OWB retrofit to abandoned hydronic baseboard system

I bought a house in central Virginia a year ago. 1900's farm house. ~3000 sqft, two stories, stick-built, been decently renovated over the decades (new windows, siding, HVAC etc). Currently heats with a dual-fuel heat pump that was installed in 2015-ish. Ate us up with electric and propane costs over last winter; about $5k over the 5 months we heated. Really untenable.

In the basement there is still a propane boiler that was disconnected and abandoned that was hooked to a baseboard radiator system throughout the house. I am unsure of the date or reason for disconnection. Two zones (up/down), pump, valves, etc is all still intact...and in fact, the radiators are still holding pressure on the gauge on the boiler.

I am installing an outdoor wood boiler with the desire to tie-into the baseboard radiator system. Here is where I have struggled to find competent local knowledge on the best way to do this.

My idea is to have closed loops from the boiler and baseboard systems exchange through an appropriately sized plate exchanger (I was told a 5x12 70 plate would fit my needs).

My questions are as follows:

Is this system the best way to tap into my existing baseboard radiators?

In my case, is it really as simple as installing the exchanger and replacing the pumps/thermostats valves etc?

Do I need a "buffer" tank on the radiator side of the exchanger to help with heat speed and fuel consumption?

What other misc items would you include in a system like this to really make the most efficient and reliable system? (The existing old pump is a B&G NRF-22—should I make use of the deltaT new pumps Taco has?).

One last comment, I want to say that forums like this are such an incredible resource but unfortunately becoming less and less common as tech companies find ways to monetize our data. Thank you for being part of keeping "the old internet" alive!

Comments

-

I would pressure test the baseboards first to be sure you have a workable system.

Most OWF have enough fluid capacity to not need a buffer.

Yes a plate HX is the best way to separate the open and closed loop systems.

Spend the $$ on a good insulated piping system. It needs to be 100% water tight.

How many feet of baseboard? That will tell you the amount of BTU you need to size pumps, piping, etc.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot_rod , who knows as much about these things as the rest of us combined, has got it on the heating and house side of the equation.

The wood boiler, however, is another matter. Be sure and get really competent advice on setting up and plumbing the specific boiler you pick. At the very least, for a wood boiler you need a dump zone for when (not if) it runs away on you, and — in my view at least — that needs to be arranged in some manner so that it is operational in the event of a power failure.

Another point is that it won't save you overall on BTUs. The house doesn't care where the heat comes from! So do some figuring to find out how much wood you are going to need — and where you are going to get good quality hardwood firewood, seasoned at least two years. Figure on about 24 million BTU for a cord of hardwood. You can look at your bills from last year to estimate how many BTUs — and thus cords — you need per year (for reference, a cord of wood is more or less equivalent to 170 gallons of fuel oil or 270 gallons of propane).

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

on a good day the basic OWF run about 40% efficient. The gasification units are much higher. So they eat a lot of wood , and can smolder when the heat load drops

If it is an unpressurized type they just boil over as their over heat protection😉

You will learn how to load it based on weather conditions

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Assuming this will be an unpressurized name brand OWB, you will not need any sort of buffer nor a dump zone. All factory built OWB have ample onboard storage, and IF (not when) they "run away", they simply boil over and that's that. Cut into the return pipe to the gas boiler and insert plate exchanger (size may vary based on actual BTU and temp requirements, but a 70 is almost certainly adequate) there to preheat the return water before it enters the gas boiler. Run the OWB loop 24/7 and everything else inside can stay exactly as it is if you don't intend for the gas boiler to be a operational. If you do, you'll want an aquastat on the OWB supply line before the exchanger to kick the gas on when water temp falls below setpoint. As Hot Rod said, spend the money on good underground lines (NOT the drain tile wrapped junk) such as Thermopex, Rhinoflex, Insulpex, or Logstor. What model OWB would you be using and what is the distance from it to the heat exchanger's location?

1 -

Two piping options here. Both put the back up gas boiler as a parallel load. No flow goes thru it when the OWF runs, just directly from the OWF, through the HX, to the radiators.

Simple piping is fig 5 is the HX connected to the OWF, the boiler and load on the B side of the HX. In this arrangement the OWF pump runs all the time.

Option 2, fig 5.10 shows a shunt pump that flows some heat from the back up boiler to prevent the OWF from freezing if you are not around to fire it in freeing conditions. You have less heat loss to deal with also if the OWF pump doesn't need to run 24/7. But more complex piping and control wiring.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Something isn't adding up, do you have a duct sealing or similar issue causing you to lose a lot of heat from the building envelope? I bought a 6,500 square foot house in west-central Virginia (western Augusta County) in 2021 that's heated with four heat pumps and my utility is Dominion (10 cents/kWh in the winter) and my electric bill never went over $500 in a given month even during the crazy cold spell we had at Christmas a couple of years ago. Granted, this house was built in the early 2000s so it's pretty tight compared to a 1900s farmhouse, but not enough of a difference to account for the cost you're seeing, I wouldn't think.

Have you done a heat loss calculation for the home and do you know what the point where your system switches to propane is? My hypothesis is that you have unaccounted for heat loss and something strange with your LP cut-over threshold.

3 -

-

I apologize for the delay in getting back to ya'll…busy weekend.

I just measured (again to double check) the lf of baseboard in the house.

I have 64' on the downstairs loop and 56' on the upstairs loop. (So 120' total)

I also should have been explicit that the propane boiler is completely disconnected from any gas or electric lines and I have no desire to fiddle with the thing again to be honest. I would love to just utilize the lines and remove the boiler altogether. I did try to have a tech come out and pressure test the system but he just tapped the pressure gauge and said there's no need…

@GroundUp I bought 80' of thermopex ($15/ft 😬) but boiler will only sit about ~65' from house

@hot_rod I appreciate the diagrams I assume I can just get away with the same system minus the "aux boiler" as in option#1? Also, I have the heat pump as backup for weeks where we are away and traveling for extended time, but as you brought up, that doesn't solve my freezing OWB line issue…is there any reason I shouldn't use glycol on just the outdoor loop? The boiler I have on order has a 60gal capacity plus whats in the lines to the HX. I have heard glycol breaks down when heated, should I prepare to replace or boost it yearly if i go this route?

@leonz & @GroundUp I have landed on a Portage and Main "coal" shaker style boiler. It has a pretty unique firebox as the lower portion is firebrick (replaceable) and the boiler jacket is just at the top half of the fire box and around the double pass chimney. This video (https://www.youtube.com/watch?v=udibSDcUv2o&t=11s) is a pretty interesting comparison.

Here is my parts list so far:

4900 series Taco air separator

Caleffi DIRTMAG

5x12 70plate HX (https://altheatsupply.com/products/70-plate-water-to-water-heat-exchanger)

I'd think I'd like to use a deltaT pump like a Taco vt2218 but I am wondering what are the pros and cons of using a pump for each zone vs one pump and 2 zone valves (Taco Sentry etc). Does using a deltaT pump in the 2-zone valve configuration affect the performance or accuracy in any way?

@vtfarmer When I first moved to VA I was living in Deerfield…gotta be close to where you are :) I'm in Scottsville now. I do think there was some user error with the way we were controlling the heat in the house, which probably led to over-consumption of propane. We were given nothing from the previous owner regarding home systems or "this does that". so we have been figuring it out as we go…

0 -

no you don’t want to use glycol in an open system. It goes bad quickly when exposed to the air. Plus the overheat protection sometimes involves the fluid boiling over, you don’t want to put glycol through that either.

So either someone keeps a fire going when you are gone, you drain it, or have a method to keep the water moving. If you run the boiler pump to keep water moving when the fire is out, you don’t want to run the house pump🤔

To me a delta T pump operation is a limiting device, it allows the pump to operate at a constrained delta, even when the system prefers not to operate that way.

Hydronic heating systems are a dynamic system. They can, should change the heat delivery as the load changes. Big cold loads will drive a wide delta. As the space warms, the load lessens, the delta closes up. With 120 gallons or more fluid capacity, short cycling should not be an issue.

A delta p circ with zone valves is my preferred method.

A Caleffi DiscalDirtMag is another option, 3 functions in a single device.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Deerfield is indeed only about half an hour from me! I am outside of Churchville. User error may play a small factor, but given that I can keep this large house at 70 all winter using heat pumps with the cold winds up here in the hills and only spend an additional $100-300 per month on electricity makes me worry that something else is at play for you.

I will add that when I lived in southwestern Vermont before moving down here to VA I had a newer gassifying OWB and it ate 12-15 cords of split, dried wood per winter to heat a 2600 sq ft house plus 600 sq ft apartment built into the barn plus domestic HW. I felt pretty clever when I set it up, but I was happy to be rid of the burden of feeding it when I left!

1 -

I too would omit the delta T circ in favor of a delta P or even just a regular old 15-58 sized circ or two, pr just leave your existing equipment in place minus the boiler if you want it gone. Glycol is not a good idea for a system like this for the reasons HR mentioned above, and when it goes bad it becomes acidic very quickly which a P&M will NOT tolerate, being mild steel construction. If you plan to shut it down for an extended period of time during cold weather, draining it would probably be the best option but if you leave the OWB circ running, there will be some residual heat picked up from the house and sent back out to the OWB to prevent freezing. If you are buying factory direct, you will have NO support from Brian after the sale is made- this has been a very well documented problem with P&M. If you have a local dealer, please disregard the above. Being in VA, I might suggest giving Eldon Yoder a shout and taking a look at the Heatmaster C150 to compare to the P&M BL2534 you're looking at. They're much more refined than the Ultimizers, and built from 100% stainless. Plus Yoders have a great reputation for taking care of their customers unlike most Portage and Main dealers. If you're looking to get rid of the gas boiler, Bob's first drawing would be pretty close if you skipped the aux boiler portion and moved the circ & expansion tank to the supply side. Regardless of which OWB you choose, they need to have a lot of flow to stay happy so you're going to want something like a Grundfos 26-99 on the OWB circulating 24/7 through the HX, or a smaller 15-58 flowing through the HX and a second one just mixing the water jacket. The cabinets are a real pain in the butt for piping on the P&M as well, where the Heatmaster is wide open.

0 -

Avoid portage and main like the plague,

a Maertons coal stoker boiler is what you want for burning sub bit, bit coal and lignite, it will cost a little more for the freight but they have a good coal stoker based on the Iron Fireman design with a separate combustion air pipe system like the Iron Fireman coal stokers that were built in Spokane, Washington.

0 -

Thank you all for the help. I will post some pictures of the final install. I am going to go with @hot_rod recommendation of a DeltP circ with zone valves on my 2 zones.

Last questions (hopefully):

Do you have any recommendations on the brand of Delta P pump & size to replace the NRF22? Should I oversize a bit?

The two zone valves are shown in pic below (Honeywell v8043f1051)

Should I match brands with the circ pump? What would your recommended valve be here in my case?

Again, thank you—I'm a roofer so it has been very interesting to learn more about this trade.

0 -

I’m near Staunton and I specialize in Hydronics including outdoor wood boilers.

P/M me if you want help.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

What brand of forest eater did you buy?????????????

0 -

I like the Grundfos Alpha circulators. All brands have similar styles, Taco, Wilo, B&G, Aquamotion.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The existing abandoned boiler is plumbed as seen in the attached picture

as I am removing the boiler and using a plate Hx as a heat source should I utilize the same orientation of expansion tank/air scrubber and circ pump etc. (please note, it’s hard to see but beyond the expansion tank are two horizontal legs with attached zone valves for upstairs and downstairs.)

This current orientation is not as described in the boiler manual:Regardless, since I am using a brazed plate hx should my orientation be the same as what’s existing regarding locations of each “device” on supply/return?

0 -

you don’t want to keep that boiler for backup or freeze protection for the OWF?

Pipe like this for the HX, with or without the second boiler

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

here’s my update and a few more questions.

attached are pictures of my setup. I tried to follow the guidance and diagrams shared here, but if there is anything that jumps out as incorrect or poorly done please advise. I know my “tie-in” is a bit redneck😆.

I am struggling mightily against air intrusion.

outdoor wood boiler is doing great bringing in 180 degree water to hx. My gauges are reading 170 in and 150 out of the baseboard system.

i have read a lot of other posts regarding air purging, baseboard gurgling and the like. I don’t think I have a leak in the old baseboard system as I have cut off baseboard fill for hours and never saw a drop in pressure. AND I wriggled my way under this 150yr old house following all the supply and return pipes I could see and never saw a drop of moisture.For now I have the upstairs zone valve and manual valves on supply and return closed focusing on the downstairs zone. I have purged the downstairs several times. But the air eventually comes back to the point where my Alpha 15-58 tells me there is -.02gpm flow…

https://us.v-cdn.net/5021738/uploads/IOZ2GB3QEYTV/img-0998.jpeg

what are my options? So far I’ve done everything myself with y’all’s advice. Should I call a true hydronic specialist that can purge cart this?0 -

do you ever hear air hissing out if that air separator ? Are you sure it is not closed off?

The system should purge completely within hours, no more than overnight

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Never. I have even run it for an hour or so with air valve closed a few times and there is rarely ever even a pop of air when I open it manually…let alone a hiss.

now the bleeder on top of the Avey MagnaClean I can consistently get air out of. And I hear it tickling and gurgling through the small DWH Hx right above it.

One thing to note is that I have a T right before the downstairs zone return “manifold” and it has valves to shut off each side. I know very little about the routing and design of the baseboard pipes themselves; but I am learning more everyday! This last purge I closed one at a time to see if maybe there was air trapped in the “parallel” loops within the downstairs zone. One side was simple to purge but the other never relented in the amount of air being forced through the pipe and out the drain. This was even with the fast fill, pump running at 38w and 170deg water.

I have the downstairs zone running tonight with just the one return T valve open that I was about to purge. We will see if it makes a difference in the morning.0 -

I believe I got the air purged. No more gurgling or tinkling.

However I’m extremely unhappy with the system.

Both zones have been running wide open for over 36hrs now. Thermostat set to 68 and have never clicked off. House barely hovers around 64. My wife is thoroughly disappointed.

I was always told hydronic baseboard were the tops when it came to heat. This is a let down, especially in light of the time, money and effort I have invested.

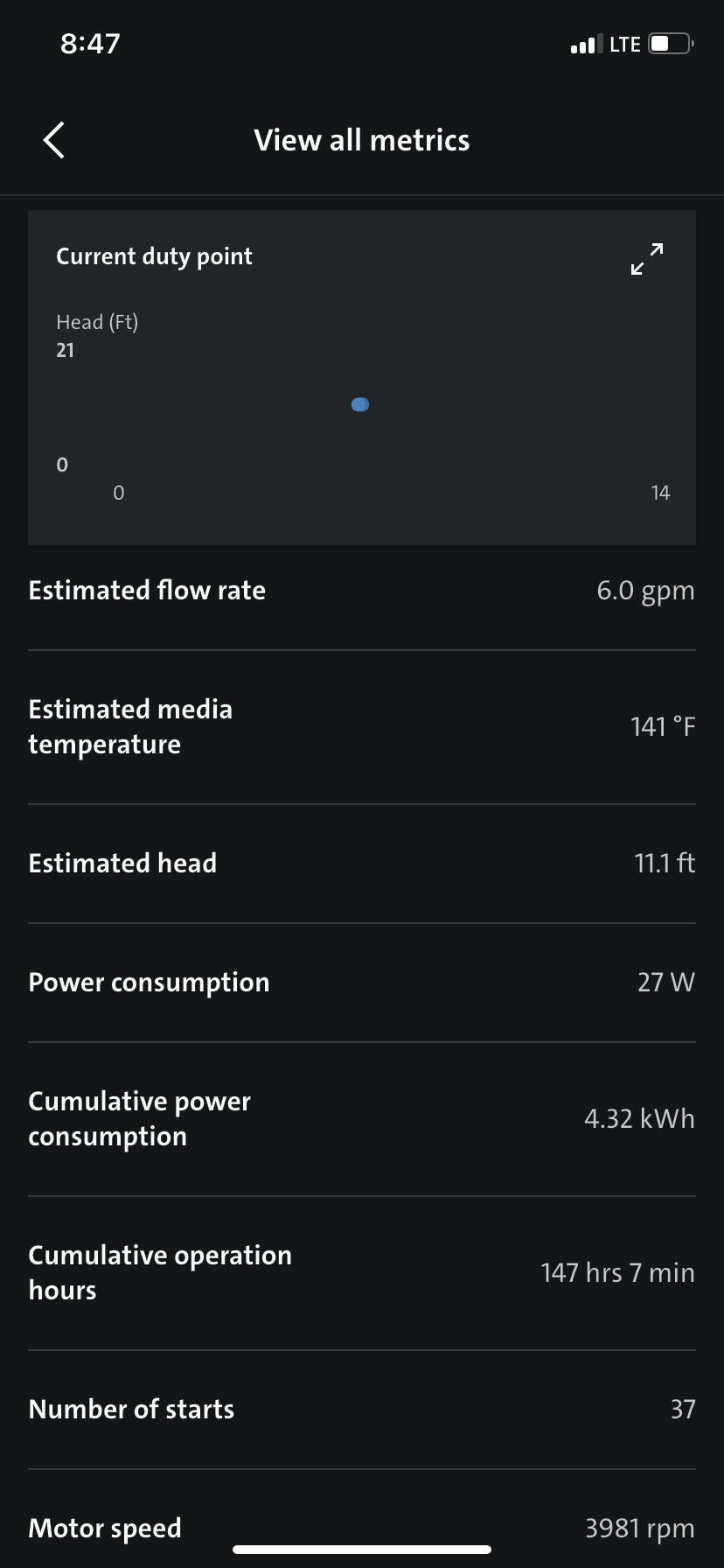

Here are the stats from the alpha pump:Supply temps are at 170 so we are consistently hovering close to a 20 degree delta with both zones wide open for the last 36 hrs.

Do I have any options? I’m honestly thinking about piping in another zone valve to run a plenum heat exchanger for my forced air. At least I know that got the house warm.0 -

At 4.6 GPM and 20F delta you get 46,000 BTU/hr. Depending on water temperature baseboard can put out about 500-600 BTU/hr per foot, so that's what you would expect from about 90 feet of baseboard. If that's about what you have, I'd say the system is working as designed, it's just undersized for the house.

Which would explain why it might have been abandoned.

0 -

64’ downstairs and 56’ upstairs. So 120’ total.

I do know we have insulation problems which I am working to fix. But the baseboards are just lukewarm and I have to think they should be working better. Again, seriously frustrated that 4 months of work and $15k later my wife just asked if we could turn it off and turn back on the heat pump.

Would adding more emitters in select locations around the house ameliorate the issue? Are hydronic radiators better than slantfin baseboard?

I’m obviously desperate and defeated at this point.0 -

I'm not a heating pro, just a homeowner/mechanical engineer. I maintain a 100-year-old 4-unit condo building that I live in near Boston.

We have the original cast iron radiators and piping that the house was built with 100 years ago. With one cast iron radiator per room, we can heat this 4800 sq ft building with 110 or 120-degree water. That gives you an idea of how much radiation was typically installed in early-1900's houses like yours.

So your house probably had similar cast iron radiators. Unfortunately, it sounds like someone unwisely ripped out all the cast iron radiators which would have heated your house quite nicely, and replaced them with an inadequate linear footage of baseboard.

Let's take a look and compare. You say you have 120 ft of baseboard, which in the best case with very hot water will give you 600 BTU/ft, or 72,000 BTU/hr. That might be just enough to heat your drafty old house, or it might not. A tight house of your vintage might need around 20 BTU/hr/sq ft, or 20 x 3000 = 60,000 BTU/hr. But if your house is leaky (probable), you might need 30 BTU/hr/sq ft, or 90,000 BTU/hr. Now your 72,000 BTU/hr radiation is inadequate.

In our condo building, our original cast iron radiators give us around 1000 sq ft total EDR (equivalent direct radiation). Our building is quite tight for a 100-year-old house, so we lose only about 15 BTU/hr/sq ft on a zero-degree design day, meaning we need only 15 x 4800 = 72,000 BTU/hr from our radiators. According to the charts, 1000 sq ft EDR needs only about 130 degree water temperature for that BTU output. And in practice, the required water temperature is actually much less (I still haven't figured out why). In reality, we could heat this place with 110-120 degree water very easily.

So unfortunately, whoever tore out your old cast iron radiators probably left you with marginally inadequate radiation. My non-professional preference would be to take the last step in your renovation and go back to cast iron radiators, which will make a massive increase in the heat output of your heating system. Yes, it will cost, but you've already sunk a great deal of $$ into the existing system, and you only need one more step to make it work properly.

But if you already have forced air ducts and can run another zone to a heat exchanger for the forced air, that might be the cheapest solution.

0 -

I agree with @jesmed1. You're under radiated. So this isn't the end of the world. Go ahead and use the heat pumps for the remainder of the season and plan on how to add radiation. Find some classy old cast iron rads.

Miss Hall's School service mechanic, greenhouse manager, teacher, dog walker and designated driver

0 -

The problem is not under-radiation (ie, not enough radiators). Or at least the immediate problem is.

What is the BTU rating on the boiler?

0 -

You said on Feb 11 that the system had been running non-stop for 36 hours, and the house temp only reached 64.

In central VA (Roanoke), weather records show a constant outside air temp of 30 degrees for the 11th. (Temp was higher the previous day, which makes your numbers look even worse. But we'll give your system the benefit of the doubt for the moment.)

Then your inside delta T was 64-30=34 degrees. And you got that from 46,000 BTU/hr as @DCContrarian showed above.

99% heating design temp for Roanoke is 7 degrees. That's a delta T of 68 - 7 = 61 degrees.

Ratio of the delta T's is 61/34 = 1.8

That means on a design day, you will need 1.8 x 46,000 BTU/hr = 82,800 BTU/hr.

But 120 feet of baseboard radiating at 600 BTU/ft gives you only 72,000 BTU/hr at best. Using a more reasonable 500 BTU/ft gives you only 60,000 BTU/hr radiation.

So your radiation still appears marginal.

As a sanity check, 82,800 BTU/hr / 3000 sq ft = 28 BTU/hr/sq ft design heat loss. That is within the expected range for an old house in your area. Fairly leaky.

These numbers depend to a large extent on the actual outdoor air temperature you had while the boiler was running non-stop and the house was staying at 64. If outdoor air temp was higher than 30 during that time (avg temp the previous day 2/10 was above 40), you had even less of a delta T, and you'll need even more BTU's for design day.

1 -

Have you clean out the dirt separator ever. It could be a lack of flow issue

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot_rod flushed the dirtmagPRO twice and this is second cleaning of the MagnaClean magnet I just pulled:

Here are update stats from Alpha pump after constant running for ~24 hrs. Return temp is a bit lower than actual since I grabbed screenshot after I flushed Dirtmag and added cold makeup water- usually hovers around 150

warmer day today in Scottsville Va. house got up to 65-66. Flow gpm is faster than usual using autoadapt so maybe you are right HR.

here is the old boiler tag @DCContrarian :@jesmed1 thank you for your math and anecdotes! My plan for this weekend is to install a third zone to a plenum air exchanger. Hopefully that will warm my pregnant wife up and get me out of winter. Although next weekend here looks like a possibility of single digits.

should my project this summer be to find nice sized cast iron radiators and install in select “cold spots” in the house?

My input temps are 170 from hx and I am confident I can keep up with feeding the wood eater in the yard.

Really appreciate every single piece of input from everyone. I was very close to losing it for a minute there. I’m sure everyone has been there a time or two: juggling everything else in life and a failed project just nudges you over the edge.1 -

OK, to summarize:

You have a boiler capable of producing 107,000 BTU/hr.

You have radiators capable of putting out 72,000 BTU/hr.

Your actual measured heat output is 42,000 BTU/hr.

The heat is not getting to the radiators. I would try to solve that problem before changing anything else, adding more variable to the equation won't make it easier to solve. The output of the radiators is going to be entirely determined by two things, the entering water temperature and the water flow rate. You said earlier the radiators are only warm, not hot. That's your problem. It could be caused by the water not being hot enough, or the flow not being sufficient, or both.

Once you get the system working well, the most you're going to be get out of the system as currently configured is going to be 72,000 BTU/hr, the limit of the radiators. As @jesmed1 points out above, that may not be enough for the coldest days, but it's a lot more than the 42,000 BTU/hr you're getting now.

1 -

Can you bump up the wood boiler temperature a bit? Anything extra would help get more heat into the house.

the water to air heat exchanger should definitely help.

0 -

the pump is reading. 141 and 149. That is a low SWT for fin tube.

what temperature do you have at the first baseboard?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Where are you seeing those numbers?

At 6 gpm that's only 24,000 BTU/hr.

0 -

Agree with others that your first priority should be getting the baseboard to max output. You've already boosted the gpm by 30% (4.6 to 6.0) so that's good.

The air heat exchanger may be tempting because it's easy to plumb, but remember that you're then diverting those BTU's from the baseboard. You're limited by what you're getting out of the flat plate heat exchanger, and if that HX output is insufficient, diverting some of it to the air handler won't help. Given that you were extracting only 42,000 BTU/hr from the HX, unless you make the adjustments to roughly double that, you'll still be short of BTU's on design day.

So keep focus on improving flow rate and temps to baseboards.

Yes, I would start thinking about strategic spots to add cast iron rads. That's a good summer project.

0 -

The temperature in the circs that he is showing on the GO ap.

Those calculated gpm numbers are not always accurate. I have seen them off as much as 80%

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I'm only seeing the 141F. Where are you seeing the 149?

0 -

The post on Feb 11

Different head also, that is why I asked if there are several pumps involved?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

On Feb 7, he said he was getting 180 supply from the OWB, and 170 supply to the baseboard with 150 at the return, for a delta T of 20.

On his Feb 11 screenshot, the pump temp is showing 149, which seems consistent with his report of 150 coming out of the baseboard (the pump is on the return).

On his Feb 13 screenshot with the Dirtmag, the pump temp is showing 141, which he said was not representative because the screenshot was taken after removing/replacing the dirtmag and adding some cold makeup water. He said the return "usually hovers around 150."

So it seems his original report of 170 supply to the baseboard and 150 at the return is still representative of how the system is running.

Then the only question is what the "real" flow rate is. @hot_rod why are those gpm estimates so potentially inaccurate?

0 -

I see now, pump is on return. Flow is going through two HX always. Maybe 1” pex piping?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements