened up. I scraped out as much of the gunk as I could but probably wasn’t very effective more than 8 inches or so into the pipe. Who knows how far back the gunk goes. Is there any great way to clean this out deeper before repiping and sealing it all in?

0 -

Maybe flush water through it (if possible) and use a small hand snake.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

After you get all the crud out that is possible and assuming that both returns drop into a wet return pipe before rising up into the Hartford Loop return, you could:

Add a valve to isolate the wet return from the boiler and add a full size drain valve to the lowest point on the wet return.

Then run the boiler in the "no return" mode. This is shutting the valve to prevent any return going into the boiler. Open the new drain valve to waste the return water down a drain. You will have to monitor the water level in the boiler as you do this.

The wet return at the boiler also performs as a "P" trap and is where any crud from the return lines will collect. Your "no return" mode will flush the returns.

If you go to the "Silent Steam" U-tubes by Gordo S. you will see that they often do that with a new boiler install.

After some operation, just draining the wet returns with the drain valve will remove more debris before it gets into the boiler.

Also remove the handle from the valve that isolates the returns from the boiler when finished with the no return operation.

1 -

thanks.

i was wondering if there was a tool designed for the purpose. Guess not. Ive got a stiff hose i think i can snake in to flush it out. That and a length of 1/2” copper pipe to scrape it loose will hopefully do the trick.

Thats a good idea to run it to flush but the valve i would be flushing from is just a boiler drain - not full port. Will the gunk likely get cought in the drain opening and plug it up?0 -

The drain port needs to be on the lowest point of the wet return piping to keep the crud out of the boiler.

If you rely on the boiler drain itself then the crud will settle into the bottom of the boiler and not get out, especially with a small drain tap.

Check out the U tube by Gordo.

0 -

Yep ive got you. The drain is on the bittom of wet return and I do have a valve isolating wet return from boiler. But the drain is not full port. Its a standard boiler/silcock drain on the bottom of the wet return

0 -

The full port isolation and drain valve goes at the low point of the wet return just before the Hartford loop, you don't want to push the debris into the boiler during flushing. As @JUGHNE stated, it may make more sense it you watch some of the Youtube ''Silent Steam Team" boiler install videos where @Gordo explains the wet return flush setup.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

OK, I'd add a full port valve or change the existing one. You have to add the boiler isolation valve anyway.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

As far as a scraper, I'd probably start with a piece of 1/4" or 5/16" all thread (3 foot long) an make a half circle scraper out of metal or heavy plastic and double nut it on the end of the all thread, The all thread can be extended if needed. The flush hose may fit over the top of the half circle scraper.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

ive got an isolation valve on the return already.

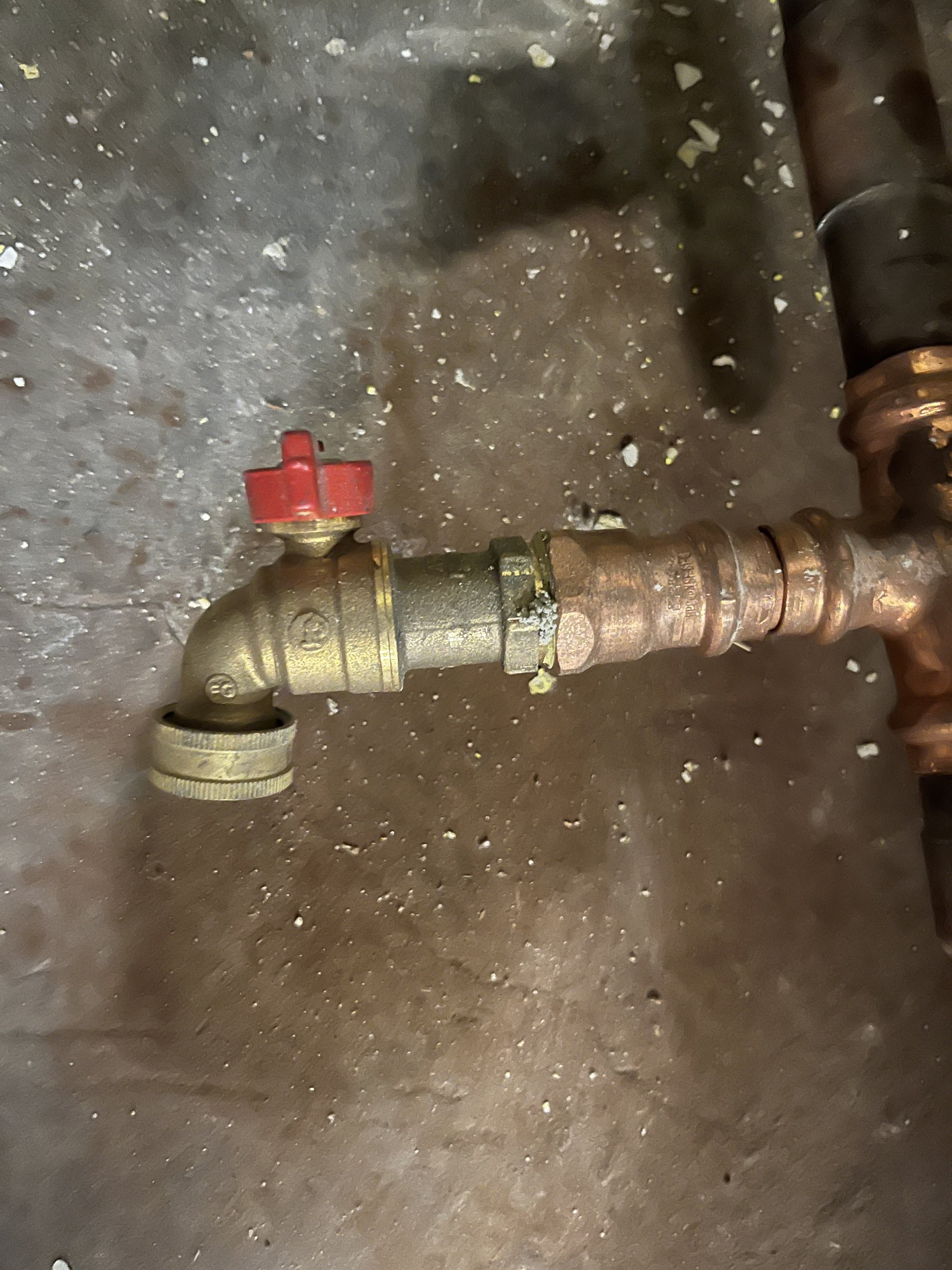

heres my two options to drain from on the wet return. they’re both 3/4 and I don’t think eother is full port. I am hoping not to have to replace either valve if I can avoid it. The red handle is near the boiler, and has 60 feet of wet return between it and where the main is currently opened up. The blue handle is right below where the main is opened up, but I think its probably a more restrictive valve.

best option?0 -

Yeah, I'd probably use what you have, certainly better than not doing it at all. Full port valves just give better flow, in your case you could just let it run longer, if needed.

They Both look easy to change (threaded) if you wanted to. The Red handled drain valve is probably a ball valve, may not be full port.

You could flush from Blue to Red then the other way too.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

-

I think we've all done that sort of thing at least once…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

i just did it twice! One for each open pipe!

0 -

Oops, one problem solved, made another, S#it happens. Quick 'pressure washer' the evidence away, No Don't, it will probably make a bigger mess.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

there one side almost done. Copper is dry-fit. Not yet soldered.

Other side waits till fridayPipe is heavy.

0 -

I like it, it should drain good. Maybe the only thing I would have done differently is put the vents in a place with better access. Maybe it is not as awkward to get to them as the pictures look to me.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

thanks. I hear you about the vents but theres no good place for them. Ive got them pitched right now (they weren’t before) so hopefully its years before I have to get to them again!

I was kinda shocked I put it all together and it actually lined up perfectly with the copper. Hopefully I have as good of luck with the other side

0 -

I was thinking something like this. But maybe it looks better from here.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

-

Let us know what happens when you run the boiler.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

yep will do. Thatll be sunday after my nephew comes and solders the copper. Ive never done anything over 3/4 and he knows what hes doing with it so Im gonna let him show off

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements