Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

Gas Boiler - Inadequate Heating - Seeking Feedback/Solution

Options

wgardner26

Member Posts: 9

in Gas Heating

Hello – As the weather is beginning to get cold in the northeast I realize that I need to finally address a heating problem that we lived with last winter and quickly forgot about as the weather improved. Unfortunately, just like any problem, it is not going to get better by itself. Hopefully, the experts on this site can provide me some guidance.

Problem - Our boiler cannot maintain the indoor temperature above 65F when the outdoor temperature is below the mid-20’s. When the temperature drops to the low-teens, the maximum indoor is in the 60F area. The boiler will nearly run continuously and the boiler output temp never seems to get up to 120F on these cold days, which then doesn’t offer much heat capacity for the baseboards, especially near the end of the loops. This is not a recent issue, the heating system has been inadequate over at least the last few years, but seems to be getting worse.

System overview

• Crown CXE-5 150K BTU “input”, circa 1997, Nat Gas, conventional open combustion, power exhaust via 3” pipe through foundation wall, combustion air from basement (not tightly sealed)

• Four zones, one circ pump

• The aquastat is set at 190 (hi), 10 (diff), no low limit. No ODR.

• Tech inspected recently and found no obvious issues – outdoor temp in upper 50s. No air in system.

• Serviced/cleaned/inspected last fall – no issues except replaced leaking relief valve

• Aquastat replaced two years ago due to failure

House

Two story colonial, unfinished walk out basement, 3800 SF, built in 1998, northern NJ. Two story entry/foyer. 2x4 construction. Medium air-tightness. Bought house in 2006.

Previous owners had large wood stove in FR – might have masked poor performance of heating system. Heat loss calc per Slant/fin app: ~100K BTU. Heavy use of gas fireplace makes heat loss estimate via gas use challenging (seen posters provide analysis using gas bill and degree days).

Zones

(1) indirect hot water (41 gal, Amtrol),

(2) 1st flr (105ft baseboard, 230ft loop), main living area (~2,100 SF)

(3) 2nd flr (63ft baseboard, 200ft loop), 3BR/2Bath

(4) 2nd flr (16ft baseboard, 110t loop) guest BR/laundry (doors typically shut w/ thermostat set at 62F).

Aside from my boiler potentially not operating property my thought is the first floor loop is too long. Includes 30ft of piping in unheated crawl space to supply family rm (350SF). 20ft baseboard. Floor and pipes are insulated. Three exterior walls, over 50% windows, 12ft ceiling, 8-40K BTU sealed gas fireplace.

Potential Solution – Replace boiler with high efficiency model. Add second zone to 1st floor or remove HW baseboard from family room and replace with electric (we primarily heat the FR with a sealed gas fireplace) – would remove 20ft baseboard and 70ft from overall loop. Concern is if we have the FR area on a separate zone, that zone will not run very often and the water in pipes will get very cold. Electronic heat option seems like a sub-optimal solution.

Once again, any insights/suggestions would be greatly appreciated before spending 10K on a new system. I received two quotes last year – neither performed a heat loss calc. If helpful, I can post pics of my system – not sure what items would be of interest.

Thank you.

Problem - Our boiler cannot maintain the indoor temperature above 65F when the outdoor temperature is below the mid-20’s. When the temperature drops to the low-teens, the maximum indoor is in the 60F area. The boiler will nearly run continuously and the boiler output temp never seems to get up to 120F on these cold days, which then doesn’t offer much heat capacity for the baseboards, especially near the end of the loops. This is not a recent issue, the heating system has been inadequate over at least the last few years, but seems to be getting worse.

System overview

• Crown CXE-5 150K BTU “input”, circa 1997, Nat Gas, conventional open combustion, power exhaust via 3” pipe through foundation wall, combustion air from basement (not tightly sealed)

• Four zones, one circ pump

• The aquastat is set at 190 (hi), 10 (diff), no low limit. No ODR.

• Tech inspected recently and found no obvious issues – outdoor temp in upper 50s. No air in system.

• Serviced/cleaned/inspected last fall – no issues except replaced leaking relief valve

• Aquastat replaced two years ago due to failure

House

Two story colonial, unfinished walk out basement, 3800 SF, built in 1998, northern NJ. Two story entry/foyer. 2x4 construction. Medium air-tightness. Bought house in 2006.

Previous owners had large wood stove in FR – might have masked poor performance of heating system. Heat loss calc per Slant/fin app: ~100K BTU. Heavy use of gas fireplace makes heat loss estimate via gas use challenging (seen posters provide analysis using gas bill and degree days).

Zones

(1) indirect hot water (41 gal, Amtrol),

(2) 1st flr (105ft baseboard, 230ft loop), main living area (~2,100 SF)

(3) 2nd flr (63ft baseboard, 200ft loop), 3BR/2Bath

(4) 2nd flr (16ft baseboard, 110t loop) guest BR/laundry (doors typically shut w/ thermostat set at 62F).

Aside from my boiler potentially not operating property my thought is the first floor loop is too long. Includes 30ft of piping in unheated crawl space to supply family rm (350SF). 20ft baseboard. Floor and pipes are insulated. Three exterior walls, over 50% windows, 12ft ceiling, 8-40K BTU sealed gas fireplace.

Potential Solution – Replace boiler with high efficiency model. Add second zone to 1st floor or remove HW baseboard from family room and replace with electric (we primarily heat the FR with a sealed gas fireplace) – would remove 20ft baseboard and 70ft from overall loop. Concern is if we have the FR area on a separate zone, that zone will not run very often and the water in pipes will get very cold. Electronic heat option seems like a sub-optimal solution.

Once again, any insights/suggestions would be greatly appreciated before spending 10K on a new system. I received two quotes last year – neither performed a heat loss calc. If helpful, I can post pics of my system – not sure what items would be of interest.

Thank you.

0

Comments

-

Something doesn't add up here. Your system and boiler should be able to heat your house just fine based upon your info.

3800 sq. ft. should require less than 95k btus at design temp. Your BBs are capable of emitting about 90k btus @ 170* AVERAGE SWT. Your boiler should have an output of about 120k btus and allowing for a piping loss of 15%, that would give you about 102k btus going to the BBs.

When you say you're only getting 120* SWT during cold weather, that definitely suggests something is wrong at the boiler.

I wouldn't replace any equipment until someone can properly diagnose what the problem is.

Can you post some pics of the boiler, it's near piping, and the controls?

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Try clocking the gas meter to see how much gas the boiler is really using. Make sure all the gas appliances except the boiler are turned off. On your gas meter you will find a 1/2 or 2 cu ft dial, you want to time how long it takes to use a certain amount of gas

This chart should help.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge3 -

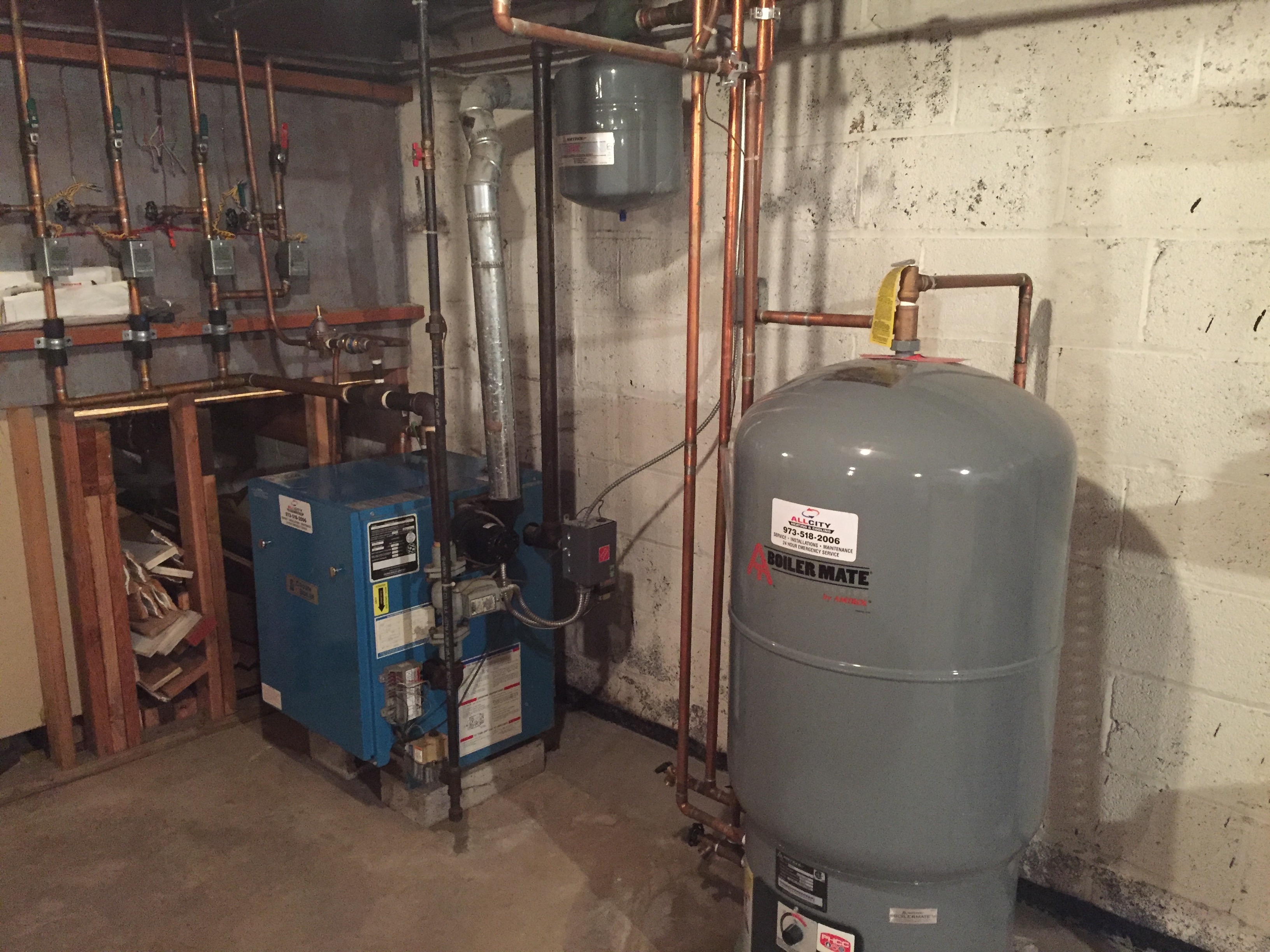

Thank you for the feedback. As requested, I have attached several pictures of my system. Please let me know if any other images would be helpful. With respect to the gas usage, I will need to wait for colder weather. It will be unusually warm in the northeast.

0 -

Ditto to @BobC. Turn off all other gas appliances. Turn thermostat all the way up. Click meter to see how much gas is being burnt. Should take less then two minutes0

-

It looks like the circulator is too small based upon the loop lengths and in the wrong place adding to the issues

"Zones

(1) indirect hot water (41 gal, Amtrol),

(2) 1st flr (105ft baseboard, 230ft loop), main living area (~2,100 SF)

(3) 2nd flr (63ft baseboard, 200ft loop), 3BR/2Bath

(4) 2nd flr (16ft baseboard, 110t loop) guest BR/laundry (doors typically shut w/ thermostat set at 62F)."

Based upon your info and the pics shown I am going to assume;

1. That you don't have a problem with hot water

2. The second floor zone (guest and laun) would heat fine.

3. The other bedrooms on the second floor would get warmer than 60 if none of the other zones are on.

Based upon some quick calcs, the first floor needs about 6 gpm and almost 19' of head. The head loss can be alot higher due to the pressure drop of the zone valves, just a guess at the Cv of the valve adding about 6' of head.

The 007 that is there can get you 6 gpm but only about 9' of head. So whats going to happen is the temperature drop will be large. Add in the other zones and at about 9gpm and 15' foot of head design-wise, we are under 8' of head. Also with the circ on the return pumping into the expansion tank hurts the performance.

So, several options:

1. need a bigger circ like a 0014 or a 0011(but will be noisy)

2. Split the first floor into two loops, can still be one zone but by splitting in half, the head loss will go down drastically. If you want to make it a new zone, go ahead.

3. Move the circ to pump away from the expansion tank. This is not a fix just a better practice if you are doing any of the above repairs.

Dave H

Dave Holdorf

Technical Training Manager - East

Taco, Inc

0 -

I did not crunch any numbers but that pump just "looks" too wimpy for the system.

The gas meter may clock correctly, you would have to open all zones to keep the boiler running before..................................

it possibly goes off on high limit, the vent inducer will probably keep running making one believe that the boiler is still on. This has fooled many people with hot air furnaces as the blower fan noise covers the fact that the burner is off on high limit for a few minutes until things cool off.0 -

The boiler will nearly run continuously and the boiler output temp never seems to get up to 120F on these cold days,

If the issue was lack of flow through the baseboards, I would expect the boiler to be frequently reaching the high limit setting. If it is running all of the time and never reaching the high limit, something is limiting the boiler output. I agree with the other guys - check the gas consumption.

0 -

You have to run the boiler for only a few minutes to clock the meter, it shouldn't heat your house up much at all even on a mild day.

You mentioned un-insulated crawl space, does that space have outside air vents thru foundation wall. Those are often overlooked in the winter and are quite a heat loss item.0 -

Thank you all very much for taking the time to provide feedback.

The result of the gas usage chart was 36 CF/ HR (50 sec rotation) with all zones active and no other gas appliances. Is this roughly equivalent to 36K BTU/HR (saw a conversion online)?

Yes, good hot water and heat to smallest heating zone.

The first floor zone splits off the same return as the hot water rather than having all four zones directly tied into the return manifold - is that correct? Picture included (1st flr zone is on the far right).

Circ pump is a TACO 007-F4.

Pic of temp/pressure gas included from test I just ran. Temp dropped quite a bit due to cold idle loops hitting the system.

Can back pressure adversely impact the heat output? I have included a picture of the boiler exhaust.

Thank you all once again.

0 -

Could you have been looking at the 2 cubic feet dial and not a 1/2 cubic dial.

If not then could there be LP orifices in the boiler or a real problem with NGas pressure.0 -

If you clocked the meter correctly, then yes, you're only inputting about 36k btu into the boiler.

Did the dial stop at all during clocking? If not, then the gas flow to the boiler is severely restricted. That could mean the line is too small or the pressure is too low.

If the dial stopped during clocking, then something is shutting the boiler off and your reading is invalid.

I agree with Dave that your probably under-pumped. But that's probably a secondary issue if your readings are correct.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Can you post a picture of the face of your meter, and tell us which dial you clocked?0

-

Meter pic below. Used the 1/2 FT dial - small red mark. Took several readings - all about 50 seconds.

If I have a gas flow problem then who would handle - HVAC tech or the gas company?

Thank you.

0 -

I'd say it's time to bring in a contractor that knows what he is doing. Do you see how easy it was for you to determine your problem? I suggest using the find a contractor feature here, but that is your choice. I would definitely get someone else looking at that boiler. Where are you located?0

-

Paul (and others - Bob, Dave and JUGHNE) - Thank you very much for sharing your knowledge. The techs who have visited never considered the gas usage. They basically said that although everything looked fine I probably needed a new boiler. I live the Morristown, NJ area.0

-

The techs not considering that are unqualified to be doing the work. @wgardner26 .....I am a homeowner, with a mechanical background. I am not an HVAC tech but the symptoms your system has are about as basic as it gets.0

-

I would start with the gas company, tell them you are not getting enough gas pressure to your house.....in essence you imply that your meter is not turning fast enough, which is actually true.

That should get you some response.

Is your meter right at the house?

You still need a contractor who would clock the meter just like you did, then check the gas pressure at the burners, after the gas valve.

Please let us know the results. Thank You. 0

0 -

When you clock the meter have all zones calling so the boiler does not shut off. Make sure all other appliances are off. Using the 1/2 foot dial let it make two complete rotations the seconds obtained can then be divided into 3600 (number of seconds in an hour) then multiply that number times 1025 (BTU heat content of a cubic foot of gas in your area) that will give you BTU's per hour which should match up to the required input on your rating plate on boiler.

Based on your findings then if under fired you need to contact a professional to check gas pressures inlet and outlet to the gas valve.

Meters by the way never run fast they actually slow down over time. That meter looks pretty old as it still has the number index instead of digital so have the local gas company check it and they should also be able to check the gas pressure.

It would still be a good idea to have a professional check you system.1 -

Gas company measured pressure at the boiler (before boiler cutoff valve) of 7 inches, which I was told is in spec for supply pressure. I suppose my next step is to have a tech verify the boiler gas cutoff valve is not clogged? Are the cutoff valves known to have problems? Thank you.0

-

Did they check the pressure at that point with the boiler running?0

-

My wife thinks the boiler was running, but not 100% certain.0

-

-

I had a problem a couple of years ago where the pressure was dropping below 4" WC at the input to the gas valve when the boiler ran. The gas company ended up replacing the gas main to the house, the old one was over 50 years old and full of rust.

It the 7"WC was with the furnace running it could be the gas valve or a gas orifice problem.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

I don't see that venting system as safe. The inducer on the boiler is to pull combustion air in, not exhaust the flue gases out the side wall. It might be legal to vent in stainless steel otherwise with our forced air furnaces, it needs double wall flue pipe to the wall and a wall mounted ventor to pull the flue gases out of the venting system and out of the basement. I just ordered one.

Could be possible that the pressure switch is cutting out so watching the flames or watching the gas meter for a while makes sense.0

Categories

- All Categories

- 87K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 57 Biomass

- 425 Carbon Monoxide Awareness

- 113 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.7K Gas Heating

- 106 Geothermal

- 160 Indoor-Air Quality

- 3.6K Oil Heating

- 70 Pipe Deterioration

- 981 Plumbing

- 6.3K Radiant Heating

- 388 Solar

- 15.4K Strictly Steam

- 3.4K Thermostats and Controls

- 54 Water Quality

- 44 Industry Classes

- 48 Job Opportunities

- 18 Recall Announcements