do you need two circulators in a primary secondary system

My question is..

For a primary secondary system do you NEED 2 circulators ?? one for the boiler loop and one for the secondary loop? I ask because I believe i saw in Dan Holohan book a pri/sec set up and in the image there was only the one circulator and it was on the secondary side on the supply manifold…

I just need to get this right/wrong image out of my head..

Thanks in advance

Comments

-

-

Yes. You do need at least two. But one of them may be part of the boiler and its trim, which can be misleading. Whether you need only one on the secondary or more than one depends on how the system is zoned and the controls for the zoning.

The other place you need a mandatory circulator is on the output (mixed) side of a mixing valve or tempering valve.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

@Jamie Hall That was my understanding as well.. I just was a little mislead by either my imagination or my want to have things easy🤣

Thanks @EBEBRATT-Ed

0 -

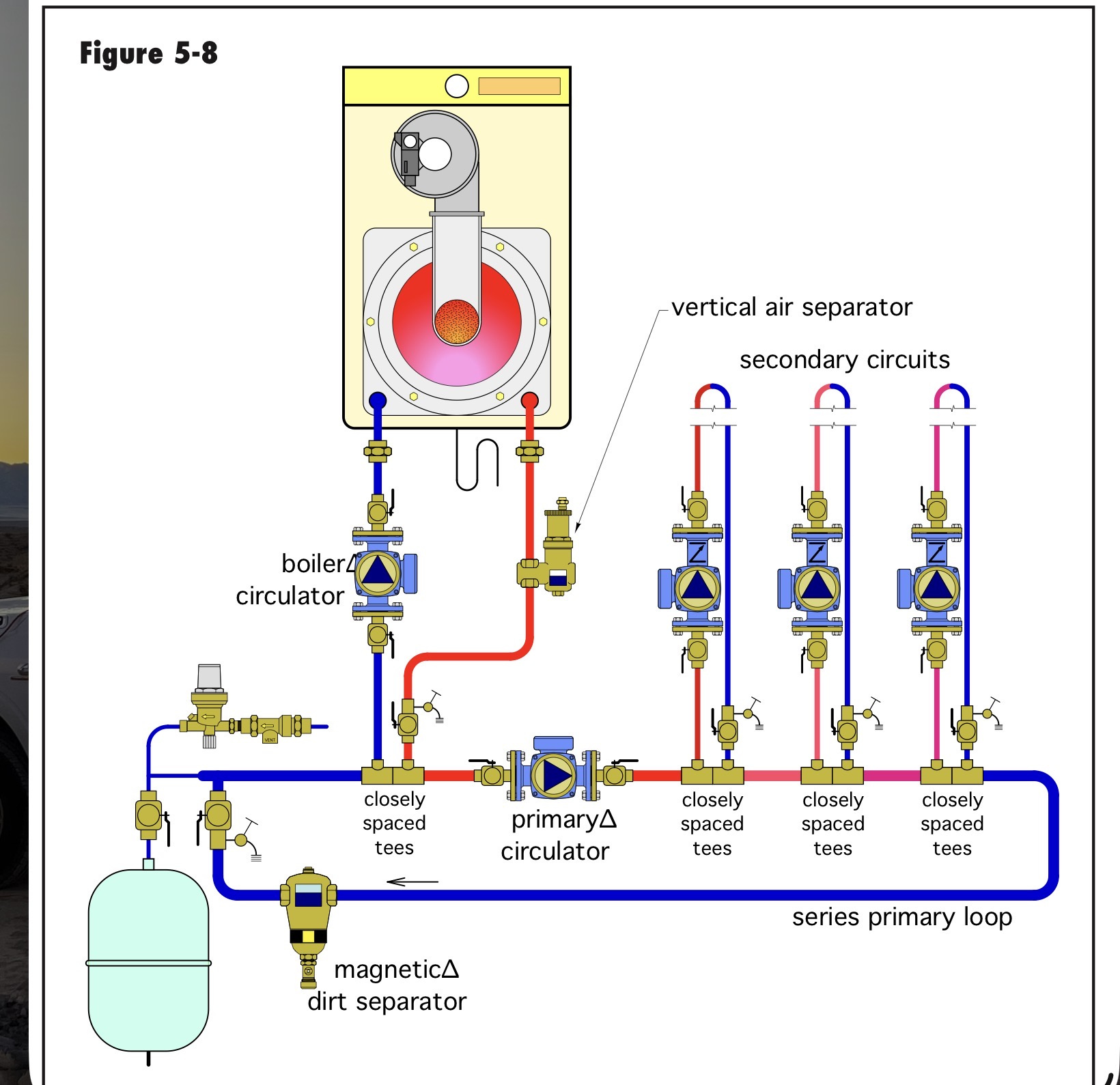

here is an example where 3 or more circs are required.

This is a dedicated series primary loop system. It is series because the zone pumps are in series to one another

Boiler loop, primary loop and zone pumps

If the expansion tank was connected at the boilers pump, then the boiler loop is the primary loop.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

thank you for the example.

So if the "primary circ was removed" and the expansion tank was piped before the boiler loop circ, would this still work? (Im going with no) I'm assuming not because of hydraulic separation.

0 -

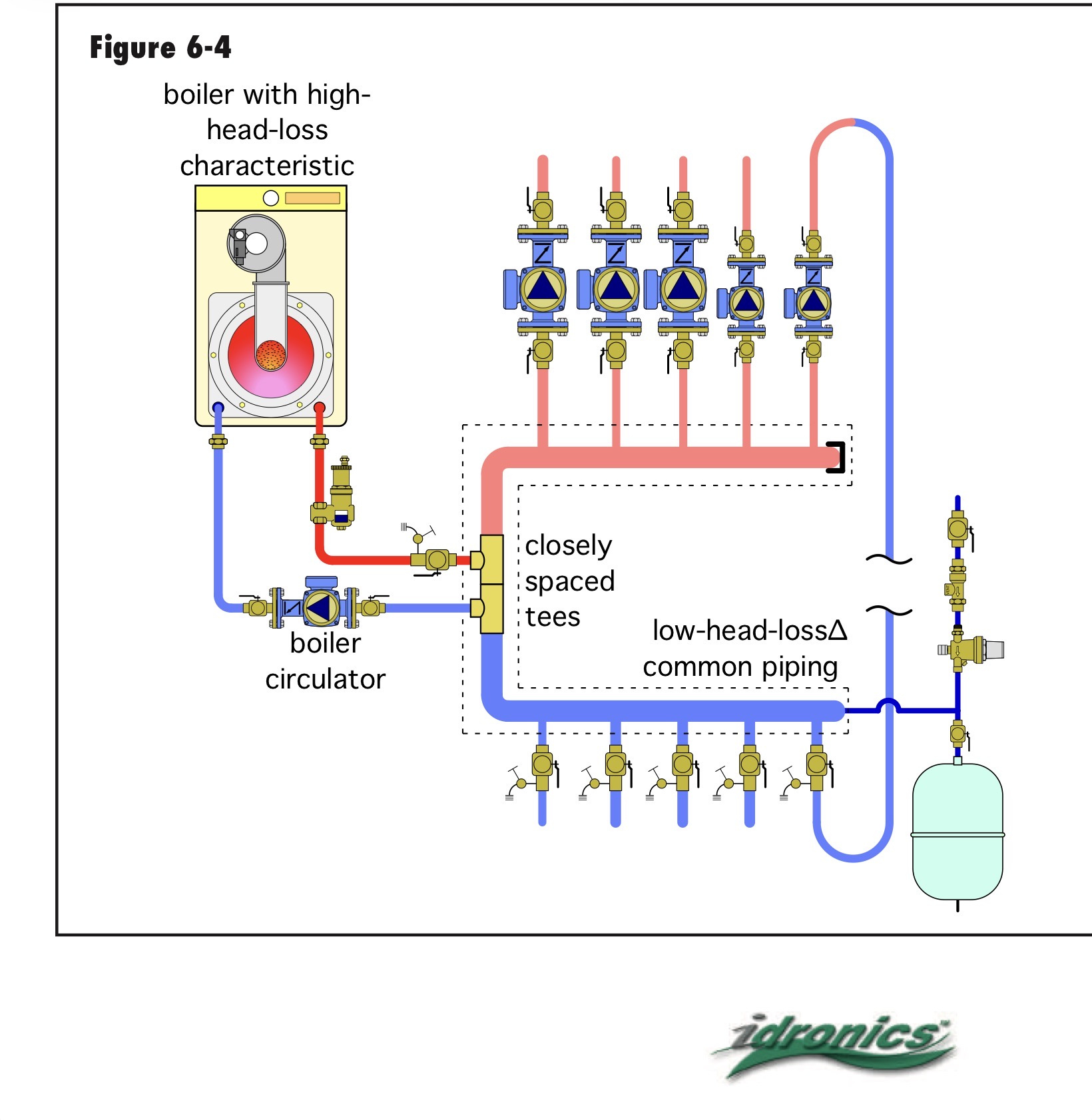

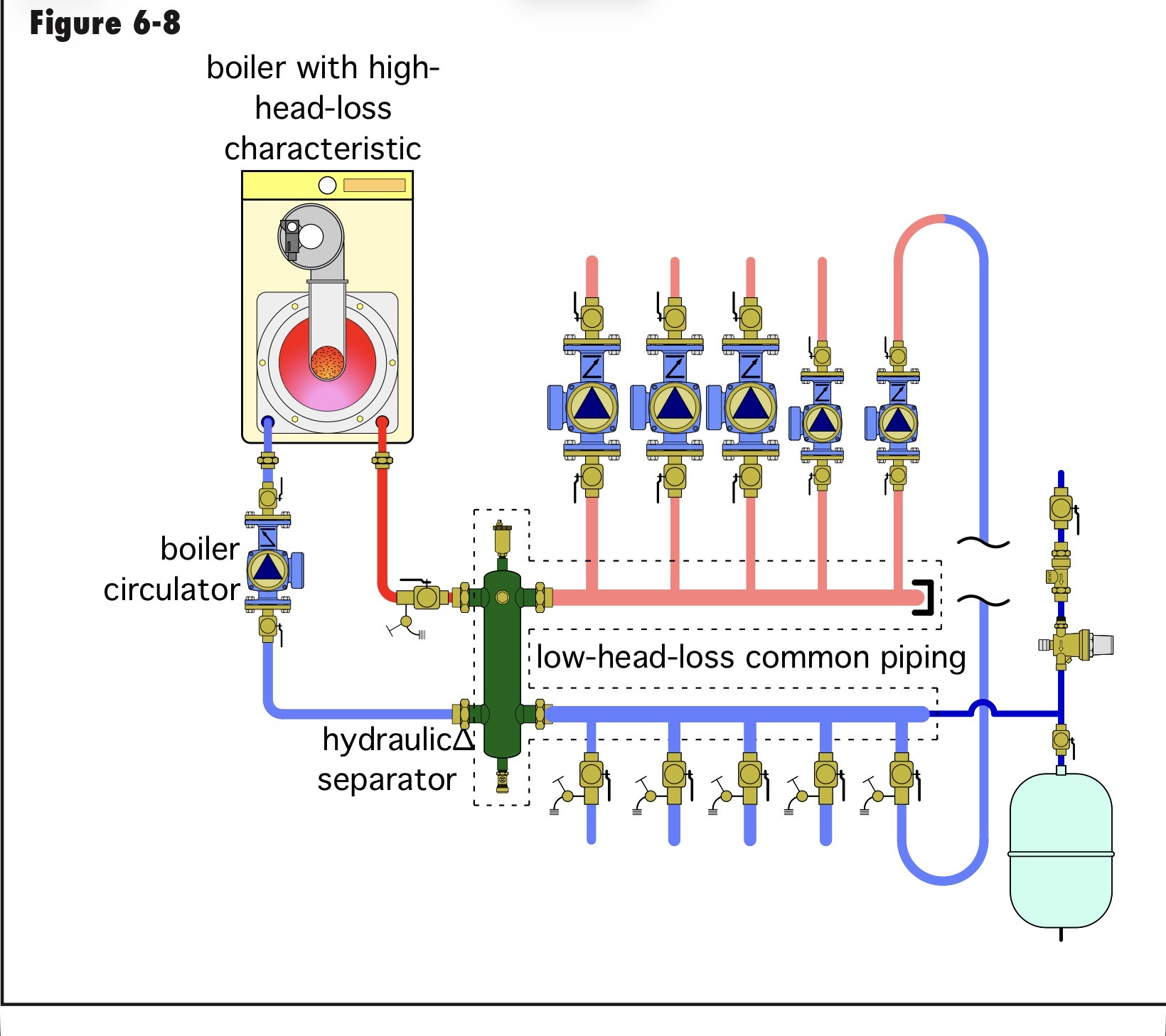

here are some options where only two circs are required. These show multiple zone pumps, but the concept is still two separate piping circuits with either closely spaced tees, or a separator acting as the tees.

The series P/S two posts up would not work with the primary loop removed.

more about “separation” here

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

I"m sure @hot_rod will answer on the "pumping away" — but in my mind they both would. It's as much a matter of figuring out where the lowest pressure in the system is likely to be, and placing your expansion tank (and automatic feed, if used) at that location. And both of those arrangements do that

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

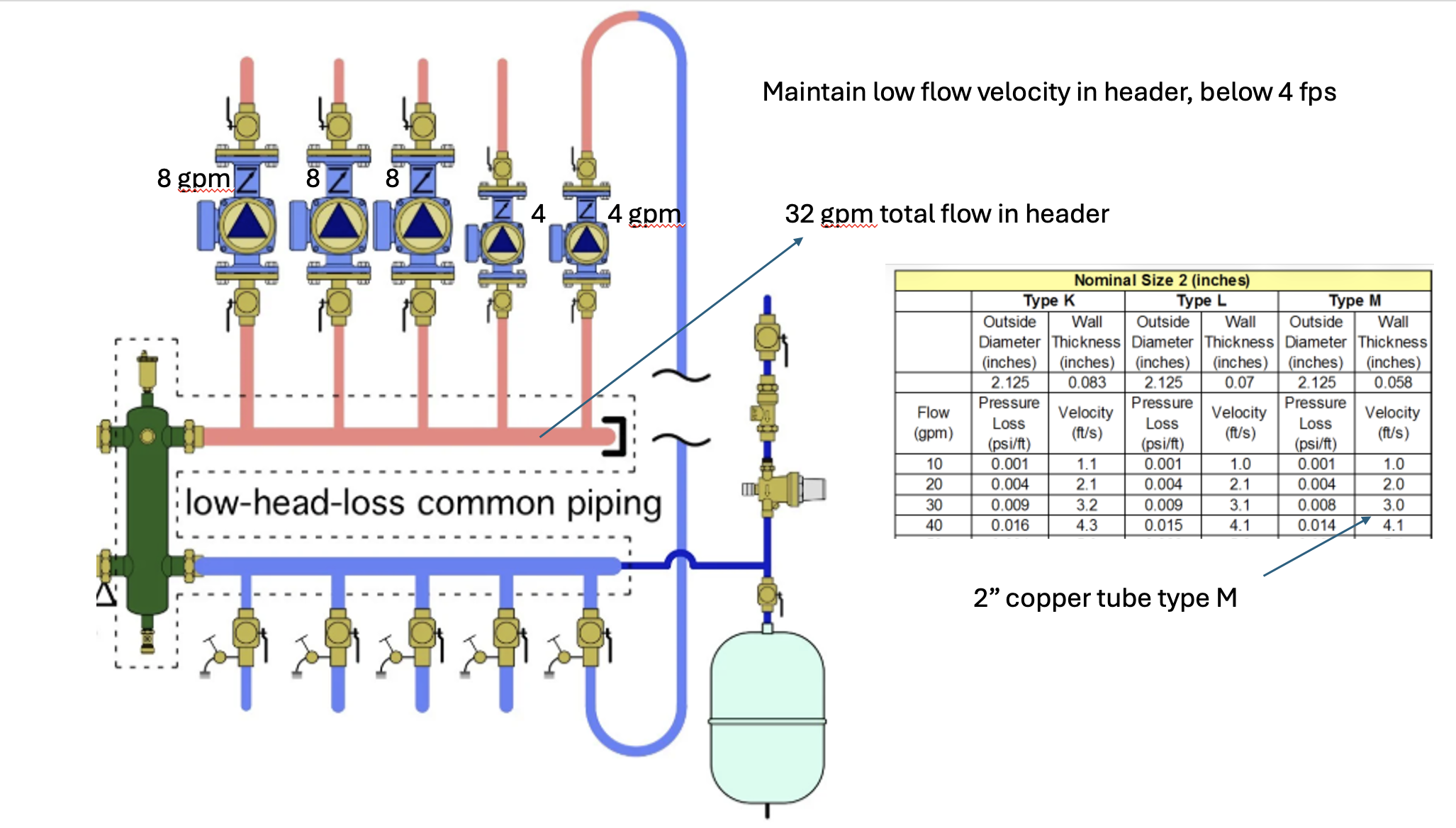

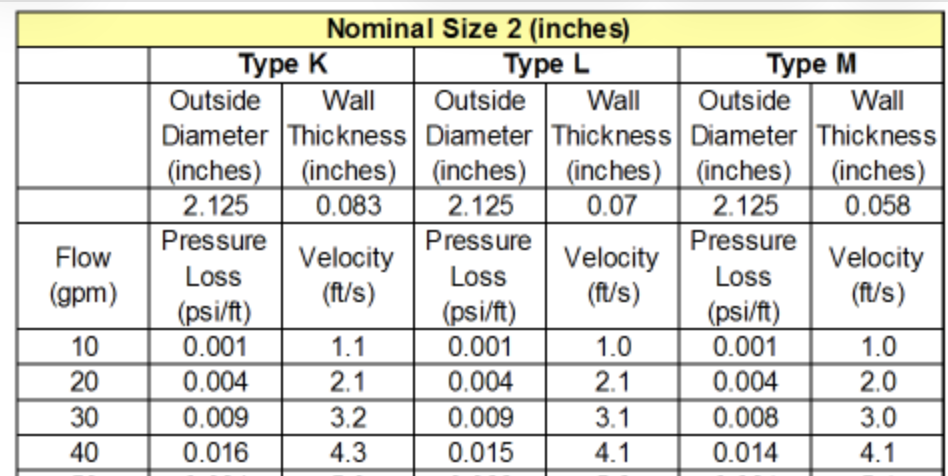

The key point on any piping with multiple pumps or zones is the header pipe needs to be LARGE. Sized to handle the flow of all the pumps combined, ideally at a low velocity around 2-4 fps.

The large (low head loss) header pipes become the "extension" of the PONPC

In this example lets say the 3 large circs are 8 gpm each, 4 gpm on the smaller, so 32 gpm total through the header.

So 2" type M copper would be the choice, just over 3 fps velocity.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Yes, but you may be referring to a "bypass" piping system as was common on 80% boilers to help mix return water on low temp systems. The bypass system only needs one circulator, but it has a limited use. True P/S piping needs at least two circulators and that is not negotiable.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements