A lower main from another basement

Good morning, I am a Contractor trying to help friend of mine that is semi-retired in the industry. He was asked to solve a problem of a steam boiler that was only replaced four months ago and is not properly heating the building. The old boiler that was replaced is no longer there and so has disappeared the man that installed the one in the photo……

The building is one on the outside, but has two separate basements. It appears that one basement is about 150 years old and the other is about a 100. In the one basement is an abandoned steam boiler from the 1960's. That steam main and dry return were extended into the other basement (the photo attached) many years ago and is about 6" higher than the boiler in the photo. Those mains are basically sitting on the crawl space floor……

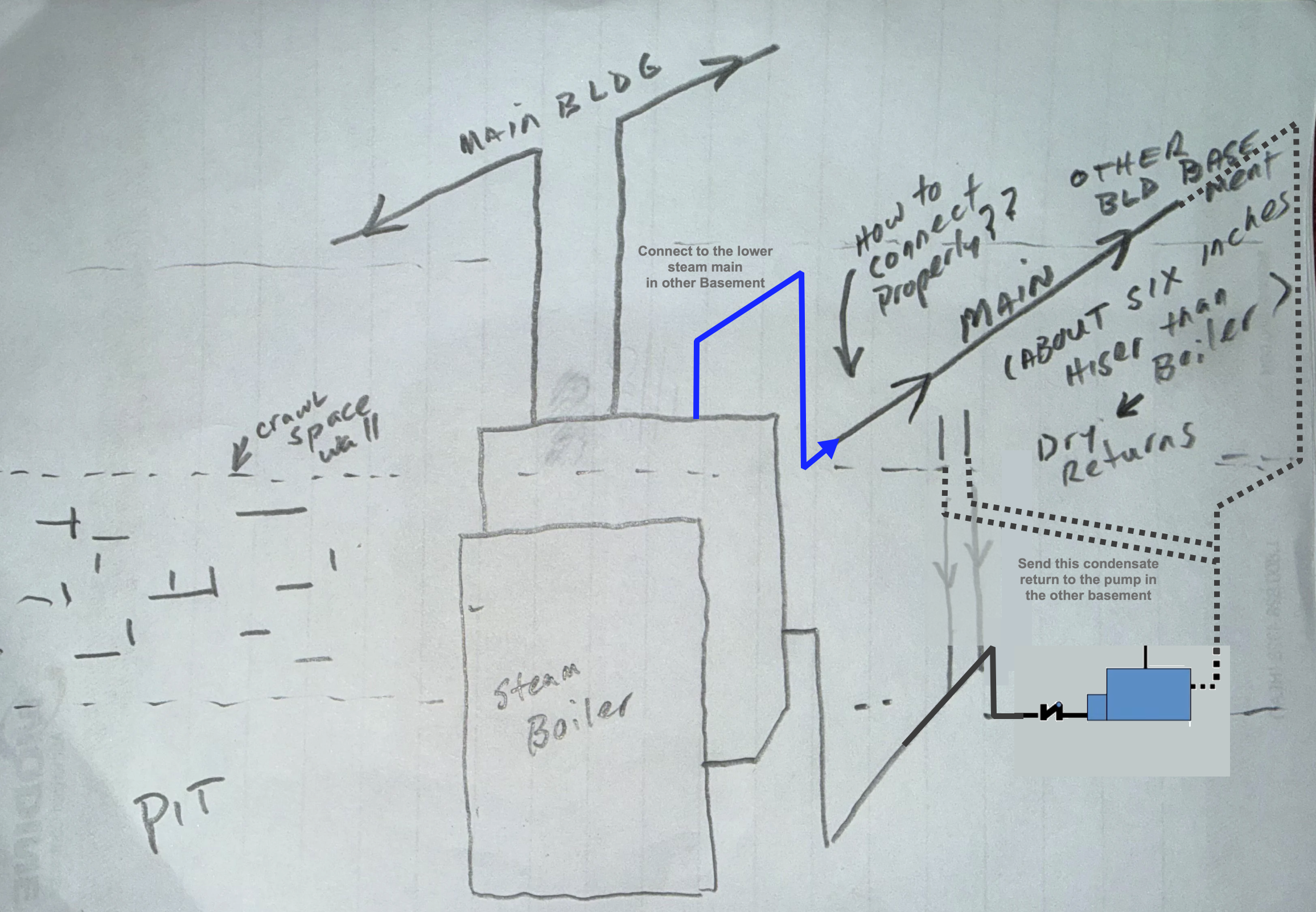

I have made a drawing to eliminate the bullhead tee in the boiler room but do not have knowledge on the proper way (if there is a way) to tie in the lower steam main that goes to the other basement.

I thought one of you guys might have an idea and be able to mockup my drawing.

Thanks

Keith.

Comments

-

S long as that low main and its associated dry return are above the water line of the new boiler, it's really not a problem. Other guys may have — will have! — other ideas, but I'd take your drawing — which is MUCH better than what is there now!! — and add a third T with the leg up, go up about six inches or so, elbow horizontal and go about six inches or as needed, then elbow down and pick up that low main with a T (main on the leg) and continue on down to a wet return. I'd tie the dry returns together and just drop them down to a wet return as well — with a generous vent where they tie together (at least one Goroton #2, maybe 2).

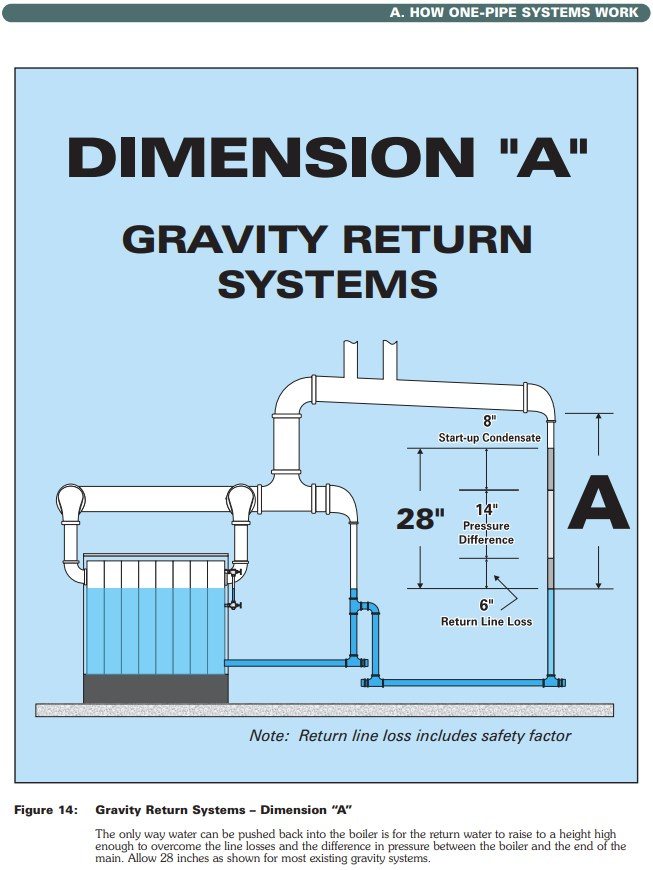

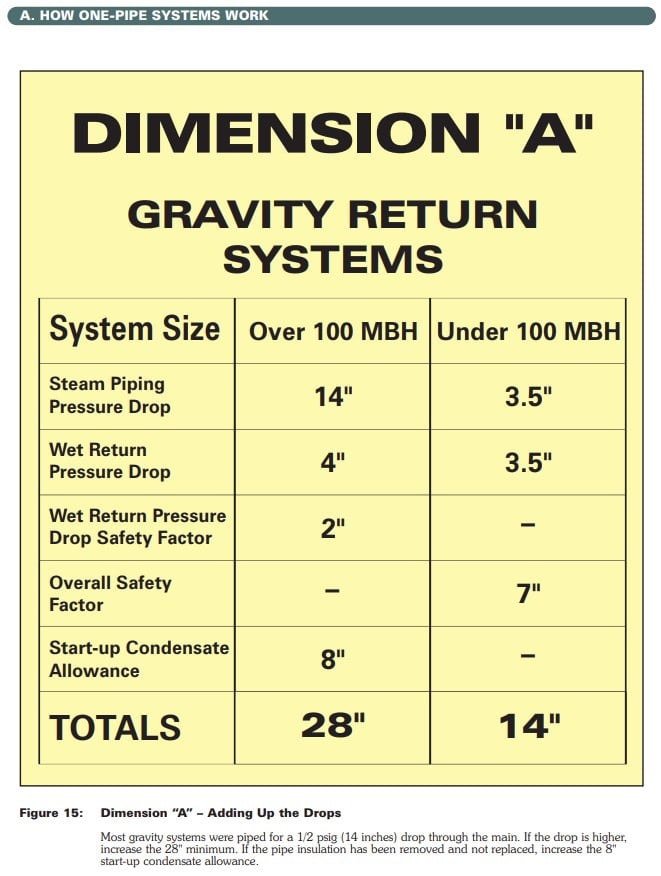

Now that is absolutely dependent on the whole show being well above the water line of the new boiler. If the dry return isn't well above ("well above" depends on the operating pressure — at least 14 inches, if you can operate at half a pound) you will need to drop the dry returns into a condensate receiver and have a boiler feed pump.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I love Jamie's response but I will give you a little more wiggle room if this system is 1-pipe (I can't tell if yours is):

If the dry return isn't well above ("well above" depends on the operating pressure — at least 14 inches, if you can operate at half a pound)

What Jamie wrote above only comes into play in a 2-pipe system. In a 1-pipe system, there is no concern about additional height requirements due to pressure. In a 1-pipe system, no matter what the pressure is, the water line will not rise either at the boiler, or at the far end of the main. But still, keep the pressure low regardless for other reasons!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

It is a 1-pipe to the individual radiators.

Jamie thanks for your insight. I have mockup my original to what I believe how you would pipe it. Please let me know that I interpret your suggestion correctly.

Thanks

Keith.

0 -

@ethicalpaul So this is wrong, from the Peerless One Pipe info.?

0 -

My Church customer with a steam boiler, that I serviced for many years, had a unique situation. It was originally a coal fired boiler in a basement connected to a one pipe steam boiler. Basements in Cape May, NJ are all at or above grade, that is because most of downtown Cape May is at or below sea level and at high tide during the occasional Nor'easter all the basements that were below grade would flood. Not a problem for a coal boiler, since there were no electrical parts to be worried about.

Then one day the church wanted to put an oil burner in that basement and found that they were constantly needing to move the burner from the basement floor when a storm was brewing so it wouldn't get wet. That turned into a plan to remove the boiler from the basement and place it in the parking lot next to the church. After building a boiler room the boiler was taken apart and reassembled in the new space about 7 feet higher than the old location.

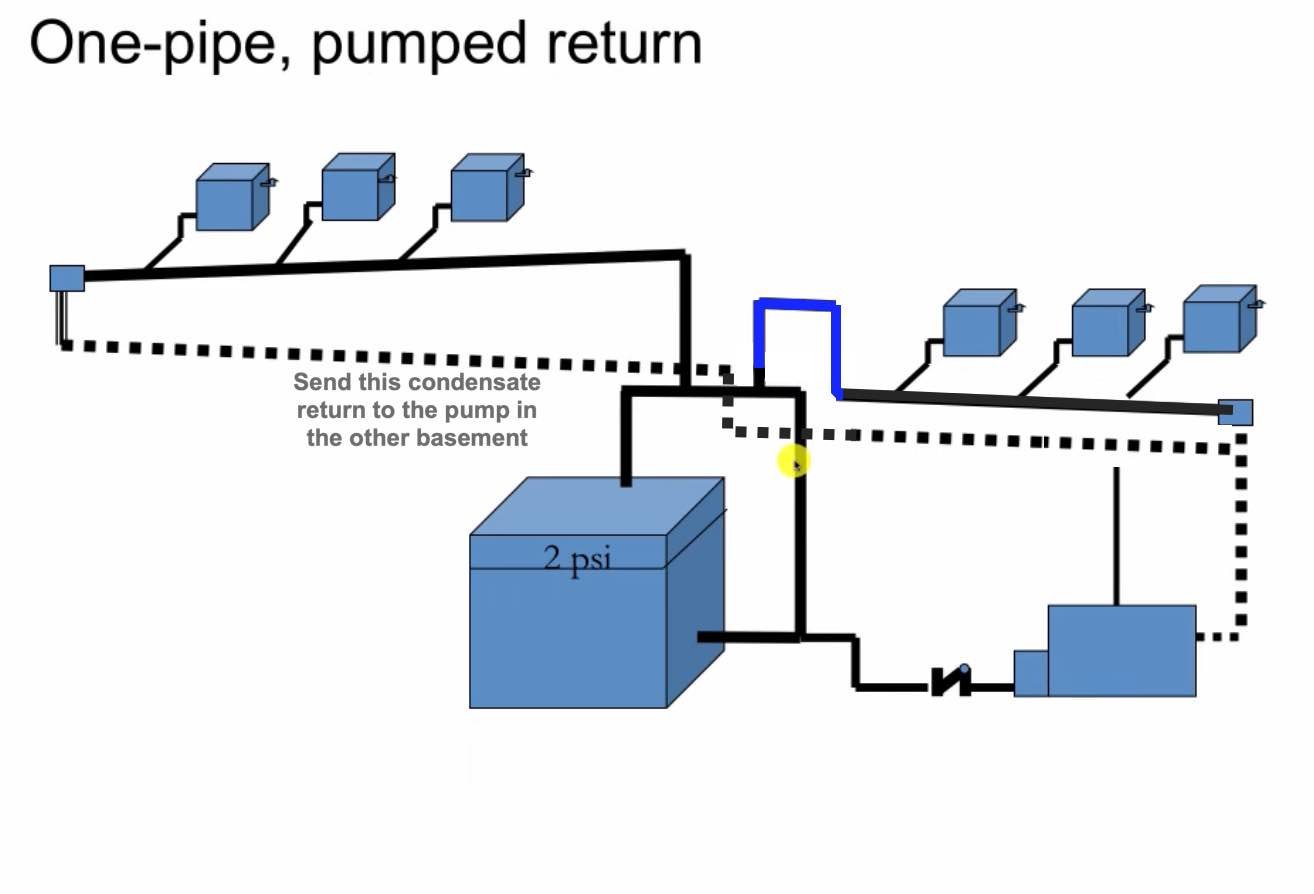

How do you deal with a water line that is 7 feet higher than the original design location? Well someone smarter than me did just that. With the addition of a condensate return pump the steam boiler would make steam then the steam would go to the basement and connect to those steam lines in the basement to feed the building’s one pipe steam radiators. The dry returns would go through the crawlspaces and get back to the basement where they became wet returns and filled a condensate return tank, then get pumped back into the boiler. Pretty Nifty!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Yes. If you'd like to talk about it more I will make a new discussion post so as not to distract from this gentleman's topic. Click "agree" below if you'd like me to do that.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

-

If your dimension A from the other basement is not enough for the boiler water line then you could try this idea.

By adding a condensate return pump in the lower basement and sending a the condensate from both systems to the tank in the lower basement you will be able to use the pump to feed the boiler and still maintain the lower system's operation and function. You will need to add traps at the ends of all the dry returns before piping the condensate to the Tank

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements